Preparation method of micro-electrolytic iron-carbon filler for degrading industrial wastewater

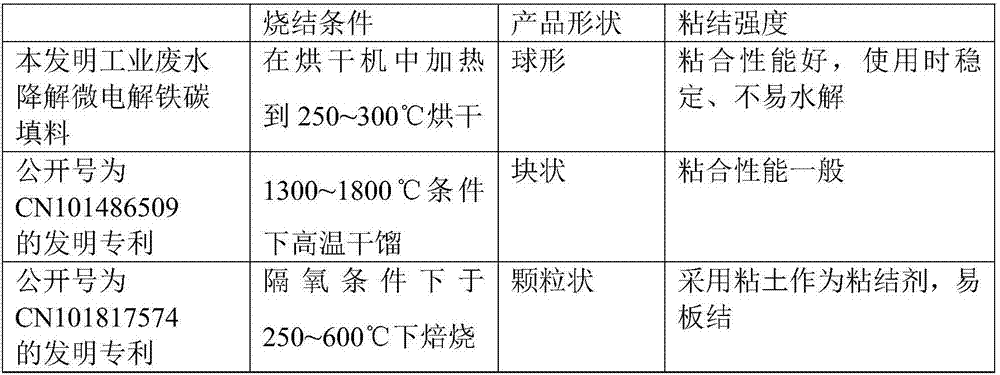

A technology of industrial wastewater degradation and micro-electrolysis of iron, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of affecting the use effect of fillers, easy decomposition in water, and reduced activity of fillers, etc. problems, to achieve the effect of simple and reasonable preparation method, not easy to hydrolyze, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for degrading micro-electrolytic iron-carbon fillers from industrial wastewater, comprising the following steps:

[0026] (1) Prepare binder: mix sodium silicate, calcium chloride and hydroxypropyl cellulose uniformly by weight to obtain binder;

[0027] (2) Mixing: put iron powder, activated carbon and binding agent into the mixer by weight ratio and mix evenly;

[0028] (3) into a ball: put the raw material mixed in the step (2) into a ball into a ball;

[0029] (4) Drying and molding: heat the pellets obtained in step (3) to 250-300°C in a dryer to dry, and then they can be molded to obtain industrial wastewater degradable micro-electrolytic iron-carbon fillers.

[0030] The prepared industrial wastewater degradable micro-electrolytic iron-carbon filler consists of the following components: 55-70 parts by weight of iron powder, 30-40 parts by weight of activated carbon and 1-2 parts by weight of binder;

[0031] The iron powder is iron powder w...

Embodiment 1

[0037] The micro-electrolytic iron-carbon filler for degrading industrial wastewater consists of the following components: 65 parts by weight of iron powder, 35 parts by weight of activated carbon and 1.5 parts by weight of binder;

[0038] Iron powder is iron powder with 4% carbon content;

[0039] The binder consists of 6 parts by weight of sodium silicate, 2 parts by weight of calcium chloride and 2 parts by weight of hydroxypropyl cellulose.

[0040] The method for preparing the above-mentioned organic pollutant degradation micro-electrolytic iron-carbon filler comprises the following steps:

[0041] (1) Prepare binder: mix sodium silicate, calcium chloride and hydroxypropyl cellulose uniformly by weight to obtain binder;

[0042] (2) Mixing: put iron powder, activated carbon and binding agent into the mixer by weight ratio and mix evenly;

[0043] (3) into a ball: put the raw material mixed in the step (2) into a ball into a ball;

[0044] (4) Drying and forming: heat ...

Embodiment 2

[0046] The micro-electrolytic iron-carbon filler for degrading industrial wastewater consists of the following components: 55 parts by weight of iron powder, 30 parts by weight of activated carbon and 1 part by weight of binder;

[0047] Iron powder is iron powder with 4% carbon content;

[0048] The binder consists of 5 parts by weight of sodium silicate, 1 part by weight of calcium chloride and 1 part by weight of hydroxypropyl cellulose.

[0049] The preparation method is as in Example 1, wherein the drying temperature in step (4) is 300°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com