Sputter coating method

A sputtering coating and sputtering technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of difficult sputtering of strong magnetic targets, difficulty in improving film quality, and low target utilization and other problems, to achieve high sputtering rate, increase utilization rate, and improve the effect of crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

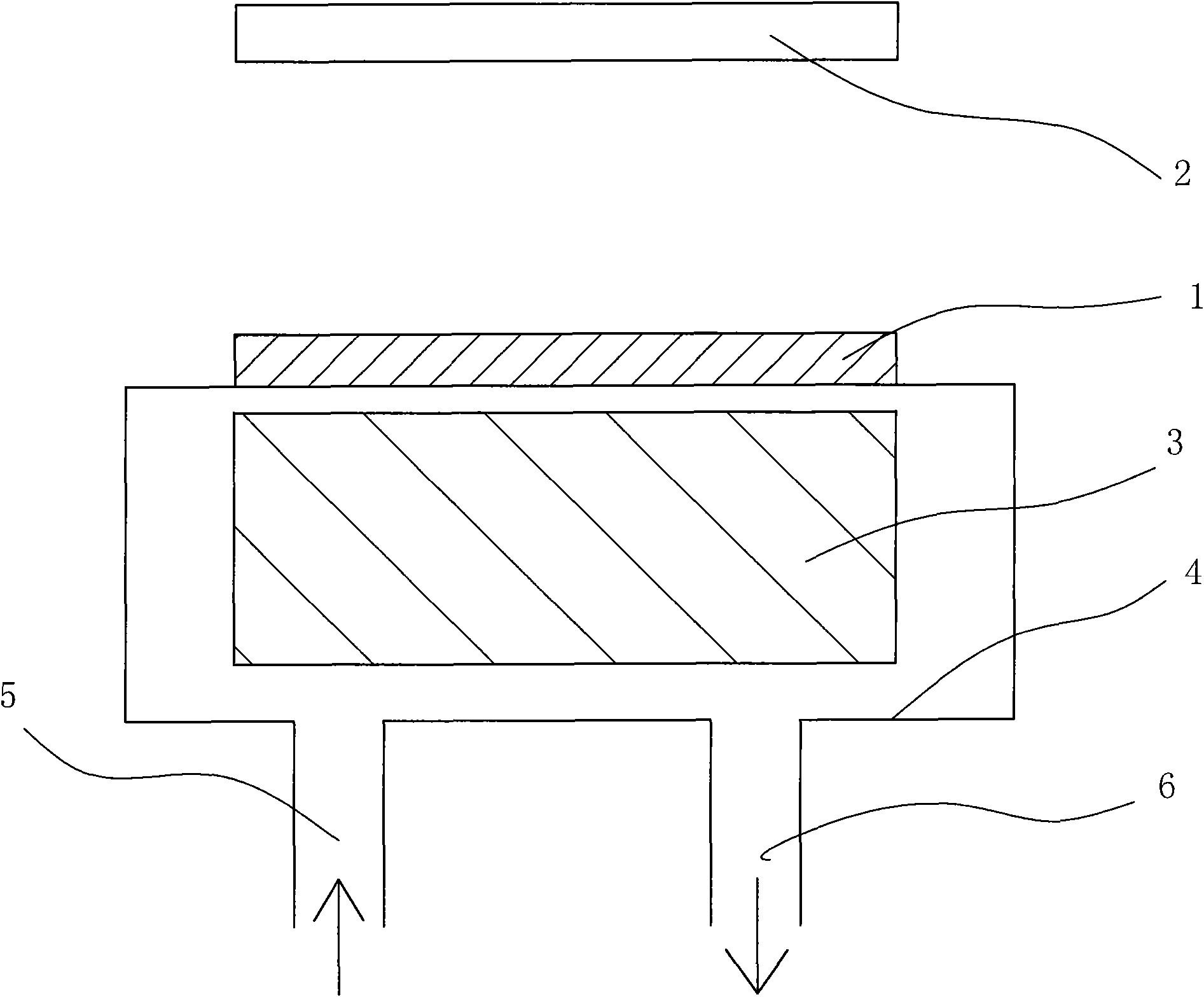

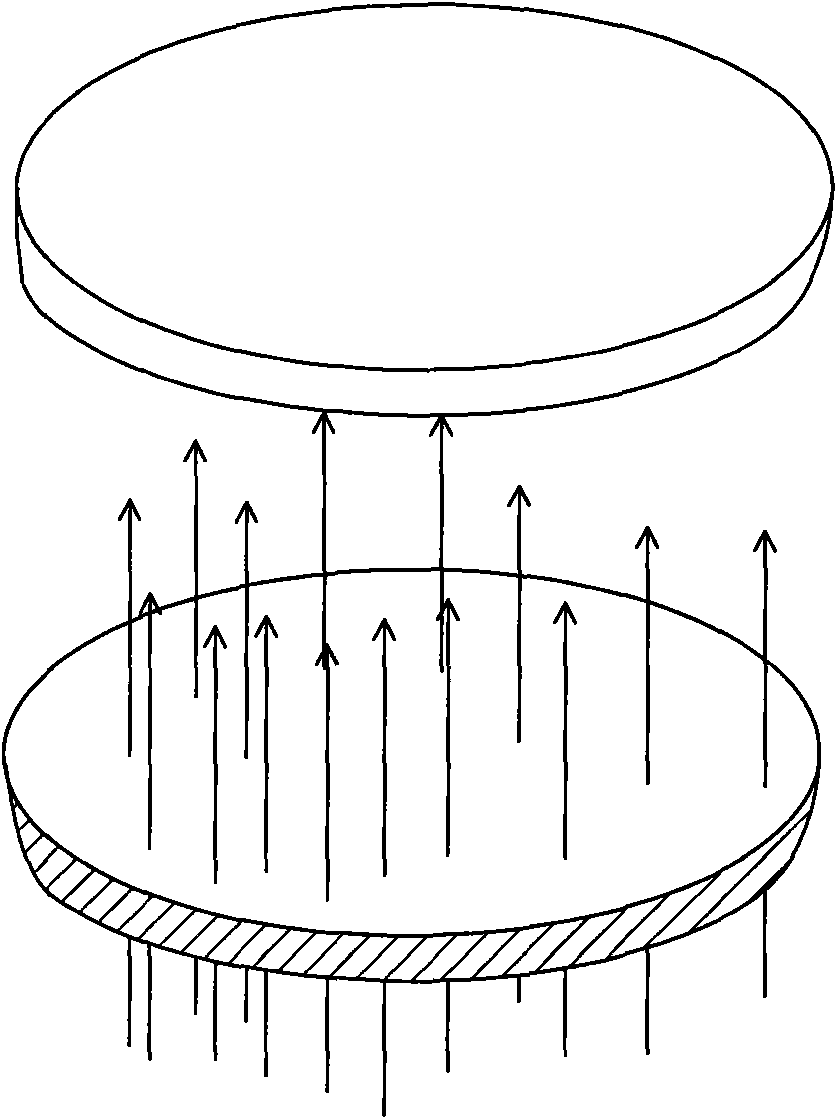

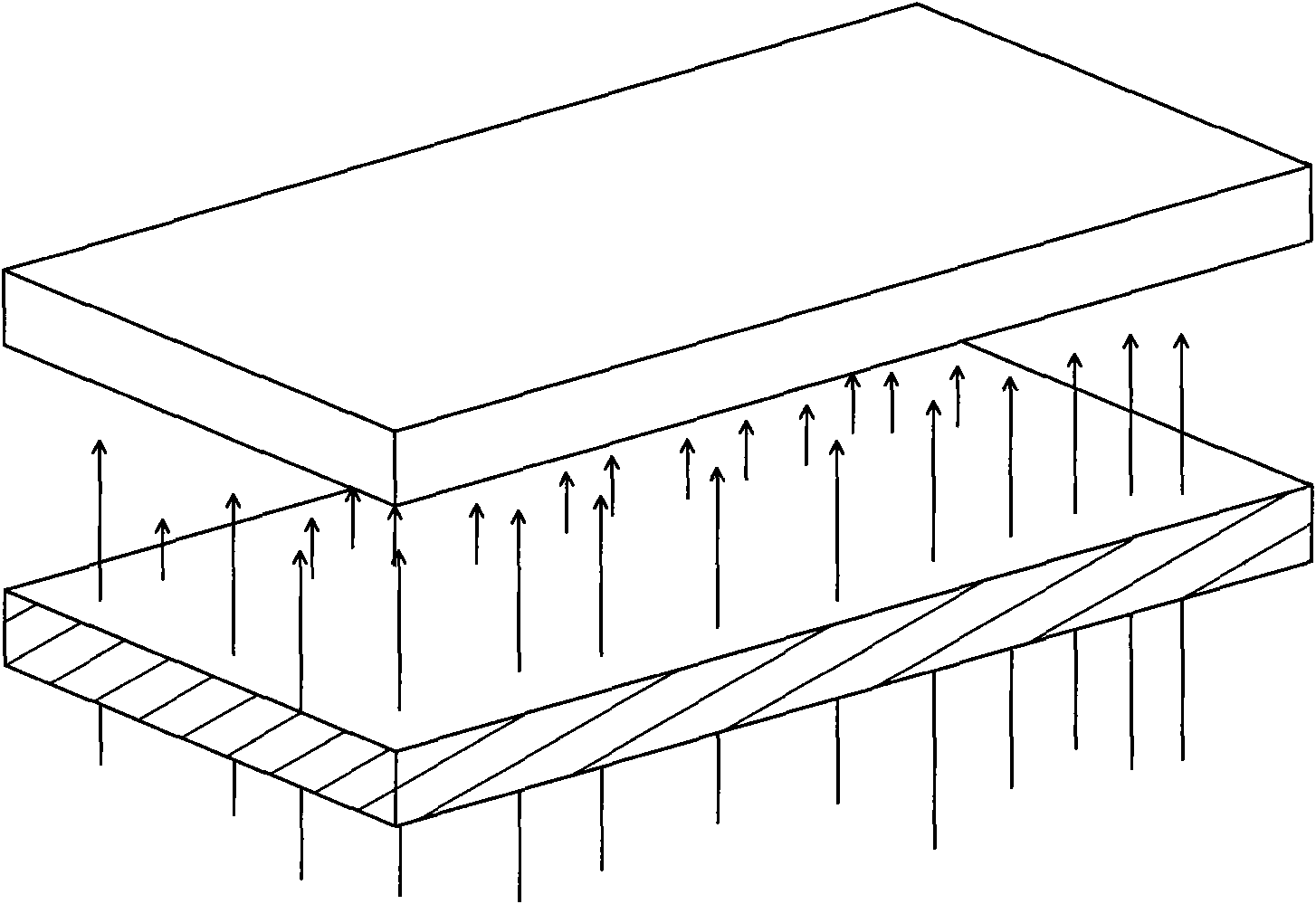

[0023] Embodiment 1: A sputtering coating method, using magnetic field assisted sputtering mode coating, see attached figure 1 As shown, the target 1 and the substrate 2 are arranged in parallel in the electric field, and the target 1 is located on the surface of the cathode 4, so that a plasma region is formed between the target 1 and the substrate 2, and the ions bombard the target 1 to generate sputtering, and the sputtered Atoms or molecules of the target are deposited on the substrate 2 to form a thin film. The target 1 is located in the magnetic field generated by the magnet 3, and the direction of the magnetic field is set perpendicular to the surface of the target.

[0024] In the present embodiment, the generation method of the magnetic field that the described direction is perpendicular to the surface of the target is to set a magnet 3 in the sputter coating cathode 4, the magnet 3 can be a permanent magnet or an electromagnet, and one pole of the magnet 3 points to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com