Copper etching liquid with little lateral etching

A technology of copper etching and side etching, which is applied in the field of copper etching solution, can solve the problems of large side erosion and the stability of a large amount of foam, and achieve the effects of reducing side erosion, good stability, and uniform etching

Pending Publication Date: 2017-05-31

JIANGSU AISEN SEMICON MATERIAL CO LTD

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, most metal copper etching solutions on the market have problems such as large side erosion, formation of a large amount of foam, or poor stability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

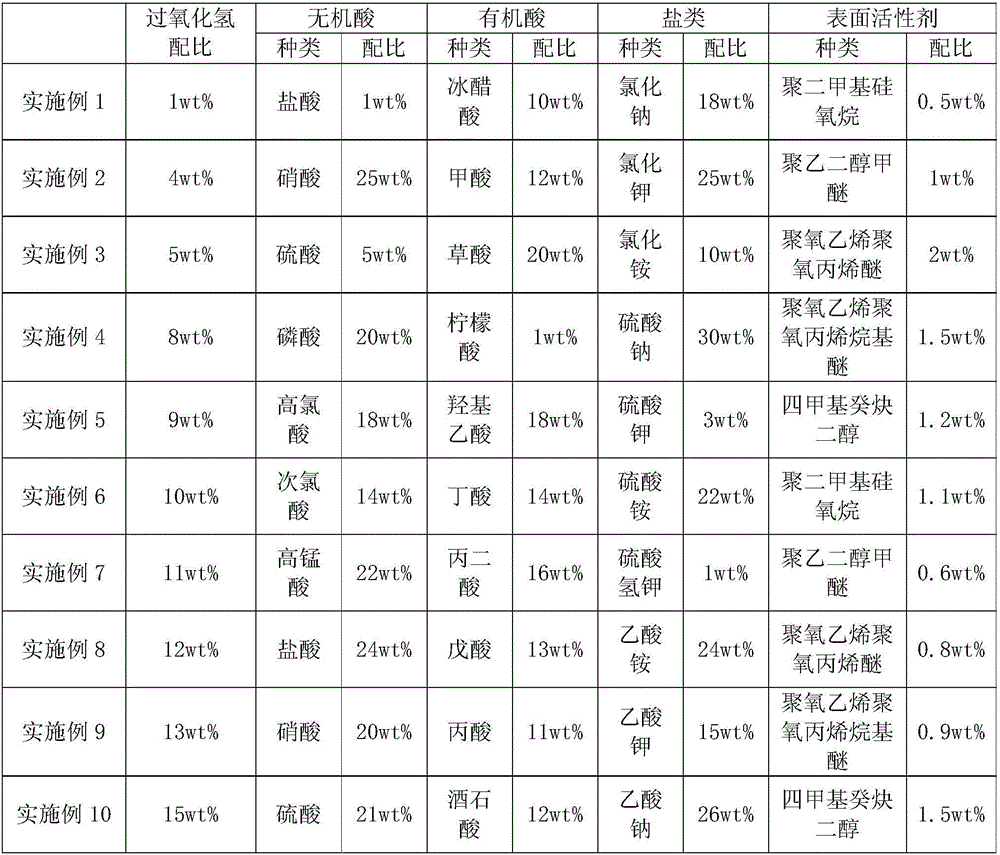

Embodiment 1~10

[0016] Prepare copper etching solution according to the formula in Table 1.

[0017] Table 1:

[0018]

[0019] Note: The part of the total proportion less than 100wt% in Table 1 is deionized water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of semiconductor machining and relates to copper etching liquid with little lateral etching. According to a formula, the copper etching liquid comprises 1-15 wt% of hydrogen peroxide, 1-25 wt% of inorganic acid, 1-20 wt% of organic acid, 1-30 wt% of salts, 0.5-2 wt% of a surface active agent and the balance deionized water. The surface active agent is one of polydimethylsiloxane, methoxypolyethylene glycol, polyoxyethylene polyoxypropylene, polyoxyethylene poly(propylene oxide alkyl ether) and tetramethyl decynediol. The copper etching liquid is even in etching, the lateral etching phenomenon is reduced, foam is avoided, and the stability is good.

Description

technical field [0001] The invention relates to the technical field of semiconductor processing, in particular to a copper etchant with small side erosion. Background technique [0002] Etching is the chemical removal of unwanted metal to a certain depth. Etching technology is widely used in decoration, circuit boards, precision machining and electronic parts processing and other fields. [0003] At the beginning of etching, the surface of the metal plate is protected by graphics, and the rest of the metal surface is in contact with the etching solution. At this time, the etching proceeds vertically to the depth. When the metal surface is etched to a certain depth, new metal surfaces appear on both sides of the bare, and at this time, the etchant not only etches in the vertical direction but also on both sides. As the etching depth increases, the etched area of the metal surfaces on both sides also increases. The final result of side erosion is that the lines or dots of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/18

CPCC23F1/18

Inventor 杜冰顾群艳梁豹鲍杰赵建龙张兵向文胜朱坤

Owner JIANGSU AISEN SEMICON MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com