Cleaned coal dehydration process and equipment combination for realizing same

A clean coal and process technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of cake agglomeration of filter press, complicated process system, complex process system, etc., and reduce maintenance costs , save engineering cost and simplify the effect of dehydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

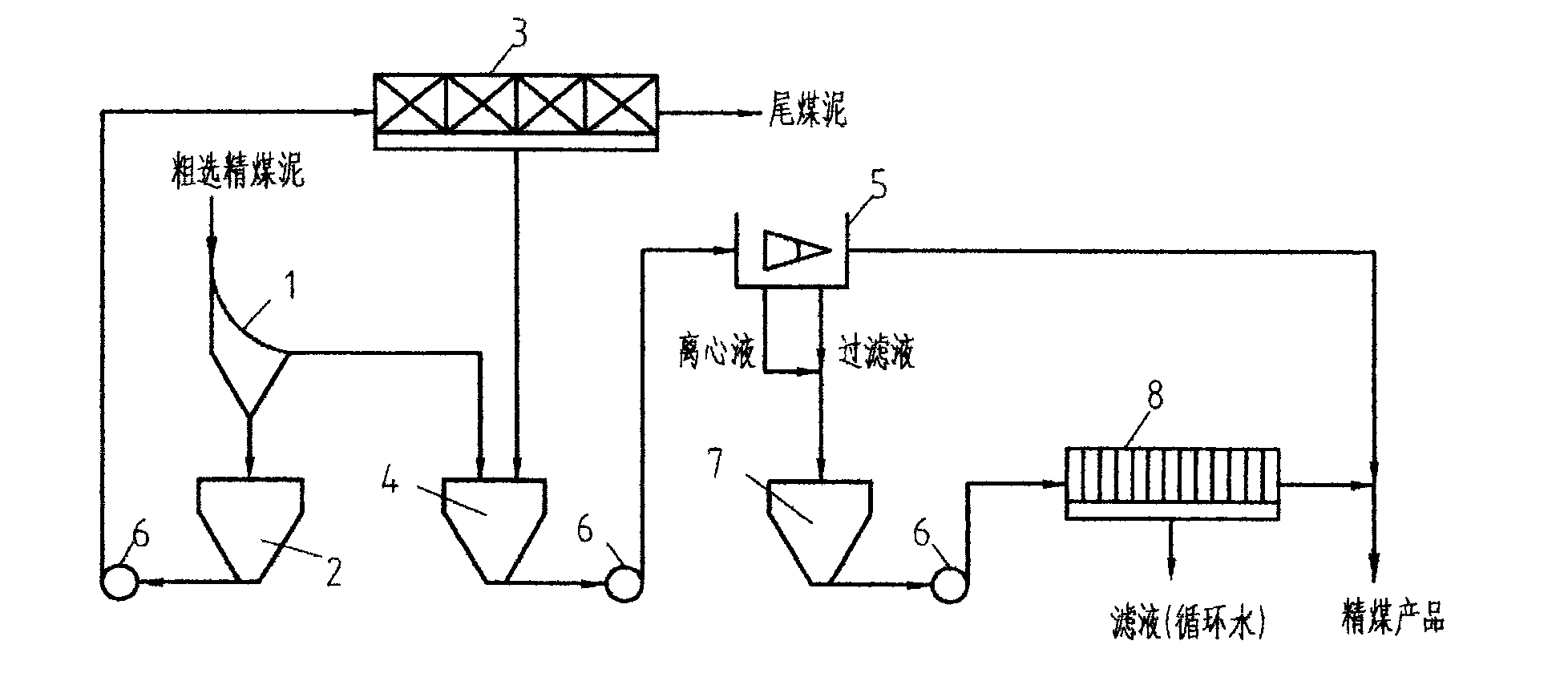

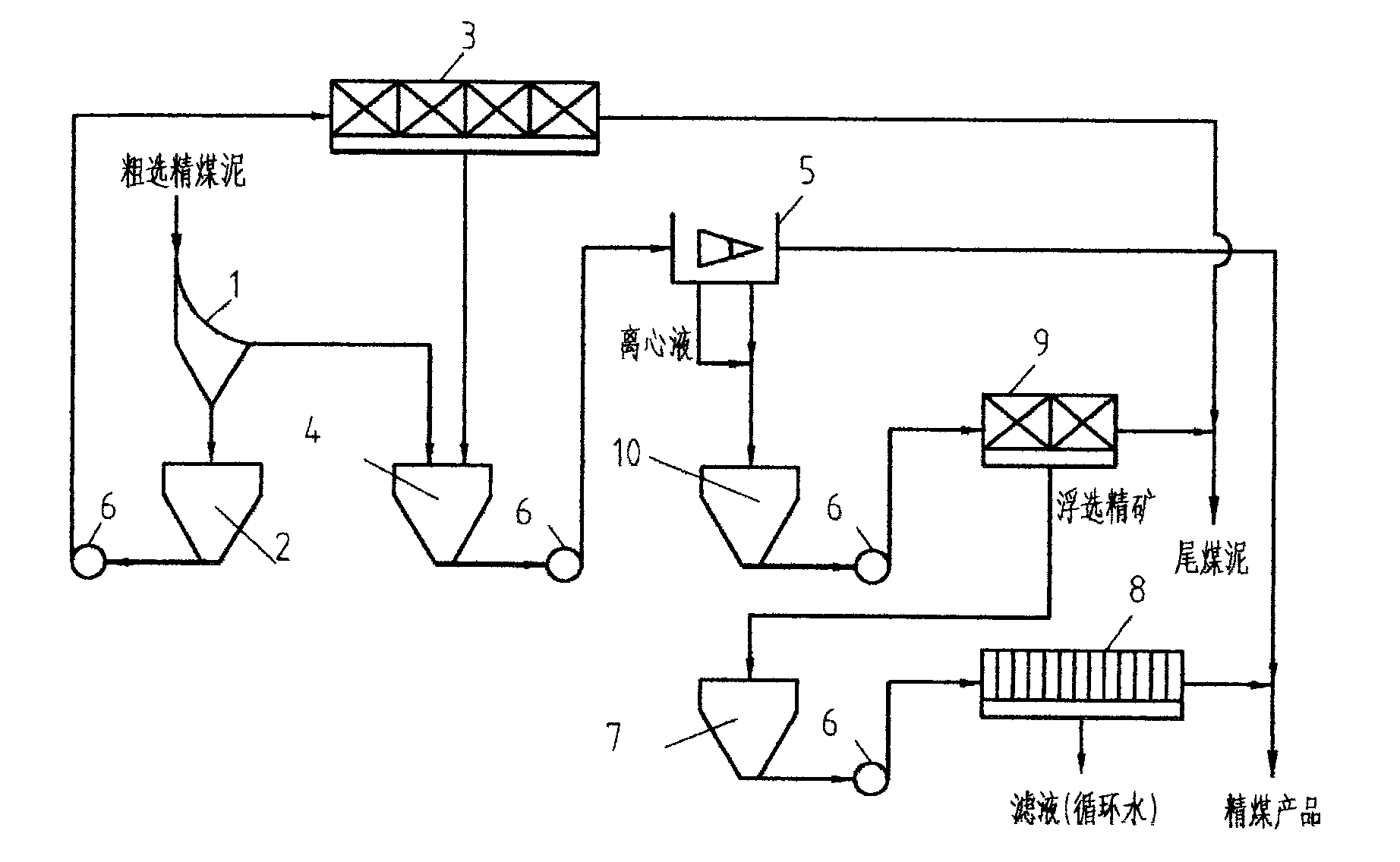

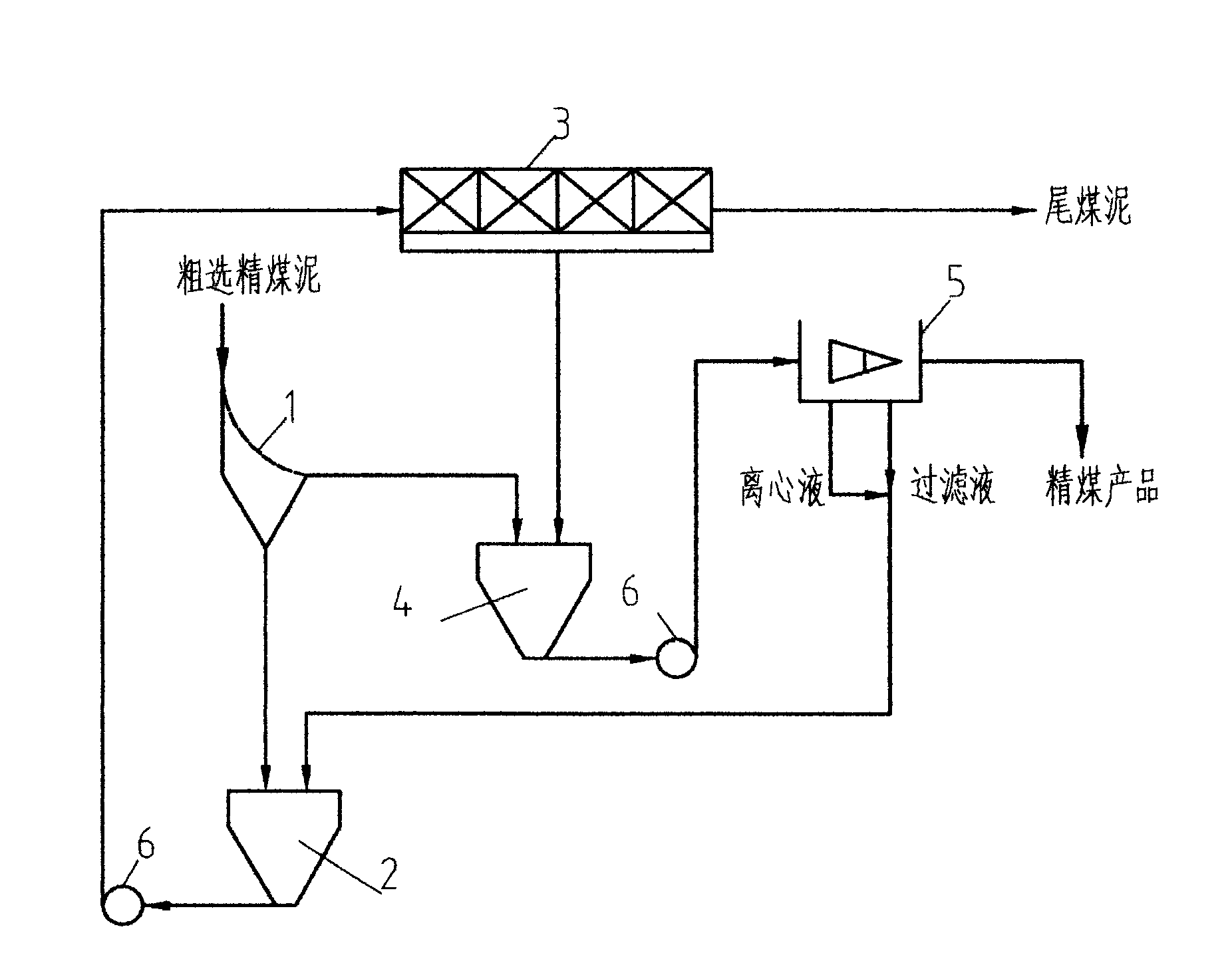

[0016] In the prior art, the centrifugate and filtrate of the sedimentation filter centrifuge must be pumped into the filter press for dehydration, or the clean coal is selected through the secondary flotation operation and then pumped into the filter press for dehydration. When the present invention is used instead, it is only necessary to remove the filter press and the secondary flotation machine, and return the centrate and filtrate of the sedimentation filter centrifuge to the original flotation operation. The clean coal in the centrifugate and filtrate is selected by flotation and then enters the sedimentation filter centrifuge for dehydration, while most of the water and a small amount of high-ash coal slime in the centrifugate and filtrate are discharged through the flotation machine to tailing slime system.

[0017] In the actual production process of the coal preparation plant, the coarsely selected fine coal slime pre-selected by the dense medium coal preparation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com