Rotational flow coarse graining sedimentation dehydration device and method thereof

A dehydration device and coarse-graining technology, which is applied in the direction of chemical instruments and methods, separation methods, and multi-stage series refining process treatment, etc., can solve the problems of limited application, poor dehydration quality and stability, and improve the separation effect , Guarantee the effect of miniaturization and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The structure of the present invention will be explained in detail below in conjunction with the accompanying drawings.

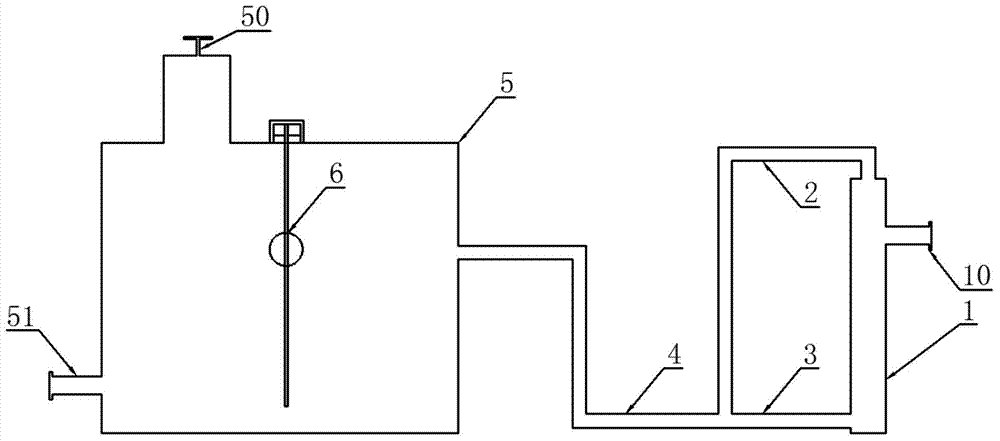

[0027] Such as figure 1 The cyclone coarse-graining settling dehydration device of the present invention shown includes a coarse-graining processor and a settler; the coarse-graining processor is used to gather the small oil droplets in the oil-water mixture into large oil droplets, and the settler will Oil-water separation after coarse granulation treatment.

[0028] The coarse granulation processor includes a cyclone 1, and the cyclone 1 is provided with a liquid inlet 10 for the oil-water mixture to flow in, an overflow port and an underflow port. The overflow port and the underflow port are respectively connected to the overflow pipe 2 and the underflow pipe 3, and the ends of the overflow pipe 2 and the underflow pipe 3 are connected to each other and to the mixed liquid pipe 4; the other end of the mixed liquid pipe is connected to the settler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com