Method for processing oily sludge in oil field

A treatment method and technology for oil sludge, which are applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Cost, simple effect of dehydration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

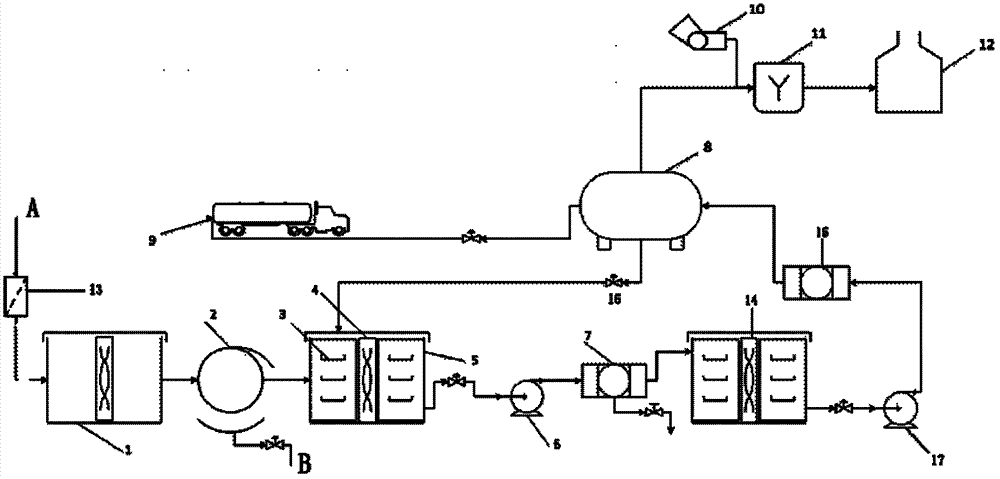

[0026] 1. Preliminary treatment of sludge

[0027] Set up a stacking pool, 520 tons of oily sludge collected from the production unit, with a water content of 93% and 1.2% crude oil, put it into the stacking pool 13 for natural settlement for 1 day, and remove larger solids in the original oily sludge. Phase objects, if the collected oily sludge does not contain larger solid phase objects or the content is small, it can be directly processed in the next step;

[0028] 2. Dewatering of oily sludge

[0029] The liquid phase oily sludge in the stacking tank is pumped into the filter tank 1, and is preliminarily filtered through a 5-mesh filter. After the preliminary filtration, 518 tons of oily sludge are obtained, and the flocculant polyacrylamide is added according to 1 / 1000 of its mass. After stirring at a speed of 30 rpm for 30 minutes, the screw dehydrator 2 is used for dehydration treatment. After dehydration, the moisture content of the oily sludge is 62%, and the volume ...

Embodiment 2

[0037] 1. Preliminary treatment of sludge

[0038] Set up a stacking pool, 658 tons of oily sludge collected from the production unit, with a water content of 95% and a crude oil content of 1.6%, is put into the stacking pool 13 for natural settlement for 1.5 days, and the larger solids in the original oily sludge are removed. Phase objects, if the collected oily sludge does not contain larger solid phase objects or the content is small, it can be directly processed in the next step;

[0039] 2. Dewatering of oily sludge

[0040] The liquid phase oily sludge in the stacking tank is pumped into the filter tank 1, and is preliminarily filtered through a 5-mesh filter. After the preliminary filtration, 650 tons of oily sludge is obtained, and the flocculant polyacrylamide is mixed according to 3 / 1000 of its mass. After stirring at a speed of 30 rpm for 30 minutes, the screw dehydrator 2 is used for dehydration treatment, and the moisture content of the dehydrated oily sludge is ...

Embodiment 3

[0048] 1. Preliminary treatment of sludge

[0049] Set up a stacking pool, 956 tons of oily sludge collected from the production unit, with a water content of 97% and 1.3% crude oil, put it into the stacking pool 13 for natural settlement for 2 days, and remove larger solids in the original oily sludge. Phase objects, if the collected oily sludge does not contain larger solid phase objects or the content is small, it can be directly processed in the next step;

[0050] 2. Dewatering of oily sludge

[0051] The liquid-phase oily sludge in the stacking tank is pumped into the filter tank 1, and is initially filtered through a 5-mesh filter. After the preliminary filtration, 951 tons of oily sludge is obtained, and the flocculant polyacrylamide is added according to 1 / 1000 of its mass. After stirring at a speed of 30 rpm for 30 minutes, the screw dehydrator 2 is used for dehydration treatment, and the moisture content of the dehydrated oily sludge is 50%.

[0052] 3. Primary an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com