Heat-sensitive material closed loop adsorption dehumidification two-stage drying system

A heat-sensitive material, closed-circuit circulation technology, applied in the direction of heating to dry solid materials, drying solid materials, fluid circulation arrangement, etc., can solve the problems of pollution, limited dust removal ability, etc., to shorten the reaction time, shorten the drying time, and ensure the activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

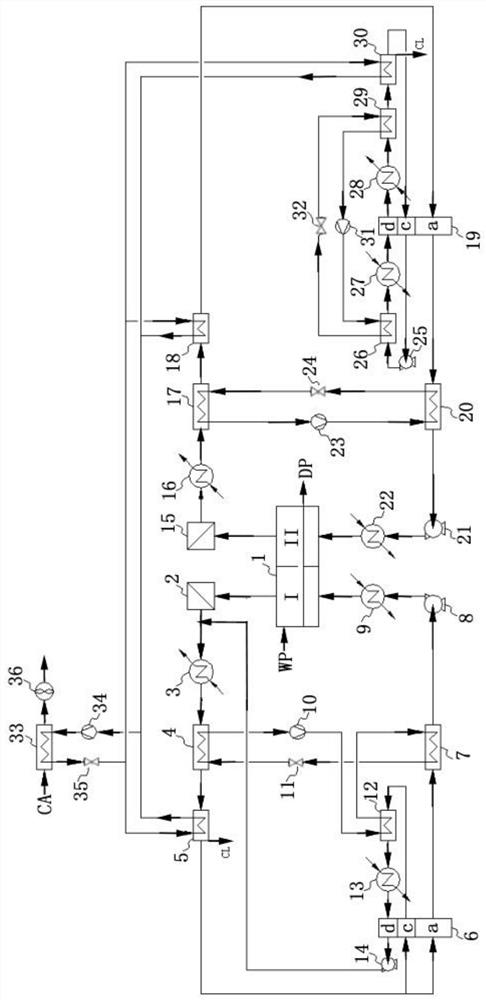

[0059] This embodiment 1 utilizes such as figure 1 The device system with the structure shown dries the LM resin with a water content of 44%, which is divided into the first drying stage and the second drying stage, and the drying medium is N 2 .

[0060] Such as figure 1 As shown, the device of the present invention includes a closed loop system, a wheel dehumidification system, a heat pump cycle system, and a drying system.

[0061] The air path of the drying process in the first drying stage is: LM resin with a water content of 44% is passed into the first drying zone I, and at the same time, the temperature is 50°C and the humidity is 2.0 from the air inlet at the bottom of the first drying zone I. g / kg dry N 2 , for drying. After the tail gas discharged from the top of the first drying zone I passes through the first gas-solid separator 2 to remove solids, the temperature discharged from the first gas-solid separator 2 is 60°C, humidity 48.9g / kg absolute dry N 2 , an...

Embodiment 2

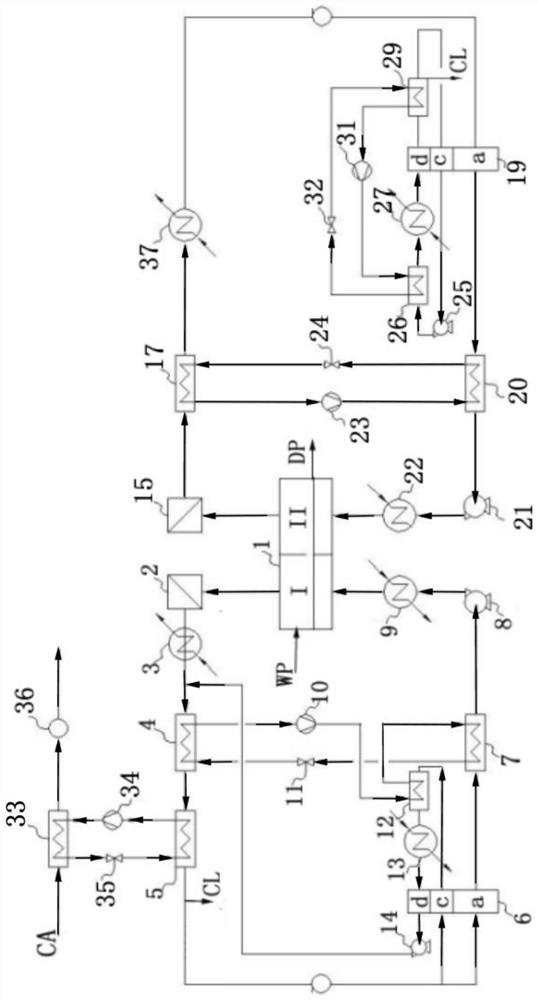

[0070] This embodiment 2 utilizes such as figure 2 The device system with the shown structure dries the LM resin with a water content of 44%, which is divided into the first drying stage and the second drying stage, and the drying medium is nitrogen.

[0071] The air path of the drying process in the first drying stage is: LM resin with a water content of 44% is passed into the first drying zone I, and the temperature is 50°C and the humidity is 2.0g from the air inlet at the bottom of the first drying zone I. / kg dry N 2 , for drying. Cool down through the first precooler 3 to obtain a temperature of 47°C and a humidity of 48.9g / kg absolute dry N 2 , and the N extracted from the first regenerative blower 14 with a temperature of 60°C and a humidity of 27.2g / kg 2 , mixed to obtain N with a temperature of 50.2°C and a humidity of 43.5g / kg 2 Through the first evaporator 4 and the second evaporator 5, the absolute dry N with a temperature of 12°C and a humidity of 8.3g / kg is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com