Brass brazing alloy

A brass brazing filler metal and alloy technology, applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problems of lower strength index, copper annealing, lower reliability of brazing joints, etc., so as to improve reliability performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

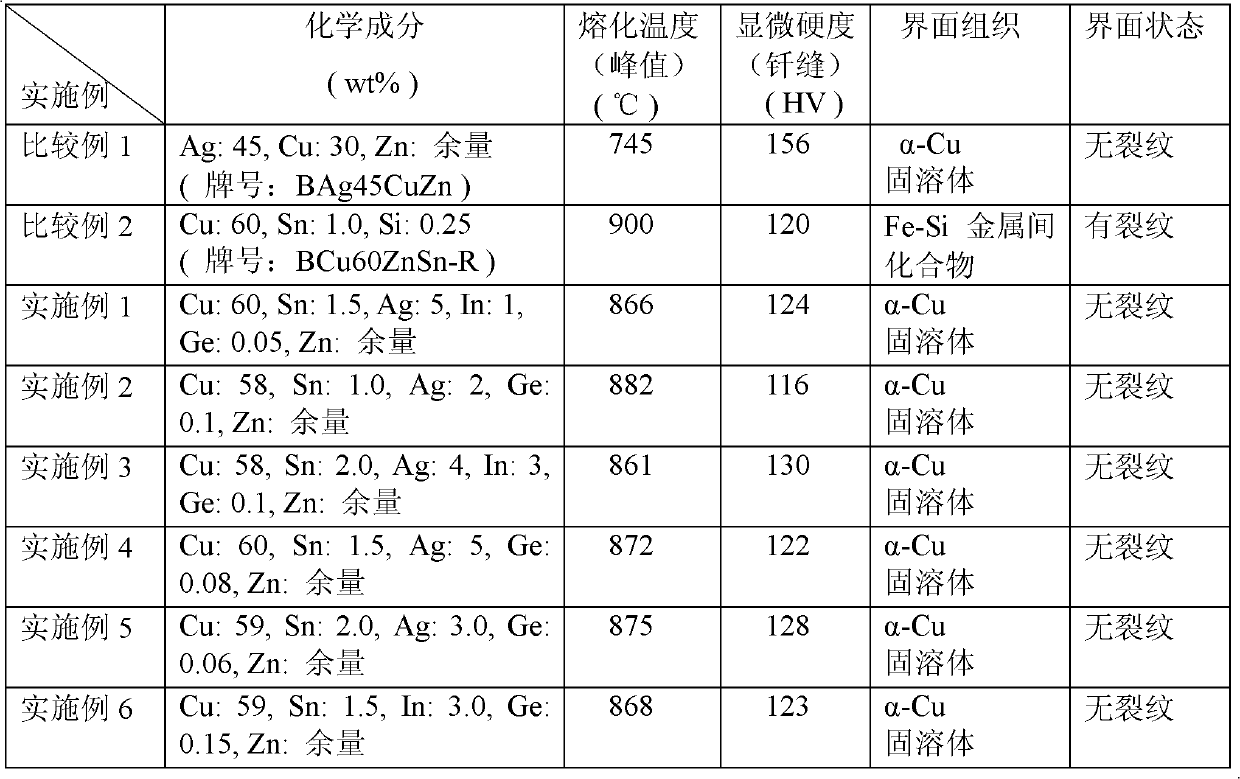

Examples

Embodiment 1

[0027] A brass solder alloy, its alloy formula is Cu: 60%, Sn: 1.5%, Ag: 5%, In: 1.0%, Ge: 0.05%, Zn: balance.

[0028] The preparation steps of above-mentioned brass solder alloy are as follows:

[0029] 1) Prepare a total of 5000 grams of each material according to the above formula;

[0030] 2) Put Cu into an induction furnace and heat it to above 1100°C and melt it;

[0031] 3) Add Zn and stir fully, while rapidly reducing the temperature of the molten metal to 920°C;

[0032] 4) After the molten metal is uniform, add Ag and stir thoroughly;

[0033] 5) Add Sn, In and Ge and stir evenly, then cast;

[0034] 6) The brazing alloy is obtained by extruding and wire drawing according to the conventional brazing filler metal processing method.

Embodiment 2

[0036] The difference between this embodiment and Example 1 is to adopt the following formula:

[0037] Cu: 58%, Sn: 1.0%, Ag: 2%, Ge: 0.1%, Zn: balance.

Embodiment 3

[0039] The difference between this embodiment and Example 1 is to adopt the following formula:

[0040] Cu: 58%, Sn: 2.0%, Ag: 4%, In: 3%, Ge: 0.1%, Zn: balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com