Coal mine downhole hydraulic jet tree-shaped drill hole way-type drilling unit

A technology of hydraulic jetting and combined drilling tools, which is applied in liquid/gas jet drilling, directional drilling, etc. It can solve the problems of time-consuming, hindering the advancement of the drill bit, and insufficient consideration of slag discharge, so as to achieve convenient use and processing, and convenient processing The effect of using and increasing drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

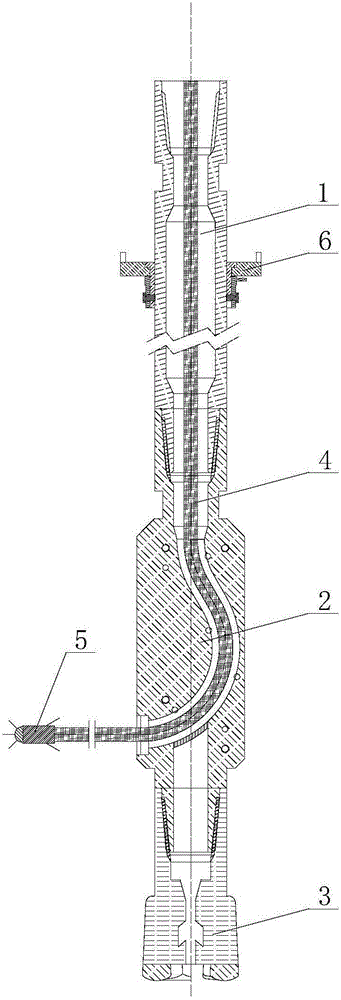

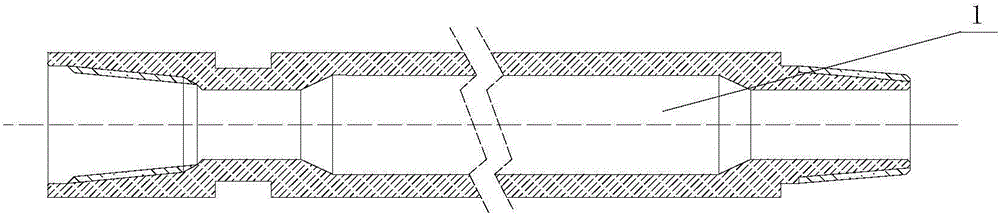

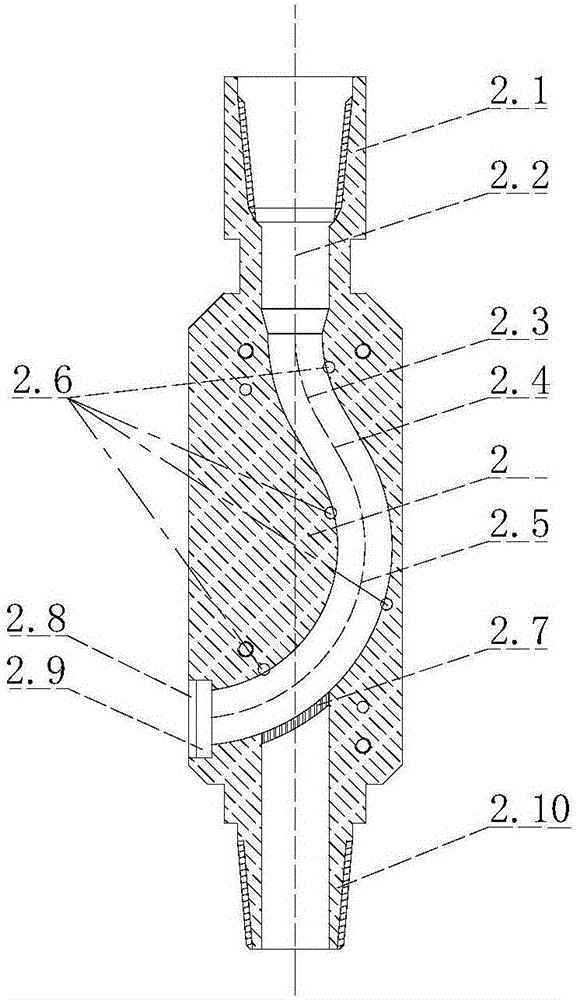

[0048] Such as figure 1 As shown, the combined drilling tool proposed by the present invention includes a drill rod (1), a guide (2), a drill bit (3), a high-pressure hose (4), a self-propelled drill bit (5) and a steering dial (6) etc. . The drill rod (1), the guide (2) and the drill bit (3) are connected in sequence, and are used together when reaming. High-pressure hose (4), self-advancing drill (5) and steering dial (6) are used when drilling tree boreholes. One end of the steering dial is fixed on the drill rod and rotates with the drill rod, and the other end is fixed on the chuck of the drilling rig, and the rotation angle of the guide (2) is controlled by the steering dial. The front end of the high-pressure hose (4) of the present invention is equipped with a self-advancing drill bit (5), and the high-pressure hose can withstand a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com