Patents

Literature

33results about How to "Full heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

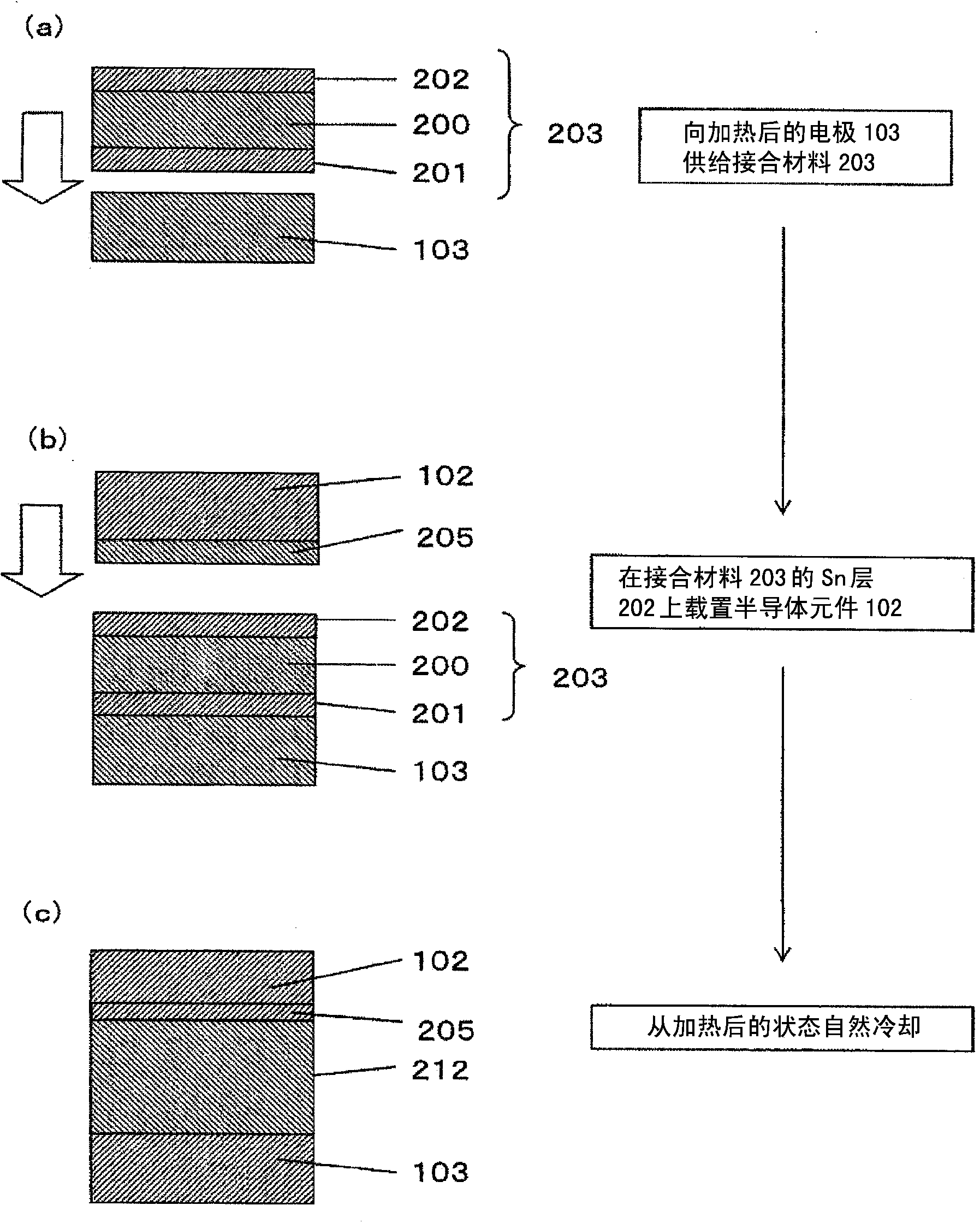

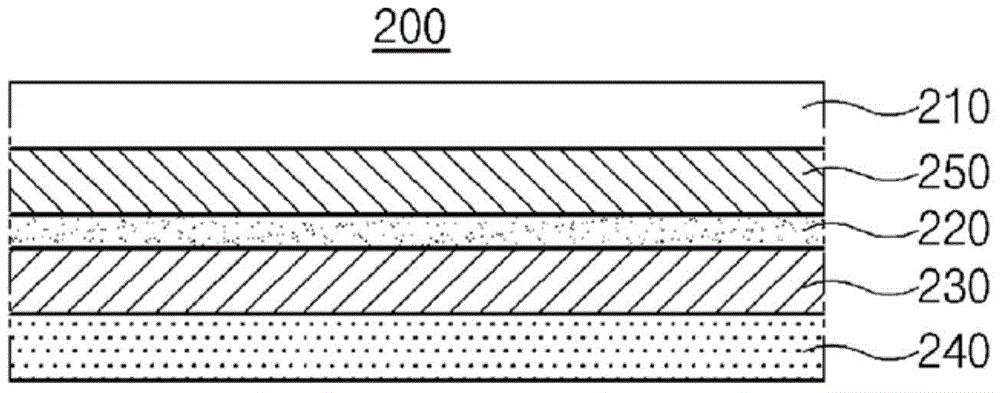

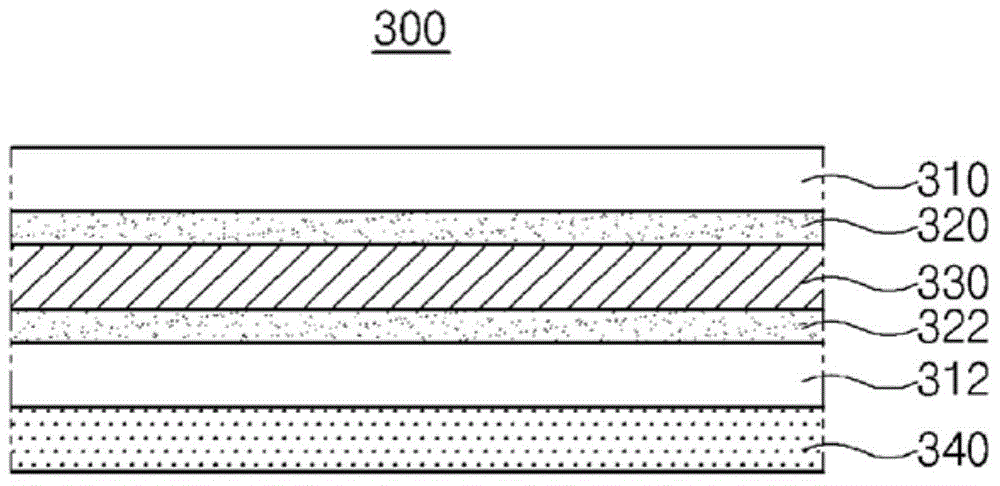

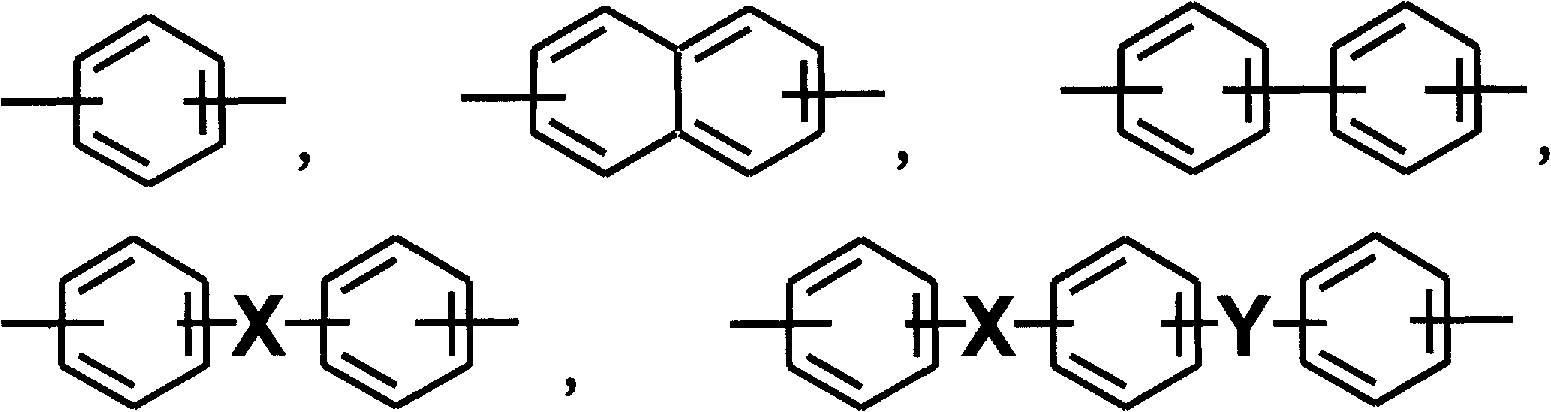

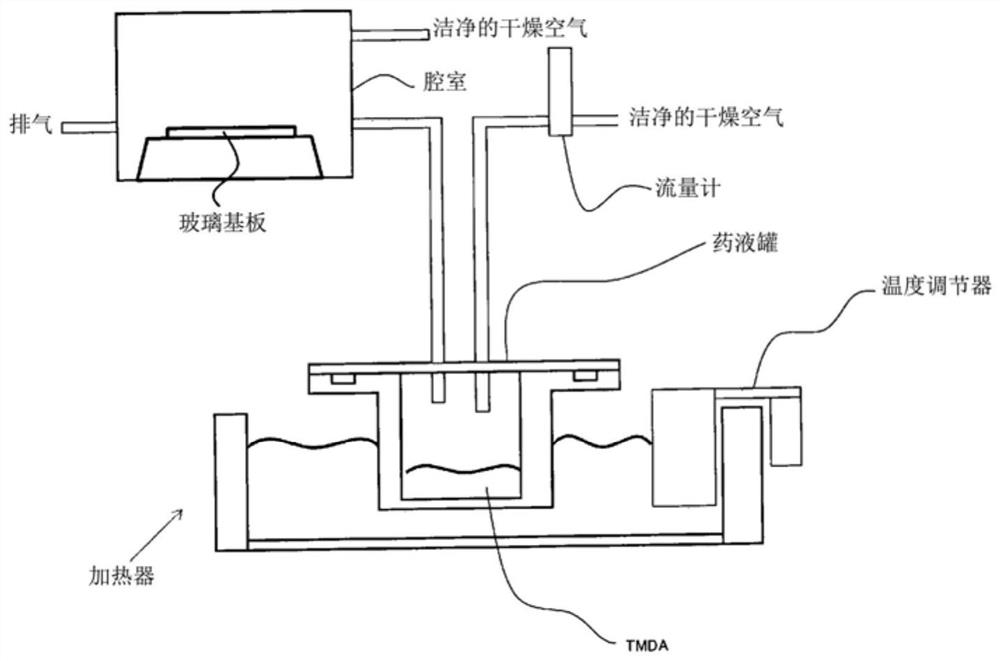

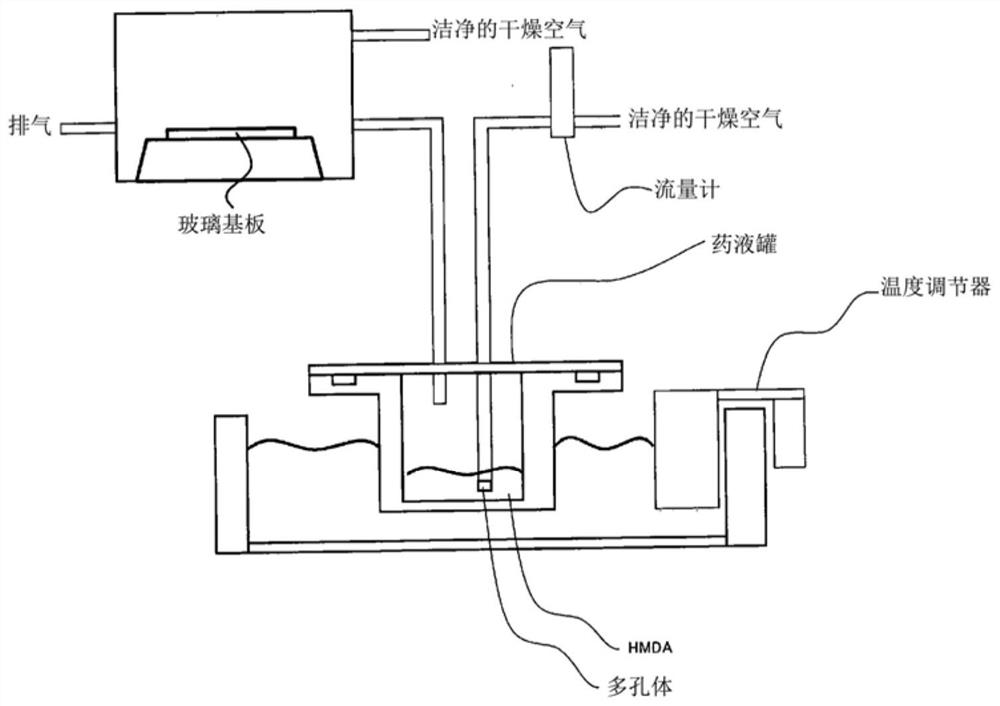

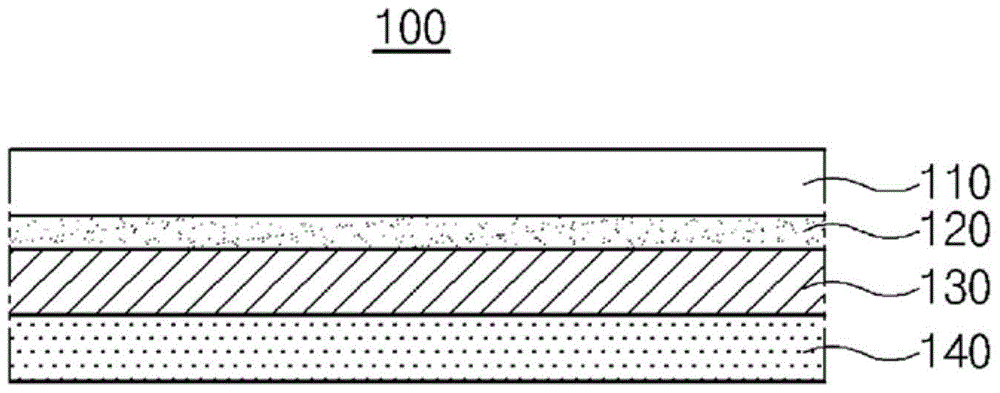

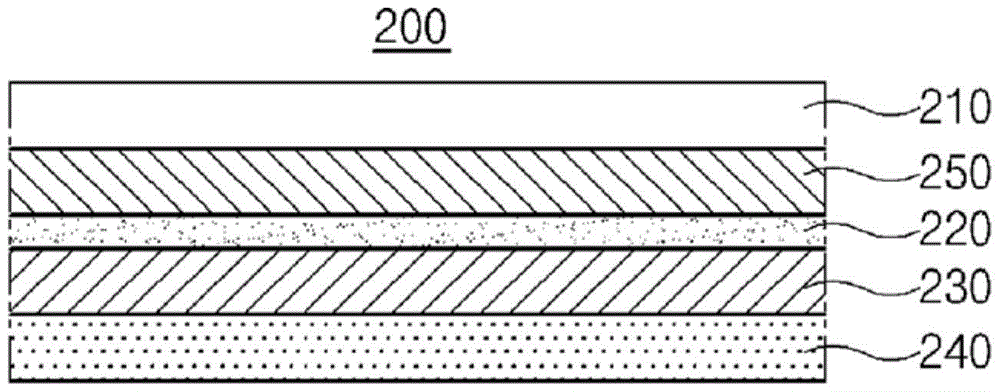

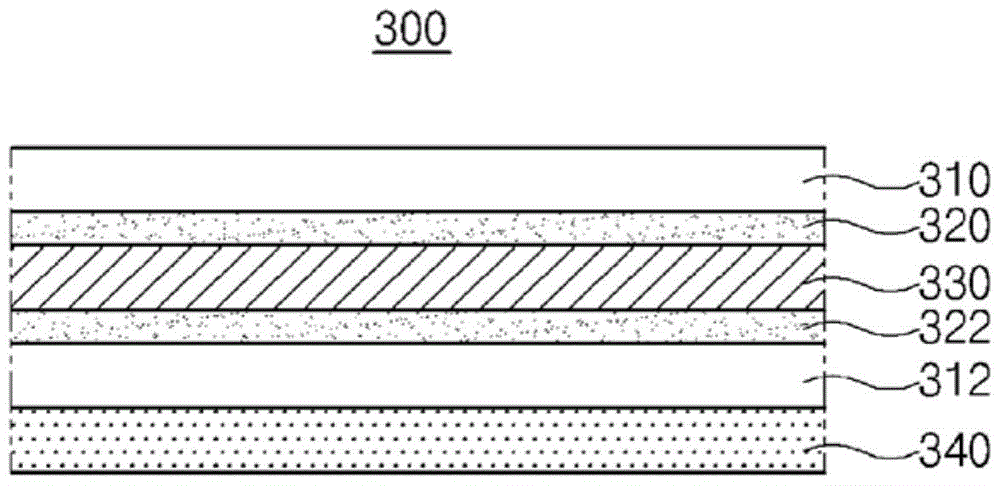

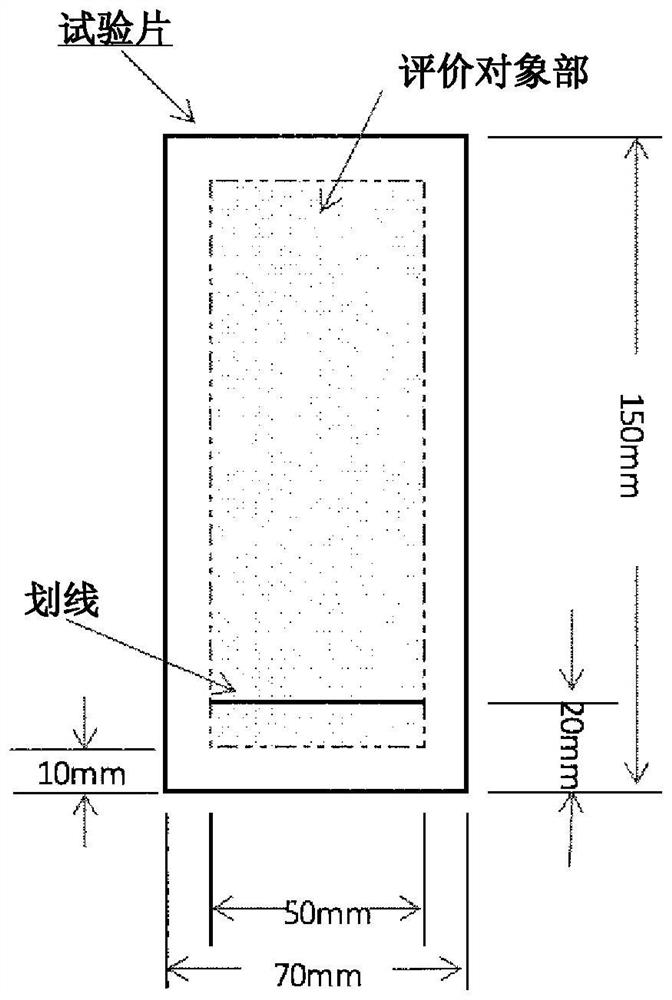

Element-processing layered structure, method for manufacturing element-processing layered structure, and method for manufacturing thin element using same

InactiveCN105612600AImprove productivityFull heat resistanceSynthetic resin layered productsSolid-state devicesLayered structureEngineering

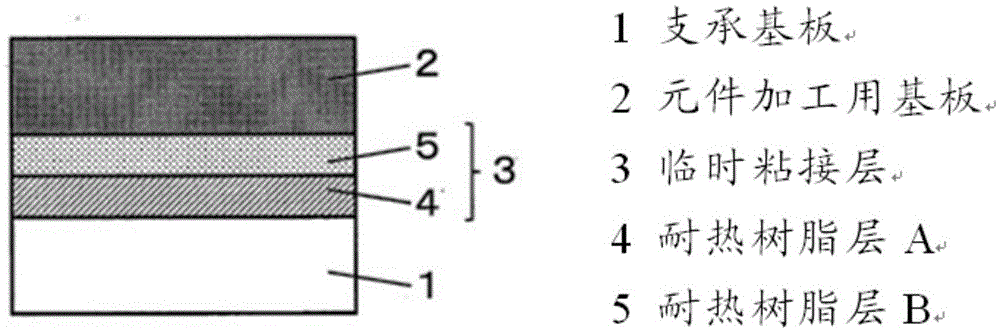

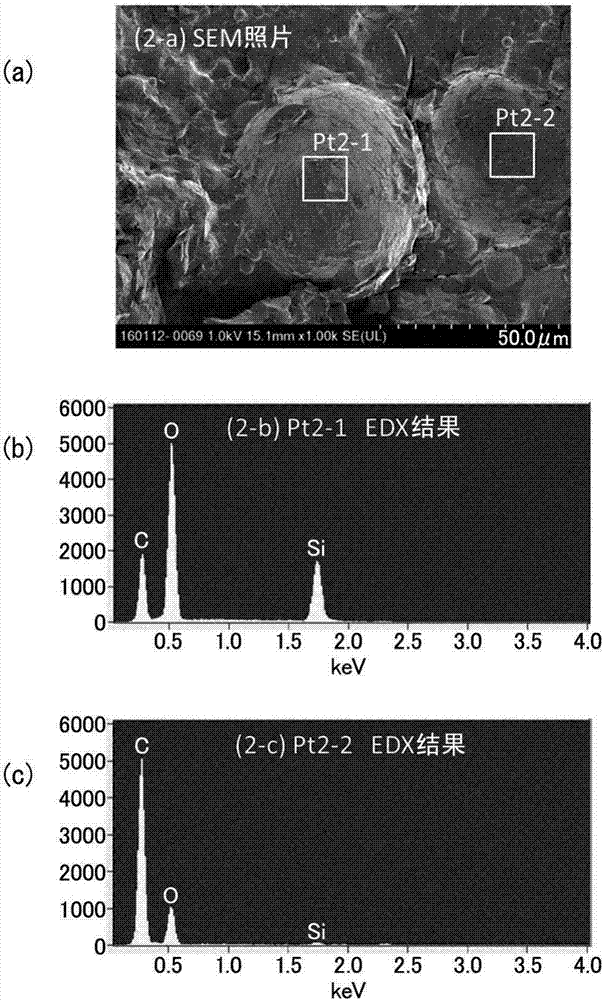

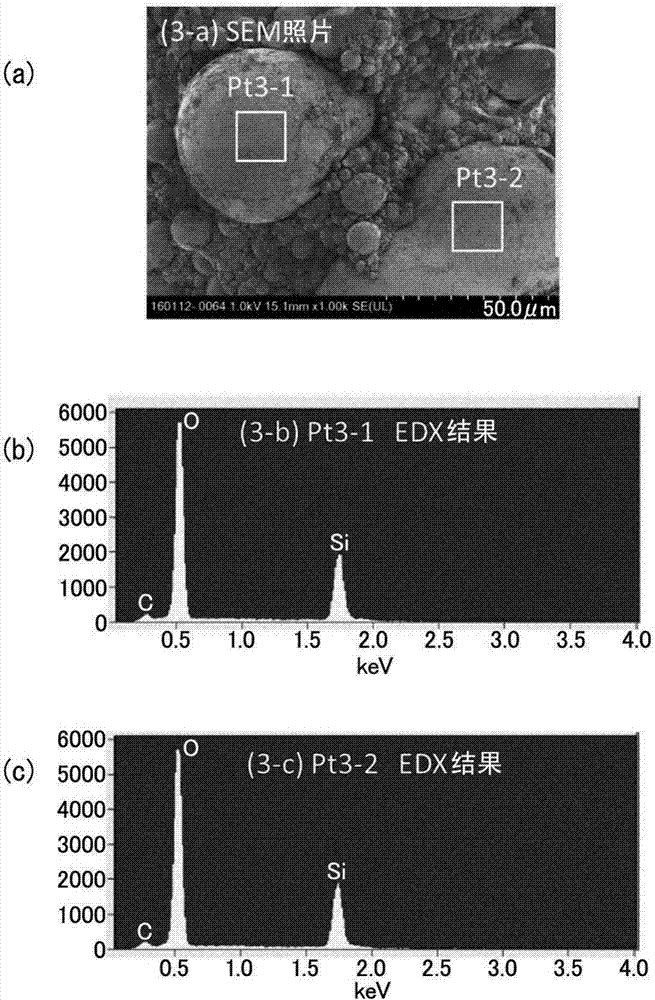

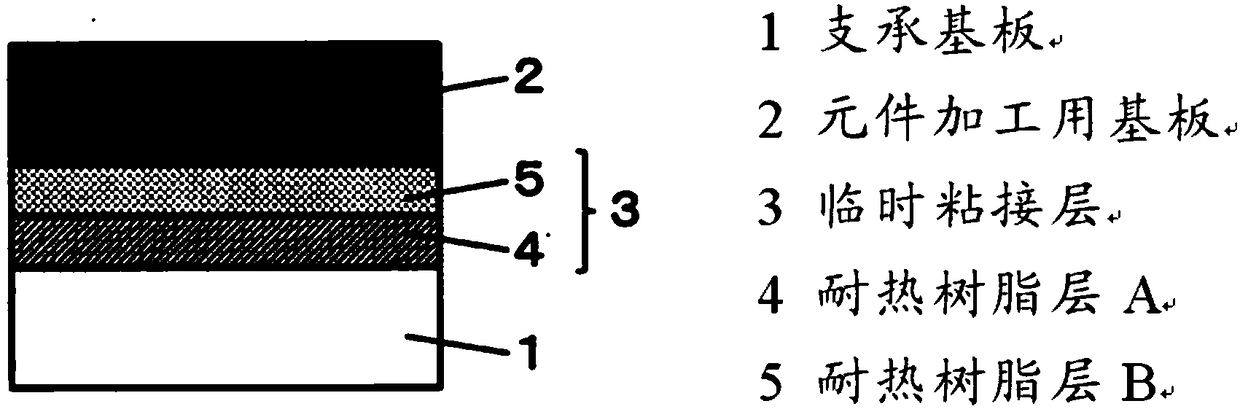

To provide an element-processing layered structure in which there is no generation of volatile compounds or occurrence of cracking in a substrate due to separation or the like during the steps for polishing the back surface and forming the back-surface circuits of a semiconductor circuit formation substrate, separation being possible in mild conditions at room temperature, and essentially no temporary adhesive remaining on the semiconductor circuit formation substrate side after separation. An element-processing layered structure in which an element-processing substrate is layered on a support substrate with temporary adhesive layers interposed therebetween, wherein the element-processing layered structure is characterized in that: the temporary adhesive layers are layered in the order of heat-resistant resin layer (A), heat-resistant resin layer (B), from the support substrate side; and the adhesive force between the heat-resistant resin layer (B) and the element-processing substrate is lower than the adhesive force between the heat-resistant resin layer (A) and the support substrate, and the adhesive force between the heat-resistant resin layer (B) and the heat-resistant resin layer (A).

Owner:TORAY IND INC

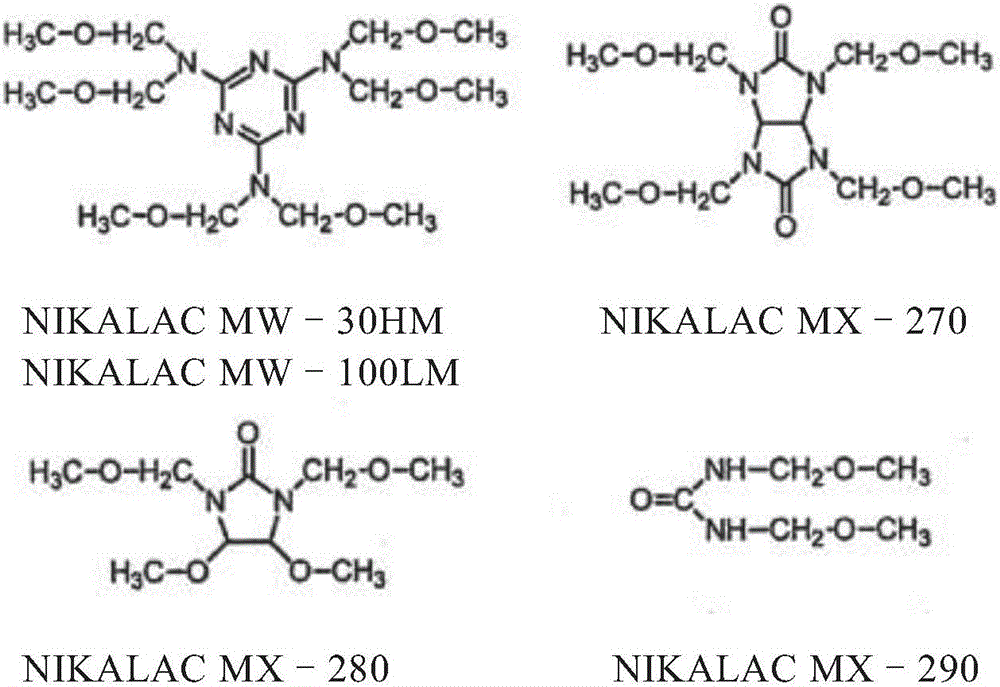

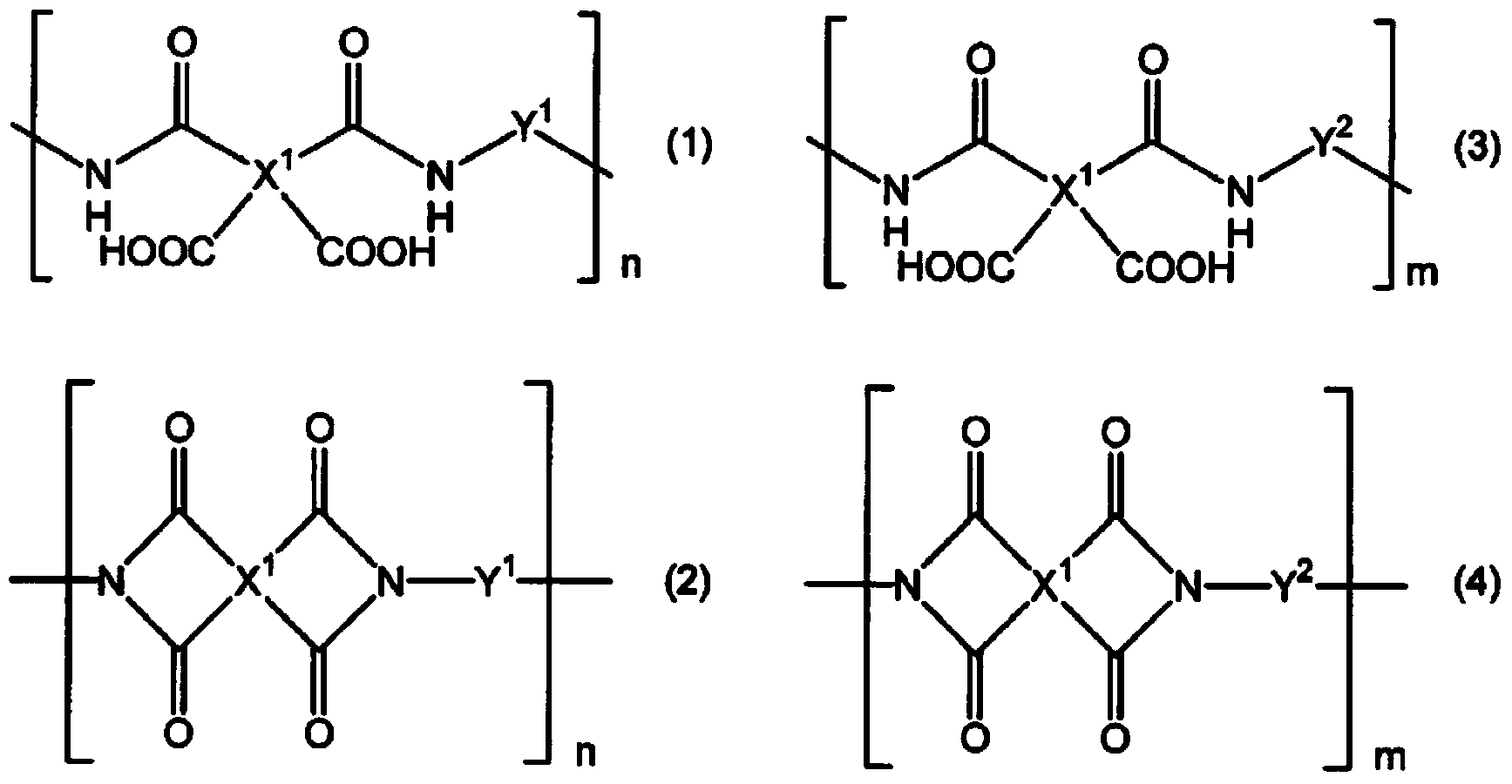

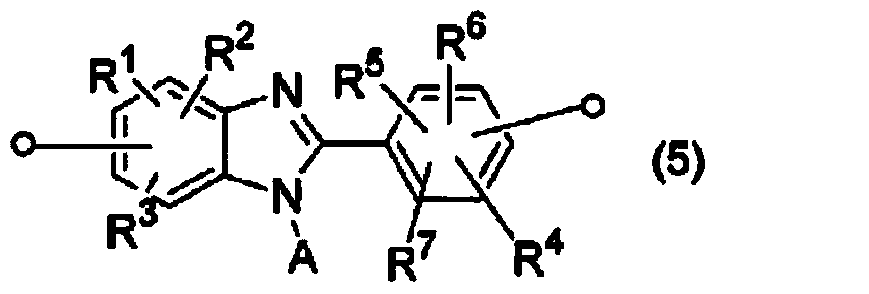

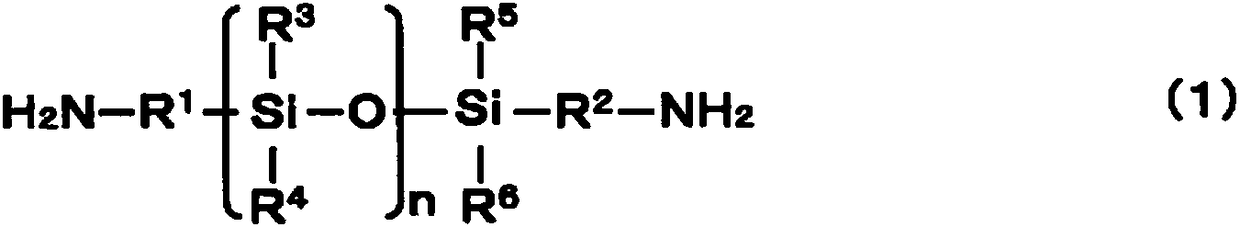

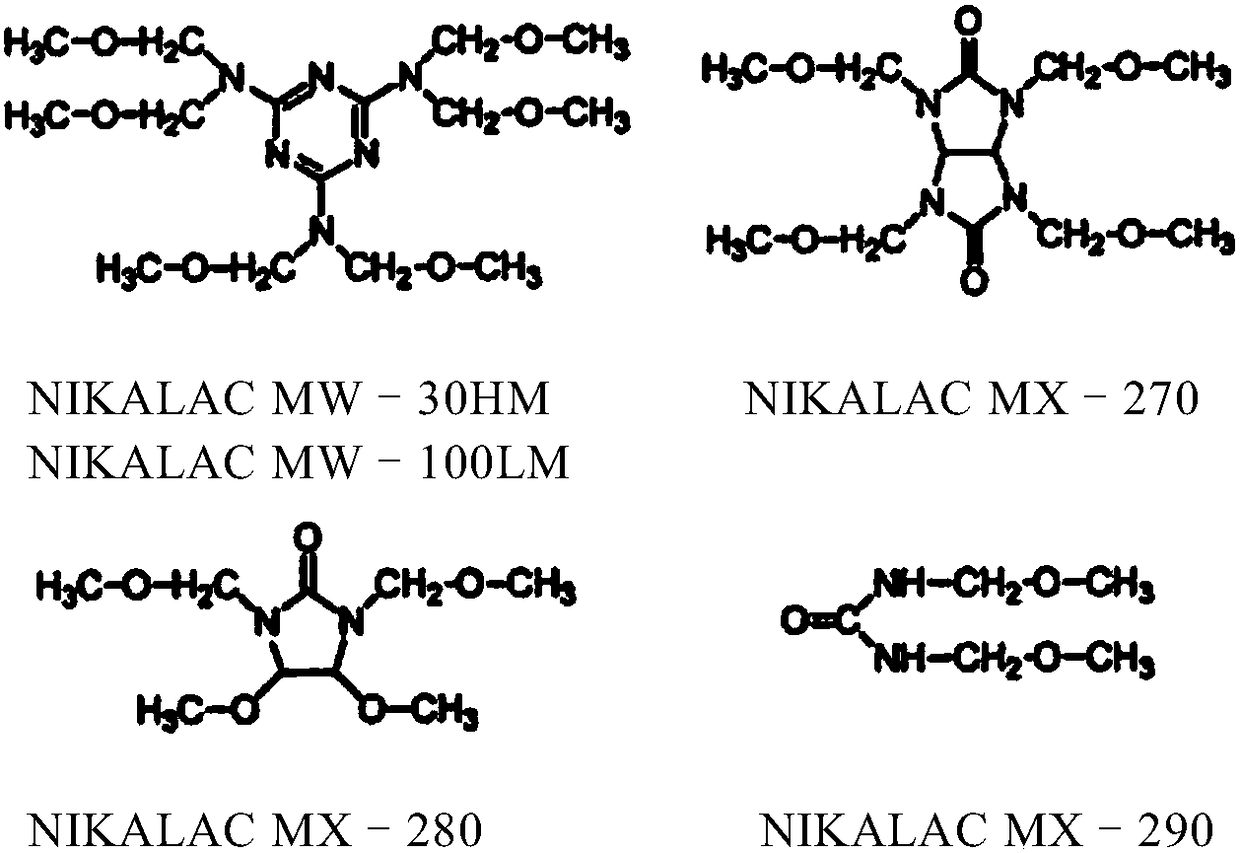

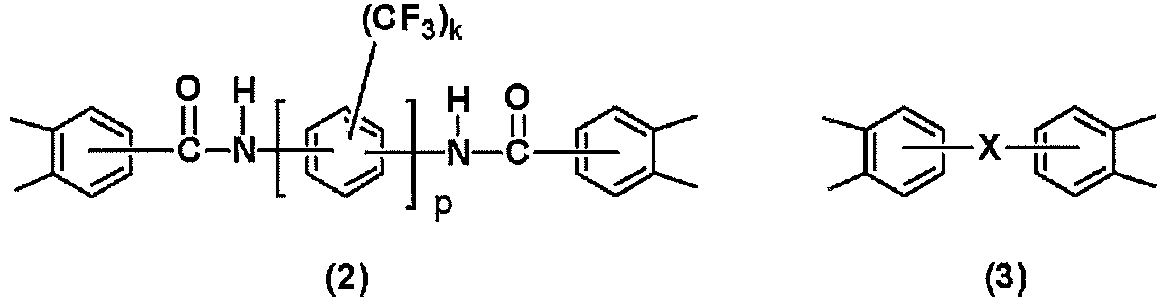

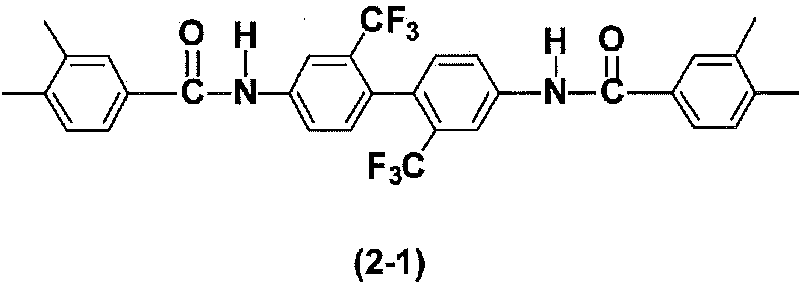

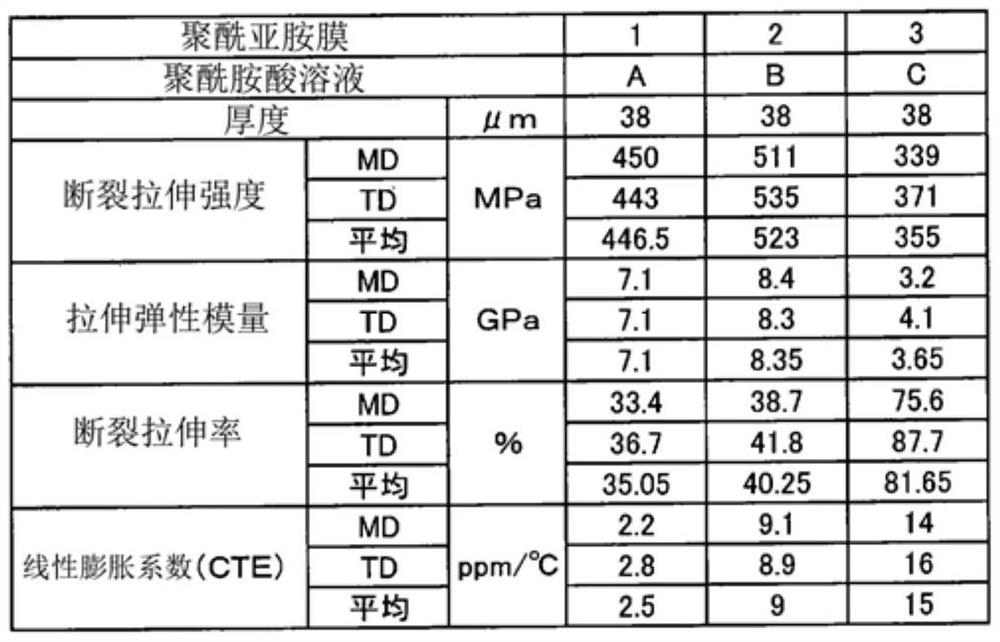

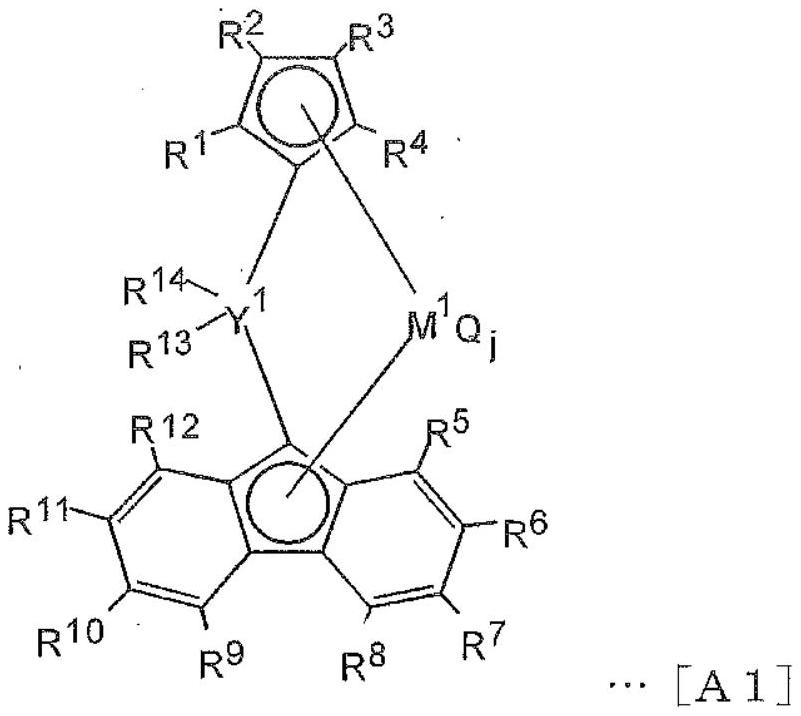

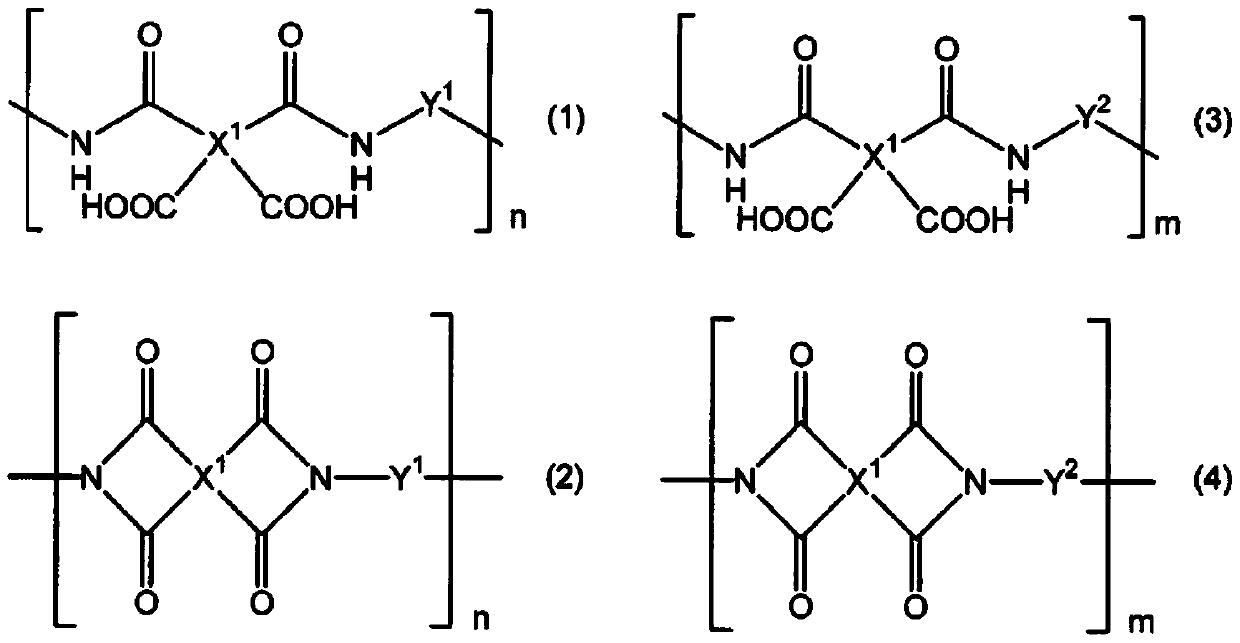

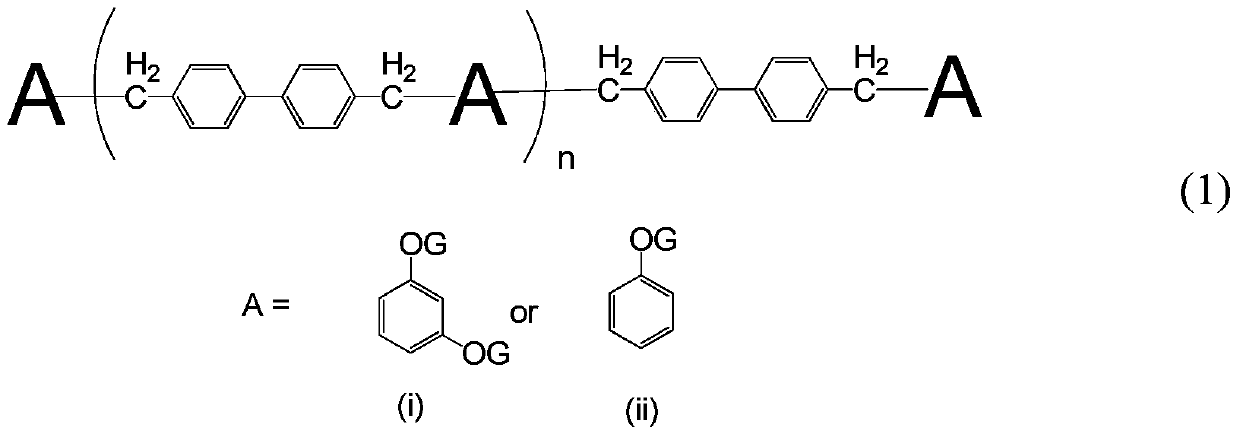

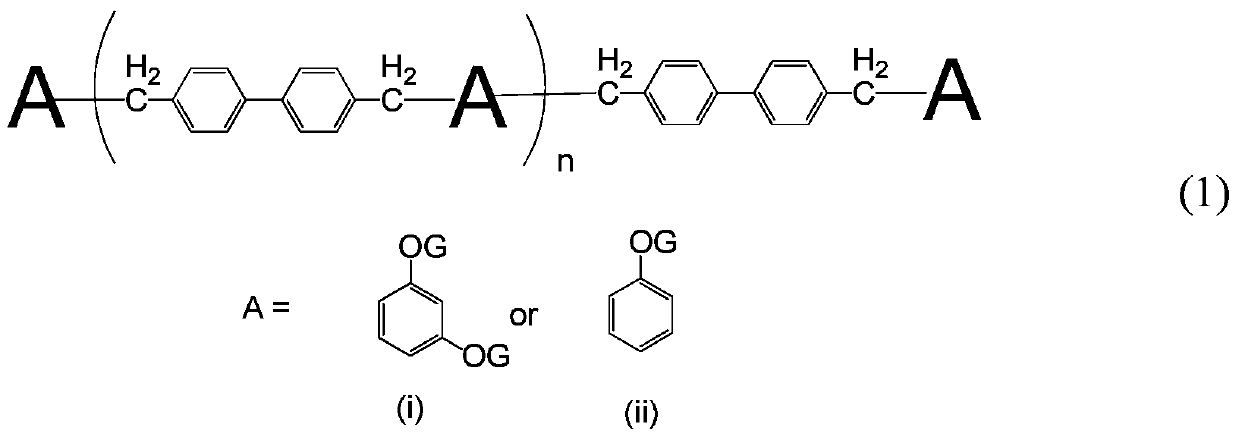

Resin composition for display substrates

ActiveCN104066768AModerate coefficient of linear expansionModerate softnessCoatingsNon-linear opticsNitrogenDisplay device

The invention aims to provide a resin composition for display substrates which is capable of forming a useful polyimide film with an appropriate linear expansion coefficient and an appropriate flexibility. The solution is that this resin composition for display substrates contains a polyamic acid which includes a structural unit represented by formula (1) and a structural unit represented by formula (3), or a polyimide which includes a structural unit represented by formula (2) and a structural unit represented by formula (4). [In formulae 1 through 4, X1 represents a tetravalent organic group having an aromatic group and two carbonyl groups, Y1 represents a divalent aromatic group or aliphatic group, Y2 represents a divalent aromatic group having two or more nitrogen atoms, and n and m represent natural numbers.]

Owner:NISSAN CHEM IND LTD

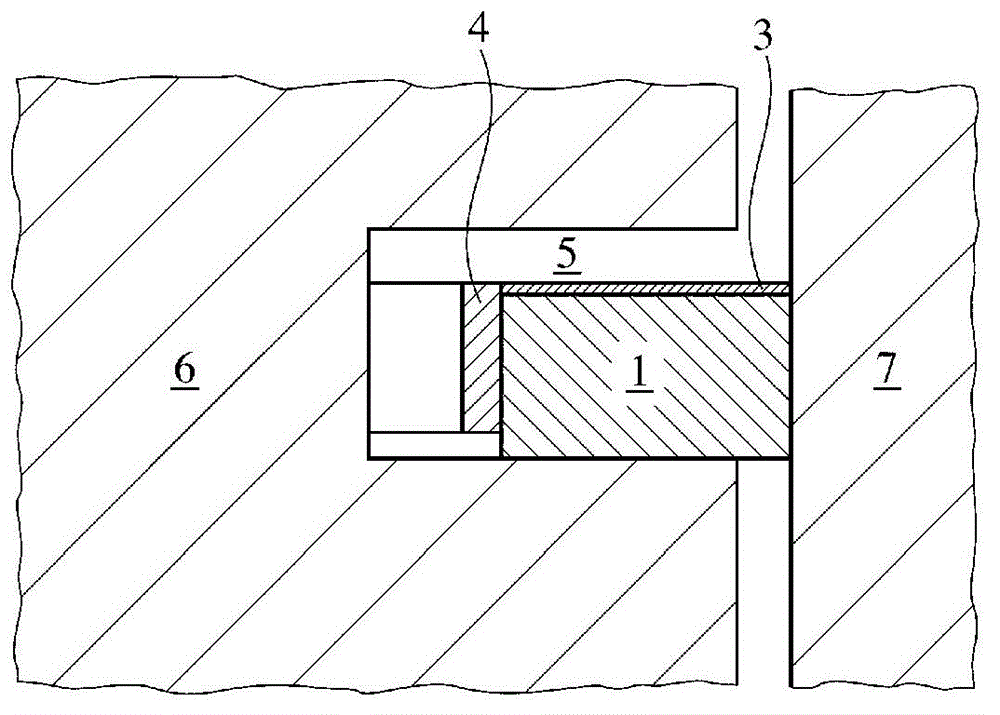

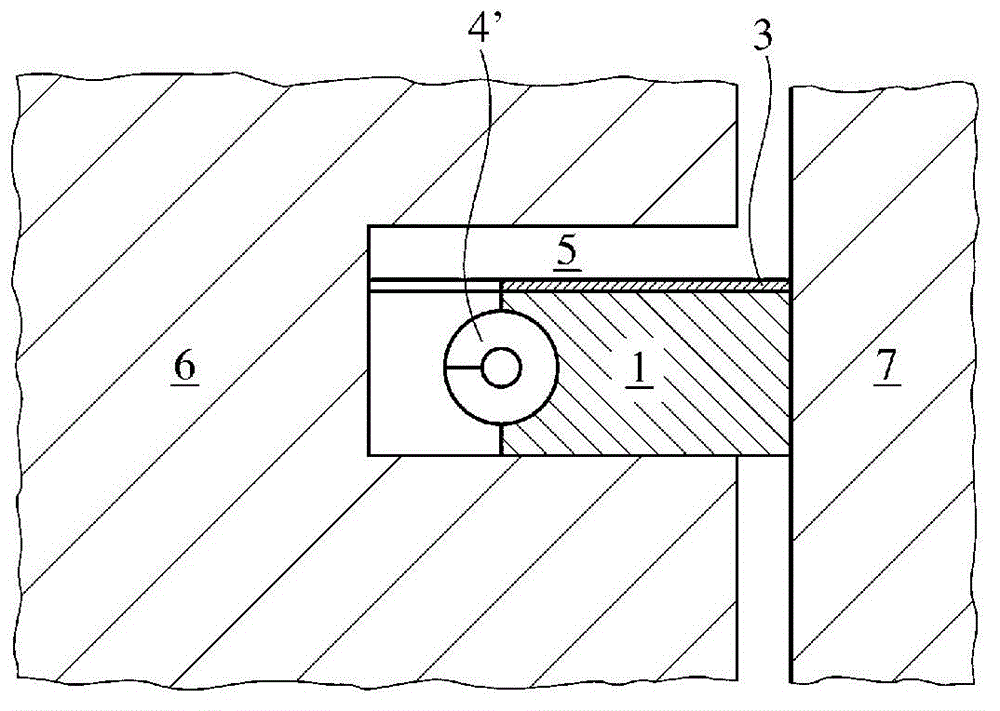

Combined piston ring

InactiveCN103339422AExcellent air tightnessReduce heat loadPiston ringsMachines/enginesCountermeasureCombustion chamber

Provided is a combined piston ring having an excellent gas seal characteristic and comprising a special gap effective for countermeasures against blow-by, wherein a combustion chamber-side side surface is not locally deformed nor melted even when receiving combustion gas from the combustion chamber side. To this end, a combined piston ring comprises a piston ring body which is produced from a high-strength heat-resistant resin and has a gap part having a step shape when viewed from the upper and lower surfaces and the outer peripheral surface, and a spring which is mounted to the inner peripheral part of the piston ring body and presses the piston ring body radially outward, and the combustion chamber-side side surface of at least the piston ring body is coated with a heat-resistant film.

Owner:RIKEN CO LTD

Oil tempered steel wire excellent in coiling workability and method for production thereof

ActiveCN1745195AImprove the winding effectFull heat resistanceSuperimposed coating processThin material handlingInorganic saltsSulfate

An oil tempered steel wire, characterized in that it comprises a wire material and, formed on the surface thereof, a coating film comprising one or more inorganic salts selected from the group consisting of a sulfate, a silicate and a borate. The coating film optionally further comprises fats and oils and / or a soap exhibiting lubricity. The oil tempered steel wire has a coating film exhibiting satisfactory heat resistance and good lubricity and thus can secure good coiling workability even in the case of a high strength wire or a wire having a heteromorphic section.

Owner:SHINKO WIRE +1

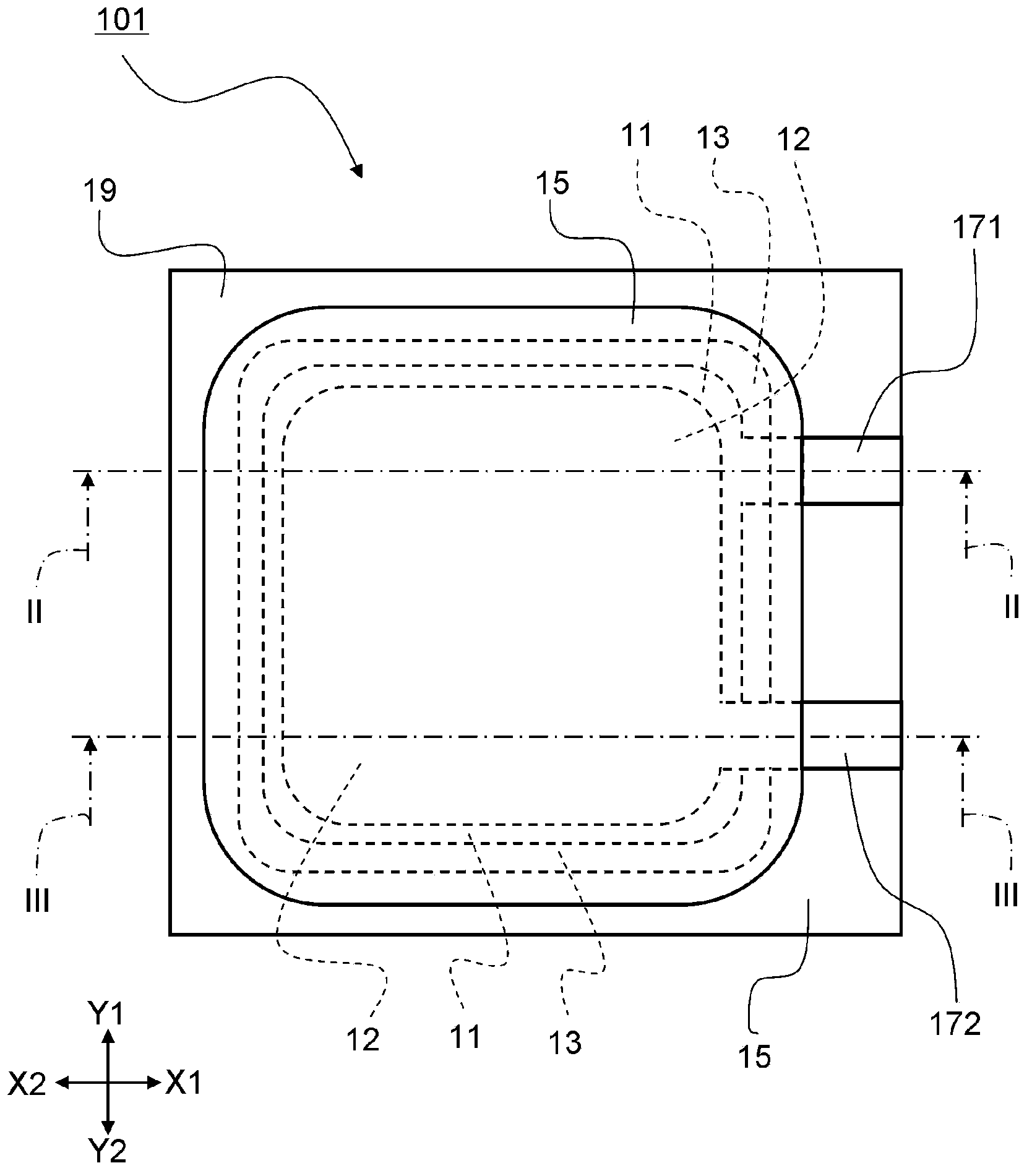

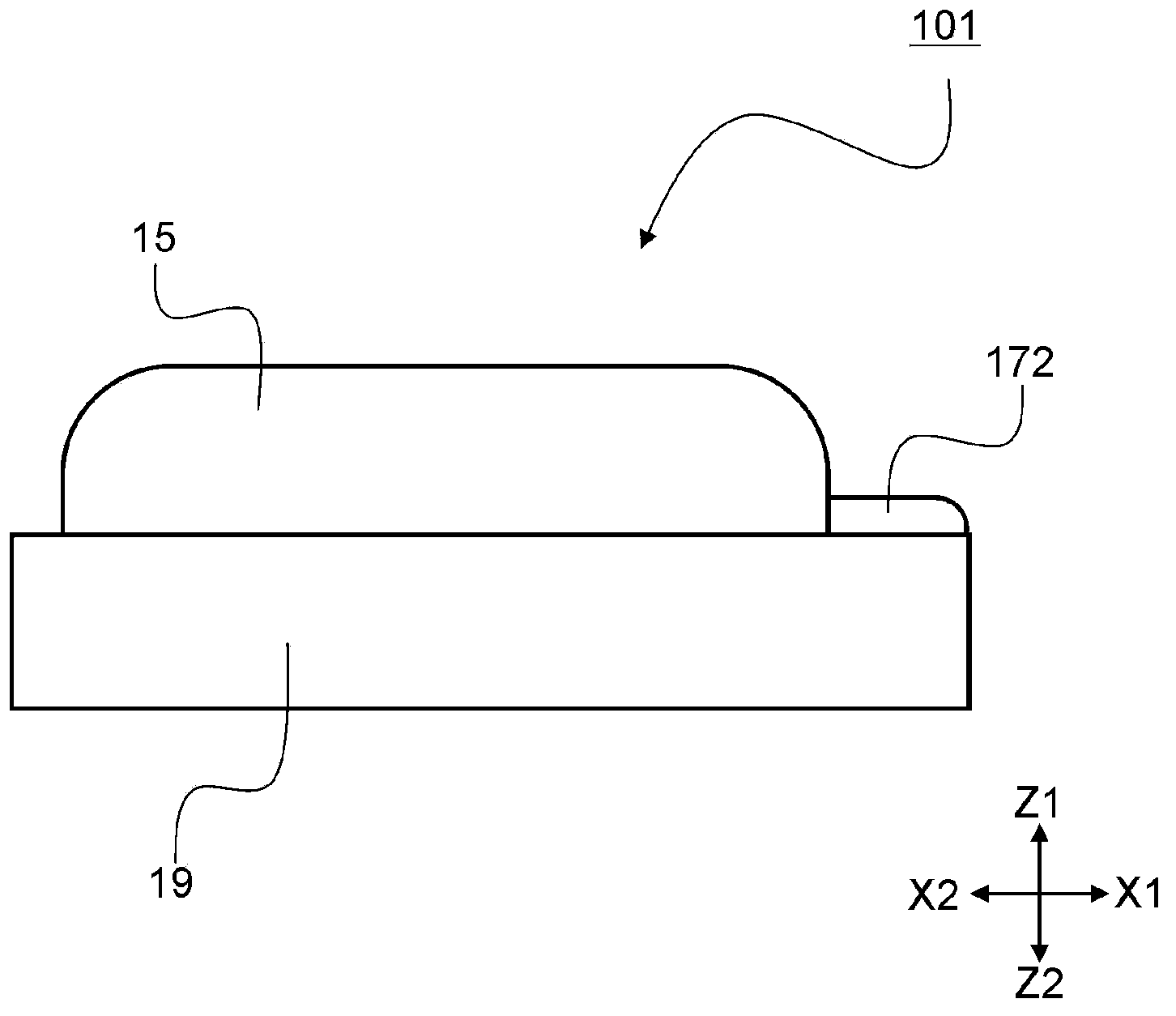

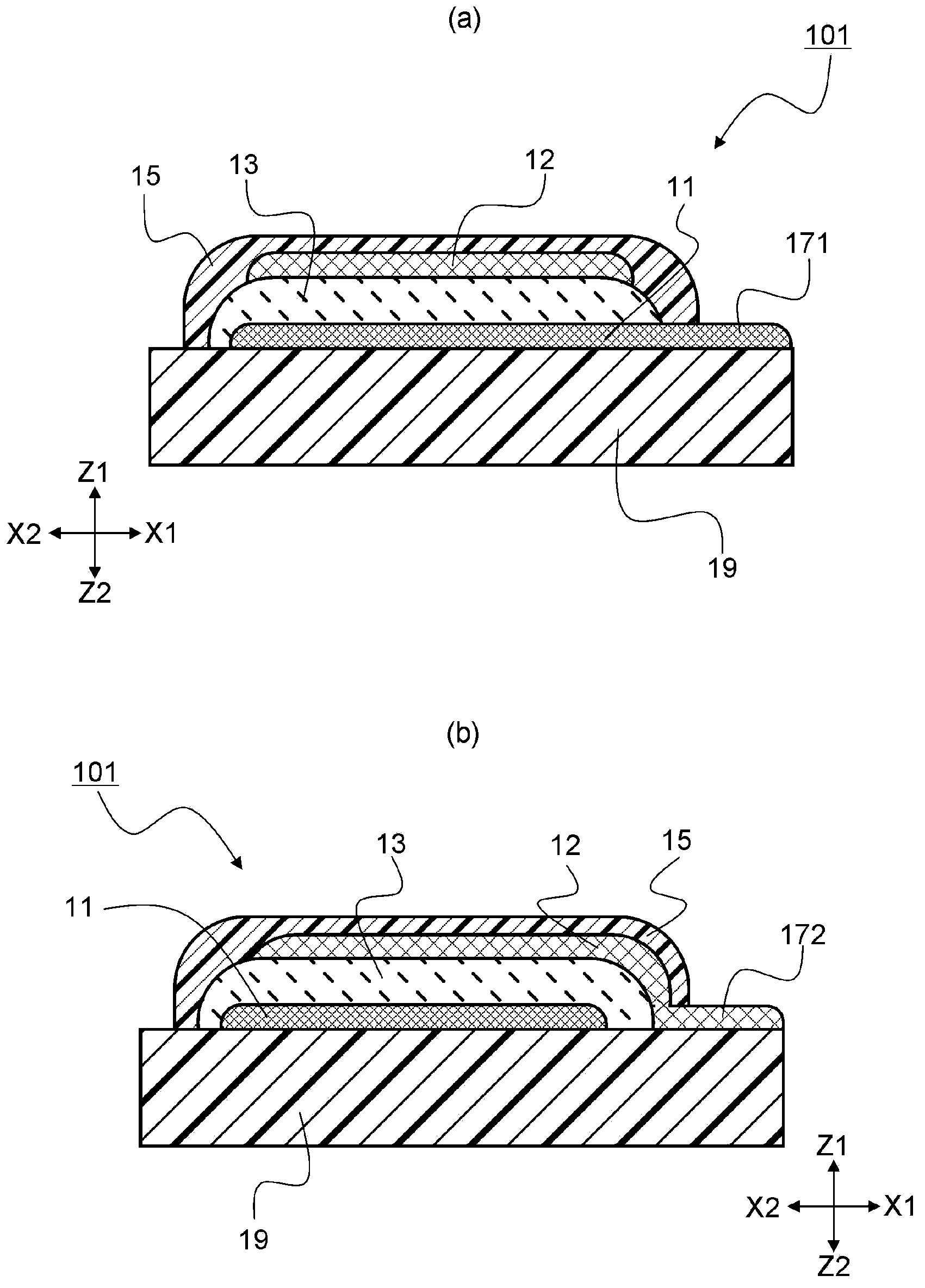

Piezoelectric element

InactiveCN103579493APolarization is easy to handleIncrease exercisePiezoelectric/electrostrictive device material selectionBarium titanateOptoelectronics

The invention aims to provide a piezoelectric element which can easily perform poling process. The piezoelectric element (101) is characterized by comprising a first electrode layer (11) stacked on a flexibility base material (19), a piezoelectric layer (13) stacked on the first electrode layer (11) and a second electrode layer (12) stacked on the piezoelectric layer (13). In the piezoelectric element (101), the piezoelectric layer (13) is formed by thermoplastic resin including barium titanate grains, the softening point of the thermoplastic resin being lower than the curie point of the barium titanate grains.

Owner:ALPS ALPINE CO LTD

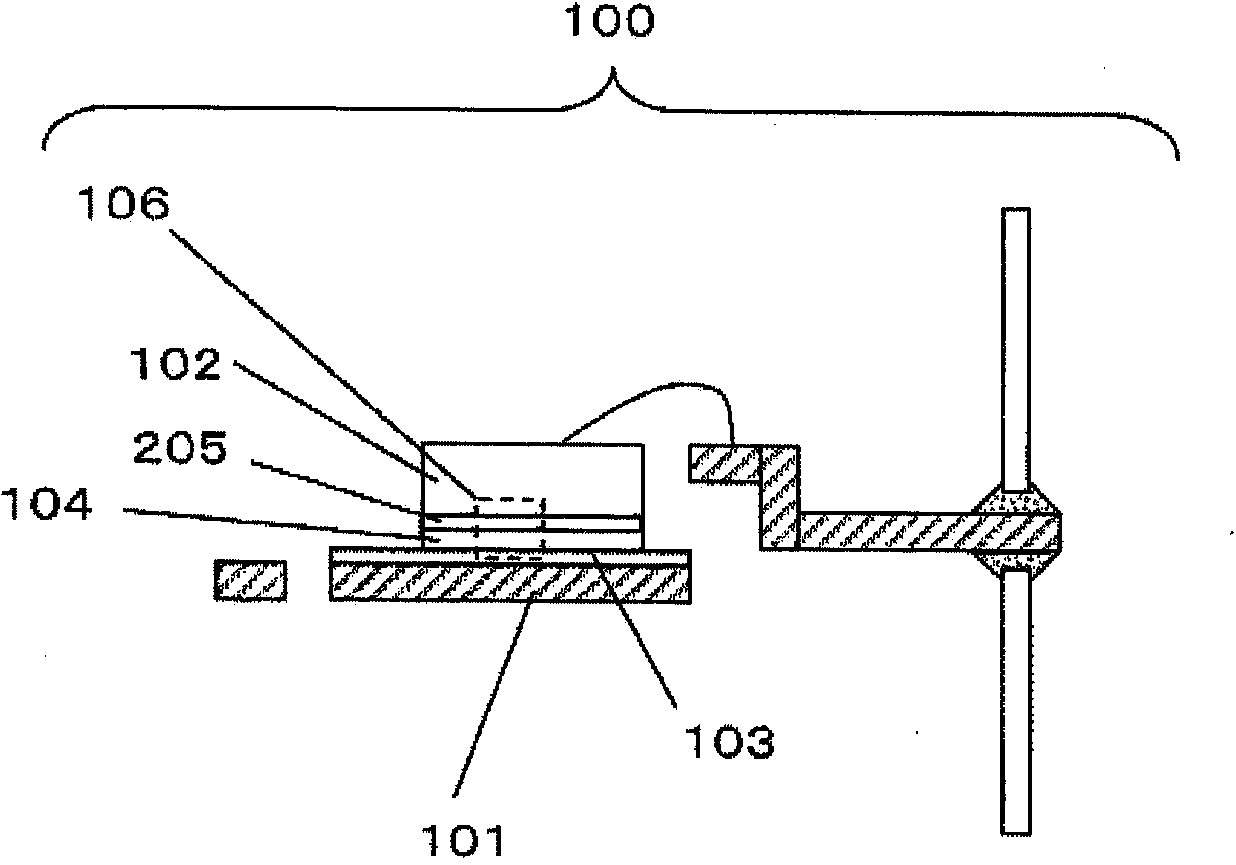

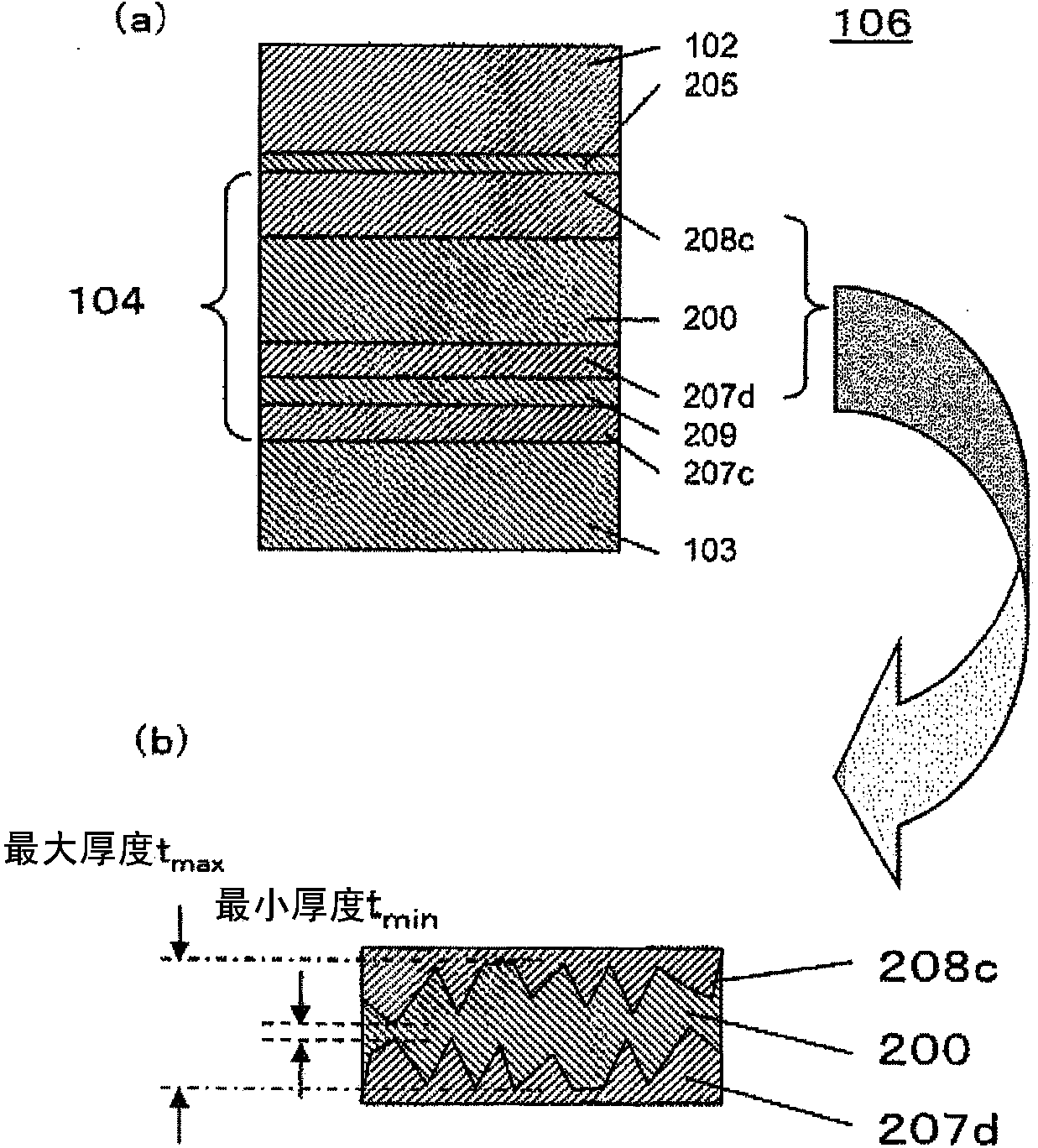

Junction structure

InactiveCN103493190APrevent peelingFull heat resistancePrinted circuit assemblingSemiconductor/solid-state device detailsIntermetallicMetal

A junction structure is provided with: an electrode of a substrate; an electrode of a semiconductor element; and a junction section that joins the electrode of the substrate, and the electrode of the semiconductor element. Starting from the electrode of the substrate and progressing toward the electrode of the semiconductor element, the following layers are placed in the following sequence in the junction section: a first intermetallic compound layer that contains a CuSn-based intermetallic compound; a Bi layer; a second intermetallic compound layer that contains a CuSn-based intermetallic compound; a Cu layer; and a third intermetallic compound layer that contains a CuSn-based intermetallic compound.

Owner:PANASONIC CORP

Heat-insulation film for high temperature molding, vacuum thermal insulator using same and process for fabricating vacuum thermal insulator

InactiveCN104582958AFull heat resistanceEasy to processLamination ancillary operationsThermal insulationAdhesion processHot melt

The present invention proposes a heat-insulation film laid so as to be molded at a high temperature, a vacuum thermal insulator having a core material with the outside coated with the heat-insulation film, and a method for fabricating the vacuum thermal insulator by coating the outside of the core material with the insulation film through a thermal-adhesion process. The heat-insulation film according to the present invention may be stably coated on the outside of the core material through the thermal-adhesion process at a high temperature.

Owner:DO YOUNG H S

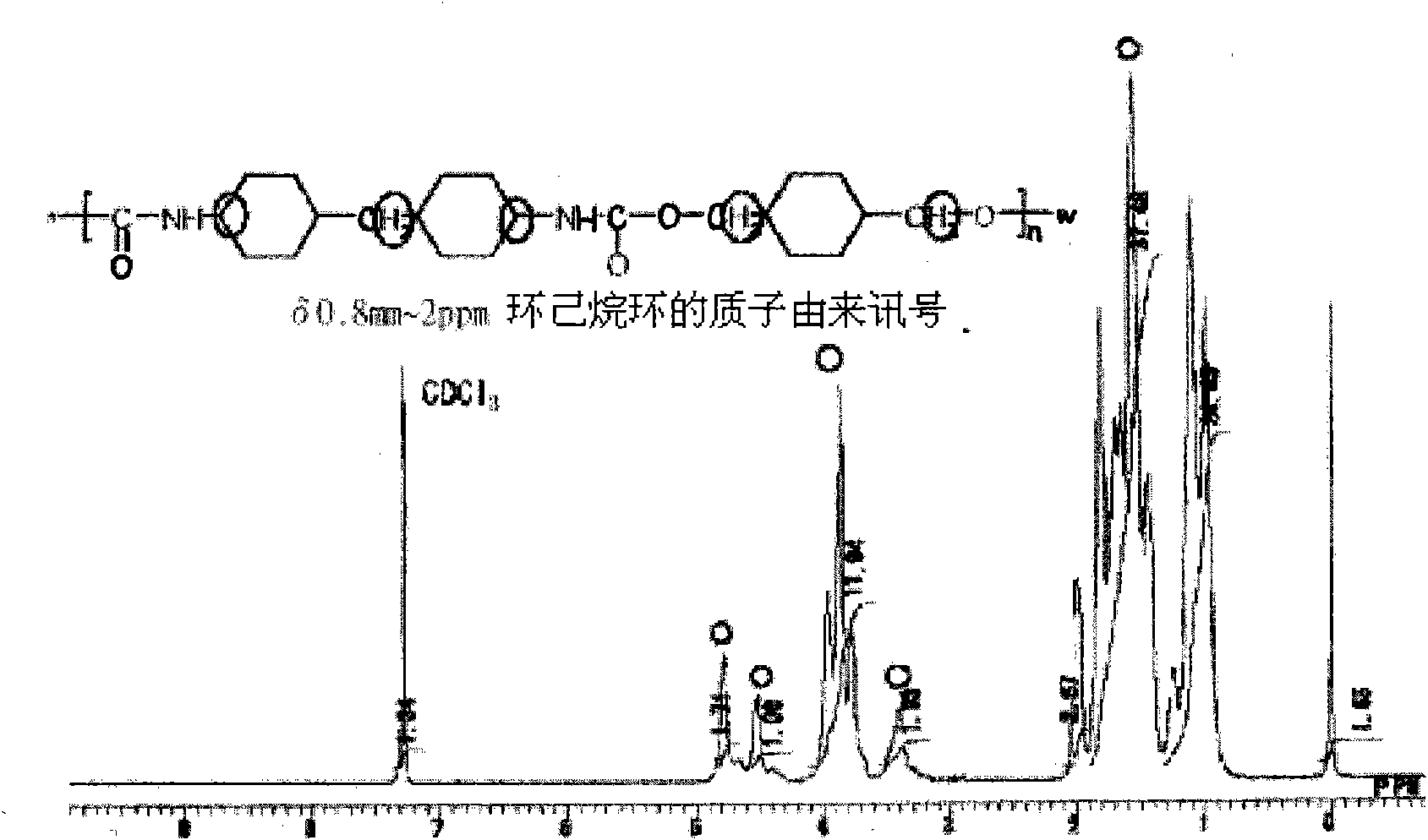

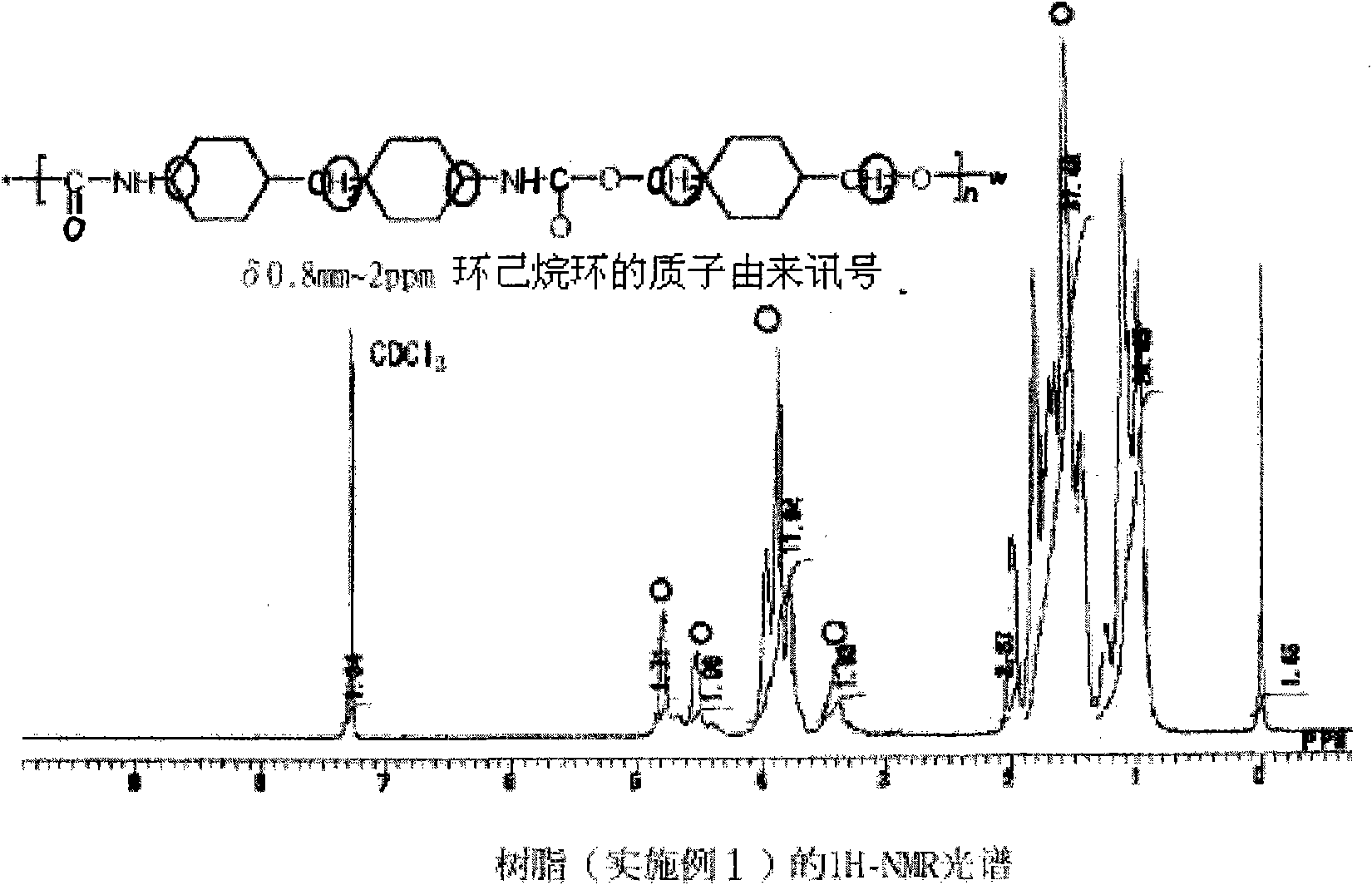

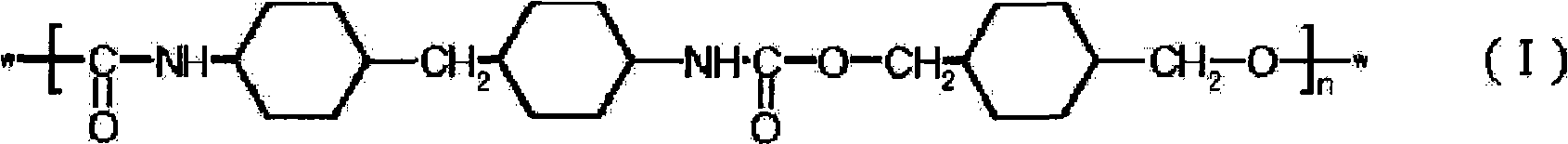

Polyurethane resin comprising alicyclic component and/or aromatic component and phase difference film using the polyurethane resin

InactiveCN101861348AFull heat resistanceThe phase difference will not decreasePolarising elementsNon-linear opticsChemistryPhenyl group

Disclosed is a polyurethane resin for a phase difference film. Also disclosed is a phase difference film that is free from heat deterioration of the film even after a step of heating the film to a temperature at or above the glass transition temperature (Tg) and then stretching the heated film and does not cause a lowering in phase difference even when the stretched film is used under high temperatures, for example, within an automobile in summer. The polyurethane resin comprises an alicyclic component and / or an aromatic component and is characterized by having a glass transition temperature of 100 DEG C or above and below 200 DEG C. Preferably, the polyurethane resin is one obtained by polymerizing a diisocyanate having a cyclohexane structure and a diol having a cyclohexane structure, or one obtained by polymerizing a diisocyanate having a phenyl group and a diol having a cyclohexane structure. The phase difference film comprises the polyurethane resin. Further disclosed is an optical film.

Owner:TOYO KOHAN CO LTD

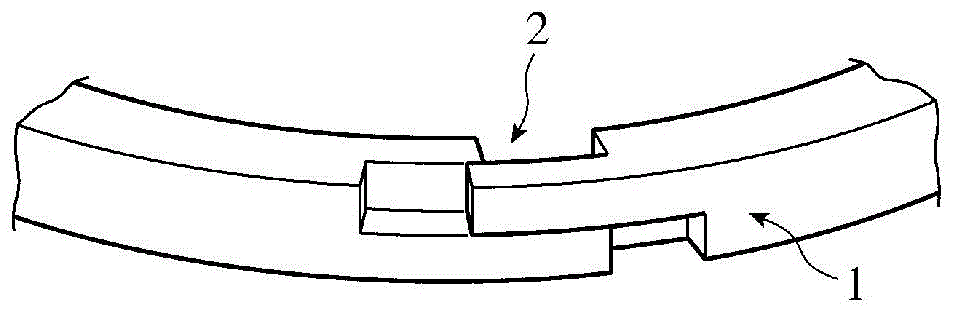

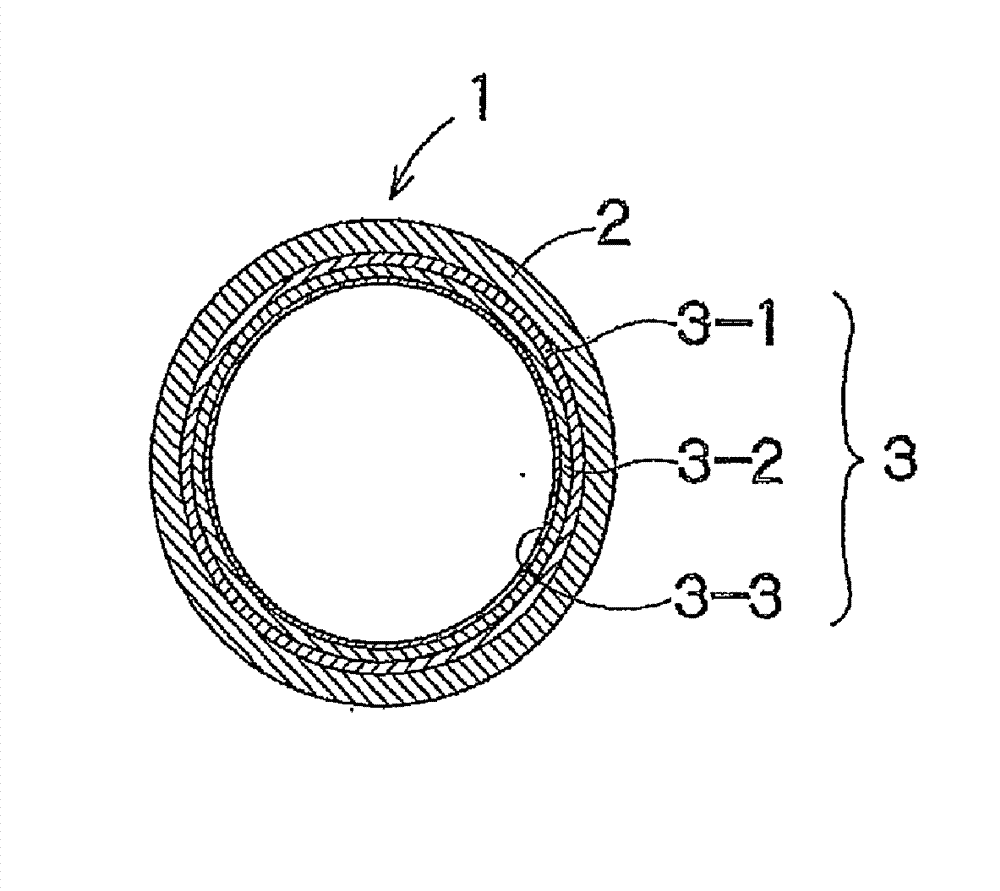

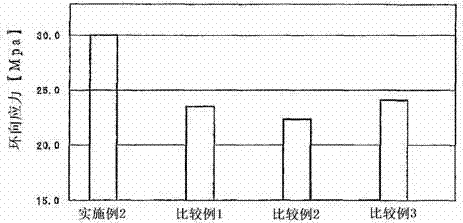

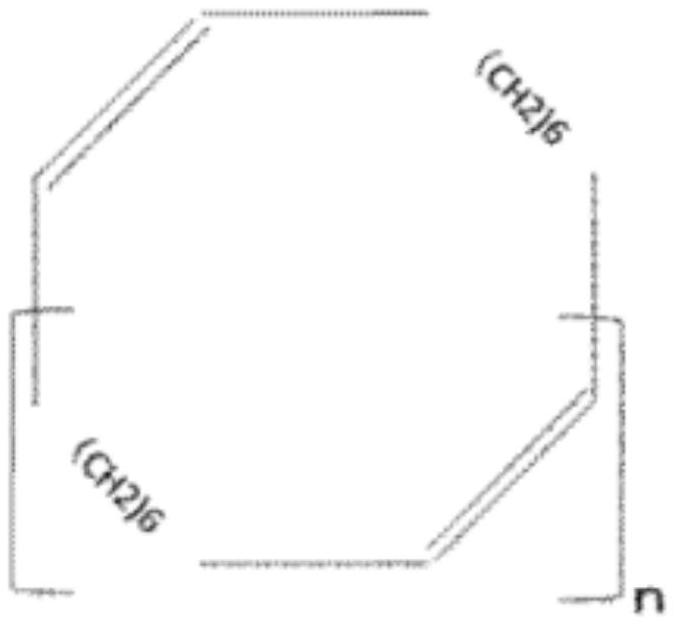

Multilayered resin tube-shaped body

ActiveCN102958688AFull heat resistanceAchieve lightweightSynthetic resin layered productsFlexible pipesHeat resistanceGasoline

Provided is an economical multilayered resin tube-shaped body that can be safely used in a high-temperature environment such as an engine compartment. A multilayered resin tube-shaped body (1) having excellent heat resistance is obtained by forming an outer layer (2) from a thermoplastic resin having a melting point of 190-300 C and forming an inner layer (3) from a thermoplastic resin having a melting point of 150-300 C and low liquid or gas permeability. The thermoplastic resin that forms the outer layer (2) is preferably a resin having a hoop stress of 10 MPa or greater in a 120 C atmosphere. Furthermore, the thermoplastic resin that forms the inner layer (3) is preferably a resin having a gasoline permeability of 1.0 g / m2day or less.

Owner:SANOH IND CO LTD

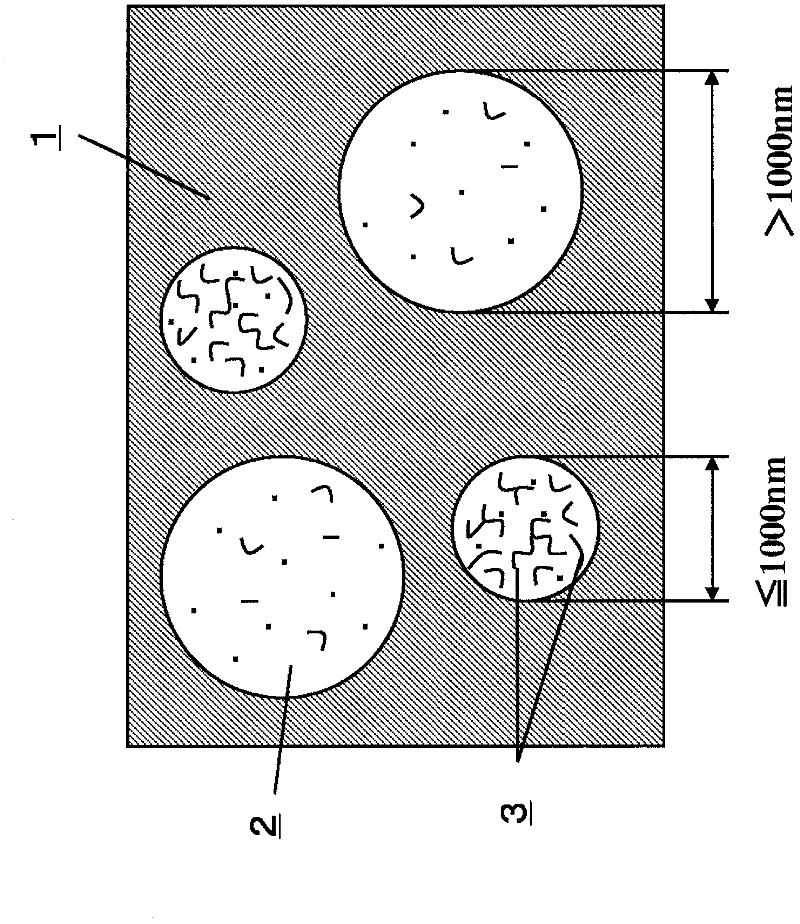

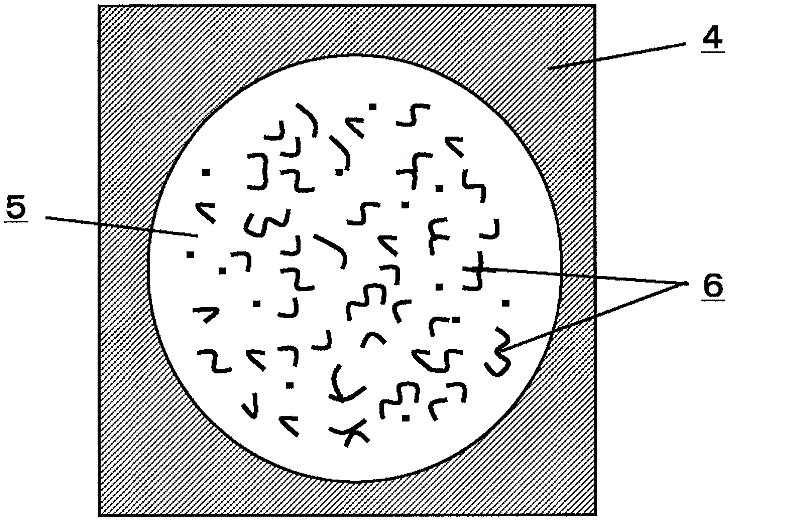

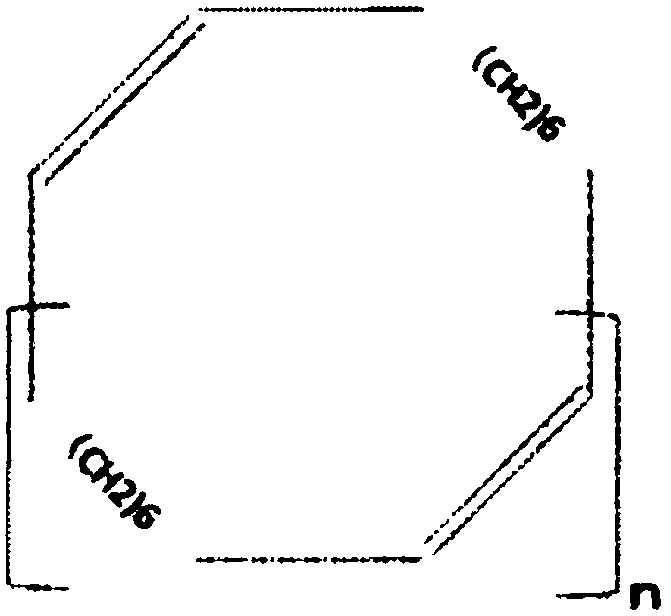

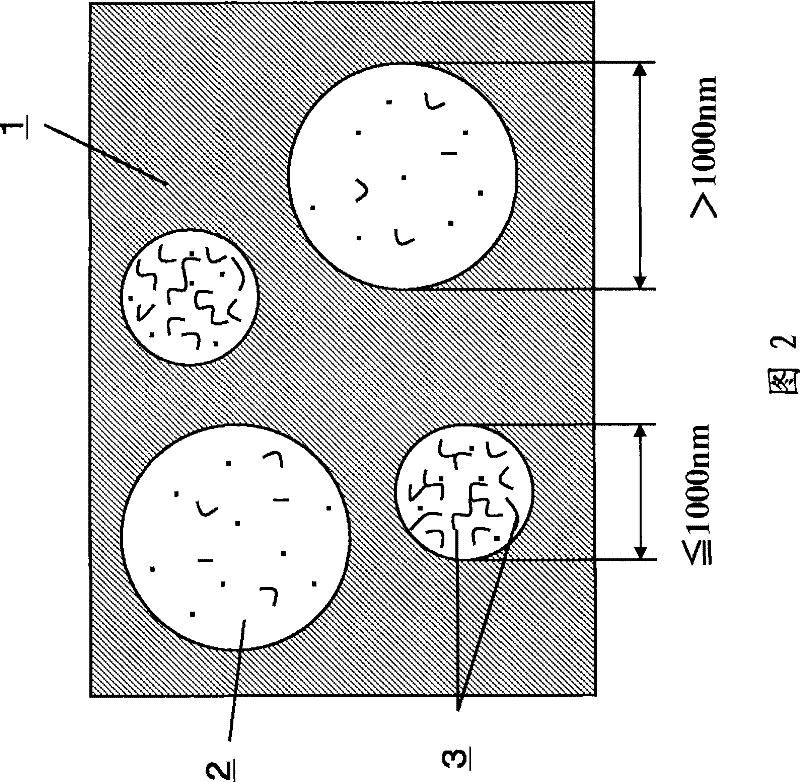

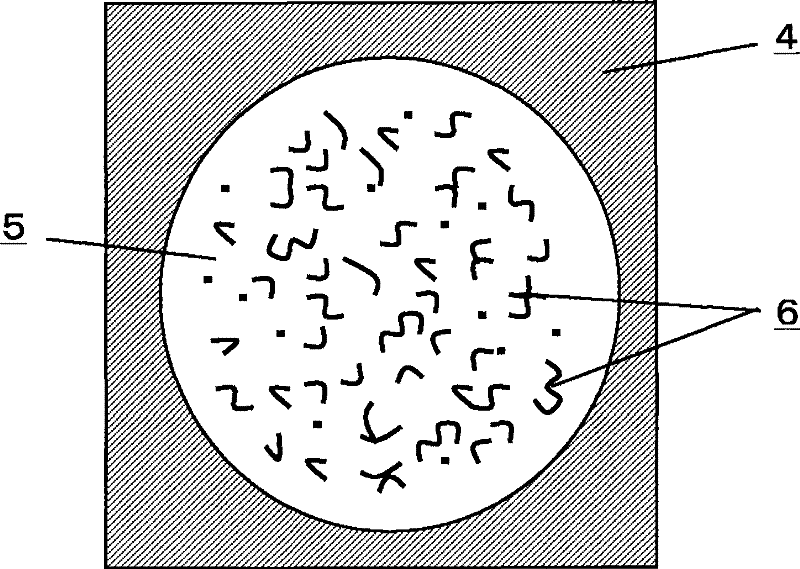

Thermoplastic resin composition, process for producing the same and molding

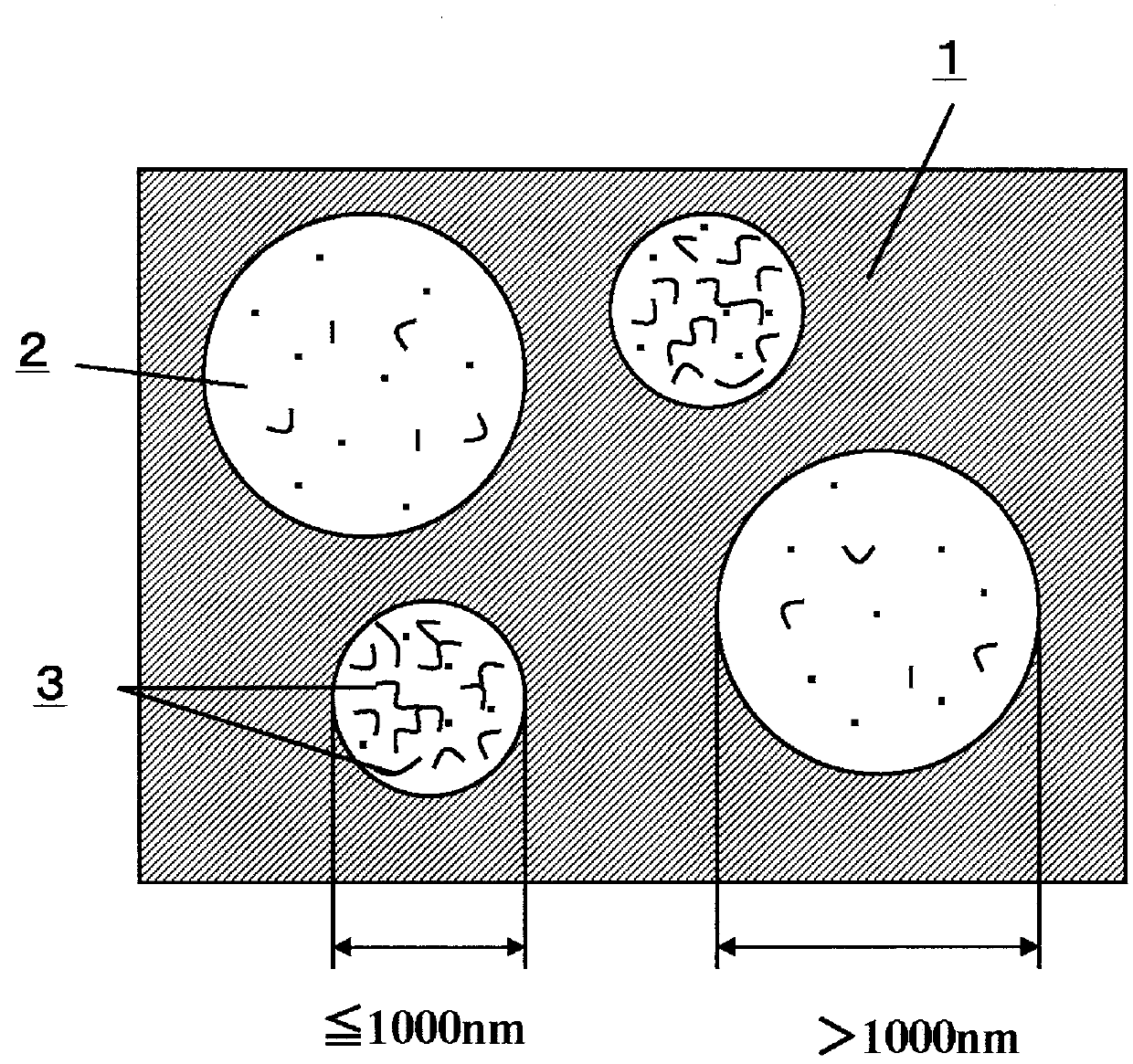

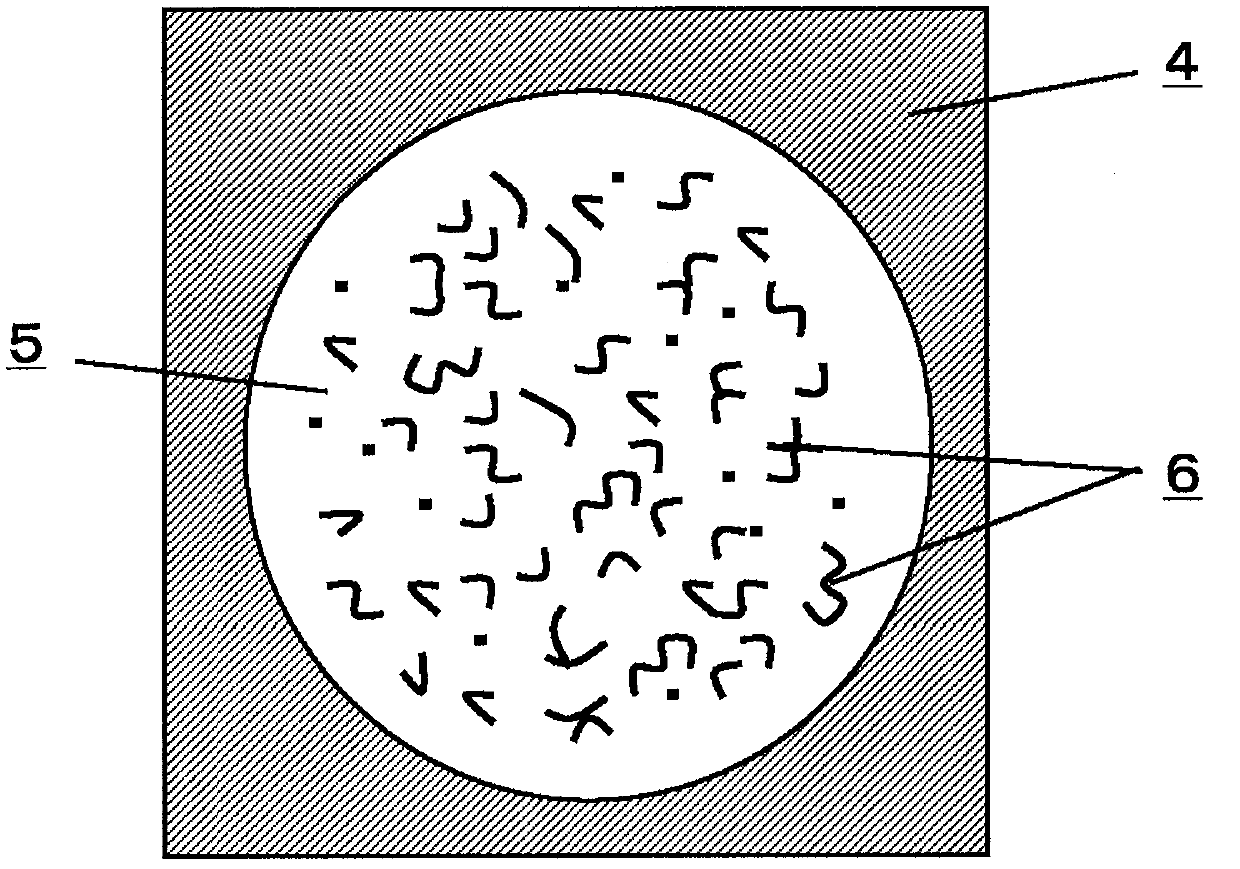

This invention relates to a thermoplastic resin composition comprising a thermoplastic resin (A) and a reactive functional group-containing thermoplastic resin (B), which has a specific structure in the morphology of the resin composition observed by transmission electron tomography, and the relaxation time T1C of each carbon nucleus by the solid NMR measurement of the thermoplastic resin composition containing a polyamide resin is kept in a specific range. The composition is excellent in the balance between contradictory properties such as impact resistance and heat resistance, remarkably exhibits a peculiar viscoelastic behavior not observed in the conventional polymeric materials, and is remarkably excellent in impact energy absorbing performance and vibration energy absorbing performance at the time of high-speed deformation.

Owner:TORAY IND INC

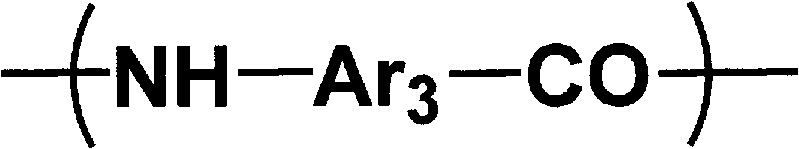

Aromatic polyamide porous film and separator for capacitor or battery using the same

ActiveCN102712778AHigh affinityImprove breathabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersMicrometerPolyamide

Disclosed is a thin porous film with an aromatic polyamide as a constituent component, and with high heat resistance, high air permeability and good affinity to electrolytes. The aromatic polyamide porous film contains an aromatic polyamide and a hydrophilic polymer with 12 to 50 parts hydrophilic polymer per 100 parts aromatic polyamide, by mass, and has a membrane thickness of 2 to 30 micrometers, Gurley air permeability of 0.5 to 300 s / 100ml, and thermal shrinkage of -0.5 to 1.0% at 200 DEG C.

Owner:TORAY IND INC

Adhesive composition

ActiveCN109476966AFull strengthFull heat resistanceMacromolecular adhesive additivesPolymer scienceAdhesive

The present invention provides a hot-melt adhesive that has a sufficiently long usable life and that exhibits superior strength and heat resistance. The present invention relates to a hot-melt adhesive composition that contains a hydrocarbon-based cyclic polymer, an alpha-olefin-based polymer, and a tackifying resin.

Owner:SUNSTAR GIKEN KK

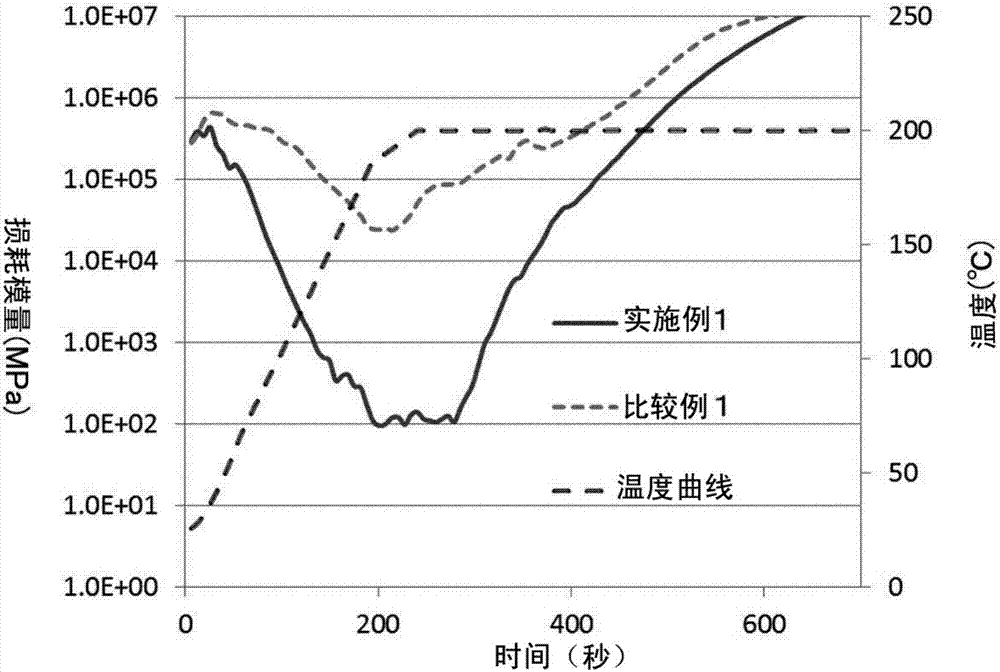

Thermosetting Resin Composition

InactiveCN107266857AFull heat resistanceHeat resistantOther chemical processesSemiconductor/solid-state device detailsEpoxyPower cycle

The present invention relates to a resin composition, and provides a curing resin composition which can obtain the full tolerance for a heat cycle test and / or a power cycle test, a sealing material using the same, a semiconductor device using the sealing material and a manufacturing method of the semiconductor device. The resin composition including at least (A) an epoxy resin, (B) a curing agent and (C) an inorganic filler, satisfies the following conditions: I-I) the minimum modulus is no greater than 104 MPa when evaluated at a set temperature of 200 DEG C after temperature increase from room temperature to 200 DEG C. at 50 DEG C. / min by evaluation with a rheometer, and the final modulus is 105 MPa or greater from 10 minutes after the initial temperature increase; (I-II) the softening point of the epoxy resin (A) is 35 DEG C or higher; (I-III) the residual solvent in the resin composition is no greater than 0.1%; and(I-IV) the equivalent value of the curing agent (B) is no greater than 90 g / eq and the softening point is 105 DEG C or higher.

Owner:ASAHI KASEI KK

Laminated body for element processing, method of manufacturing laminated body for element processing, and method of manufacturing thin element using the same

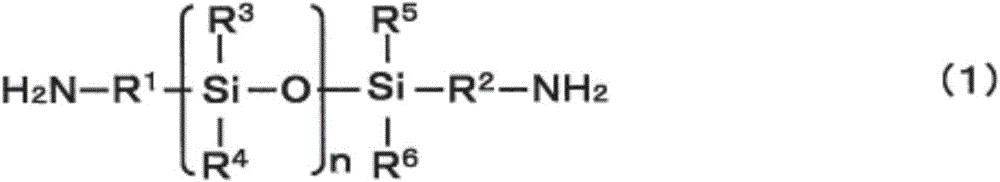

InactiveCN105612600BFull heat resistanceNo ruptureSynthetic resin layered productsSolid-state devicesAdhesion forceAdhesive

The object of the present invention is to provide a laminated body for element processing which does not generate volatile components and does not cause cracks due to peeling or the like during the back grinding of semiconductor circuit forming substrates and the back circuit formation process. The cracking of the substrate can be peeled under mild conditions at room temperature, and there is almost no temporary adhesive remaining on the semiconductor circuit formation substrate side after peeling. The laminated body for element processing of the present invention is a laminated body for element processing in which a substrate for element processing is laminated on a support substrate via a temporary adhesive layer, and is characterized in that the temporary adhesive layer is sequentially laminated from the support substrate side. The heat-resistant resin layer A, the heat-resistant resin layer B, the adhesive force between the heat-resistant resin layer B and the substrate for element processing is lower than the adhesive force between the heat-resistant resin layer A and the supporting substrate and the heat-resistant resin layer B and the heat-resistant resin Adhesion of Layer A.

Owner:TORAY IND INC

Aromatic polyamide porous film and separator for capacitor or battery using same

ActiveCN102712778BHigh affinityImprove breathabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersPolyamideCapacitor

The invention provides a porous film comprising aromatic polyamide as a constituent component that has high heat resistance, high air permeability and high affinity to electrolytes. It is a porous aromatic polyamide film comprising aromatic polyamide and a hydrophilic polymer wherein the hydrophilic polymer accounts for 12 to 50 parts by mass per 100 parts by mass of the aromatic polyamide, the thickness being 2 to 30 micrometers, the Gurley air permeability being 0.5 to 300 seconds / 100 ml, and the thermal shrinkage rate being -0.5 to 1.0% at 200°C.

Owner:TORAY IND INC

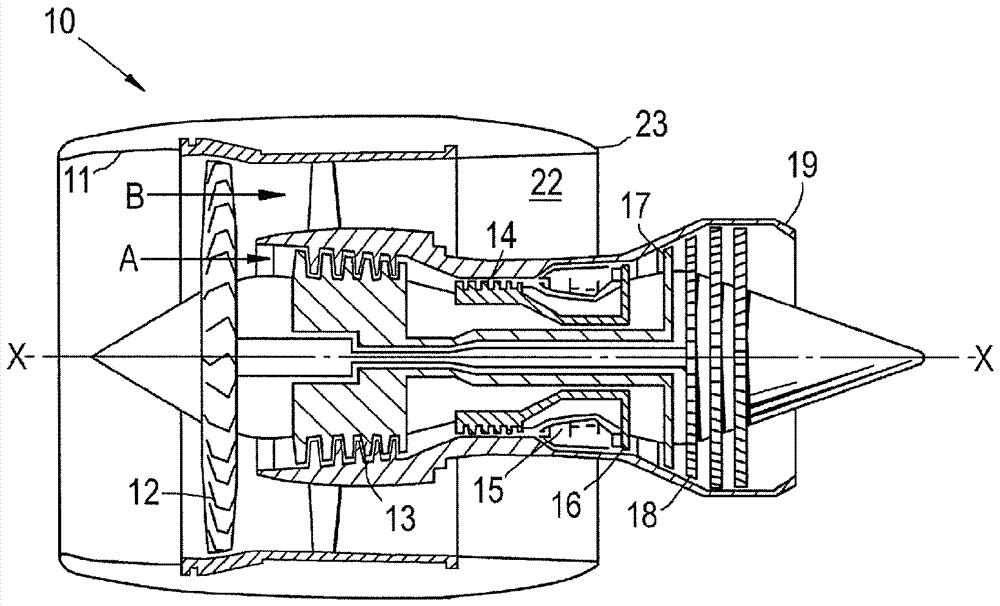

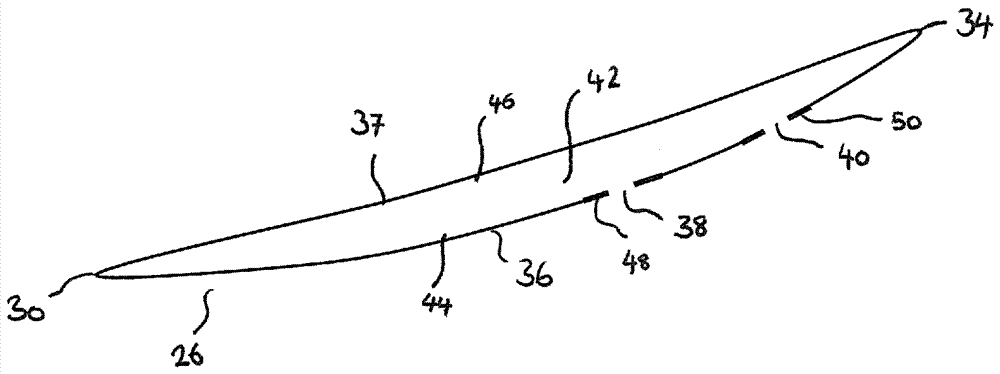

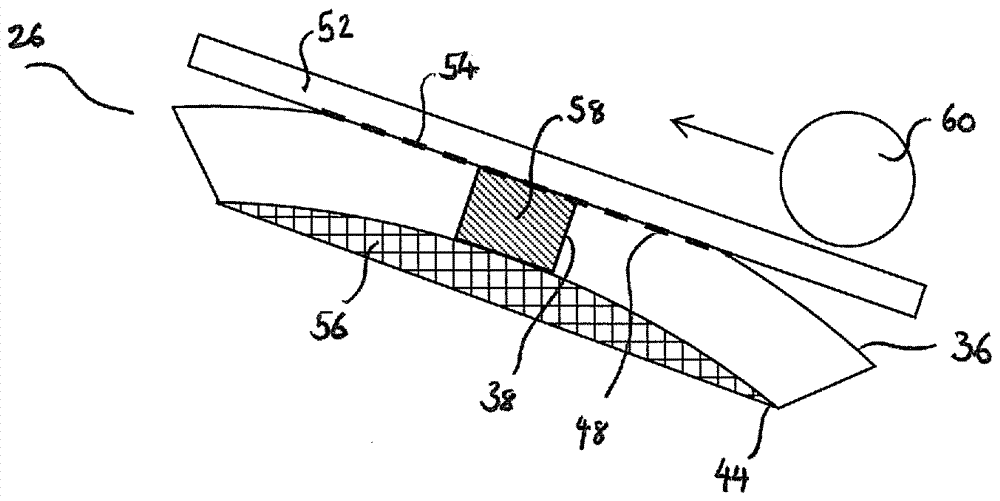

Cavity sealing

InactiveCN107538126AFull heat resistancePrevent removalTurbinesPump componentsMetallic materialsGas turbines

The invention relates to cavity sealing. A method of sealing one or more openings provided in a wall of an aerofoil for a gas turbine engine is provided, the aerofoil comprising at least one cavity which is at least partly filled with a vibration damping material. The method comprises the steps to provide a metallic material onto the wall of the aerofoil in order to cover the opening and bond themetallic material to the wall of the aerofoil to seal the opening.

Owner:ROLLS ROYCE PLC

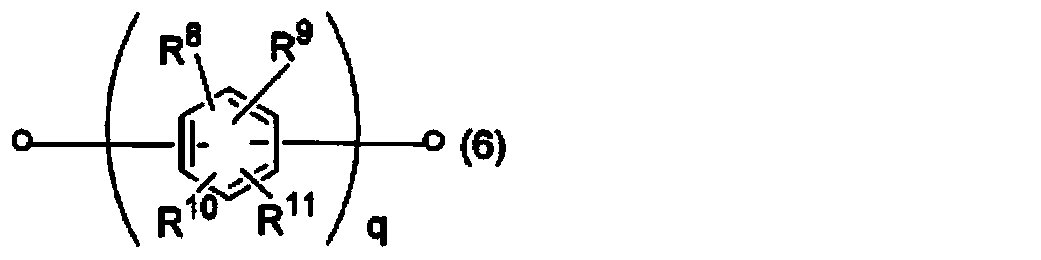

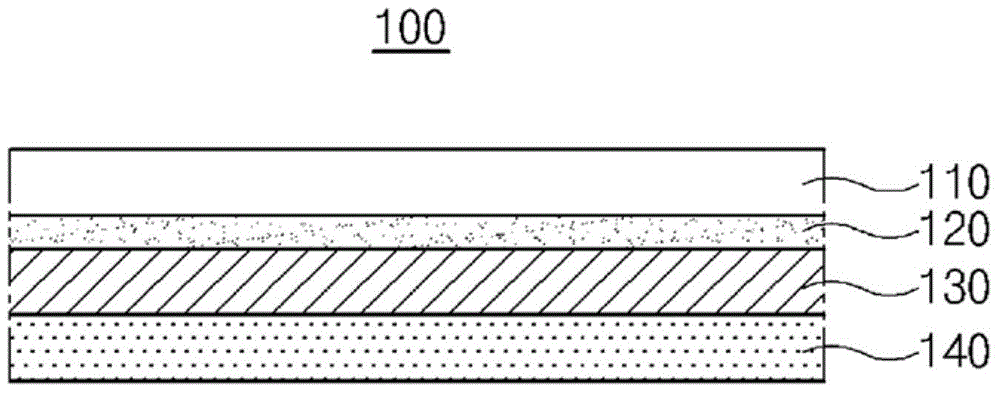

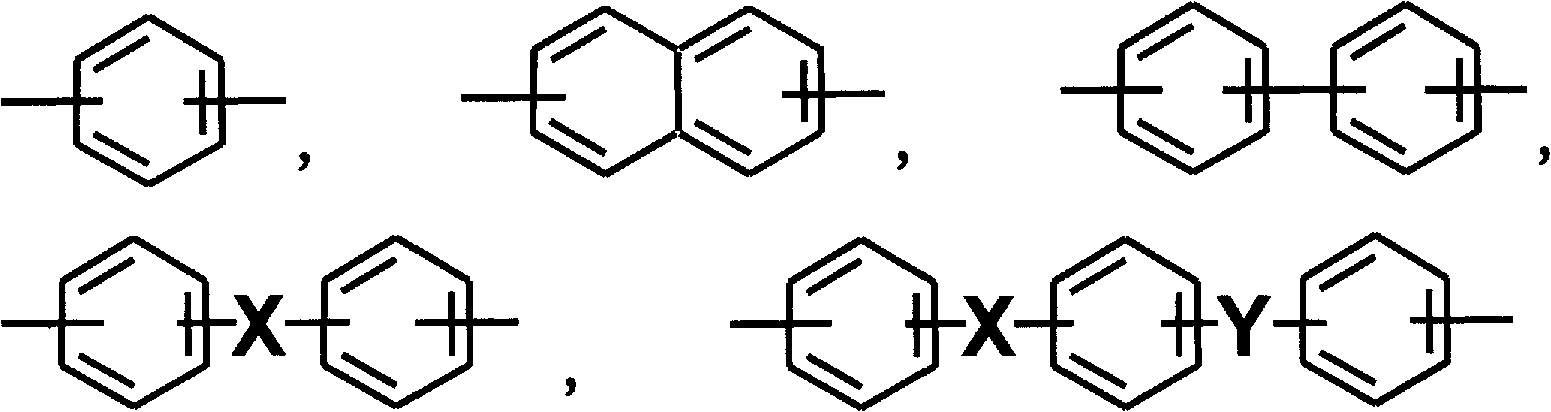

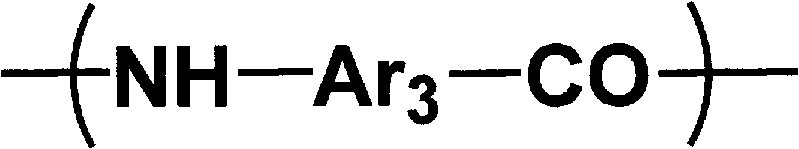

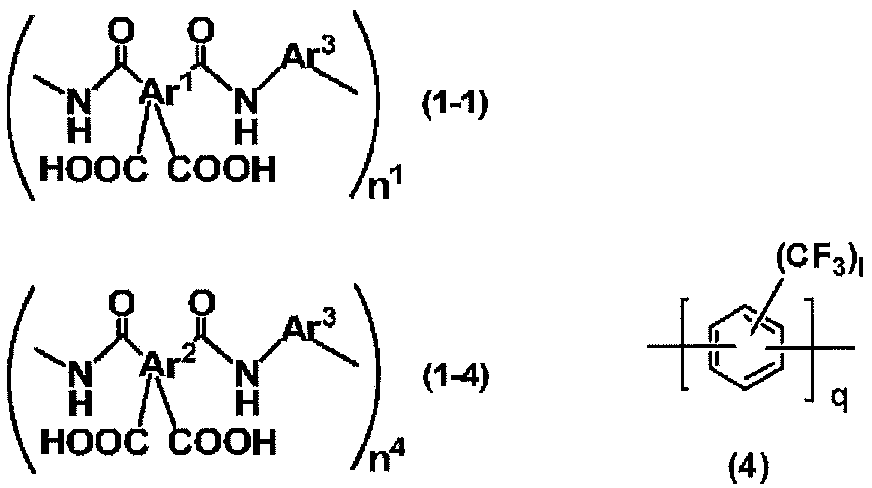

Resin composition for display substrate, resin film for display substrate, and method for producing resin film for display substrate

ActiveCN105392821BFull transparencyAppropriate coefficient of linear expansionTransistorSemiconductor/solid-state device manufacturingOrganic solventDisplay device

The present invention provides a high-heat-resistant resin composition for display substrates which, regardless of the curing conditions, gives a substrate for flexible displays that has sufficient transparency and an adequate linear expansion coefficient. This resin composition for display substrates comprises: a poly(amic acid) comprising repeating units represented by formulae (1-1) and (1-4) (wherein Ar1 and Ar2 are different from each other and each independently represent a tetravalent aromatic group having a substituent substituted with fluorine, Ar3 represents a divalent group represented by formula (4) (wherein q is 1 or 2 and l is 1 or 2), and n1 and n4 each indicate the number of repeating units ); and an organic solvent.

Owner:NISSAN CHEM IND LTD

Laminate, and method for producing laminate

ActiveCN112512792AFull heat resistanceGood adhesionSynthetic resin layered productsCellulosic plastic layered productsPolyamine CompoundPolymer science

Owner:TOYOBO CO LTD

Thermoplastic resin composition, process for producing the same and molding

This invention is a thermoplastic resin composition comprising a thermoplastic resin (A) and a reactive functional group-containing resin (B), which has a specific structure in the morphology of the resin composition observed by transmission electron microscopy tomography, and the relaxation time T1C of each carbon nucleus by the solid NMR measurement of the thermoplastic resin composition containing a polyamide resin is kept in a specific range. The composition is excellent in the balance between contradictory properties such as impact resistance and heat resistance, remarkably exhibits a peculiar viscoelastic behavior not observed in the conventional polymeric materials, and is remarkably excellent in impact energy absorbing performance and vibration energy absorbing performance at the time of high-speed deformation.

Owner:TORAY IND INC

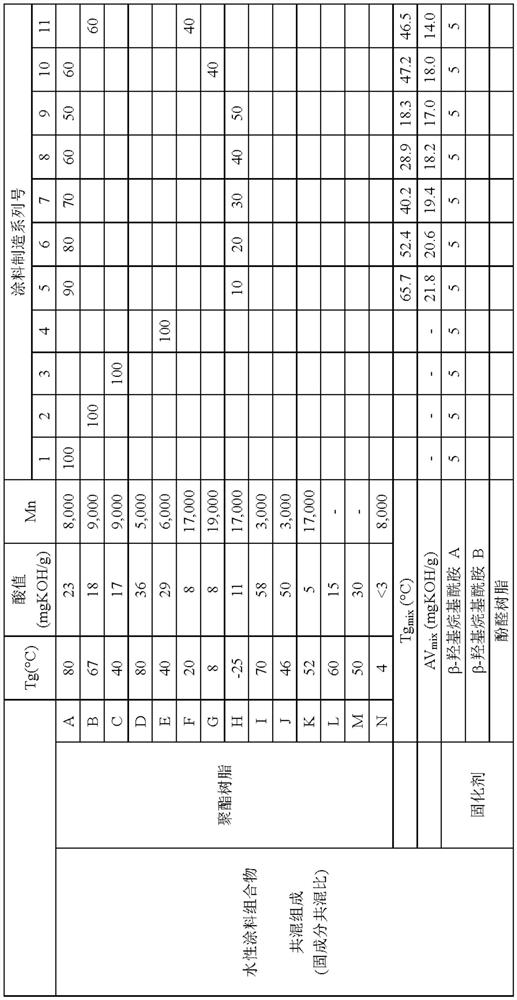

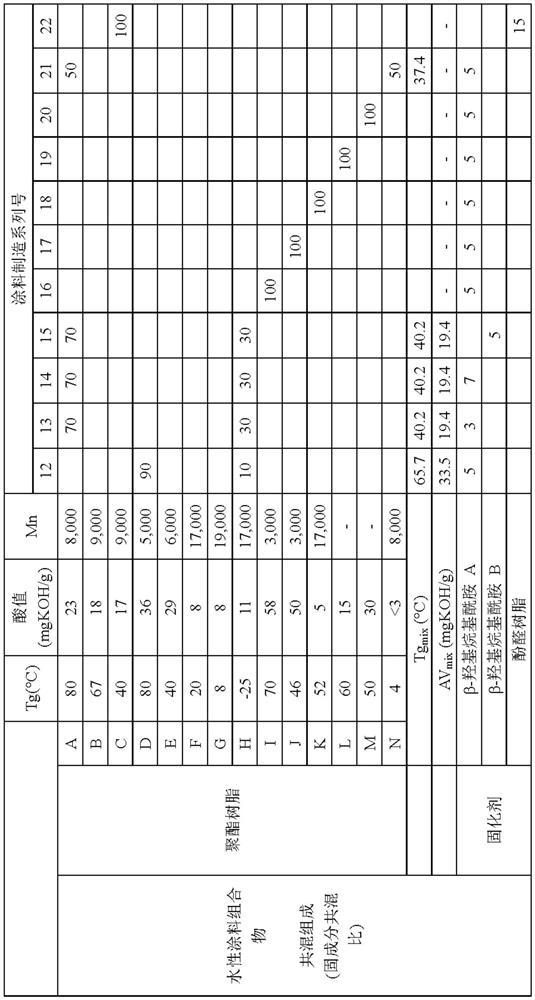

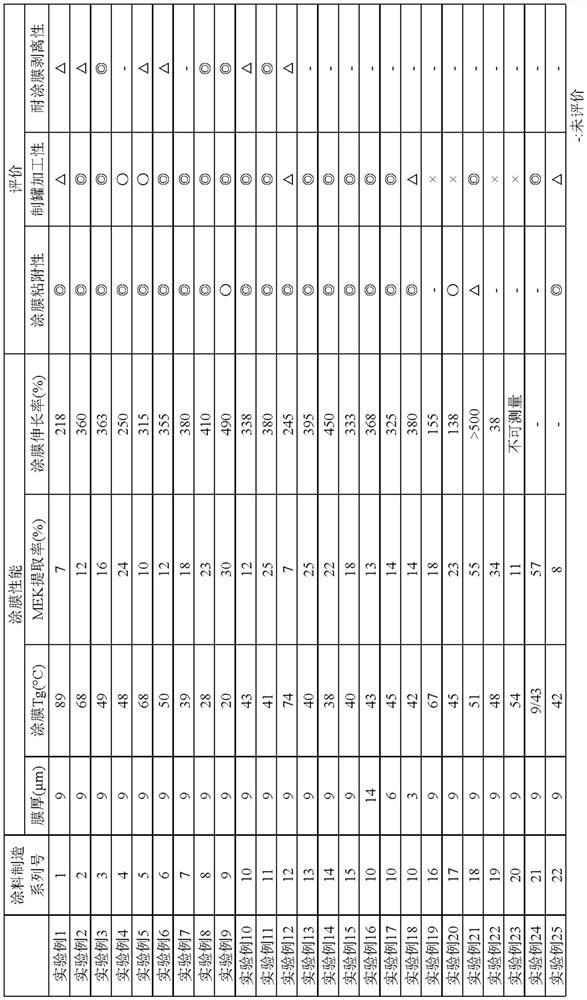

Coated metal plate and drawn-and-ironed can

InactiveCN113272132AEasy to processAvoid exposureLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePolyester resin

The present invention pertains to a coated metal plate having a coating film on at least one surface thereof. Provided are the coated metal plate and a drawn-and-ironed can comprising the coated metal plate that have excellent can production workability without metal exposure even when exposed to harsh processing such as drawing and ironing, as a result of: the coating film containing polyester resin as a main component thereof and a beta-hydroxyalkyl amide compound as a curing agent; and the elongation of the coating film under test conditions of 90 degree being at least 200%.

Owner:TOYO SEIKAN GRP HLDG LTD

Thermal insulation film for high-temperature forming, vacuum thermal insulation material using the thermal insulation film, and production method thereof

InactiveCN104582958BFull heat resistanceEasy to processLamination ancillary operationsThermal insulationHot meltHigh-temperature corrosion

The present invention proposes a heat insulating film having a laminated structure capable of being molded at high temperatures, and also relates to a vacuum heat insulating material in which the above heat insulating film is coated on the outside of a core material, and to the core material through a heat welding process. The invention discloses a preparation method of a vacuum heat insulating material whose outer side is covered with a heat insulating film. The heat insulating film of the present invention can be stably coated on the outside of the core material through a heat welding process at a high temperature.

Owner:DO YOUNG H S

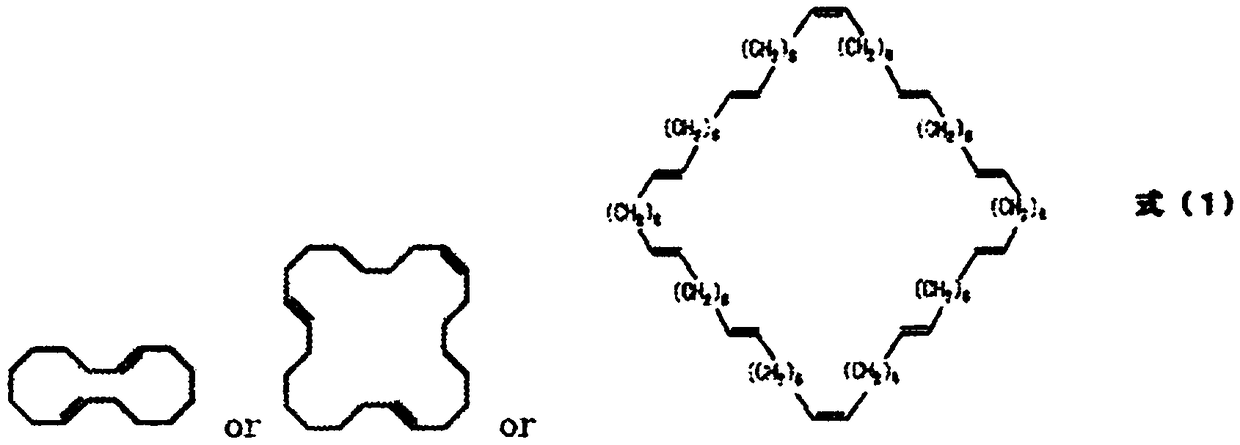

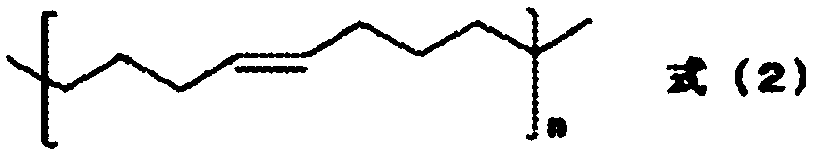

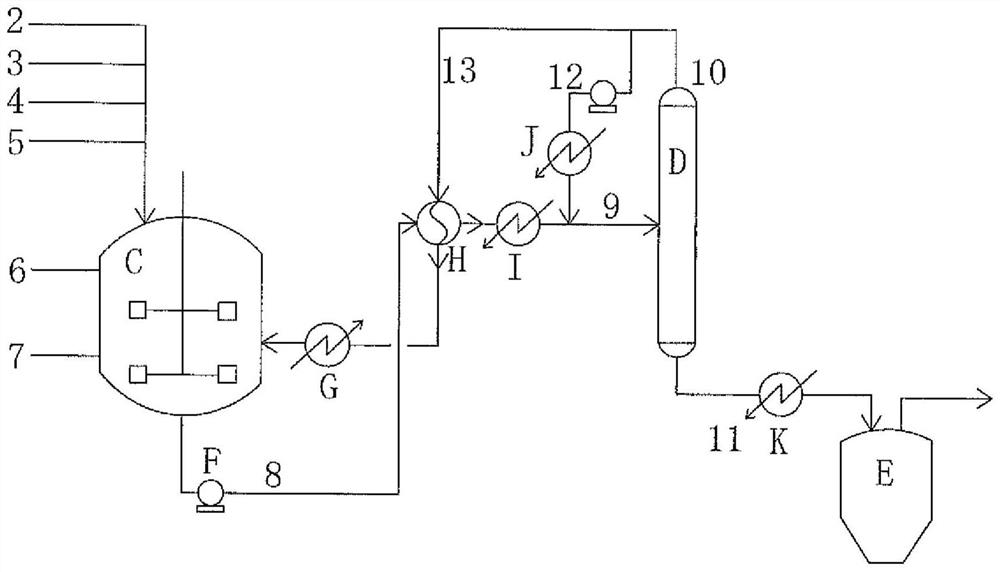

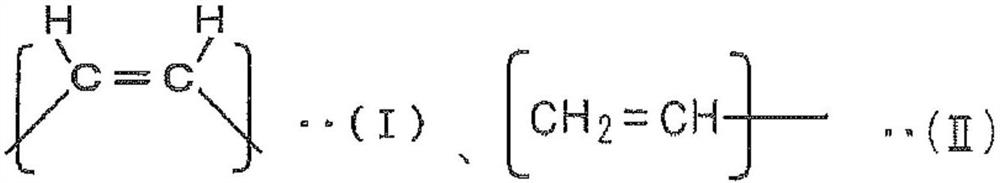

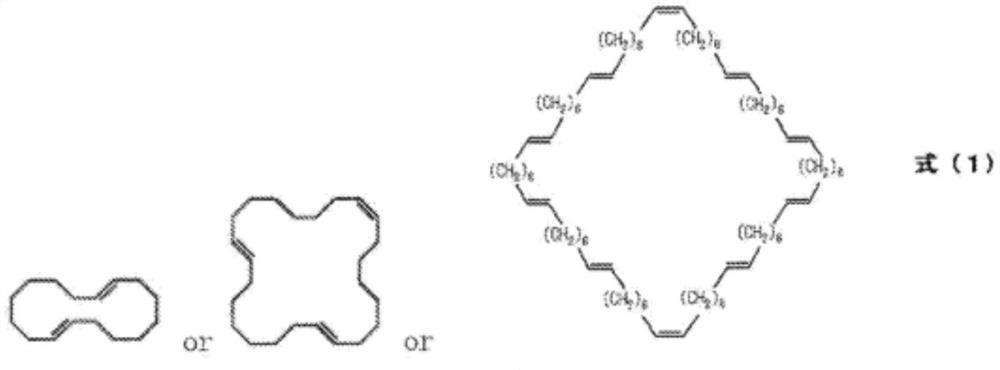

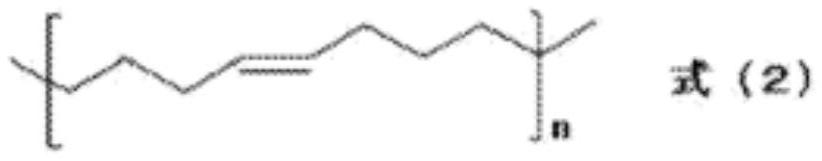

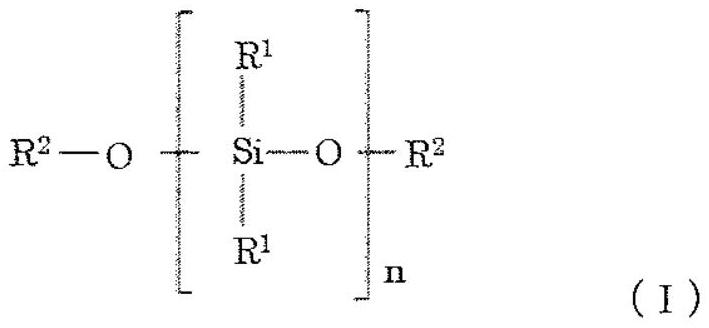

ETHYLENE/alpha-OLEFIN/NON-CONJUGATED POLYENE COPOLYMER, PRODUCTION METHOD THEREFOR, AND USE

The present invention addresses the problem of providing a novel ethylene / alpha-olefin / non-conjugated polyene copolymer which contains a specific non-conjugated polyene, e.g., VNB, as a comonomer ingredient and has a low long-chain branch content and which, when crosslinked with a peroxide, has excellent curability and satisfactory processability. The ethylene / alpha-olefin / non-conjugated polyene copolymer according to the present invention is characterized by comprising constituent units derived from ethylene (A), a C3-20 alpha-olefin (B), and a non-conjugated polyene (C) including two or morepartial structures in total in the molecule which are selected from the group consisting of those of general formulae (I) and (II), and by satisfying specific requirements.

Owner:MITSUI CHEM INC

Thermoplastic resin composition, process for producing the same and molding

The present invention relates to a thermoplastic resin composition, which is a thermoplastic resin composition comprising a thermoplastic resin (A) and a resin (B) having a reactive functional group, the composition of which is observed by transmission electron beam tomography In the form, a thermoplastic resin composition having a specific structure and containing a polyamide resin has a relaxation time T1C of the carbon core measured by solid NMR within a specific range, and the composition has an excellent balance of opposite properties such as impact resistance and heat resistance At the same time, it remarkably exhibits specific viscoelastic properties that have never been found in existing polymer materials, and is remarkably excellent in impact energy absorption performance and vibration energy absorption performance during high-speed deformation.

Owner:TORAY IND INC

adhesive composition

ActiveCN109476966BFull strengthFull heat resistanceMacromolecular adhesive additivesPolymer scienceAlkene

The present invention provides a hot-melt adhesive having a sufficiently long pot life and exhibiting good strength and heat resistance. The invention relates to a hot-melt adhesive composition containing hydrocarbon cyclic polymer, α-olefin polymer and tackifying resin.

Owner:SUNSTAR GIKEN KK

Adhesive tape for electronic parts

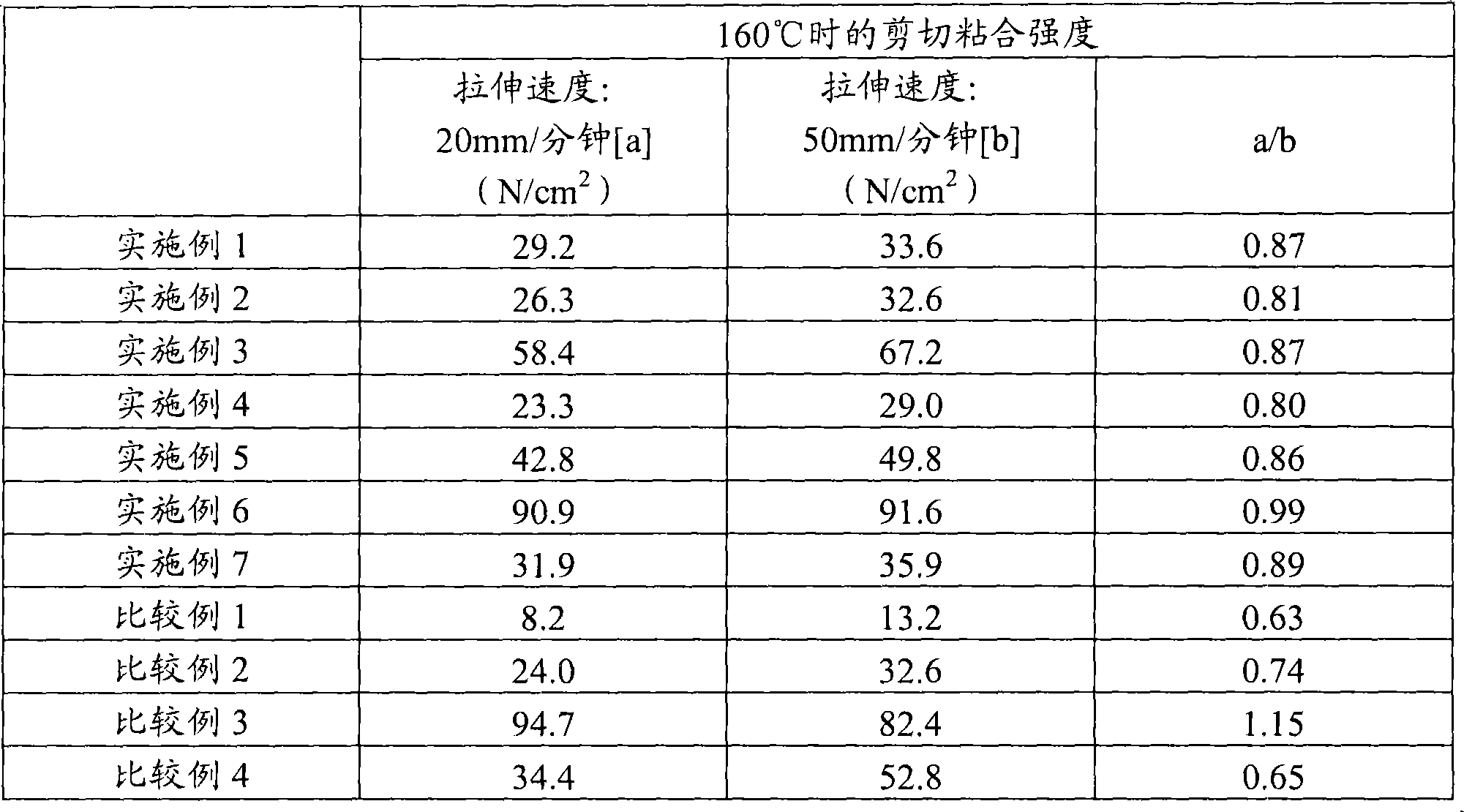

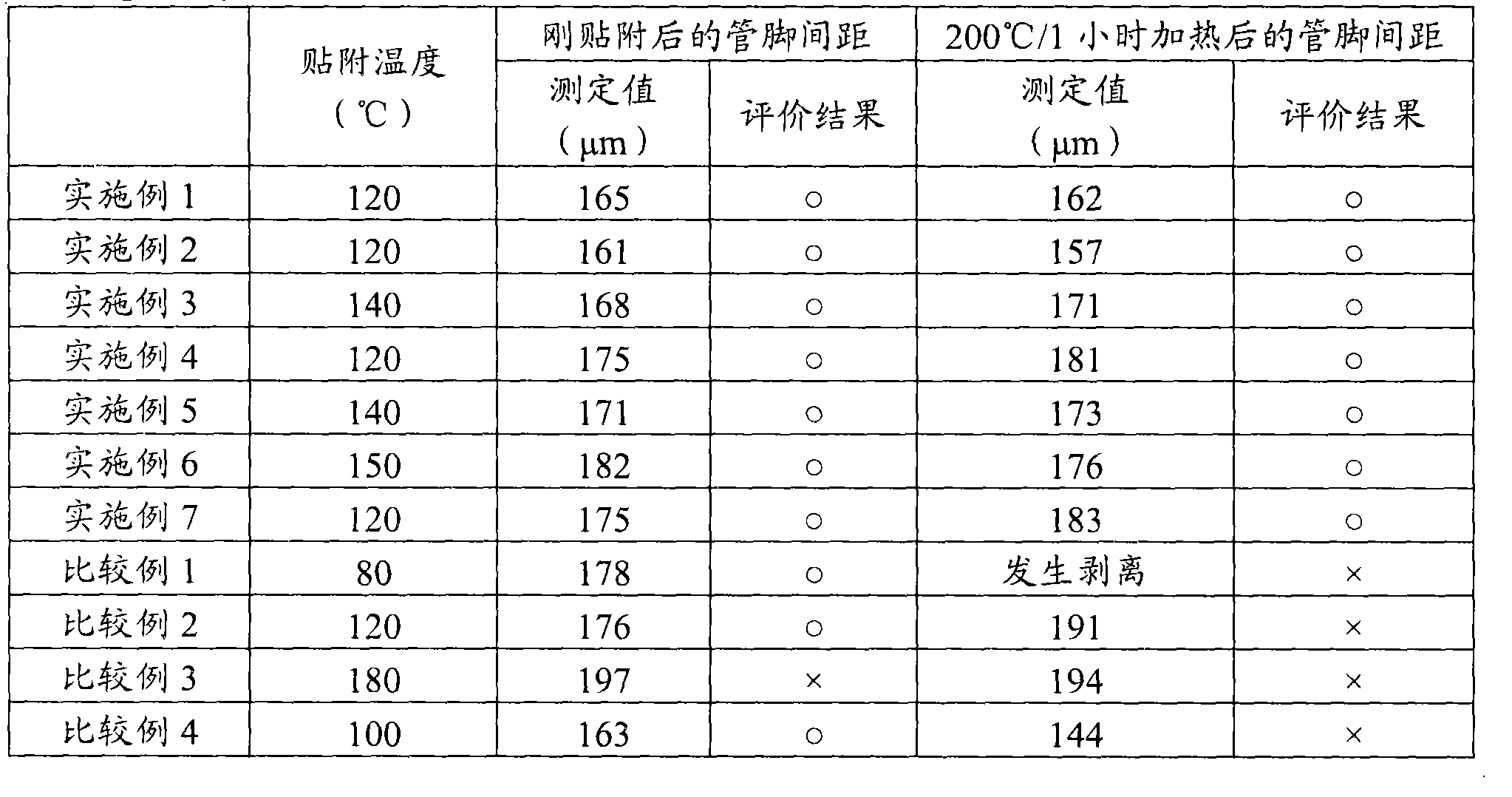

ActiveCN101063026BNo peelingNo position shiftFilm/foil adhesivesNitrile polymer adhesivesCopperUltimate tensile strength

The invention provides an adhesive tape for electronic unit which provided a thermosetting adhesive layer in at least one insulation surface, When shearing adhesive strength at the time of 160 degree heating to a copper plate of said thermosetting adhesive layer measures by a part for speed-of-testing / of 20 mm, above 20 N / cm2, and adhesive tape for electronic parts, wherein ratios (a / b) of speed-of-testing shearing adhesive strength for / of 20 mm (a) and shearing adhesive strength for 50-mm / (b) are 0.8-1.0.

Owner:TOMOEGAWA PAPER CO LTD

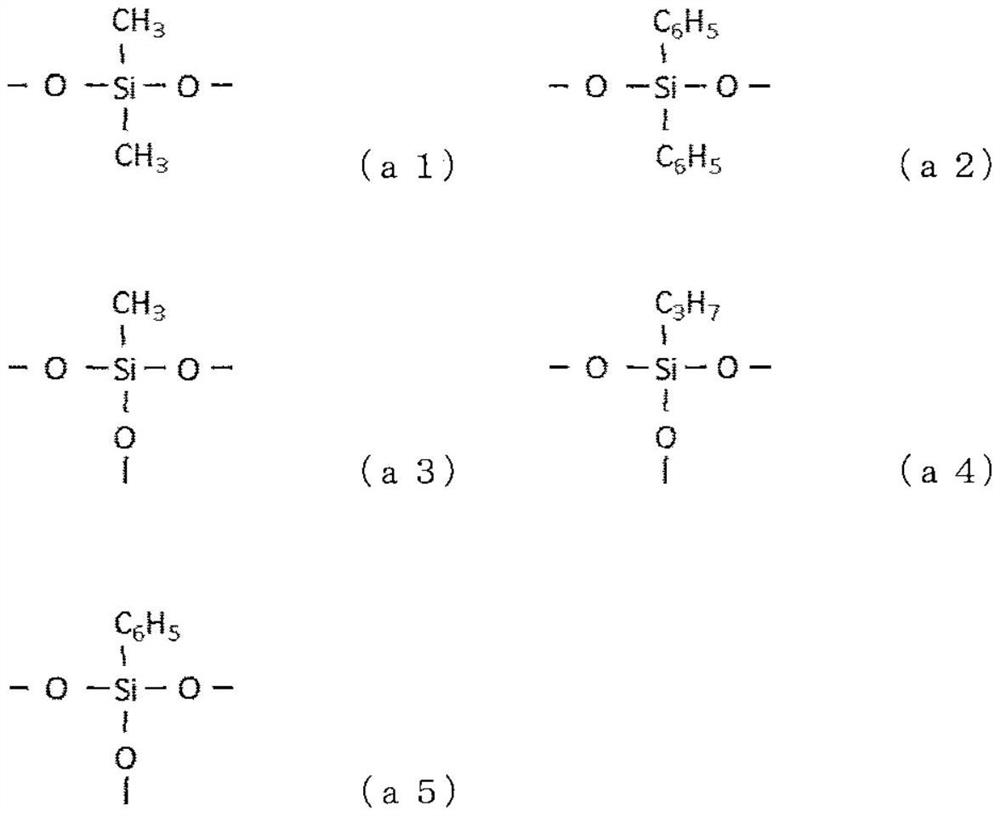

Heat-resistant coating composition, heat-resistant coating film, heat-resistant coating film-attached substrate, and method for preparing same

PendingCN113993638AExcellent corrosion resistanceAdequate tightnessFireproof paintsSynthetic resin layered productsMagnesium orthophosphateSiloxane

An embodiment of the present invention relates to a heat-resistant coating composition, a heat-resistant coating film, a heat-resistant coating film-attached substrate, or a method for preparing same, said heat-resistant coating composition including a siloxane-based binder (A), an aluminum powder (B), and an anti-corrosive pigment containing a magnesium phosphate-based compound.

Owner:CHUGOKU MARINE PAINTS

Resin composition for display substrate

ActiveCN104066768BModerate coefficient of linear expansionModerate softnessCoatingsNon-linear opticsOrganic groupDisplay device

Owner:NISSAN CHEM CORP

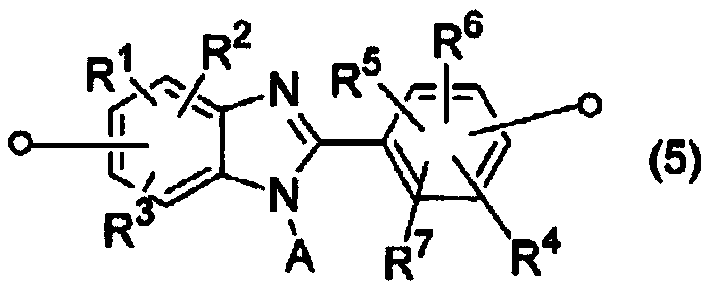

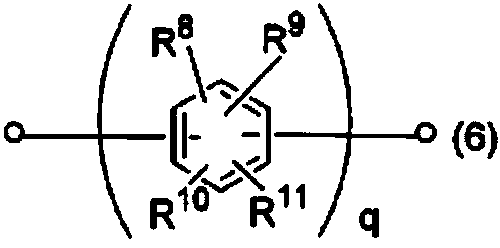

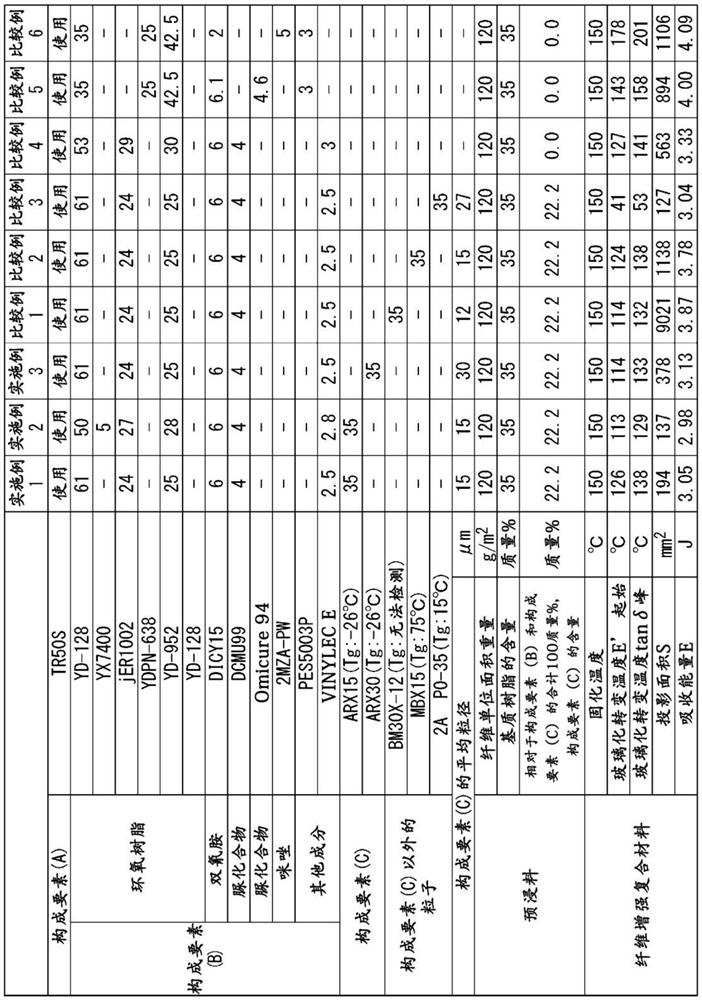

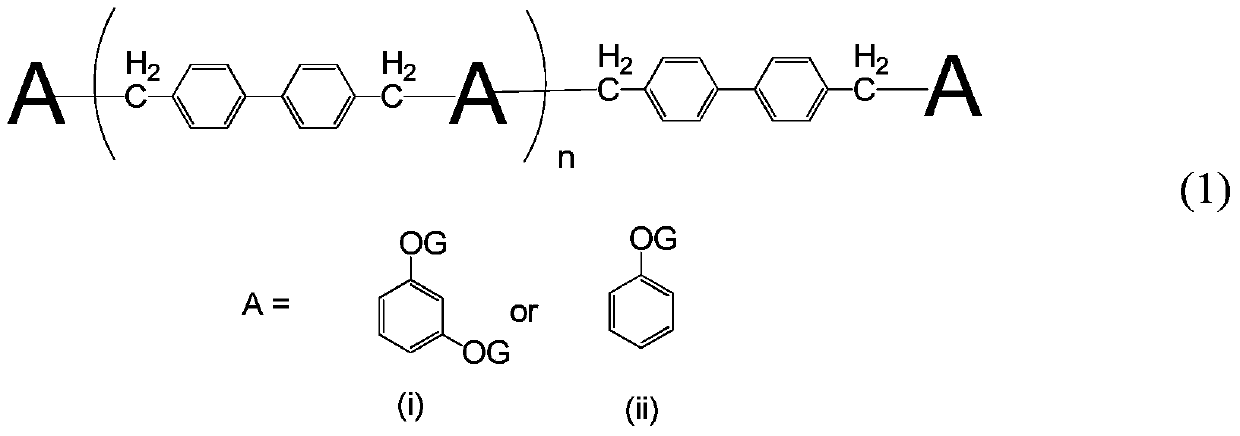

Prepreg, fiber-reinforced composite material, and method for producing fiber-reinforced composite material

Provided are: a prepreg which makes it possible to obtain a fiber-reinforced composite material in which interlayer peeling during point impact is suppressed; a fiber-reinforced composite material having excellent resistance during point impact; and a method for producing the fiber-reinforced composite material. A cured product obtained by curing this prepreg under specific curing conditions has a projected area of a damaged part of 400 mm2 or less as measured by a specific test 1, and the maximum value of tan [delta] of the cured product as measured by a specific test 2 is observed at 100 DEG C or higher. This prepreg contains a reinforcing fiber base material, an epoxy resin composition, and a polymer (C2), the polymer (C2) being present on the outermost surface of the prepreg, and the polymer (C2) having a glass transition temperature of 10 DEG C or less as observed under specific measurement conditions. The manufacturing method of the fiber reinforced composite material comprises the step of heating and forming the prepreg.

Owner:MITSUBISHI CHEM CORP

Resin composition and its forming product

The present invention provides a resin composition comprising polylactic acid and aliphatic polyester carbonate, which has practically adequate heat-resistance temperature, moldability, thermostability, solvent resistance and high mechanical strength, as well as a molded article thereof. In the resin composition, the Vicat softening point is 60 DEG C. or more, the tensile modulus of elasticity is 0.9 GPa or more, the modulus in flexure is 0.6 GPa or more, and the mixing ratio of polylactic acid (A) and aliphatic polyester carbonate (B), in terms of the ratio of (A) / (B) by weight, is 95 / 5 to 5 / 95. Further, the present invention provides a biodegradable injection-molded article having improvements in mechanical characteristics and impact resistance and superior disposal properties, particularly having strength enough to make it usable as a headgear material for use in helmets. The biodegradable injection-molded article is excellent in impact resistance, comprising mainly polylactic acid (A) and aliphatic polyester (E) and / or aliphatic polyester carbonate (B). This injection-molded article has a flexural strength of 30 MPa or more and an Izod impact strength of 3 kJ / m2 or more, and it is used as helmet headgear.

Owner:TOYOTA JIDOSHA KK +1

Photosensitive resin composition and cured product thereof

ActiveCN105527793BIncreased sensitivityFully satisfy the flexibilityPhotosensitive materials for photomechanical apparatusEpoxyPolymer science

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com