Flame-retardant aliphatic-aromatic copolyester and preparation method thereof

An aromatic and copolyester technology, which is applied in the field of flame-retardant aliphatic-aromatic copolyester and its preparation, can solve the problems of not fully meeting the preparation requirements, poor storage and hydrolysis resistance, and adverse effects in the production process, etc. , to achieve the effect of prolonging the maintenance/replacement cycle, excellent appearance and aesthetics, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

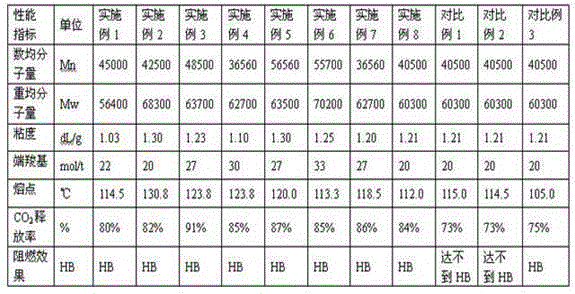

Examples

Embodiment 1

[0035] Butanediol is heated to 160 DEG C, then add 0.05wt% flame retardant A accounting for copolyester weight under stirring, wherein, the molar ratio of butanediol and flame retardant A is 2:1, control process tower The temperature is 100°C, so that the water generated by the reaction slips out, and the reaction is carried out for 4 hours, and the esterification rate reaches 98%; g was added to the reaction kettle, under the protection of nitrogen, the temperature was raised to 210°C, and 30 mg of n-butyl titanate was added to maintain the temperature in the reaction kettle at 210°C. To judge the degree of reaction, when the esterification rate reaches 95%, add the solution of butanediol and flame retardant A to it, stir for 20 minutes, after the temperature reaches 230°C, react for 30 minutes, and then start to slowly heat up to 245°C, Gradually increase the degree of vacuum, keep the temperature constant, keep the pressure in the kettle below 80Pa, and react for 3.5 hours ...

Embodiment 2

[0037] Butanediol is heated to 160 DEG C, then add 0.10wt% flame retardant C accounting for copolyester weight under stirring, wherein, the molar ratio of butanediol and flame retardant B is 2:1, control process tower The temperature is 100°C, let the water generated by the reaction slip out, react for 4 hours, and the esterification rate reaches 98%; 33.0g of 1,4-butanediol, 35.0g of terephthalic acid, 34.4g of sebacic acid, naphthalene dicarboxylic acid Add 2.5g into the reaction kettle, under the protection of nitrogen, heat up to 210°C, add 30mg of n-butyl titanate, maintain the temperature in the reaction kettle at 210°C, remove the water produced by the reaction at the same time, and weigh the reaction produced water Use water to judge the degree of reaction. When the esterification rate reaches 95%, add the solution of butanediol and flame retardant C to it, stir for 20 minutes, raise the temperature to 230°C, react for 30 minutes, and then start to slowly heat up to 245...

Embodiment 3

[0039] Butanediol is heated to 160 DEG C, then add 0.70wt% flame retardant A accounting for copolyester weight under stirring, wherein, the molar ratio of butanediol and flame retardant A is 2:1, control process tower The temperature is 100°C, the water generated by the reaction is slipped out, the reaction is 4 hours, and the esterification rate reaches 98%. 33.0g of 1,4-butanediol, 25.0g of sebacic acid, 35g of terephthalic acid, and 2.2 g of naphthalene dicarboxylic acid g was added to the reaction kettle, under the protection of nitrogen, the temperature was raised to 210°C, and 30 mg of n-butyl titanate was added to maintain the temperature in the reaction kettle at 210°C. To judge the degree of reaction, when the esterification rate reaches 95%, add the solution of butanediol and flame retardant A to it, stir for 20 minutes, after the temperature reaches 230°C, react for 30 minutes, and then start to slowly heat up to 245°C, Gradually increase the degree of vacuum, keep th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com