High-performance water-cooling heat dissipation platform for mainframe

A water-cooled heat dissipation, high-performance technology, applied in energy-saving computing, climate sustainability, instruments, etc., can solve problems such as high noise and high energy consumption, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

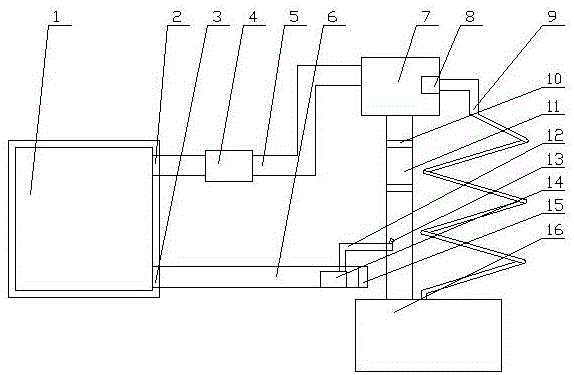

[0040] Such as figure 1 As shown: the present invention provides a high-performance mainframe water-cooled heat dissipation platform, including a sealed mainframe box 1, the top of the mainframe box 1 is provided with an air inlet 2, the bottom of the mainframe box 1 is provided with an air outlet hole 3, and the inlet The air hole 2 is communicated with the air inlet pipe 5, the air outlet hole 3 is communicated with the air outlet pipe 6, the air inlet pipe 5 is communicated with the upper end of the water-cooled cooling mechanism, and the air outlet pipeline 6 is communicated with the lower part of the water-cooled cooling mechanism. A drying mechanism 4 is arranged in the intake pipe 5 .

[0041] The water cooling mechanism includes a vertical cooling pipeline 11, the upper end of the cooling pipeline 11 is provided with an air collecting chamber 7, the lower end of the cooling pipeline 11 is provided with a water storage tank 16, and the bottom of the water storage tank 1...

Embodiment 2

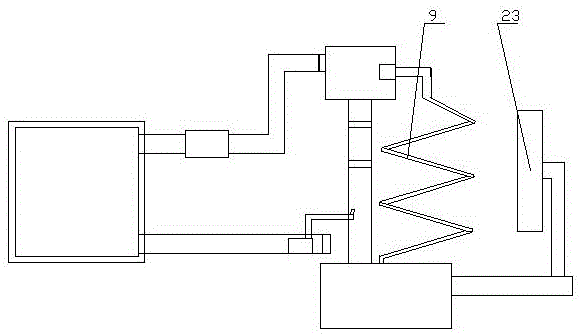

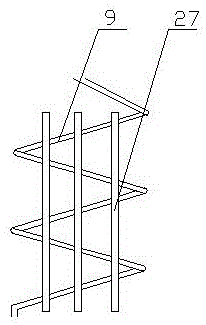

[0050] Such as figure 2 and image 3 As shown, the difference between this embodiment and Embodiment 1 is:

[0051] A cooling fan 23 is arranged corresponding to the lifting duct 9 , and a heat conduction plate 27 is vertically arranged outside the lifting duct 9 .

[0052] In order to cope with the host with more serious heat generation, a cooling fan is installed corresponding to the lifting pipe, and a heat conducting plate is vertically arranged outside the lifting pipe. The cooling fan blows air on the lifting pipe, which can cool down the cooling water faster. The heat conduction plate connects the lifting pipes on the upper and lower floors, increasing the contact surface between the lifting pipe and the wind blown by the cooling fan, which can be taken away by the fan within a unit time more heat.

Embodiment 3

[0054] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is:

[0055] The air bubble crushing mechanism 10 includes a cross-shaped bracket 21 arranged in the cooling pipe 11, an installation hole is arranged in the middle of the bracket 21, a bearing 20 is arranged in the installation hole, and a rotating rod 19 is arranged in the bearing 20. A plurality of stirring rods 18 are evenly arranged on the upper end of the rotating rod 19 , and an underwater motor 22 is arranged below the cross-shaped support 21 , and the underwater motor 22 is connected to the lower end of the rotating rod 19 through transmission.

[0056] The stirring rod 18 is a cylindrical structure, and several thorns 17 are arranged on the stirring rod 18, and the thorns 17 are cylindrical structures.

[0057] There are at least eight stirring rods 18, the diameter of the stirring rods 18 is less than one centimeter, and the diameter of the thorns 17 is less than three millim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com