Rotary magnetron sputtering target

A technology of magnetron sputtering and magnetic strips, which is applied in the field of rotating cylindrical magnetron sputtering targets for coating, and can solve problems such as sputtering power overload, sputtering power instability, and affecting film quality, achieving uniform consumption and economic benefits And the effect of significant social benefits and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Magnetron sputtering technology is a kind of physical vapor deposition. In addition to an electric field applied on the target (the electric force line is perpendicular to the surface of the target), the magnetron sputtering coating also applies a magnetic field to make the electrons be affected by the Lorentz force. The linear and helical compound movement prolongs the trajectory of electrons, greatly increases the plasma density, and greatly increases the number of positive ions, which can increase the sputtering rate. Compared with other coating technologies, the surface quality of the film layer is high and the film layer is dense; the film layer has good bonding with the substrate; the coating can be prepared at low temperature without reducing the performance of the substrate; green and clean, no pollution emission, good environmental protection .

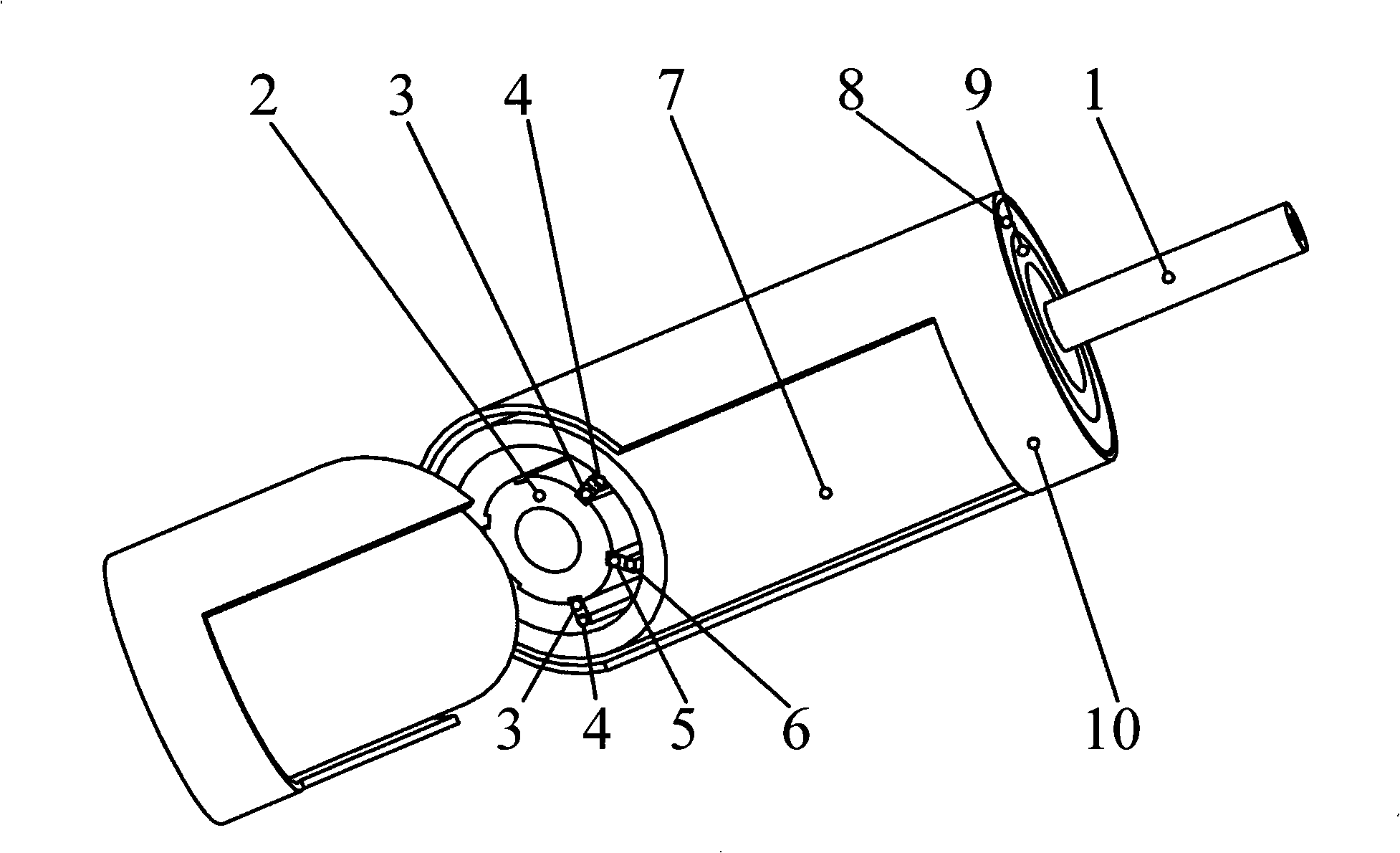

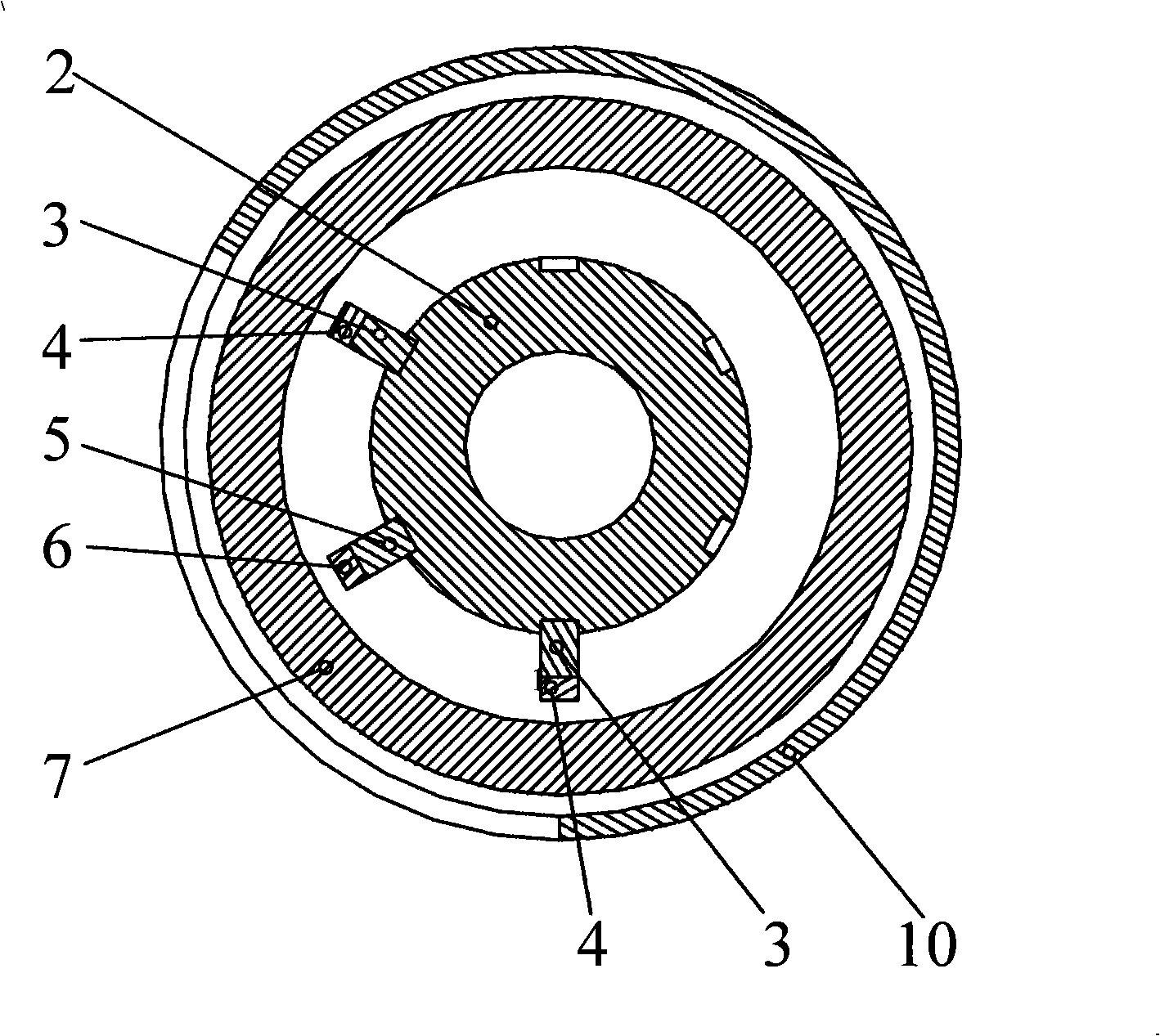

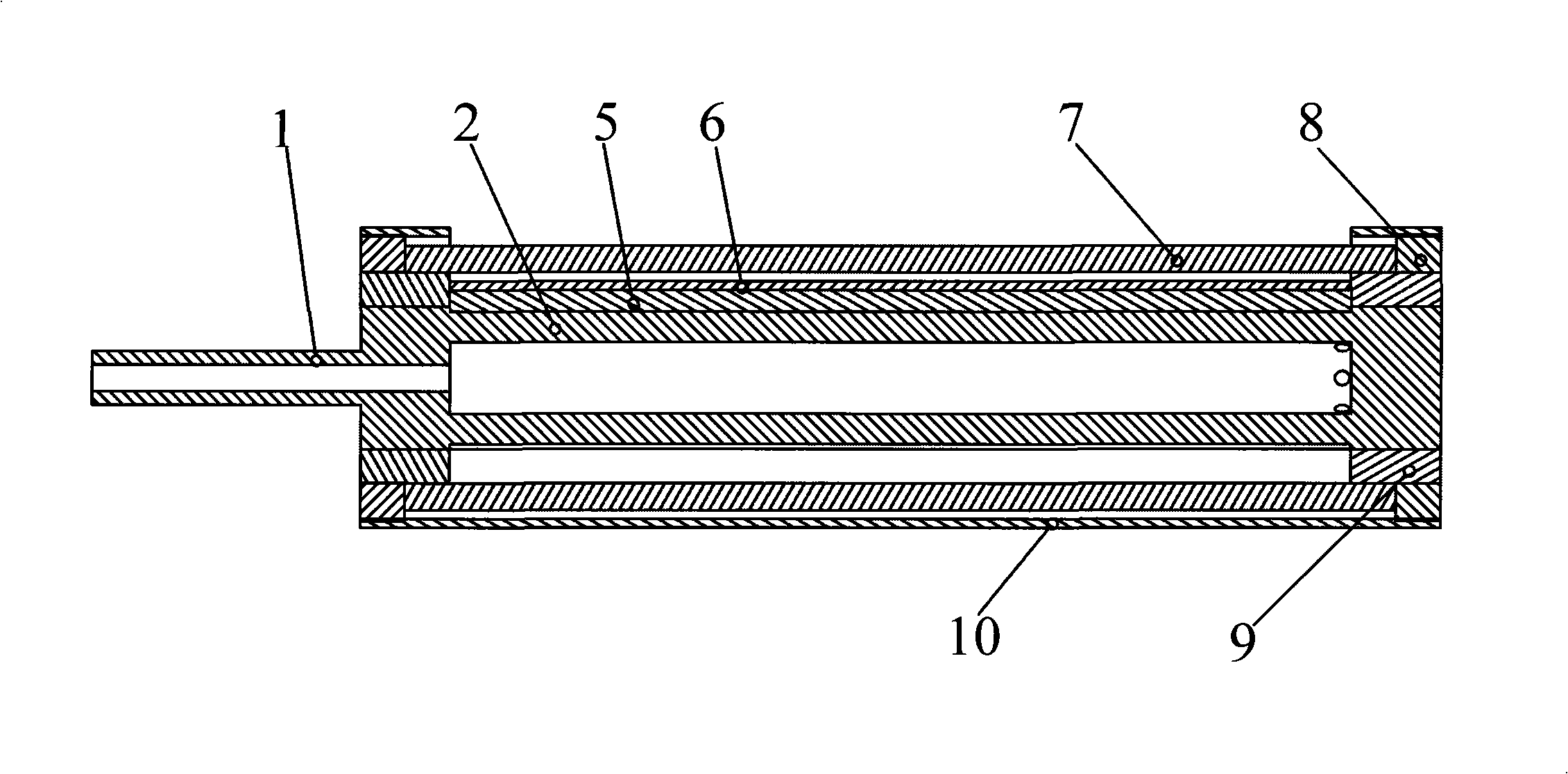

[0020] Such as Figure 1~3 As shown, the rotating cylindrical magnetron sputtering target with a shield includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com