Short-process preparation method of ultra-fine grain Mg-3Al-1Zn alloy

An ultra-fine-grained, short-flow technology, used in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve problems such as unsuitable processing of large-sized bulk materials, complex operating procedures, and unsuitable industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The material selected in this embodiment is Mg-3Al-1Zn, and the length, width and height of the sample before thermal processing are 35 mm, 35 mm, and 40 mm, respectively.

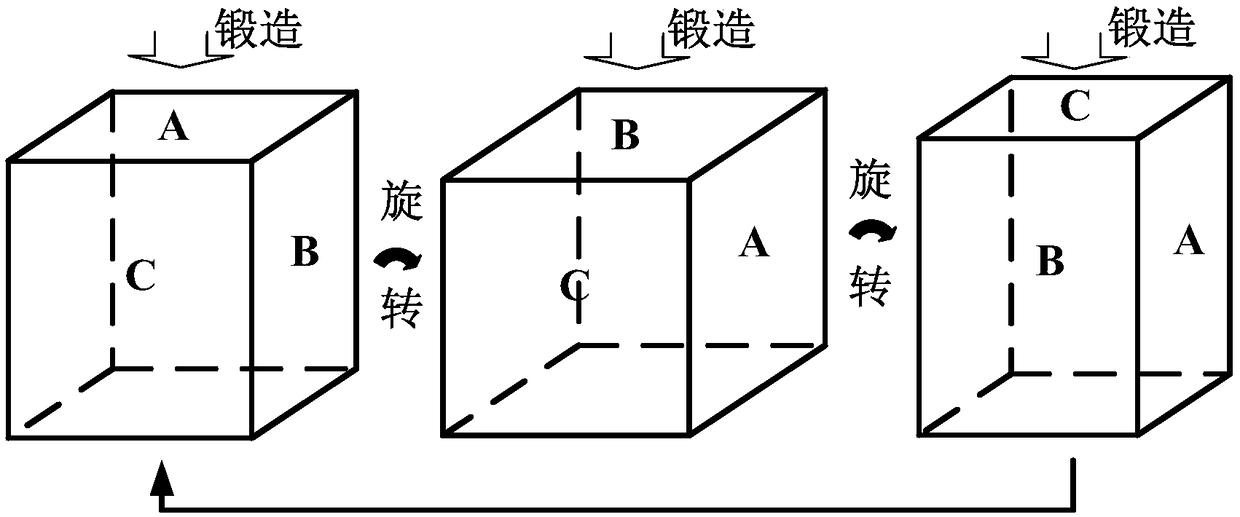

[0026] A short process preparation method of ultrafine-grained Mg-3Al-1Zn alloy, comprising the following steps:

[0027] 1) Casting process: Prepare Mg-3Al-1Zn alloy melt according to the magnesium alloy smelting method, slowly pour the melt into a square water-cooled copper mold, the size of the copper mold is 150mm*150mm*150mm, the mold cooling water capacity is 300ml, cooling The water flow rate is 3 liters per minute. During the pouring process, sulfur powder is sprinkled to prevent burning, and the ingot is taken out after cooling; under the action of the water-cooled copper mold, the solidification structure of the alloy is relatively uniform equiaxed crystals, and there are no coarse grains near the grain boundaries. The second phase basically obtains a single-phase solid solution structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com