Dehydration method during production process of toluene diisocynate

A technology of toluene diisocyanate and production process, which is applied in the field of dehydration in the process of producing toluene diisocyanate by high-pressure phosgenation method, can solve the problems of increasing production cost, insignificant economic benefits, etc., and achieves reduction of corrosion, good dehydration effect, and reduced cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

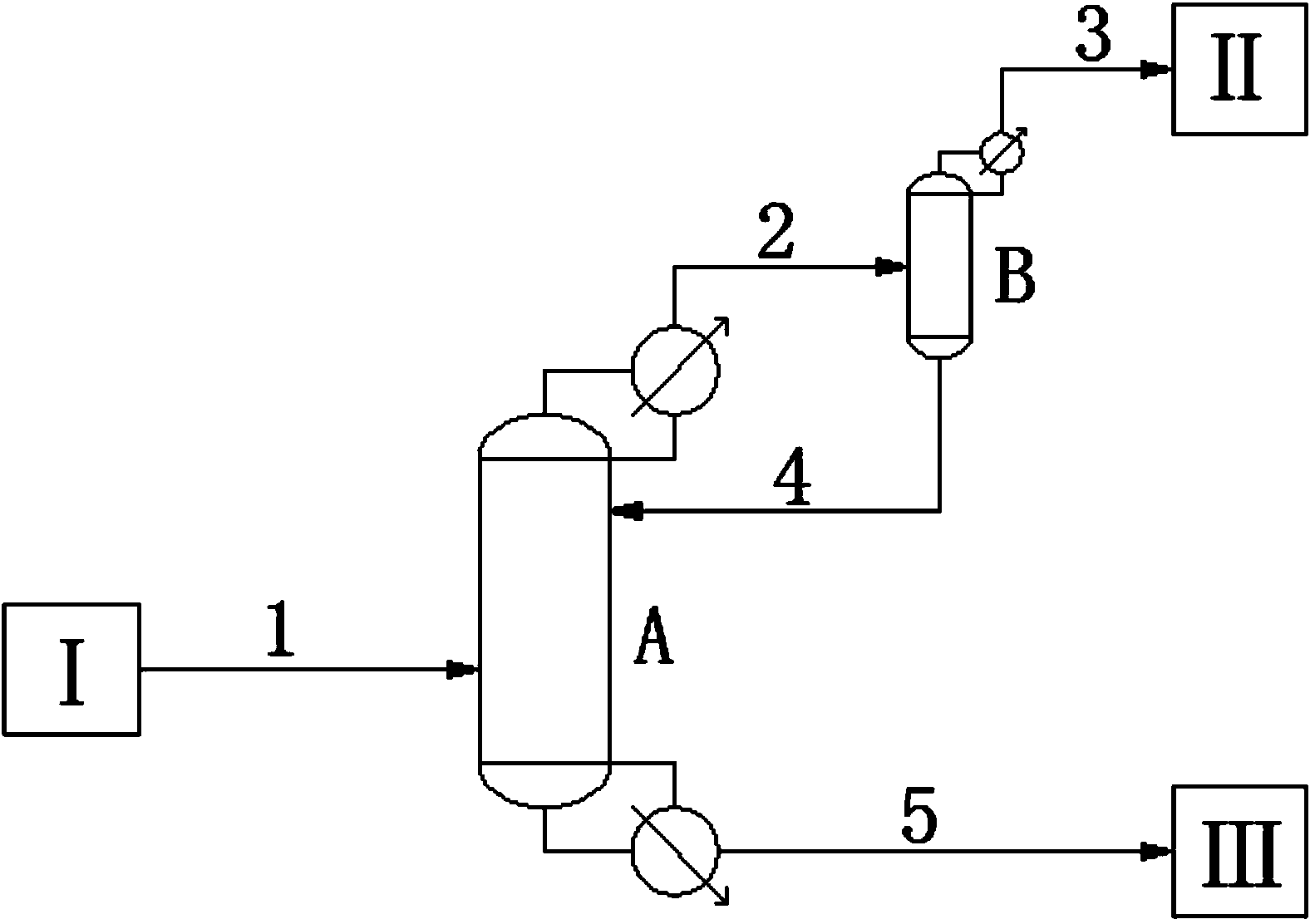

[0010] In this example, the flow of water at different locations is analyzed without dehydration. In a TDI device with an annual output of 60,000 tons / year, 100PPM of water contained in the raw material toluene diamine (flow rate of 0.592kg / h) causes toluene di The enrichment of water in the phosgenation reaction tower and the hydrogen chloride rectification tower in the isocyanate production system, the mixture stream 1 obtained from the cold phosgenation reaction stage I enters the phosgenation reaction tower A, and in the phosgenation reaction tower A Acid chloride is decomposed into toluene diisocyanate, amine salt hydrochloride is decomposed into hydrogen chloride and amine, and after phosgenation, it becomes the product TDI, and at the same time generates by-product hydrogen chloride, which contains a part of phosgene in stream 2 from phosgenation reaction tower A The top of the tower enters the hydrogen chloride rectification tower B, and the stream 3 refined hydrogen ch...

Embodiment 2

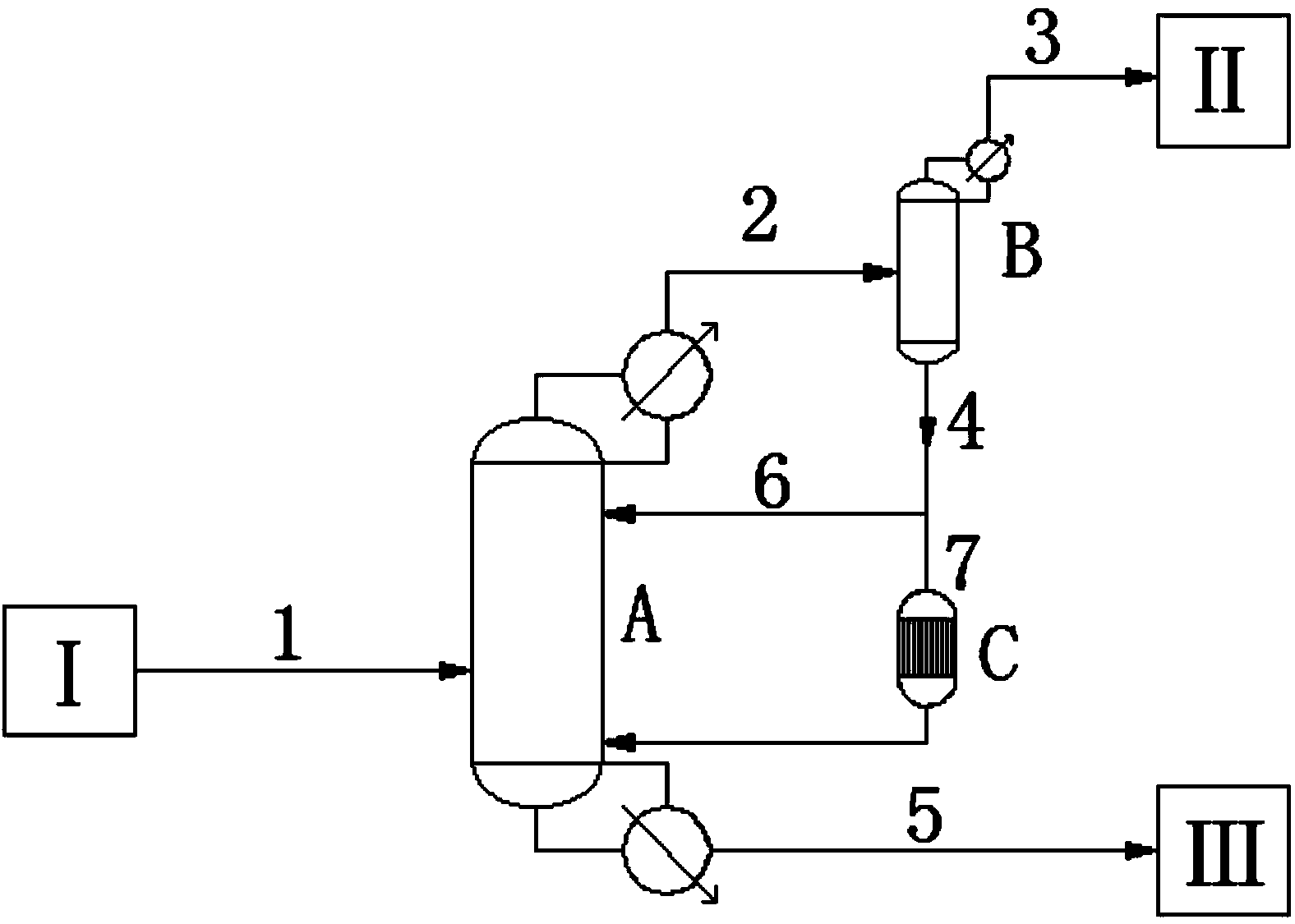

[0012] This example shows the flow of water at different positions after dehydration. In a TDI device with an annual output of 60,000 tons / year, the raw material toluene diamine contains 100PPM of water (flow rate is 0.592kg / h), resulting in In the enrichment of moisture in the phosgenation reaction tower and the hydrogen chloride rectification tower, the mixture stream 1 obtained from the cold phosgenation reaction stage I enters the phosgenation reaction tower A, and in the phosgenation reaction tower A, carbamoyl chloride is decomposed and converted into Toluene diisocyanate and amine salt hydrochloride are decomposed into hydrogen chloride and amine, and become the product TDI after phosgenation. At the same time, the by-product hydrogen chloride is generated. The stream 2 containing a part of phosgene in the by-product hydrogen chloride comes out from the top of the phosgenation reaction tower A and enters Hydrogen chloride rectification tower B is installed, stream 3 refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com