Patents

Literature

46results about How to "Consider heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble ceramic core material and preparation method thereof

ActiveCN105693254AConsider surface qualityTaking into account the dimensional accuracySolubilityPrecision casting

The invention belongs to the precision casting technique and relates to a water-soluble ceramic core material and a preparation method thereof. The water-soluble ceramic core material comprises a high-temperature ceramic material, water-soluble inorganic salts, metallic oxides and at least one amorphous ceramic material. The preparation method comprises the following steps: raw material pretreatment, raw material weighing, mixing, mold core forming, degreasing, sintering and secondary sintering. According to the water-soluble ceramic core material and the preparation method, the properties of surface quality, dimensional precision, foaming level, mechanical strength, heat resistance, water solubility, environment friendliness and the like of the mold core can be considered, and scientific research and production requirements of aluminum alloy are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

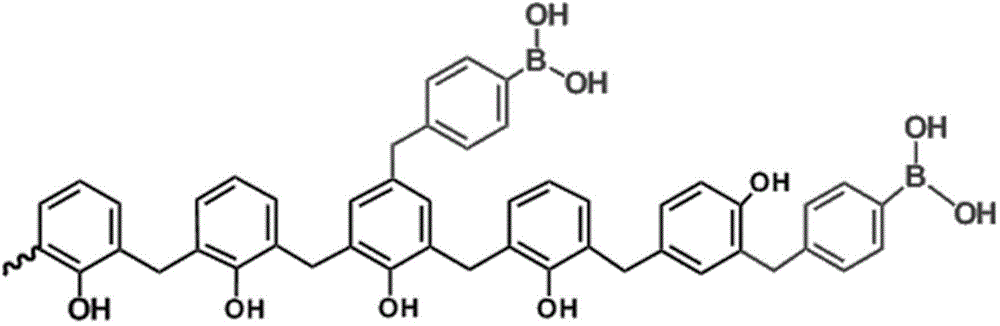

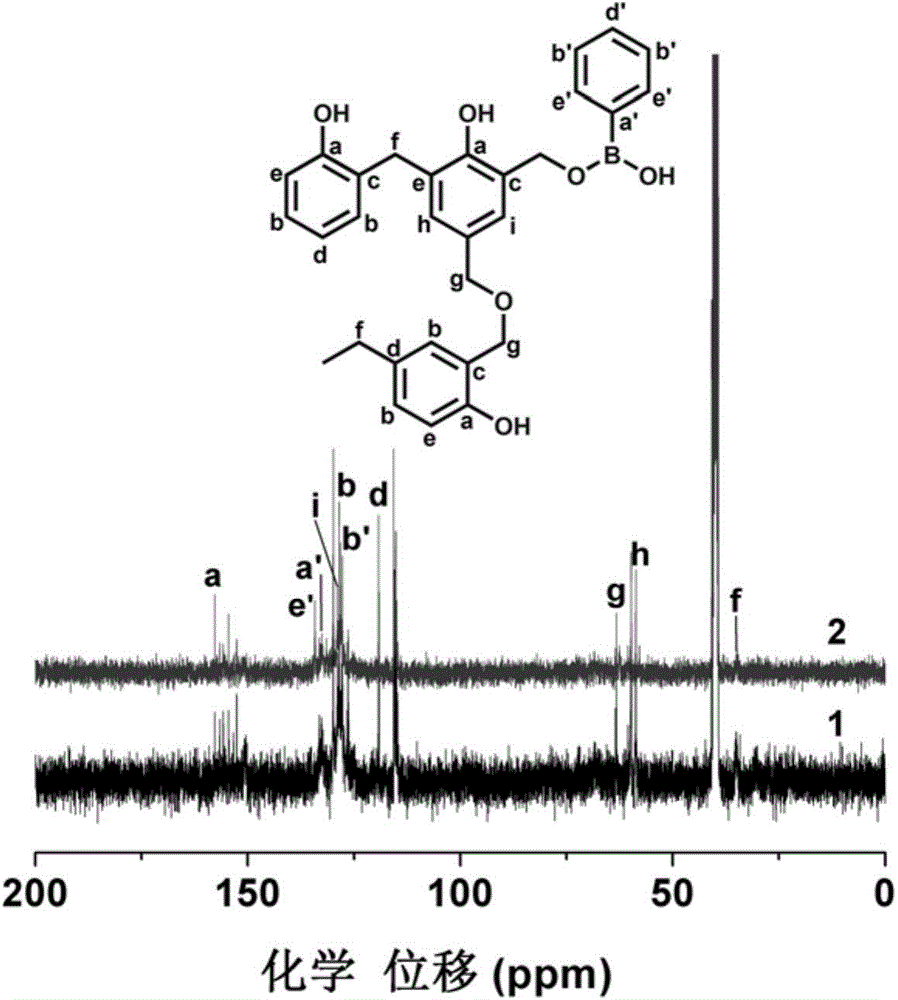

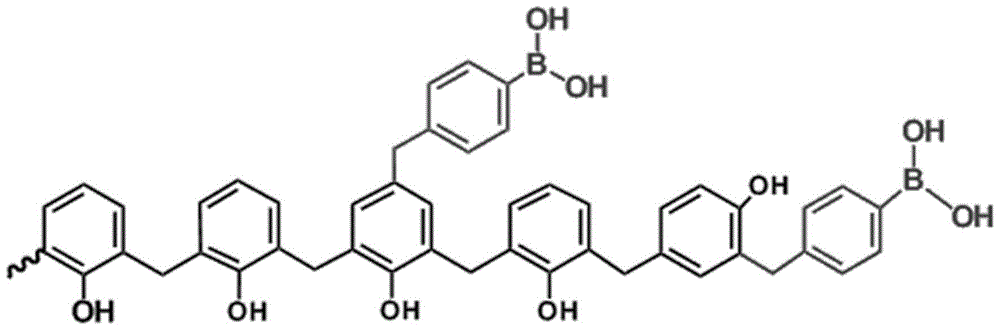

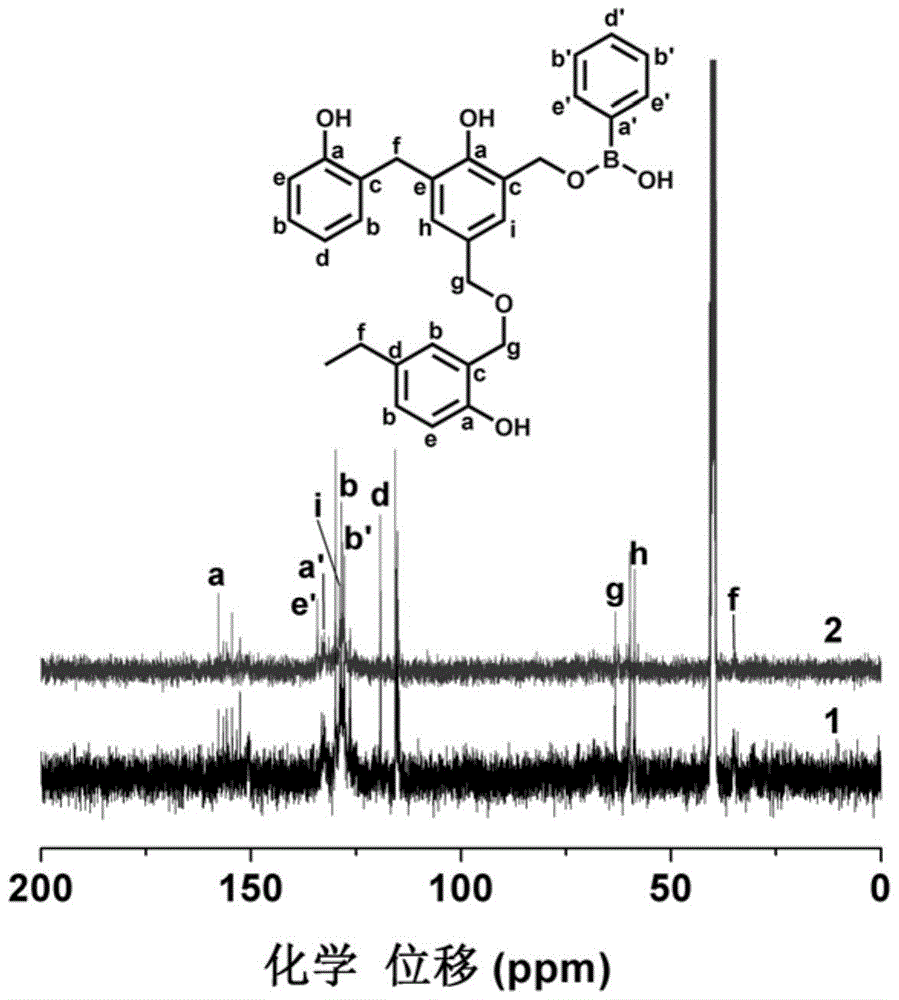

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

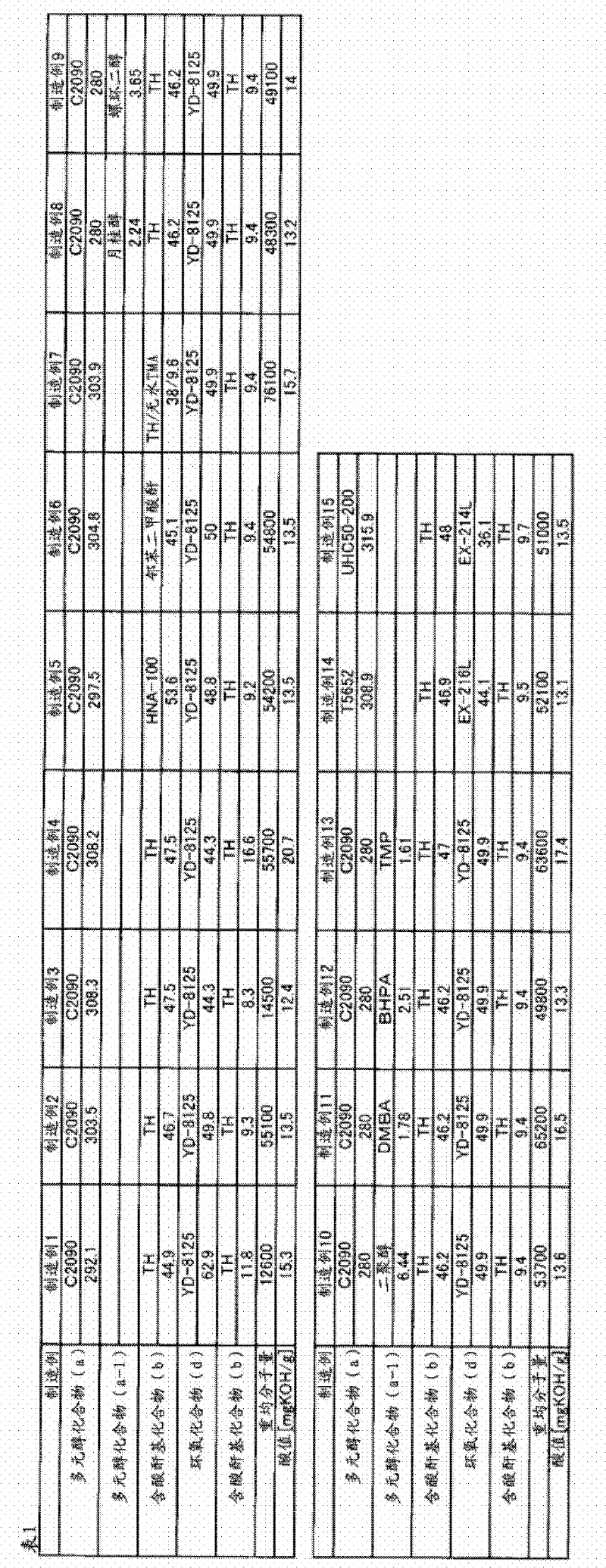

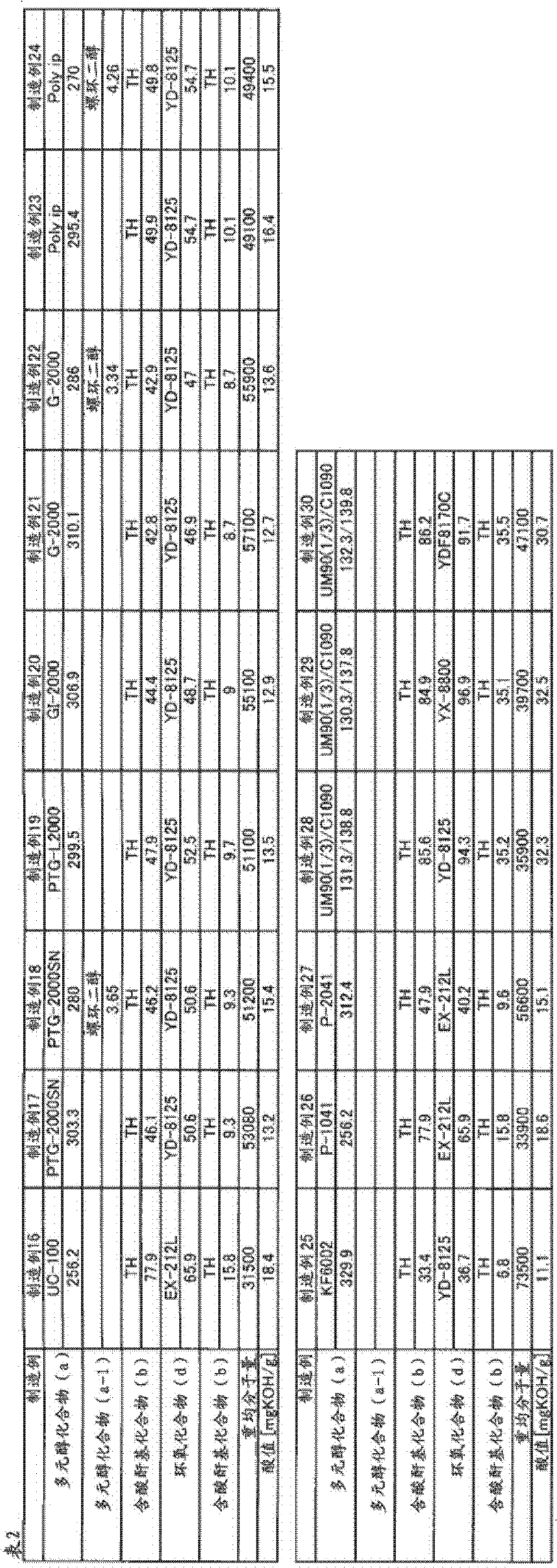

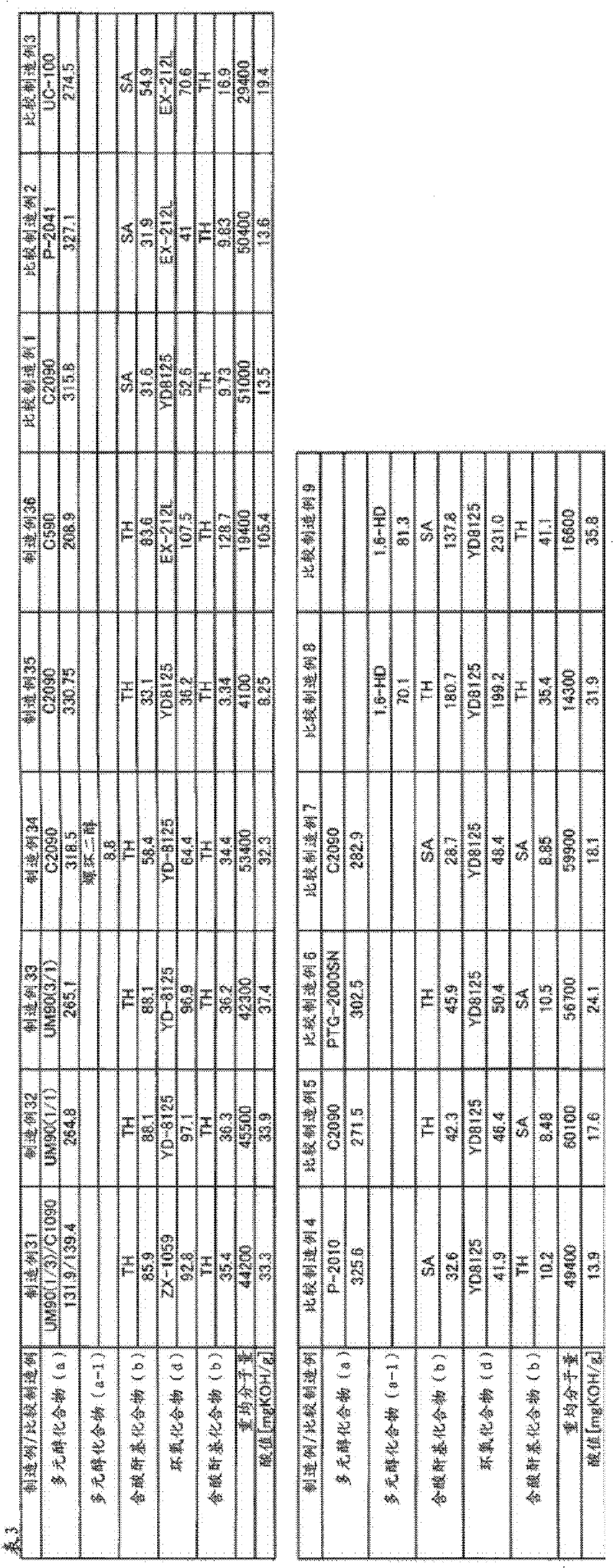

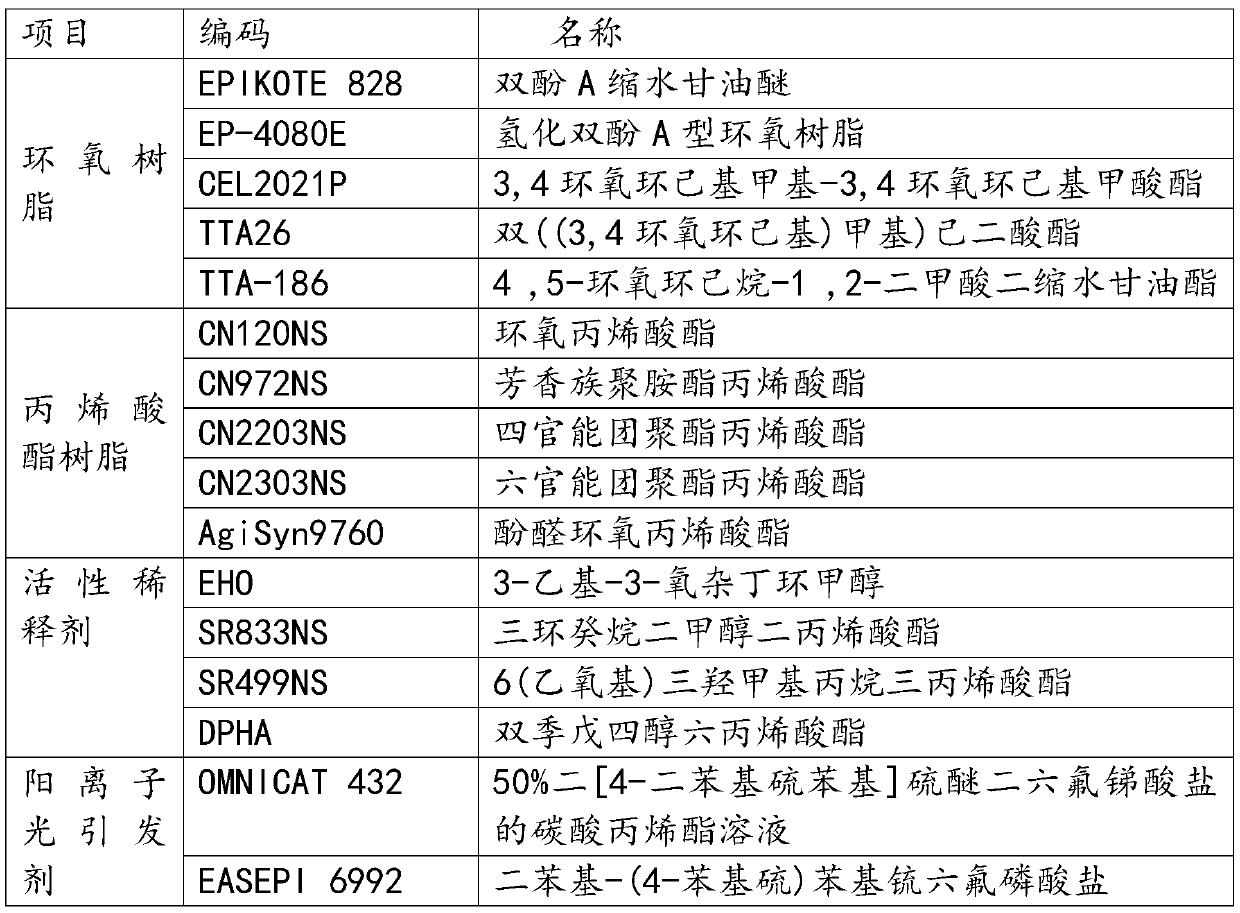

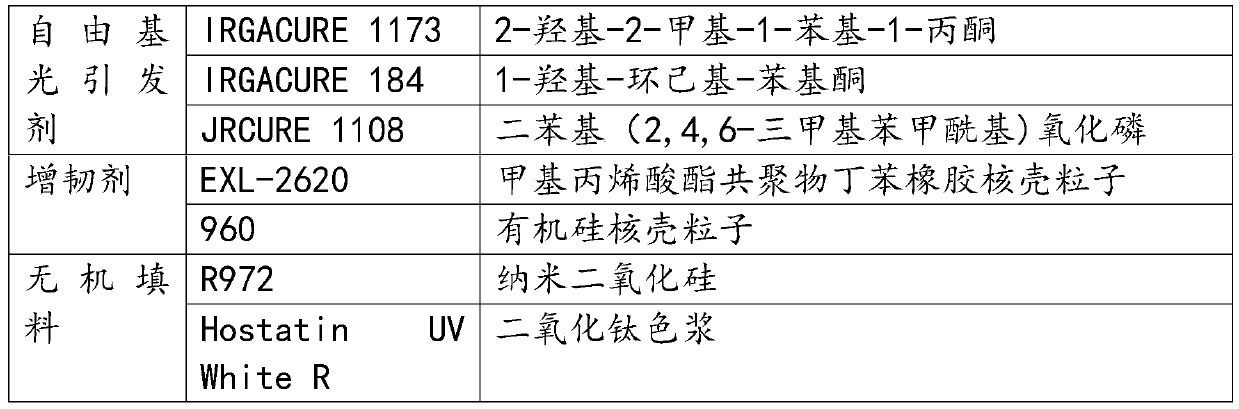

Thermosetting resin compound containing carboxyl modified polyurethane resin

ActiveCN102532483AGood adhesionTaking into account the flexibilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainEpoxide

Provided is a thermosetting resin compound containing carboxyl modified polyurethane resin, characterized by comprising the carboxyl modified polyurethane resin (A) which is at least one compound selected from a group consisting of an epoxy group contained compound, an isocyanate contained compound, and a closed isocyanate group contained compound, and a thermofixation assistant (C). The carboxyl modified polyurethane resin (A) is formed by making the polyatomic compound (a) and at least one anhydride group compound (b) selected from ring type multielement anhydride and aromatic aromatic anhydride produce reaction to generate carboxyl ester resin (c). Then the carboxyl ester resin (c) is made to react with an epoxy compound (d) in I molecules having at least two epoxy groups to produce side chain hydroxyl modified ester resion (e). Then the anhydride group compound (b) is made to react with the side chain hydroxyl modified ester resion (e) to generate the carboxyl modified polyurethane resin (A).

Owner:TOYO INK SC HOLD CO LTD +1

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

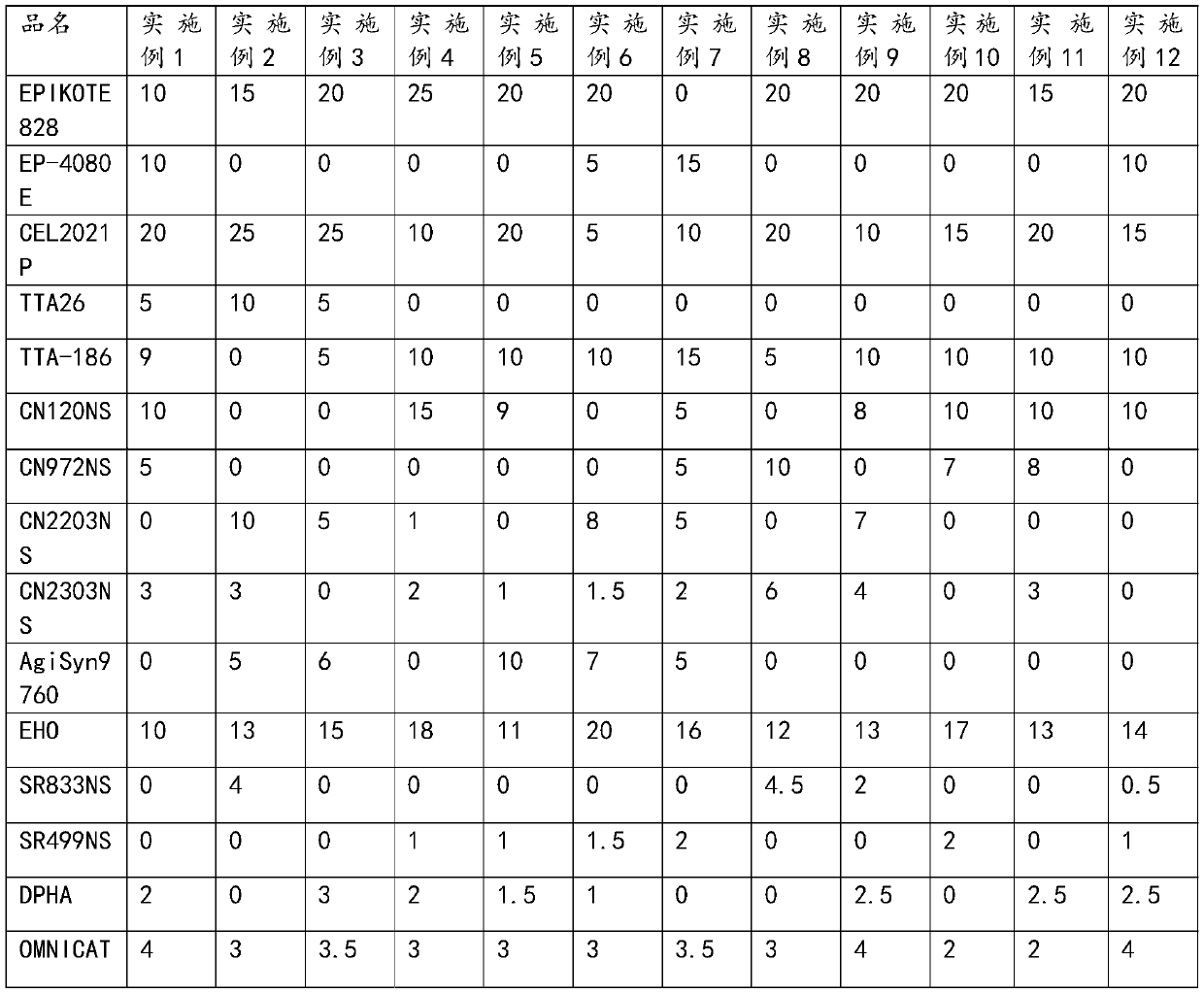

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

Fireproof heat insulation coating and preparation method thereof

InactiveCN110105800ATaking into account the fire protection functionConsider heat resistanceFireproof paintsFiberSolvent

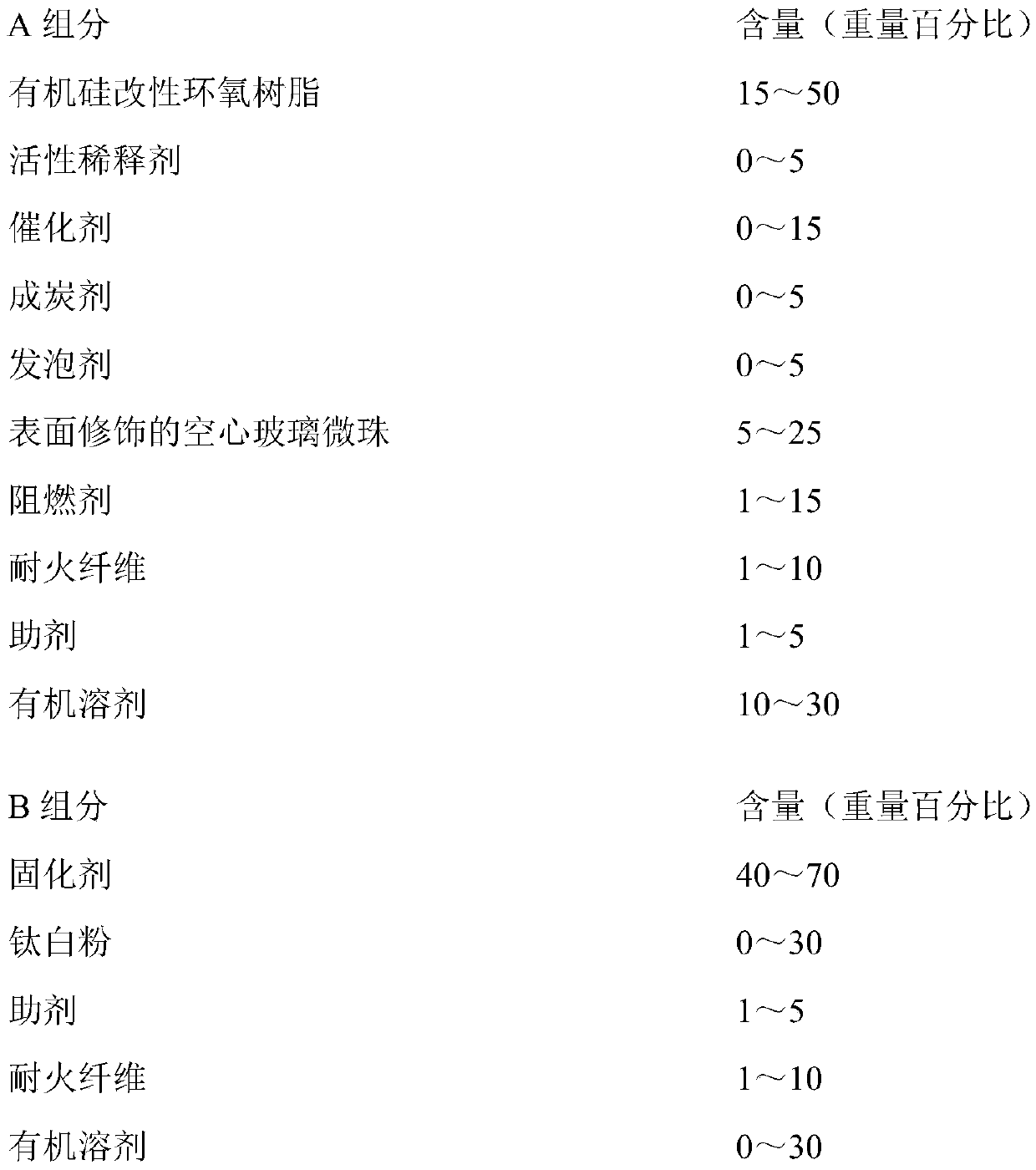

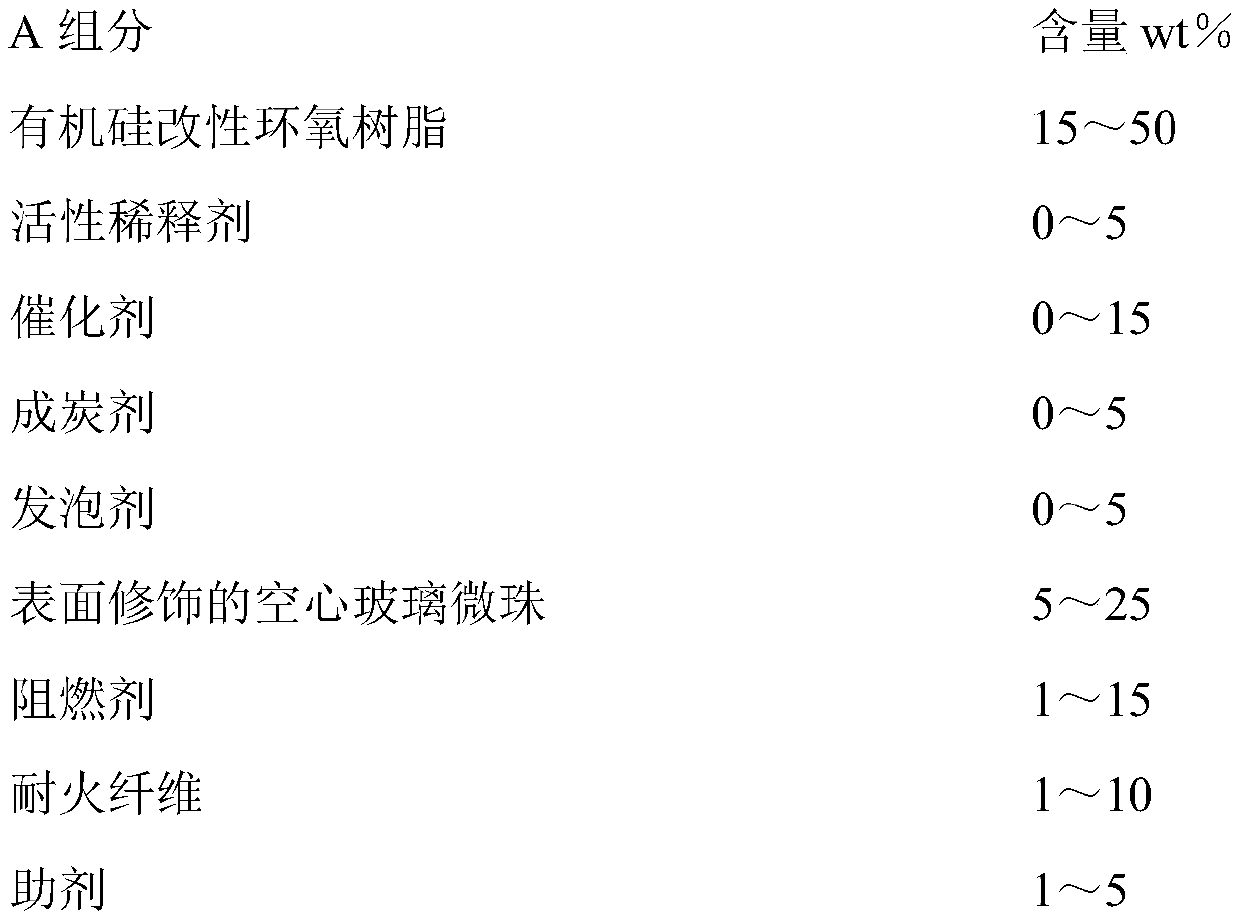

The invention discloses a fireproof heat insulation coating and a preparation method thereof. The fireproof heat insulation coating comprises: components A (weight percentage): 15-50% of organic silicon modified epoxy resin, 0-5% of a reactive diluent, 0-15% of a catalyst, 0-5% of a char forming agent, 0-5% of a foaming agent, 5-25% of surface-modified hollow glass microspheres, 1-15% of a flame retardant, 1-10% of refractory fibers, 1-5% of an auxiliary agent and 10-30% of an organic solvent; components B (weight percentage): 40-70% of a curing agent, 0-30% of titanium dioxide, 1-5% of an auxiliary agent, 1-10% of refractory fibers and 0-30% of an organic solvent, wherein the weight ratio of the components A to the components B is (1-6) to 1. The fireproof heat insulation coating has a fireproof function, a heat-insulating function and heat resistance, meanwhile has lower density, has better adhesion power with various base materials, has good matching property with various primer andfinish paints, has interlayer adhesion power, and is resistant to various types of solvent oils and organic solvents.

Owner:MARINE CHEM RES INST

Preparation method of food-grade full-degradable high-temperature-resistant polylactic acid composite material

The invention discloses a preparation method of a food-grade full-degradable high-temperature-resistant polylactic acid composite material, and belongs to the field of biodegradable high polymer materials. The composite material comprises, by weight, 100 parts of poly-l-lactic acid (PLLA), 1-10 parts of poly-d-lactic acid (PDLA) and 0.5-1 part of functional additives. Compared with traditional petroleum-based high polymer materials, the composite material has the advantages of being easy to degrade and renewable; compared with common polylactic acid, the composite material has excellent heat resistance. Thus, the polylactic acid composite material can be applied to high-temperature-resistant food packages.

Owner:CHANGZHOU UNIV

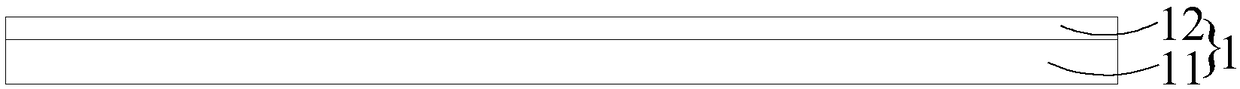

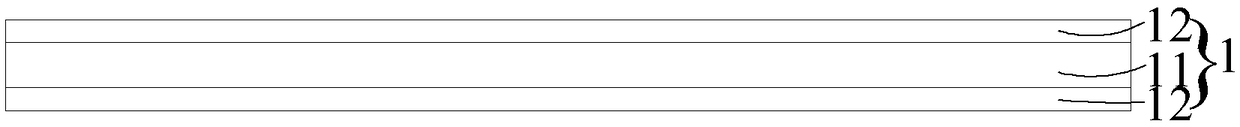

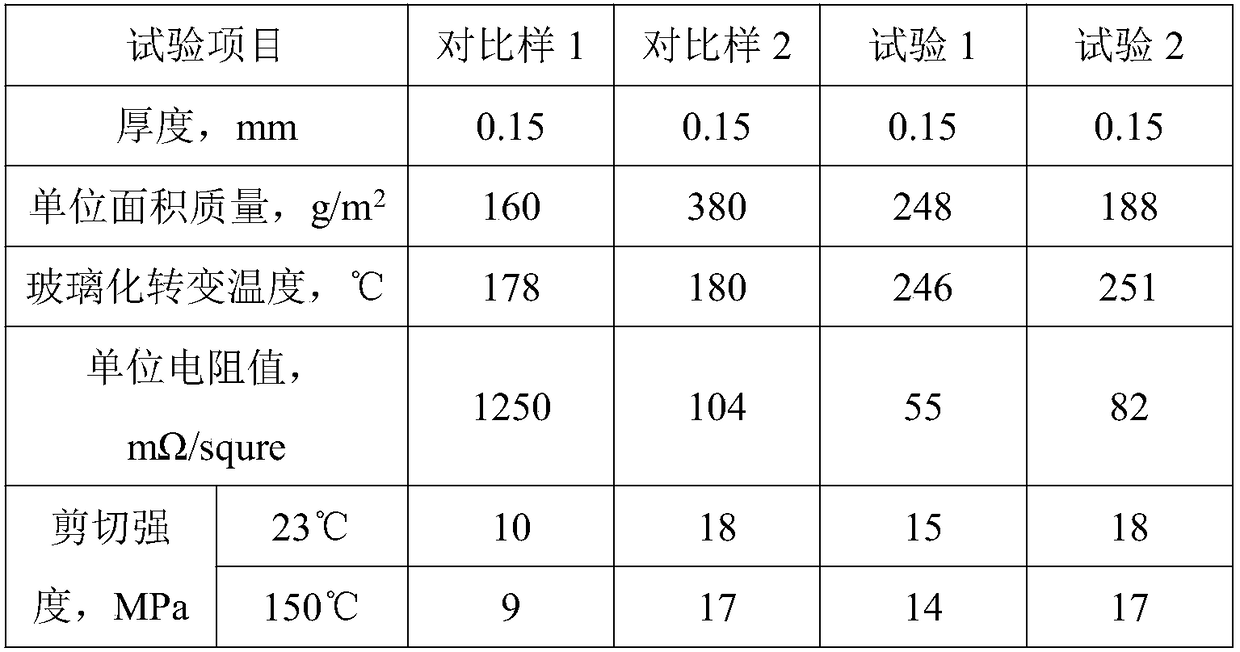

Novel aramid-paper-based copper-clad plate and preparation method thereof

InactiveCN109082944AImprove conductivityHigh peel strengthSpecial paperPaper/cardboardPaper basedThermal expansion

The invention relates to the technical field of copper-clad plates, in particular to a novel aramid-paper-based copper-clad plate and a preparation method thereof. The novel aramid-paper-based copper-clad plate comprises a substrate and copper foil and is characterized in that the substrate is formed by stacking a plurality of prepregs, and the copper foil is stacked to at least one surface of thesubstrate; each prepreg comprises modified para-position aramid paper and resin composite layers stacked to at least one surface of the aramid paper; the copper foil is adhered to the surface of theresin composite layers through glue. The aramid-paper-based copper-clad plate is good in stripping strength, small in density, excellent in dielectric property and thermal expansion coefficient, and the good thermal conductivity of the aramid-paper-based copper-clad plate can greatly expand the application range of the copper-clap plate.

Owner:LONGPONT

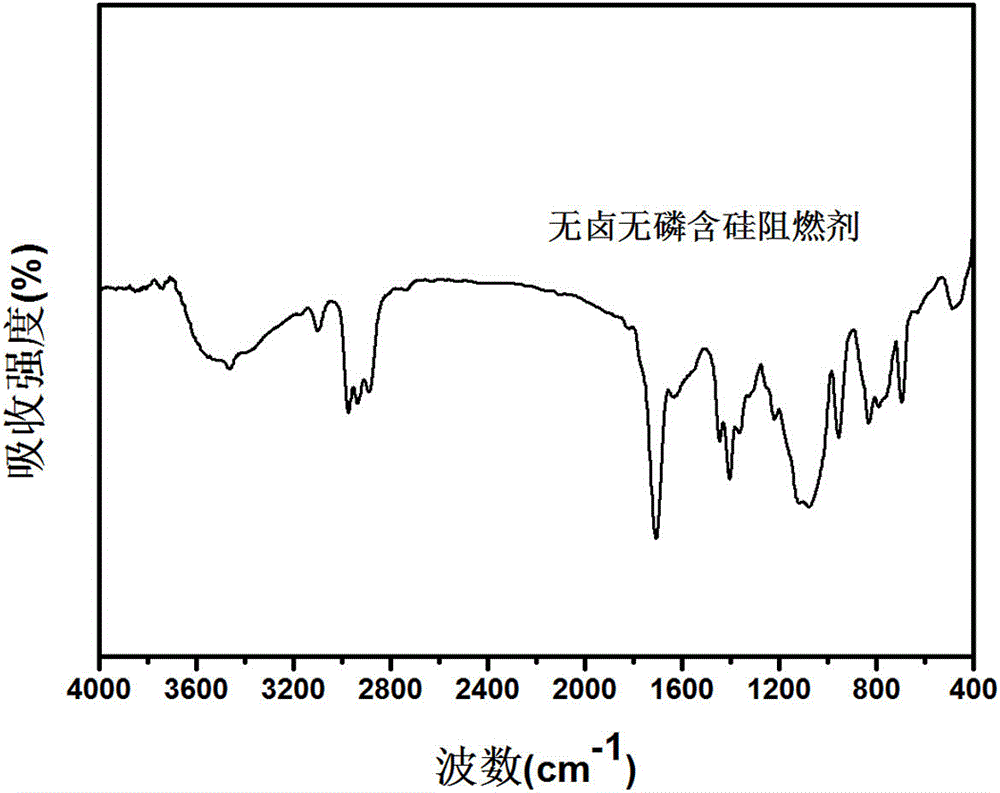

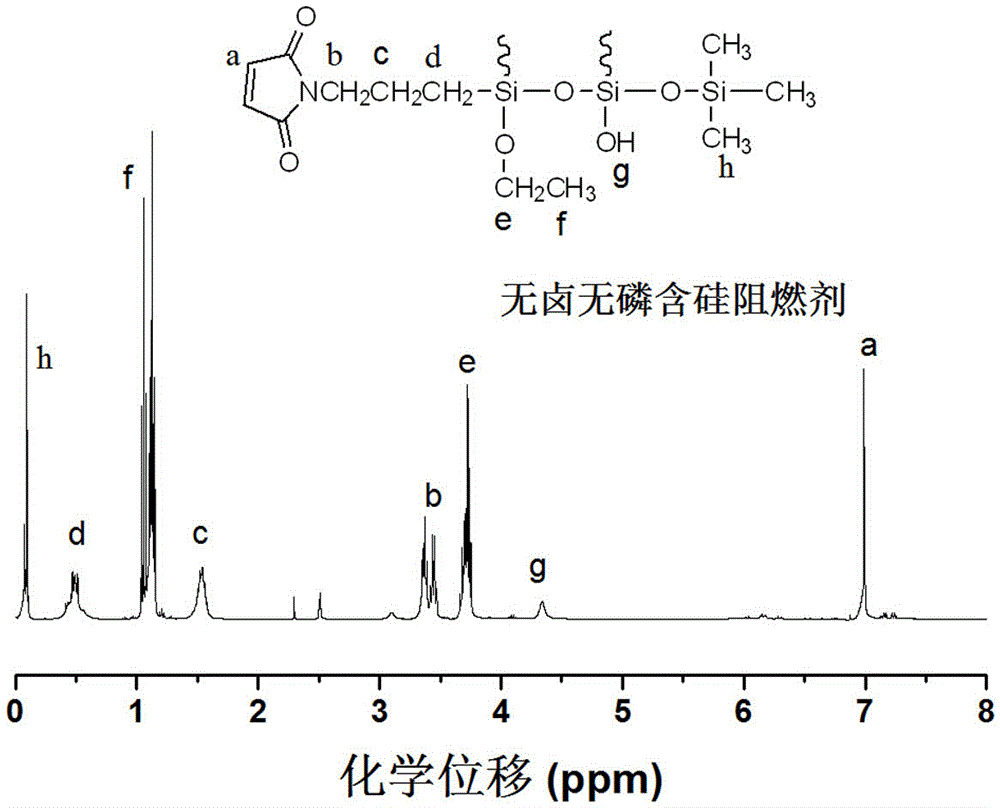

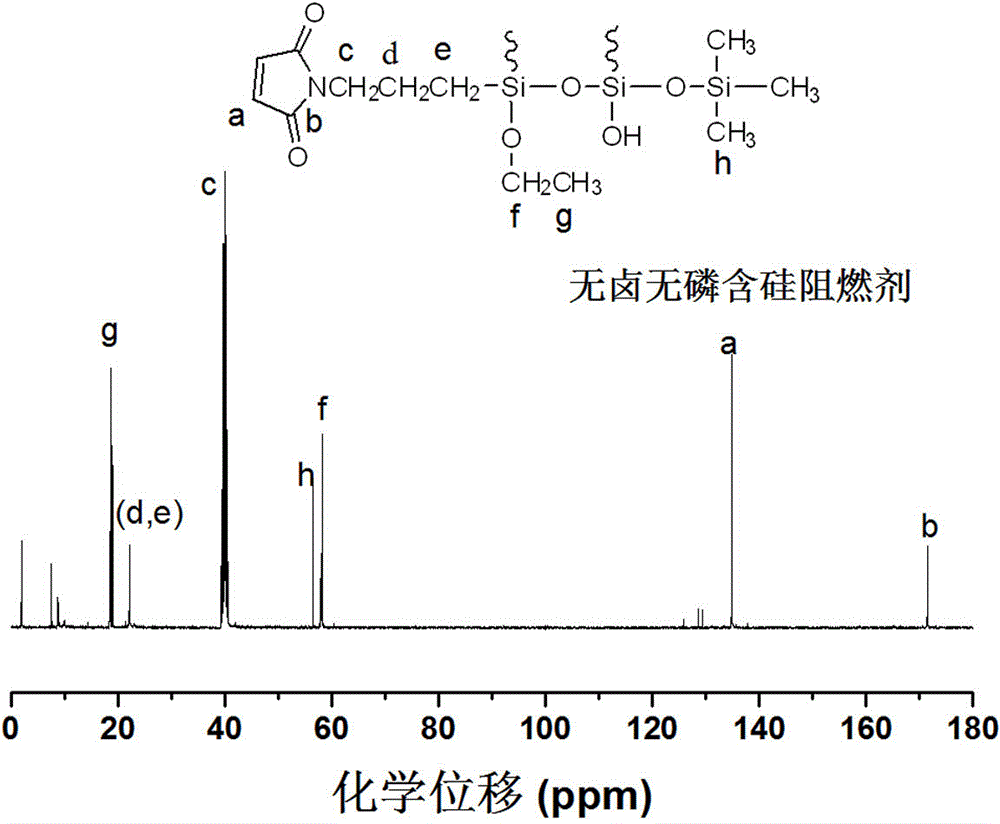

Flame-retardant bismaleimide resin and preparation method thereof

The invention discloses a flame-retardant bismaleimide resin and a preparation method thereof. The flame-retardant bismaleimide resin is prepared by the following steps: stirring 100 weight parts of bismaleimide, 0-80 weight parts of diallyl phenyl compounds and10-50 weight parts of a halogen-free non-phosphorus silicon-containing flame retardant under the temperature condition of 120-150DEG C to form a transparent liquid. The halogen-free non-phosphorus silicon-containing flame retardant is poly-maleimide hyperbranched silicon resin with the branching degree of 0.5-0.6 and the molecular weight of 2500-3400. The flame-retardant bismaleimide resin not only has excellent flame retardance performance, but also the mechanical performance can be greatly improved, in addition, the flame-retardant bismaleimide resin also maintains the excellent heat resistance, and can be used as a high-performance resin matrix, an adhesive, insulating paint and the like, and has wide application prospects in the fields of aerospace, electronic information, electrical insulation and the like.

Owner:SUZHOU UNIV

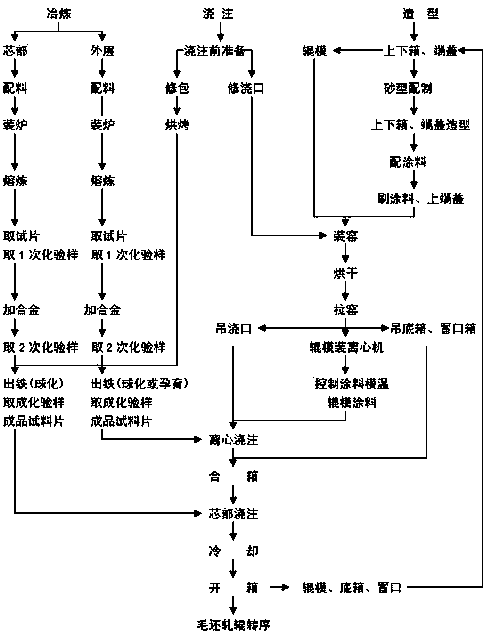

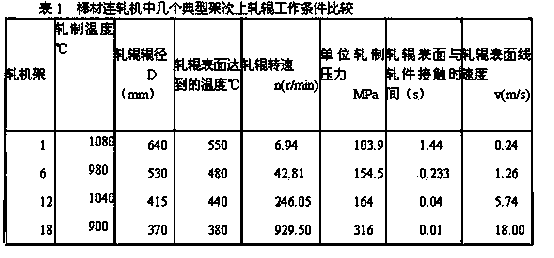

Manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls

ActiveCN103691903AThe solidification temperature range is smallGood composition uniformityMulti elementMaterial selection

The invention relates to a manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls, and belongs to the technical field of metallurgical rolls. The technical scheme includes that eutectic compositions are selected as materials of a roll working layer, and besides five elements of C, Mn, Si, P and S commonly existing in steel, not less then five alloying elements of Cr, W, Mo, V, Nb, Ti, Al, Cu, B and Mg need to be added into the roll materials to form a multi-element alloying state; carbon content of the roll materials is controlled to be 1.3%-2.8% in mass percent. The manufacturing process is small in solidification temperature range of the eutectic compositions, and particularly suitable for obtaining high-quality castings under the circumstance that feeding conditions are insufficient; the castings are crystallized simultaneously, and optimal in composition uniformity, concentrated cavity shrinkage is formed, metallic yield by casting moulding is high; the metal is solidified at the same time, and casting stress in the process of solidification is minimum; the eutectic compositions in alloy are lowest in melting point, and smelting cost is also low; liquid of the eutectic compositions is best in fluidity; castability is improved, and abrasion resistance and heat resistance are taken into consideration.

Owner:朝阳联强轧辊有限公司

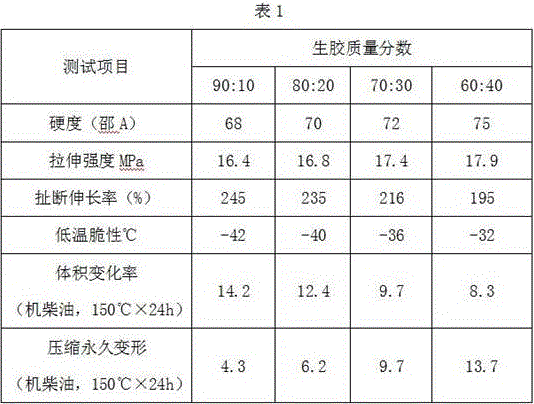

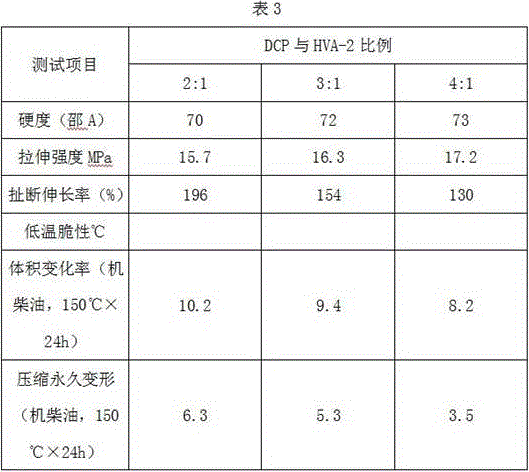

High and low temperature resistance and engine diesel oil resistance ultra-low pressure variation rubber material and preparation method thereof

InactiveCN106750645ABoth heat resistance and cold resistanceImprove heat resistanceMasticationActive agent

The invention discloses a high and low temperature resistance and engine diesel oil resistance ultra-low pressure variation rubber material and a preparation method thereof. The high and low temperature resistance and engine diesel oil resistance ultra-low pressure variation rubber material is prepared from the following components in parts by weight: 100 parts of 26 type and 40 type blending nitrile rubber, 60-100 parts of a reinforcing agent, 5-10 parts of a softening plasticizer, 4-6 parts of an antioxidant, 2-5 parts of a process auxiliary, 3-8 parts of an active agent, 2-4 parts of a vulcanizing agent and 0.5-3 parts of an auxiliary crosslinking agent. The preparation method of the rubber material comprises three steps of mastication, mixing and vulcanizing. According to the high and low temperature resistance and engine diesel oil resistance ultra-low pressure variation rubber material prepared by the technical scheme, the use temperature range of nitrile rubber is widened, permanent compressing deformation of the nitrile rubber in hot oil is greatly lowered, the service life of the nitrile rubber is prolonged, the application range of the nitrile rubber is widened, the cost is relatively low, and the rubber material can partly replace more expensive rubber materials such as chlorosulfonated polyethylene, ethylene propylene diene monomer, carboxylated nitrile and the like and has very large economic value.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

High-temperature-resistant composite antibacterial agent and preparation method thereof

ActiveCN104855416AGood resistance to high temperature discolorationImmediate effectBiocideFungicidesPhosphoric acidSilica gel

The invention discloses a high-temperature-resistant composite antibacterial agent and a preparation method thereof, and belongs to the technical field of bactericides. The composite antibacterial agent comprises a guanidine salt antibacterial agent and inorganic additives, wherein the inorganic additives are selected from one or more of boric acid, boric oxide, zinc oxide, titanium dioxide, phosphoric acid, zeolite powder, silica gel powder, glass powder, talcum powder and hydroxyapatite. The preparation method comprises the following steps: adding a small number of volatile solvents into the guanidine salt antibacterial agent and the inorganic additives, mixing to be pasty, and uniformly grinding to obtain the high-temperature-resistant composite antibacterial agent; or dissolving the guanidine salt antibacterial agent and the inorganic additives into the solvents, and steaming and removing the solvents to obtain the high-temperature-resistant composite antibacterial agent. The composite antibacterial agent can integrate the immediate action, the broad spectrum and the continuity of an organic system with the safety and the heat resistance of an inorganic system. Compared with an undoped antibacterial agent, the high-temperature-resistant composite antibacterial agent has the advantage that the heat stability is obviously improved. Other accessory components can be added into the antibacterial agent according to specific application.

Owner:WUHAN JASON BIOTECH CO LTD

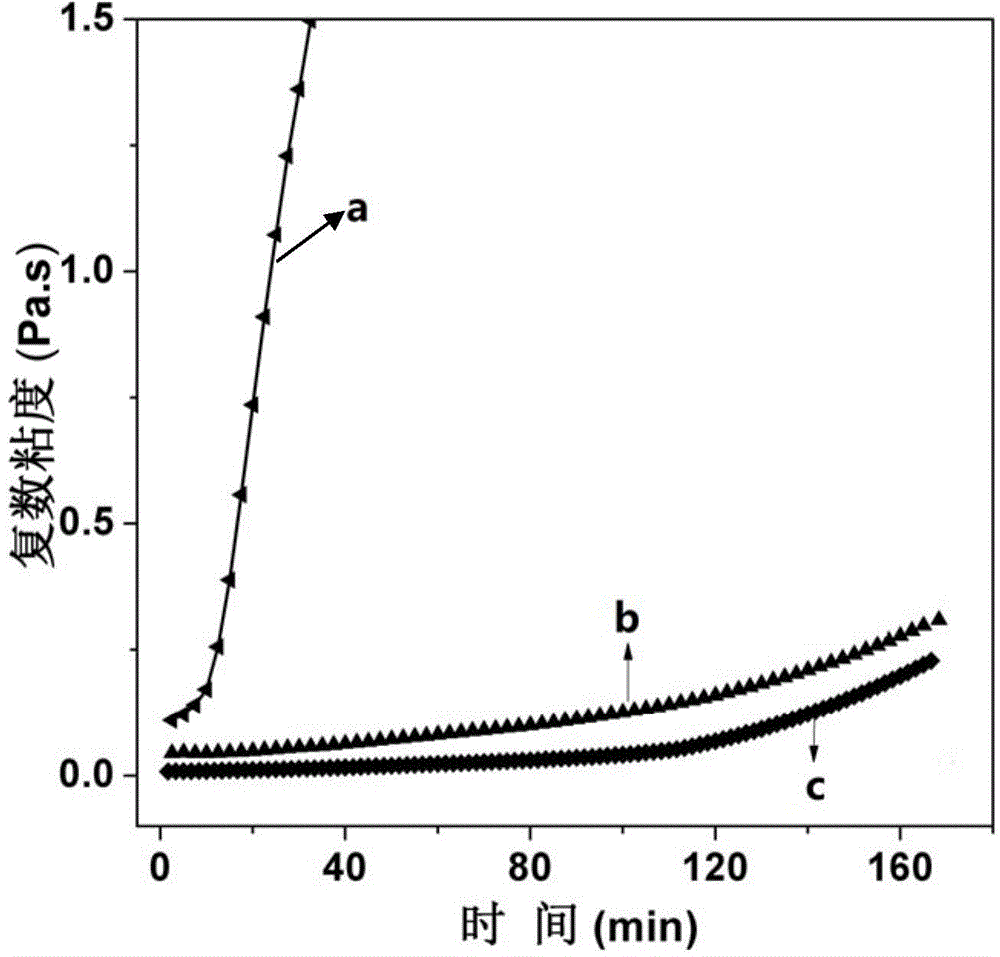

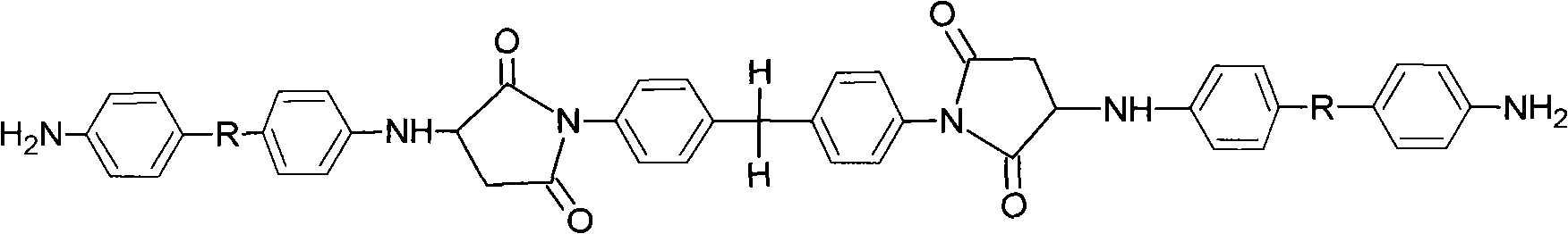

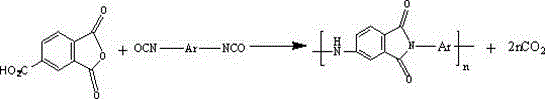

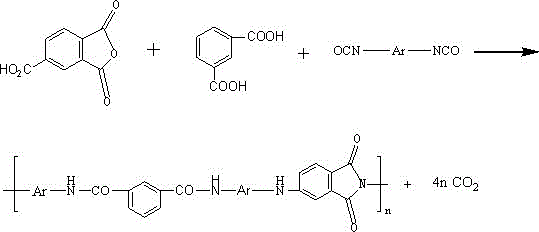

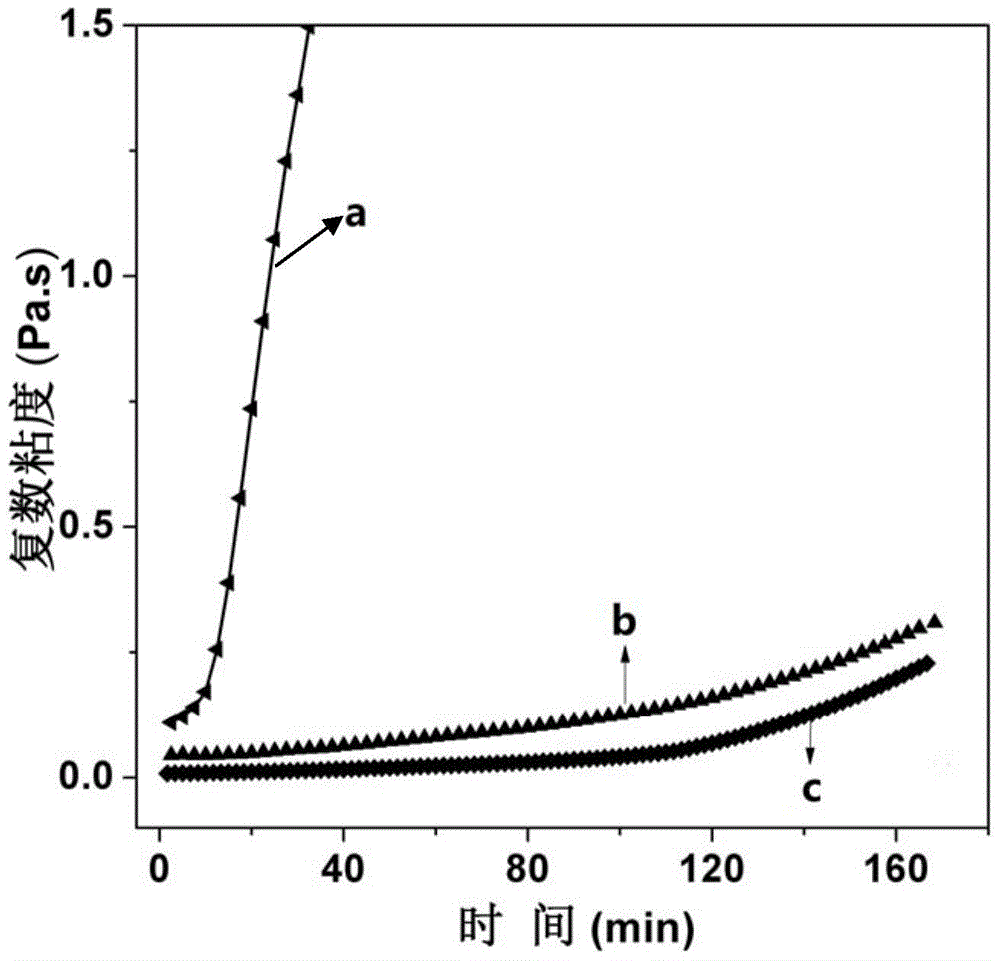

Resin prepreg constitutive rubber solution and heat dissipation rubber piece and manufacturing method thereof

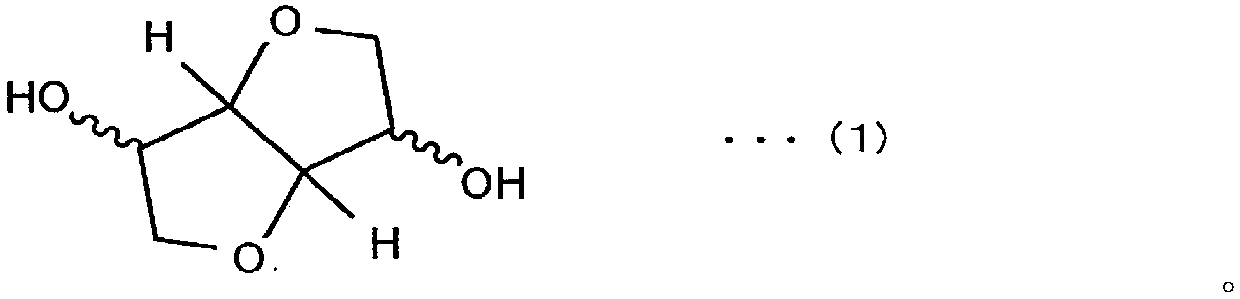

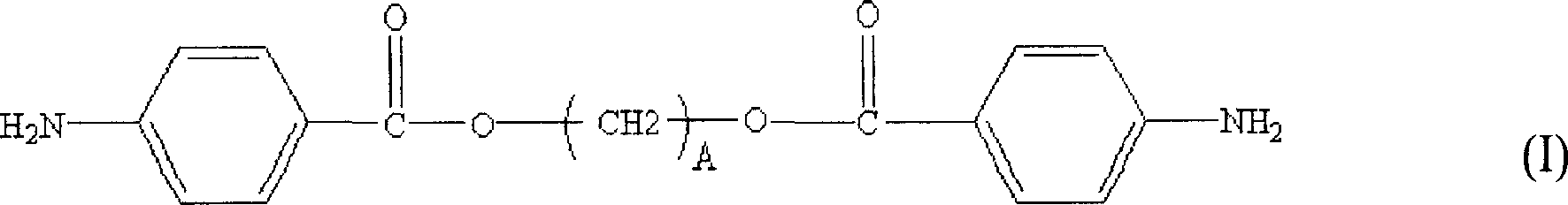

InactiveCN101613517AConsider heat resistanceTaking into account the adhesionCircuit susbtrate materialsCooling/ventilation/heating modificationsStructural componentPolyresin

The invention relates to hardening agent resin prepreg rubber solution and heat dissipation rubber pieces and a manufacturing method thereof. The main structural components of the hardening agent are shown as the formula (I), and the addition of the hardening agent enables the heat dissipation rubber piece to possess both heat resistance and adhesiveness. Since the structure of the hardening agent has polarity, inorganic powder can be uniformly dispersed in the resin prepreg composition rubber solution, thus the heat dissipation rubber piece manufactured by being dipped in the resin prepreg constitutive rubber solution has better resin characteristics and heat conduction efficiency.

Owner:ITEQ CORP

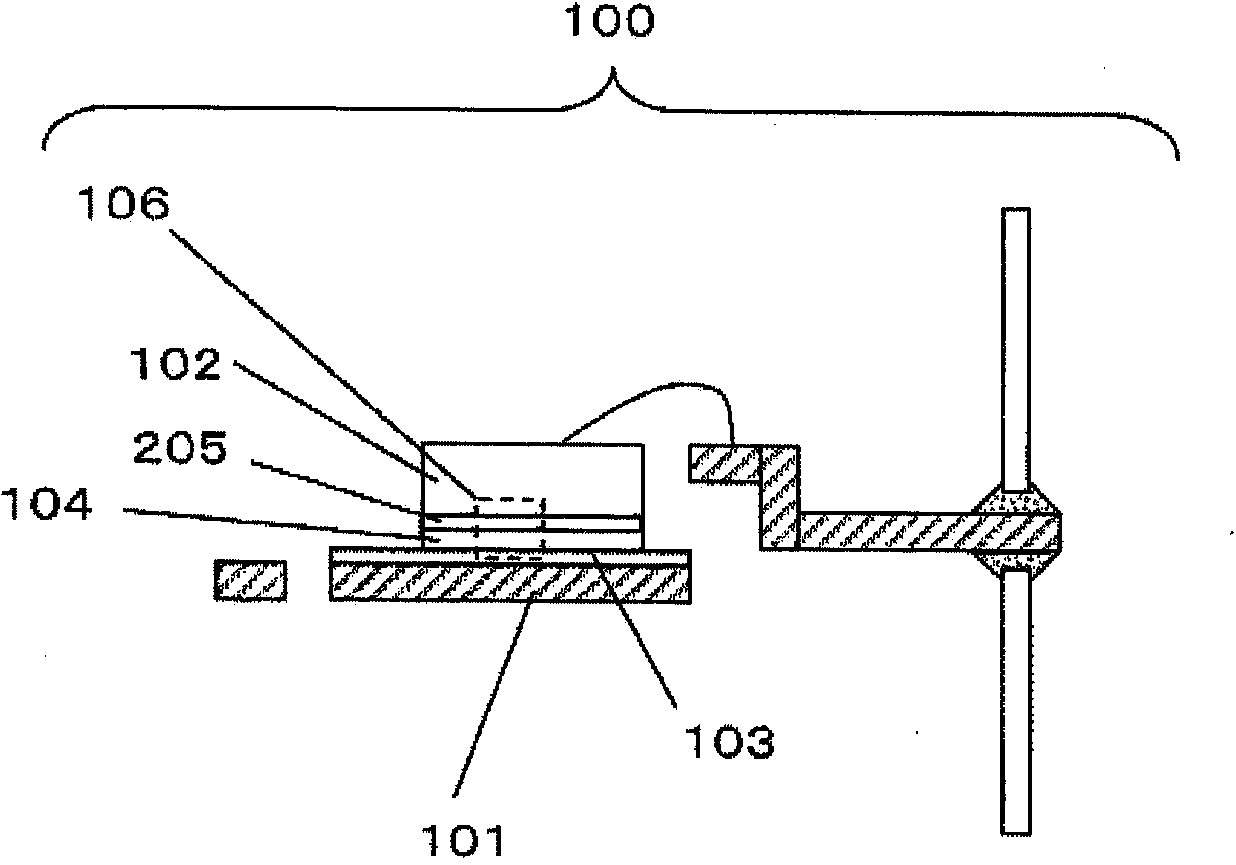

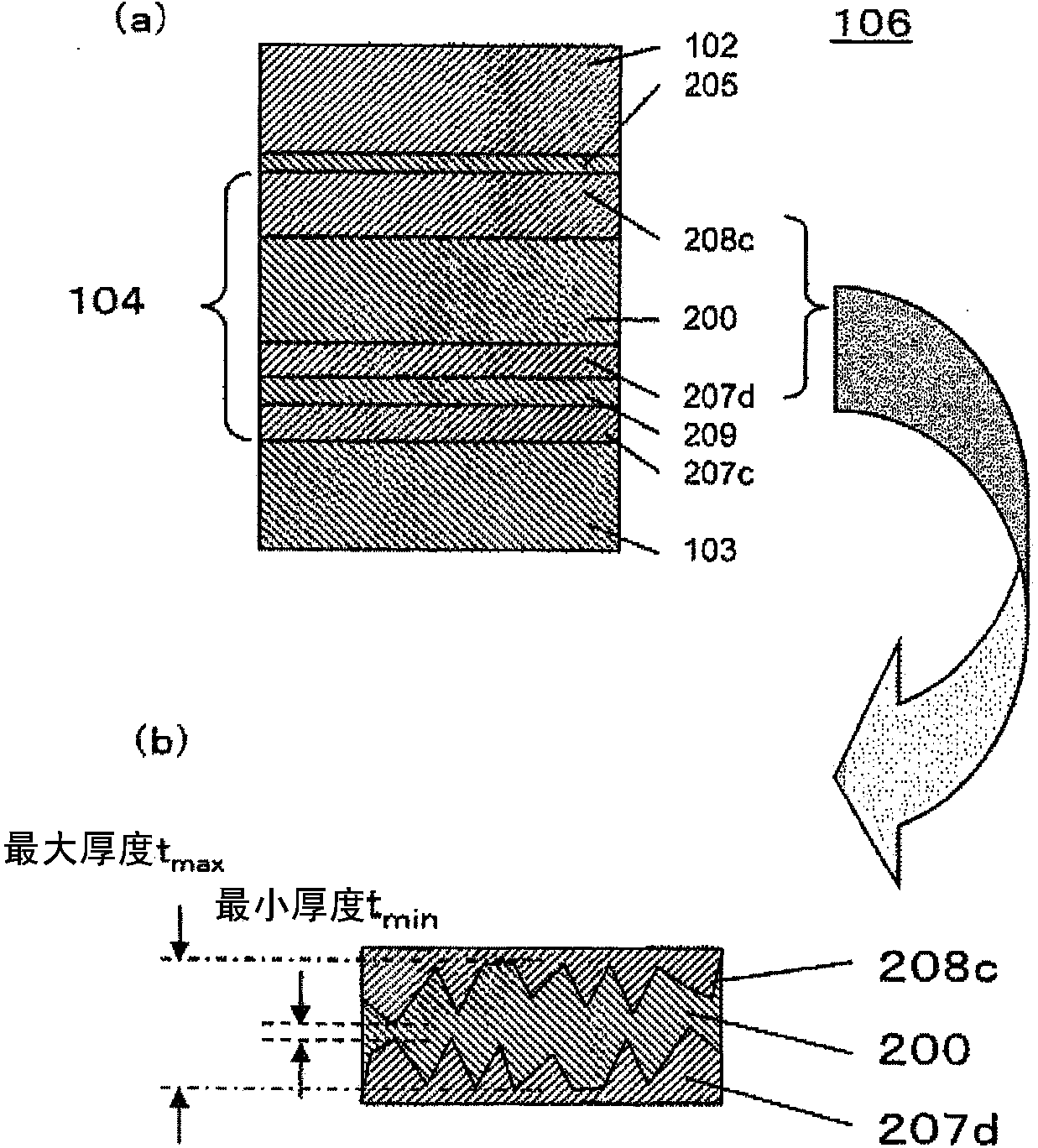

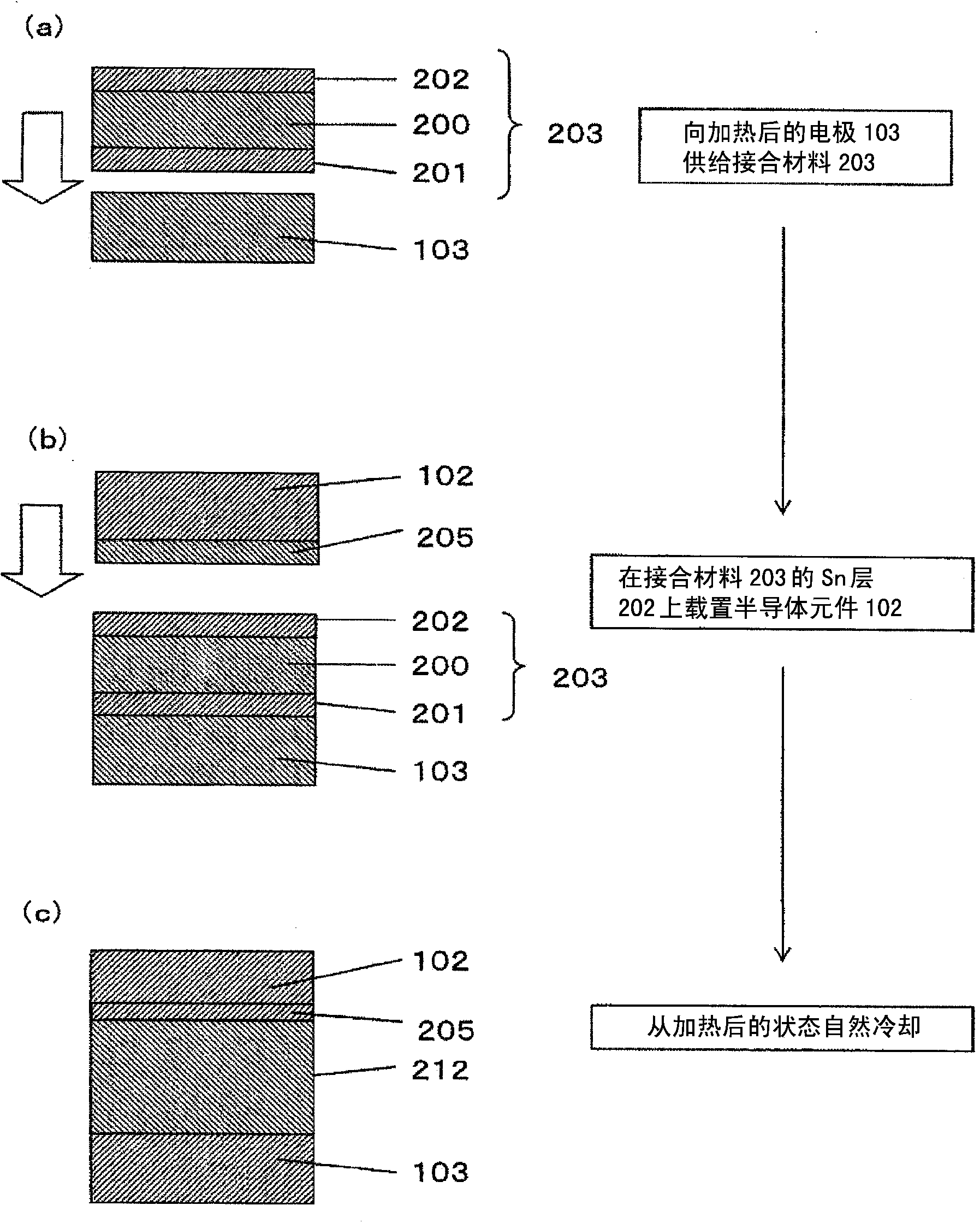

Junction structure

InactiveCN103493190APrevent peelingFull heat resistancePrinted circuit assemblingSemiconductor/solid-state device detailsIntermetallicMetal

A junction structure is provided with: an electrode of a substrate; an electrode of a semiconductor element; and a junction section that joins the electrode of the substrate, and the electrode of the semiconductor element. Starting from the electrode of the substrate and progressing toward the electrode of the semiconductor element, the following layers are placed in the following sequence in the junction section: a first intermetallic compound layer that contains a CuSn-based intermetallic compound; a Bi layer; a second intermetallic compound layer that contains a CuSn-based intermetallic compound; a Cu layer; and a third intermetallic compound layer that contains a CuSn-based intermetallic compound.

Owner:PANASONIC CORP

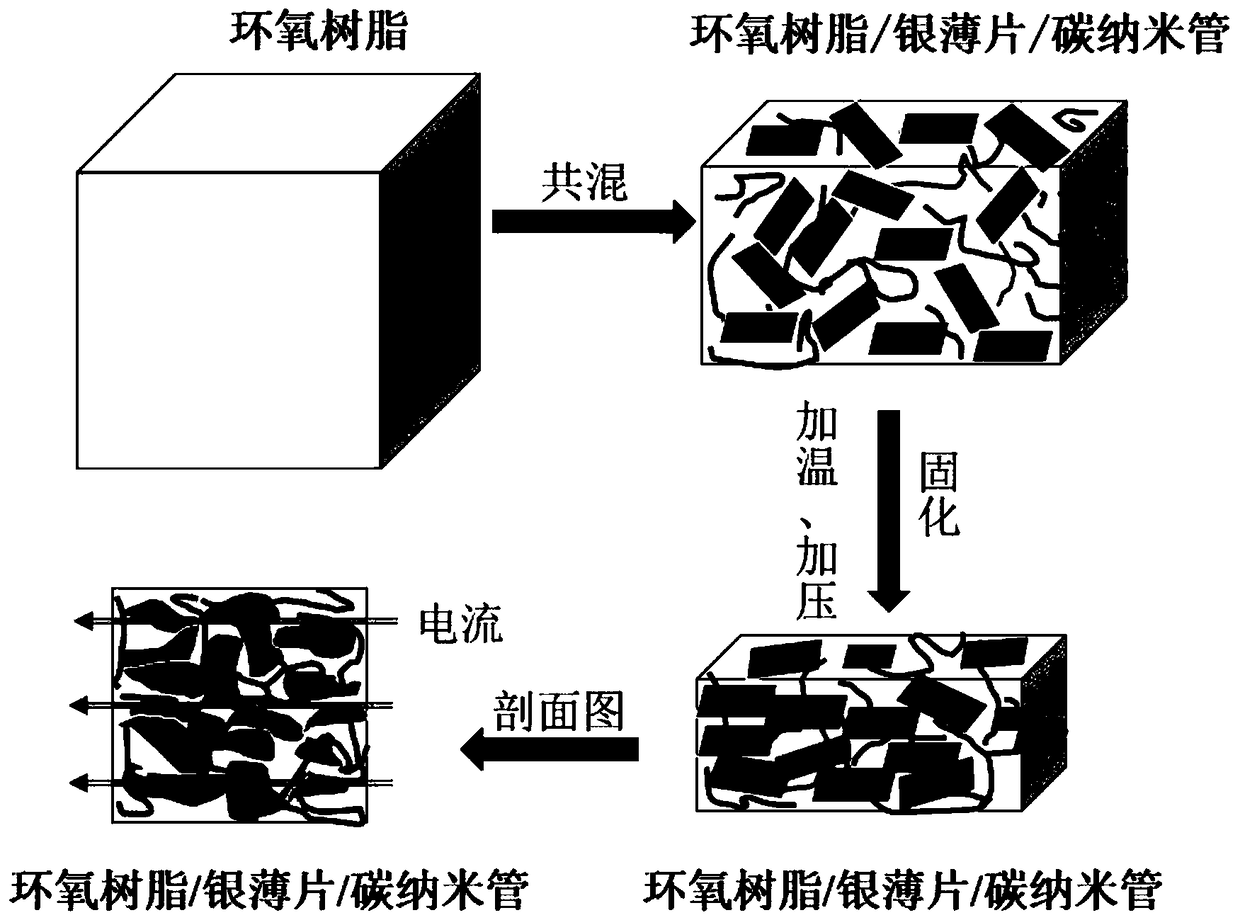

Lightning protection composite material surface film as well as preparation method and application thereof

The invention discloses a lightning protection composite material surface film as well as a preparation method and an application thereof and relates to a lightning protection composite material surface film for aerospace as well as a preparation method and an application thereof. The invention aims to solve problems in the previous aerospace composite material manufacture lightning protection method that the electromagnetic shielding property is poor, the process is complicated or weight gain is large and the like. Carbon nanomaterials and micron silver flakes are taken as conductive materials, a novel epoxy resin modified method is provided, and the heat resistance and toughness of the epoxy resin are improved. The lightning protection composite material surface film disclosed by the invention is composed of epoxy resins, micron silver flakes, carbon nanomaterials, a toughening modifier, a heat-resistant modifier, a curing agent, a UV stabilizer and a carrier. The preparation methodof the lightning protection surface film comprises the following steps: uniformly blending the raw materials, and forming the film by adopting a resin hot melting method. The lightning protection composite material surface film disclosed by the invention is capable of improving the surface quality of composite material structural members, and has the lightning protection function.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Blended rubber special protective fabric

InactiveCN104705871AConsider comfortConsider heat resistanceSynthetic resin layered productsRubber layered productsRubber materialCarbon fibers

The invention discloses blended rubber special protective fabric which is composed of a skeleton material and an attachment material. The skeleton material is a mixed material of aramid fibers and carbon fibers, and the attachment material is a rubber material in which nitrile rubber, chloroprene rubber and silicone rubber are used in a blended mode, and the attachment amount of the blended rubber material on the skeleton material is 100-180 g / m<2>. A compounding agent is added in the blended rubber material, and the compounding agent comprises magnesium oxide, zinc oxide, antimonous oxide, chlorinated paraffin, aluminium hydroxide, activated carbon, DBPO dibenzoyl peroxide, accelerant, an anti-aging agent and a swelling agent at a certain proportion. The above attachment material is subjected to the steps of mixing, rubberizing and vulcanization to achieve the preparation of the fabric. According to the blended rubber special protective fabric, inflaming retarding, gas defense and mechanical property are all considered, the fabric can be worn comfortably, the production process is simple, implementation is easy, the application range is wide, and the problems that same fabric in China is single in protective performance, poor in breathing smoothness and not capable of fully performing the synergistic effect of blending of multiple sorts of rubber are solved.

Owner:SHAANXI SCI TECH UNIV

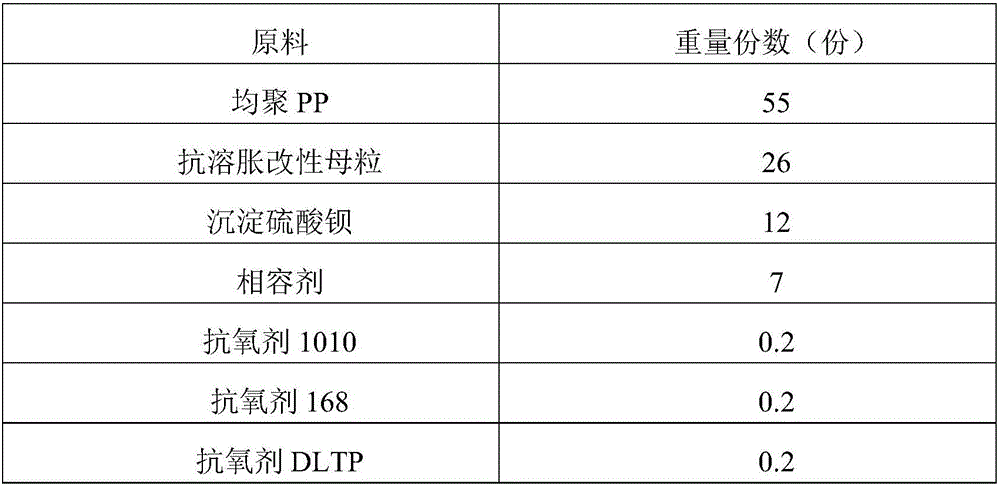

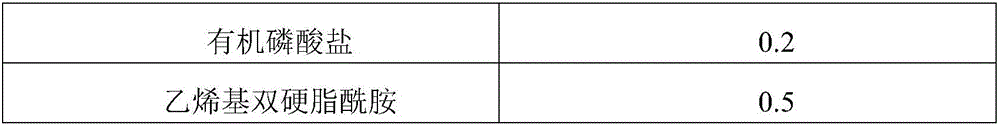

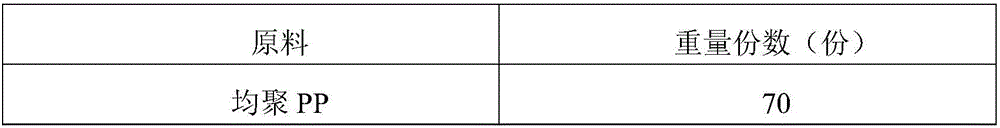

Edible oil high-temperature swelling-resistant modified polypropylene material applied to household appliances and preparation method thereof

InactiveCN106633397AChange the surface microstructureImprove surface crystallinityHigh resistanceProcedure Agents

The invention relates to the field of high-molecular materials and discloses an edible oil high-temperature swelling-resistant modified polypropylene material applied to household appliances. The modified polypropylene material comprises the following components in parts by weight: 50-70 parts of polypropylene resin, 15-30 parts of swelling-resistant modified masterbatch, 7-15 parts of inorganic filler, 3-8 parts of a compatilizer, 0.1-0.3 part of a nucleating agent, 0.1-1.0 part of an antioxidant and 0.1-1.0 part of a processing aid. The invention also discloses a preparation method of the edible oil high-temperature swelling-resistant modified polypropylene material applied to the household appliances. The method comprises the following steps: uniformly mixing the polypropylene resin, the swelling-resistant modified masterbatch and the compatilizer, then adding the nucleating agent, the antioxidant and the processing aid, then continuing to stir, then adding the inorganic filler, uniformly stirring, finally adding the mixed materials in an extruder for extruding and granulating to obtain the polypropylene material. The polypropylene material prepared by the invention has high resistance to edible oil high-temperature swelling, high gloss, good scratch resistance, good heat resistance and good rigid-tough balance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

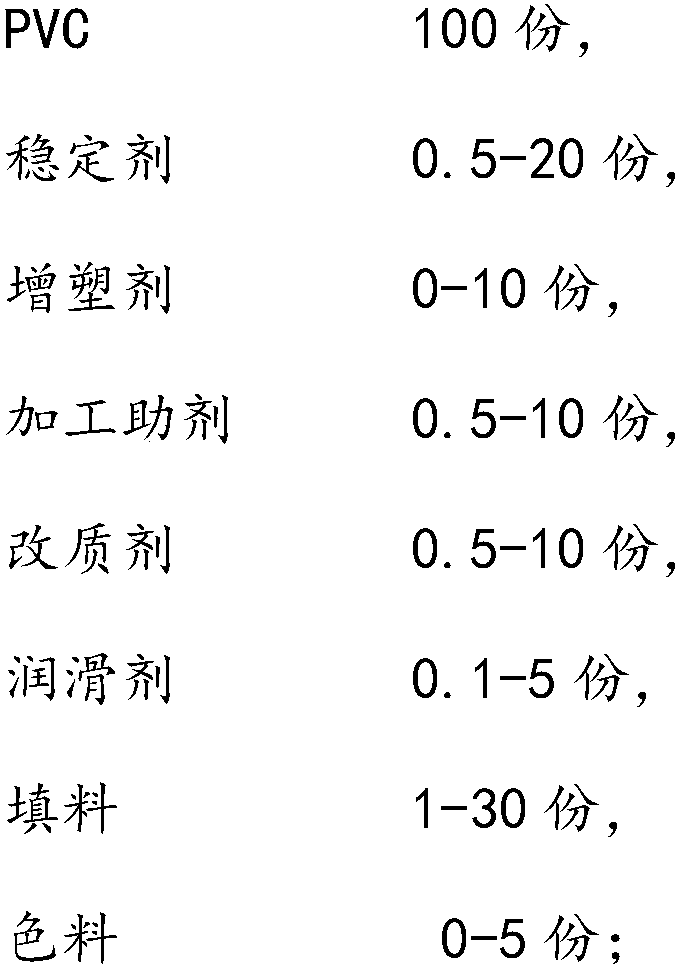

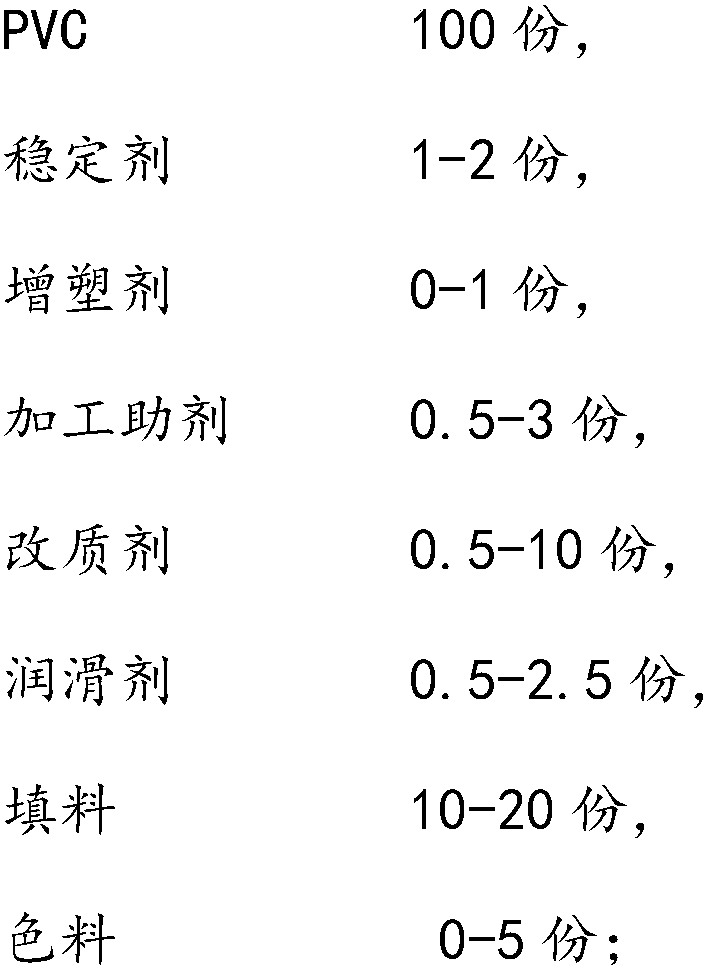

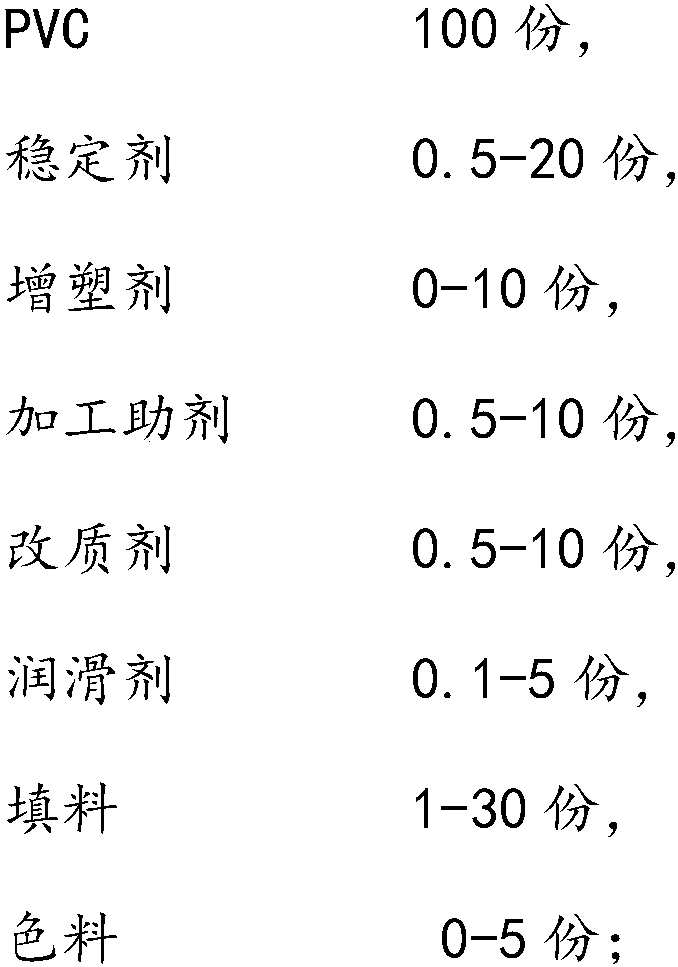

Hard PVC material composition, and preparation method and use thereof

The invention provides a hard PVC material composition, and a preparation method and a use thereof. The composition is prepared from, by mass, 100 parts of PVC, 0.5-20 parts of a stabilizer, 0-10 parts of a plasticizer, 0.5-10 parts of a processing aid, 0.5-10 parts of a modifier, 0.1-5 parts of a lubricant, 1-30 parts of a filler and 0-5 parts of a pigment, wherein a weight ratio of a new PVC material to a recovered PVC material in the PVC is (7-10):1. Compared with the prior art, the preparation method reduces the cost and increases the hardness through adding the recovered material into thePVC and optimizing the ratio of the new material to the recovered material.

Owner:无锡宏义高分子材料科技有限公司

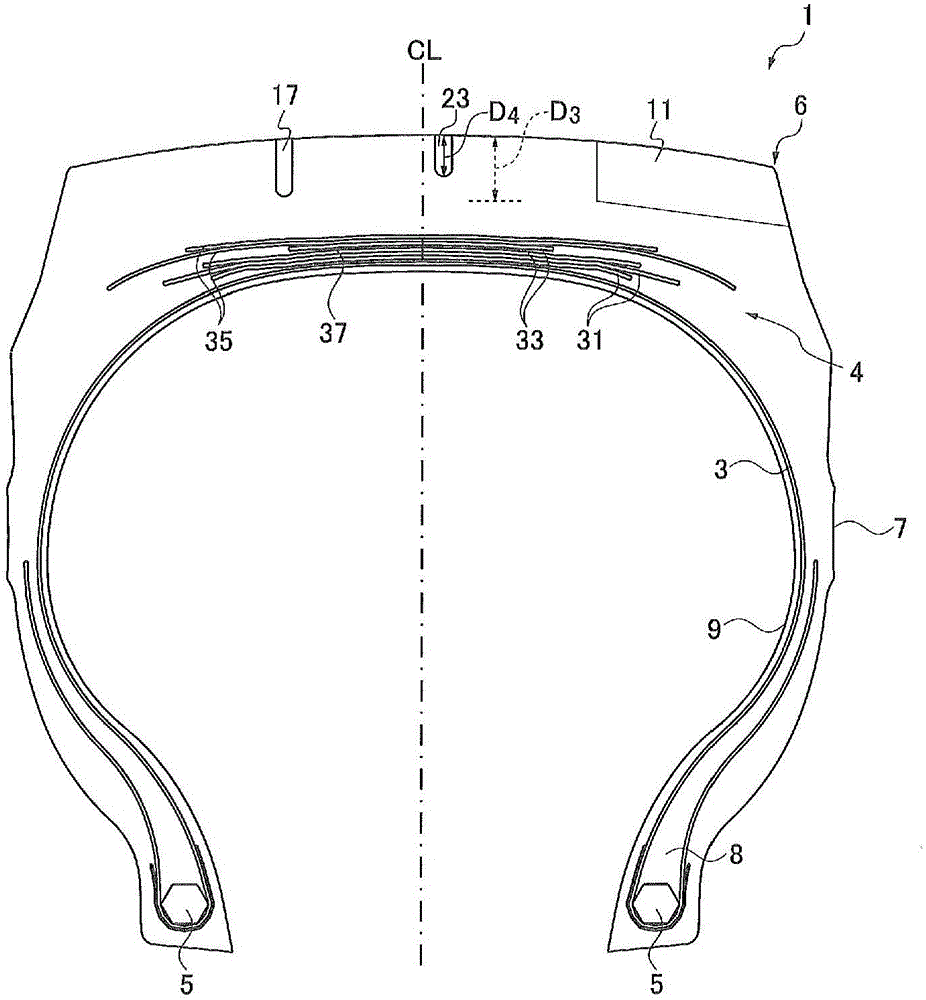

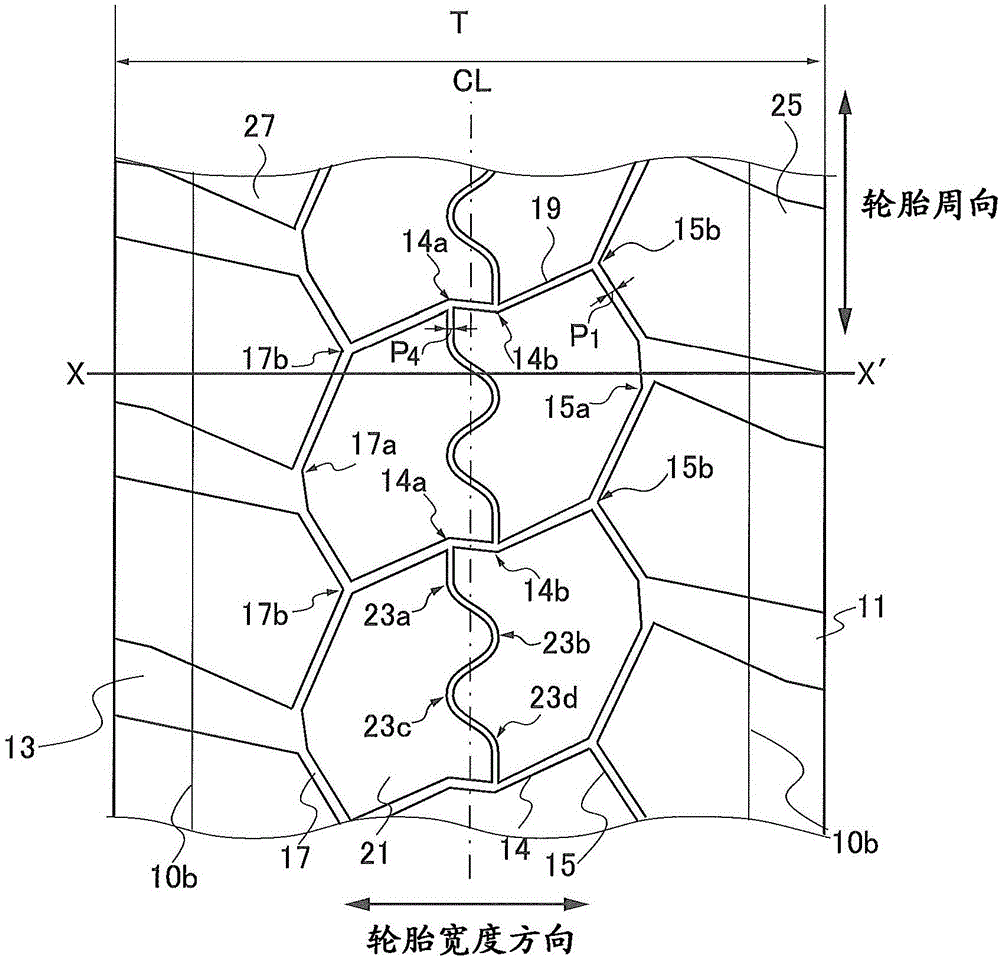

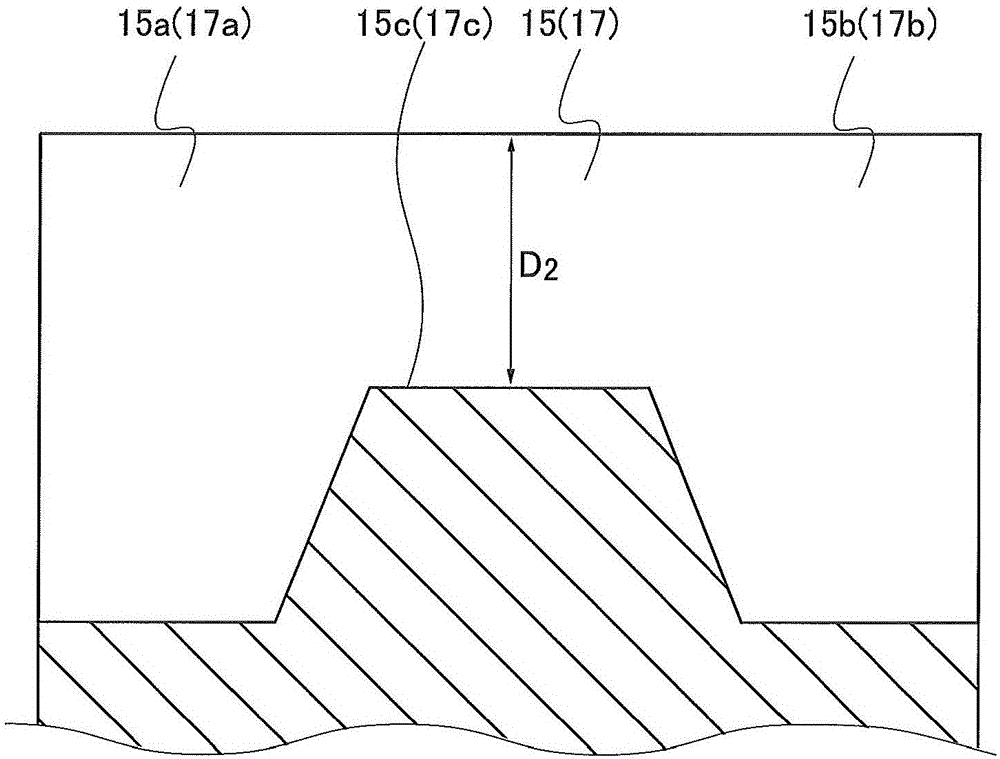

Heavy duty pneumatic tire

ActiveCN106536225AConsider heat resistanceHeavy duty tyresTyre tread bands/patternsGround contactHeat resistance

Provided is a heavy duty pneumatic tire having both stone trapping resistance and heat resistance. This heavy duty pneumatic tire is provided with a tread (6) having a tread pattern that includes: shoulder lug grooves (11, 13) extending outward in the width direction of the tire and open at ground contact ends; a pair of circumferential primary grooves (15, 17); center lug grooves (14); center blocks (21) defined by the center lug grooves and the pair of circumferential primary grooves and formed in a row extending in the circumferential direction of the tire; and circumferential secondary grooves (23) extending in the region of the center blocks in the circumferential direction of the tire and open to the center lug grooves adjoining the center blocks. The circumferential secondary grooves each have third groove bends (23a-23d) which extend in the circumferential direction of the tire while being displaced in the width direction of the tire and which are bent in an angled shape or a curved shape. If the width of the circumferential secondary grooves is P4 and the width of the circumferential primary grooves is P1, then the ratio P4 / P1 is in the range of 0.70 to 1.10.

Owner:THE YOKOHAMA RUBBER CO LTD

Preparation method of self-lubricating PAI (polyamide-imide) enameled wire paint

The invention relates to a preparation method of a self-lubricating PAI (polyamide-imide) enameled wire paint. The preparation method of the self-lubricating PAI enameled wire paint uses the characteristics of being excellent in high-and-low temperature performance and chemical stability, good in electrical insulating property, non-adhesive performance and weather resistance, incombustible and good inn lubricity of PTFE (polytetrafluroethylene) for modifying PAI so as to improve lubricity of the PAI. Simultaneously, a low viscosity PAI prepolymer solution is prepared, PTFE nanometer powder is dispersed in the low viscosity PAI prepolymer solution through a ball milling and sanding mode, dispersity of the PTFE nanometer powder is improved, and dispersion liquid obtained after above dispersion operation is finished is placed in a reactor to be heated for reaction so as to improve the molecular weight of the dispersion liquid. The dispersion liquid containing the PTFE powder is added in sold or universal PAI enameled wire paint to obtain a mixture, and then the self-lubricating PAI enameled wire paint is obtained. An enameled wire prepared from the self-lubricating PAI enameled wire paint has better lubricity than a common PAI enameled wire, and scratching problems of the enameled wire in the winding process of a high speed winding machine are solved.

Owner:TIANHENGDA ELECTRICAL ENG SCI & TECH CO LTD

A kind of preparation method of aryl boron-containing thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

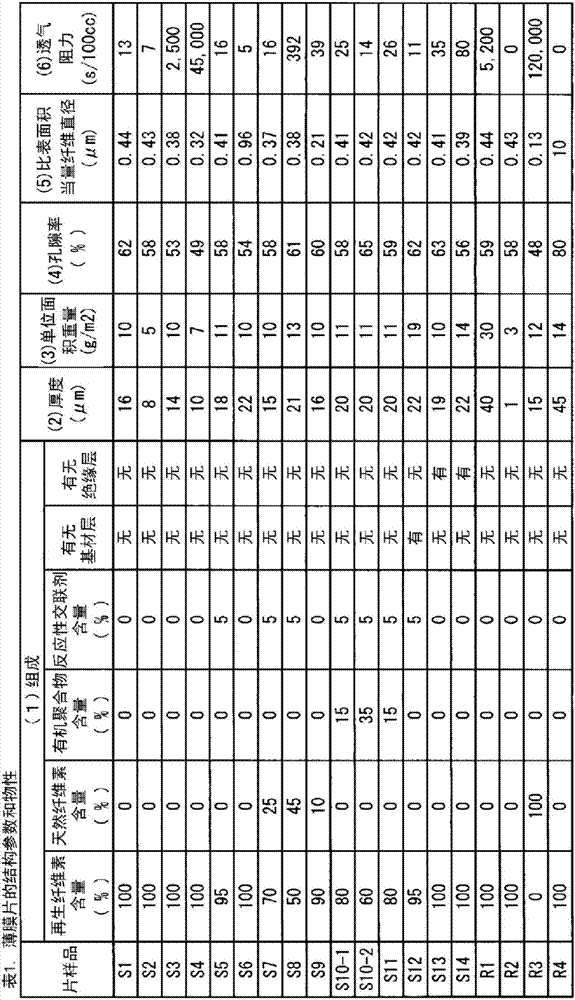

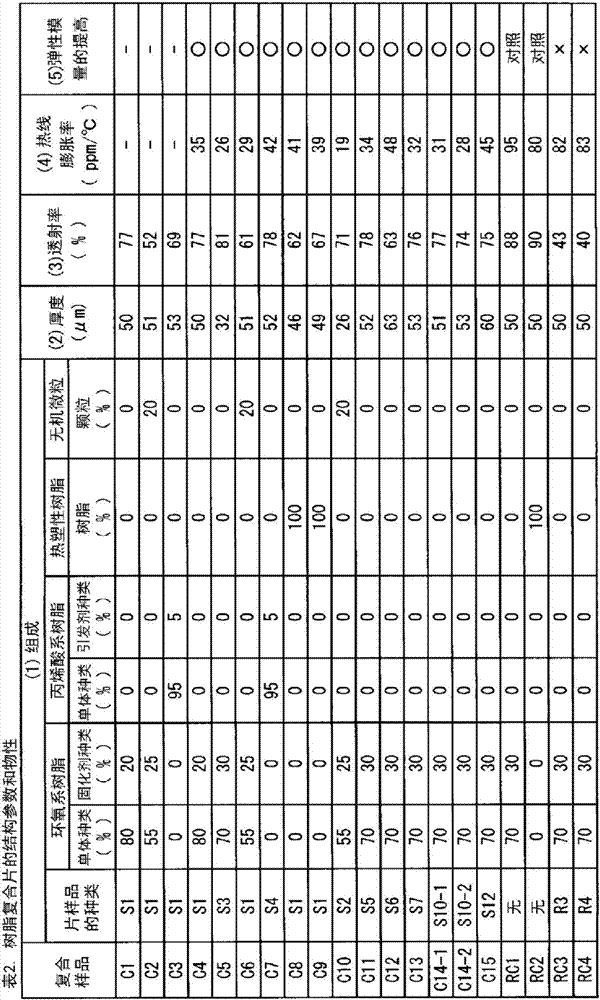

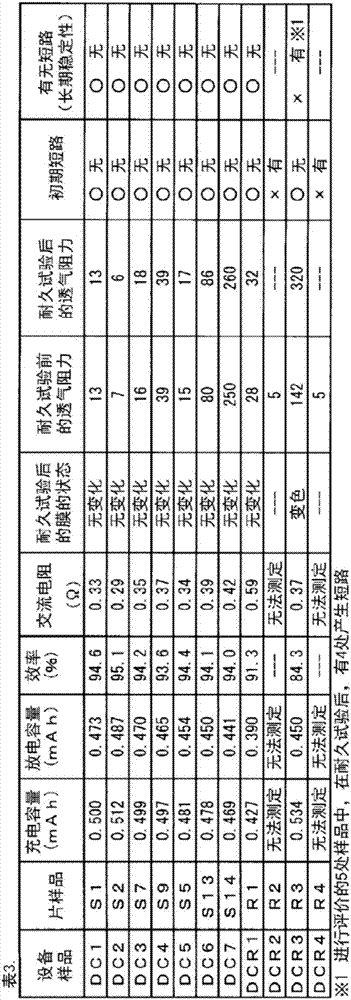

Thin-film sheet including cellulose fine-fiber layer

ActiveCN107075804AThin textureImprove uniformityHybrid capacitor separatorsElectrolytic capacitorsPolymer scienceMicrometer

The present invention provides a thin-film sheet configured from a single layer or a plurality of layers less than or equal to three layers including at least a cellulose fine-fiber layer that includes regenerated cellulose fine fibers by 50 wt% or more, wherein the thin-film sheet achieves improvements in both thermal stability (thermal coefficient of linear expansion and retention of elasticity at high temperature) and sheet strength, and is characterized in that the requirements: (1) the specific surface area equivalent fiber diameter of fibers constituting the cellulose fine-fiber layer is 0.20-2.0 micrometers inclusive; (2) the air impermeability is 1-100,000 s / 100 ml inclusive; and (3) the film thickness is 2-22 micrometers inclusive are satisfied. The present invention also provides a composite sheet, a composite prepreg sheet, a separator for power storage devices, etc., that include the thin-film sheet.

Owner:ASAHI KASEI KK

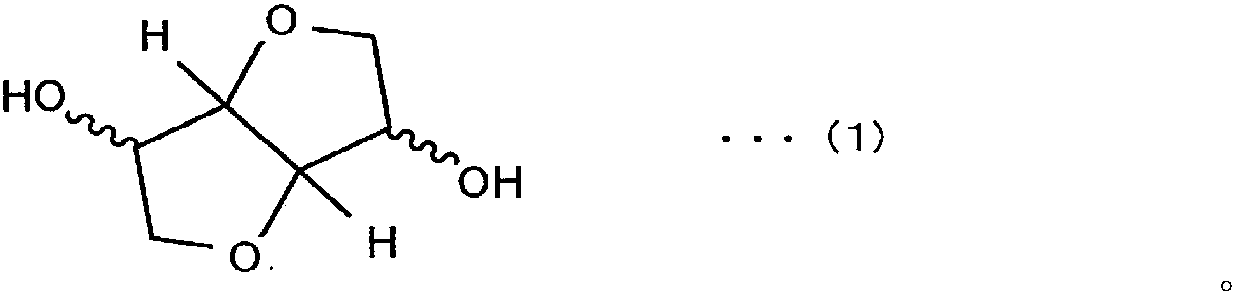

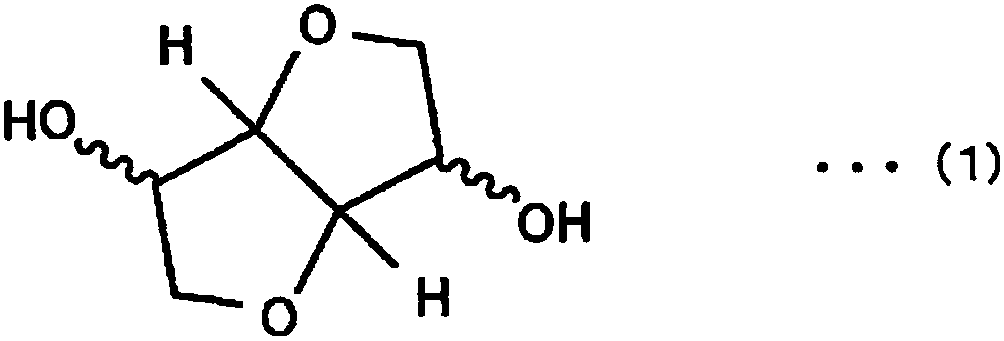

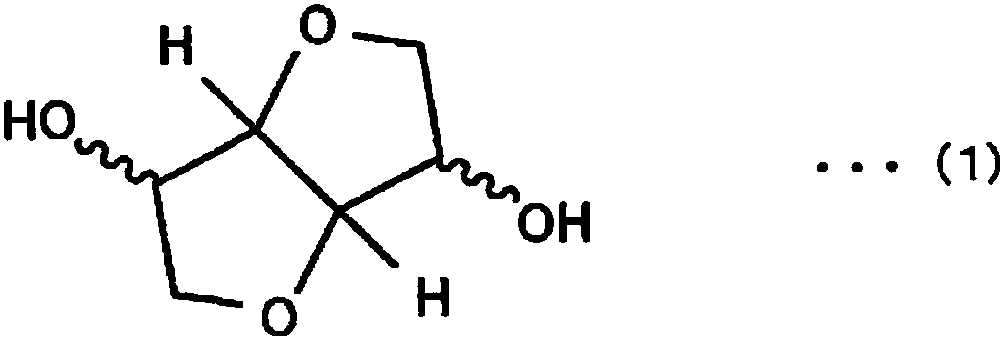

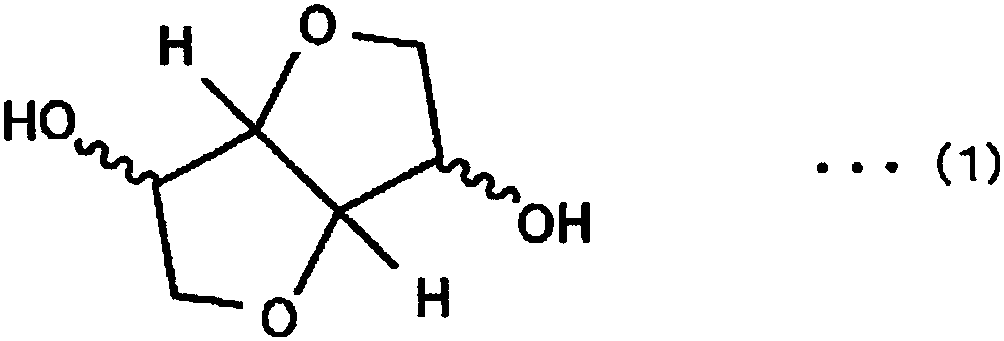

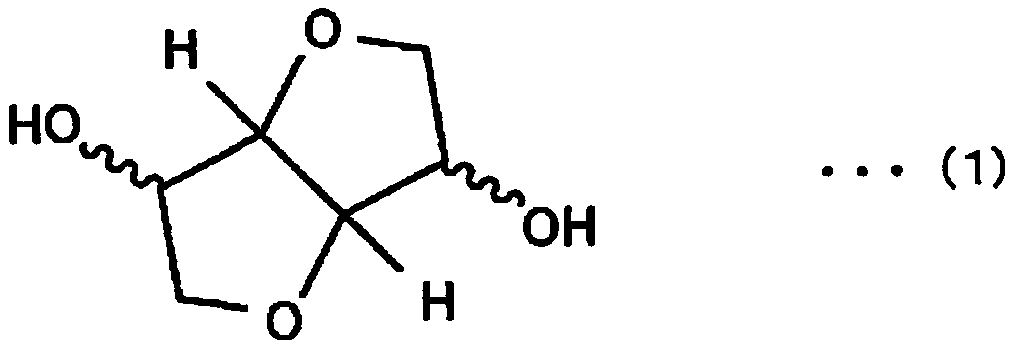

Polycarbonate resin composition, method for producing same, and molded object

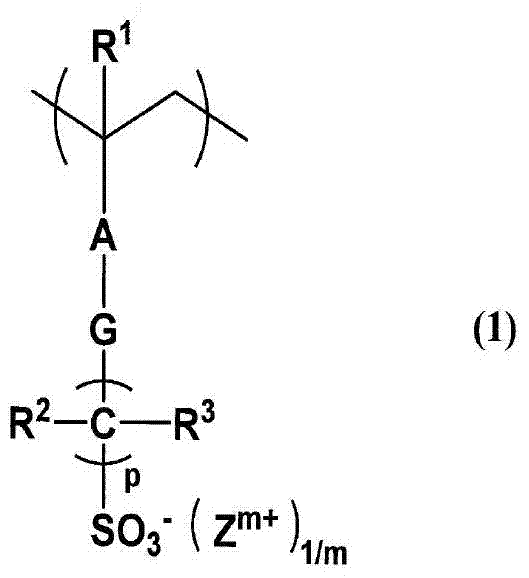

The purpose of the present invention is to provide: a polycarbonate resin composition having excellent transparency and having a high biogenic substance content rate and high levels of heat resistance, humid heat resistance, and impact resistance in a well-balanced manner; a method for producing the same; and a molded object of the polycarbonate resin composition. The present invention pertains to: a polycarbonate resin composition comprising a polycarbonate resin (A) including a constitutional unit derived from a compound represented by formula (1), and an aromatic polycarbonate resin (B); amethod for producing the same; and a molded object of the resin composition.

Owner:MITSUBISHI CHEM CORP

Polycarbonate resin composition and molded article of same

ActiveCN108603018AHigh transparencyTaking into account the substance contentPolymer sciencePolyrotaxane

The purpose of the present invention is to provide a polycarbonate resin composition that combines a high level of impact resistance with a good balance, a method for manufacturing the same, and a molded article of the polycarbonate resin composition. The present invention relates to: a polycarbonate resin composition containing a polycarbonate resin (A) including constituent units derived from acompound represented by formula (1), and a polyrotaxane (B); a method for manufacturing the same; and a molded article of the resin composition.

Owner:MITSUBISHI CHEM CORP

A kind of water-soluble ceramic core material and the method for preparing water-soluble ceramic core

ActiveCN105693254BConsider surface qualityTaking into account the dimensional accuracySolubilityDimensional precision

The invention belongs to the precision casting technique and relates to a water-soluble ceramic core material and a preparation method thereof. The water-soluble ceramic core material comprises a high-temperature ceramic material, water-soluble inorganic salts, metallic oxides and at least one amorphous ceramic material. The preparation method comprises the following steps: raw material pretreatment, raw material weighing, mixing, mold core forming, degreasing, sintering and secondary sintering. According to the water-soluble ceramic core material and the preparation method, the properties of surface quality, dimensional precision, foaming level, mechanical strength, heat resistance, water solubility, environment friendliness and the like of the mold core can be considered, and scientific research and production requirements of aluminum alloy are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Thermoplastic polyurethane and use thereof

Owner:FAR EASTERN NEW CENTURY COPRRATION

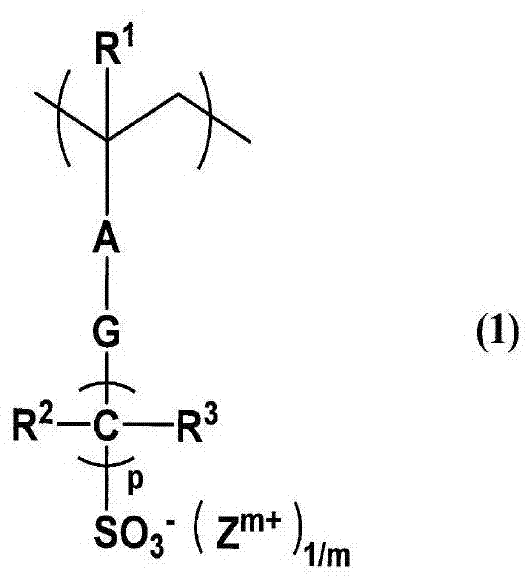

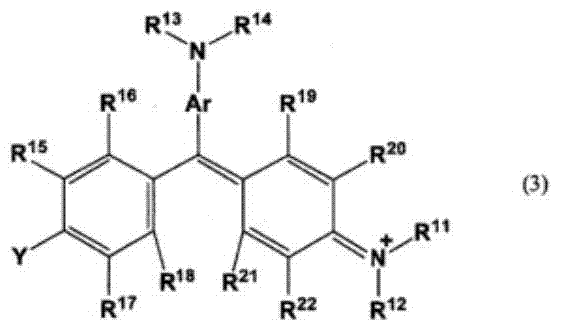

Colored composition, colored cured film, and display element

ActiveCN105246978BConsider heat resistanceAppropriate useMonoazo dyesMethine/polymethine dyesHydrogen atomHeat resistance

Provided is a colored composition suitable for the formation of a colored cured film having both heat resistance and solvent resistance. A colored composition comprising (A) a coloring agent and (B) a polymerizable compound, wherein the coloring agent contains a compound having a structural unit represented by formula (1). [In formula (1), R1 represents a hydrogen atom, a methyl group or a trifluoromethyl group, and R2 and R3 independently represent a hydrogen atom, a halo group or a substituted or unsubstituted hydrocarbon group, wherein R2 and / or R3 represents a halo group or a halo-group-substituted hydrocarbon group; A represents a bivalent group; G represents a bivalent hydrocarbon group or a single bond, wherein the bivalent hydrocarbon group may have a linking group selected from a -O- group, a -S- group, a -CO- group and a -NR7- group between a C-C bond; R7 represents a hydrogen atom or a substituted or unsubstituted hydrocarbon group; Zm+ represents a cationic chromophore; m represents a natural number of 1 to 3; and p represents a natural number of 1 to 8.]

Owner:JSR CORPORATIOON

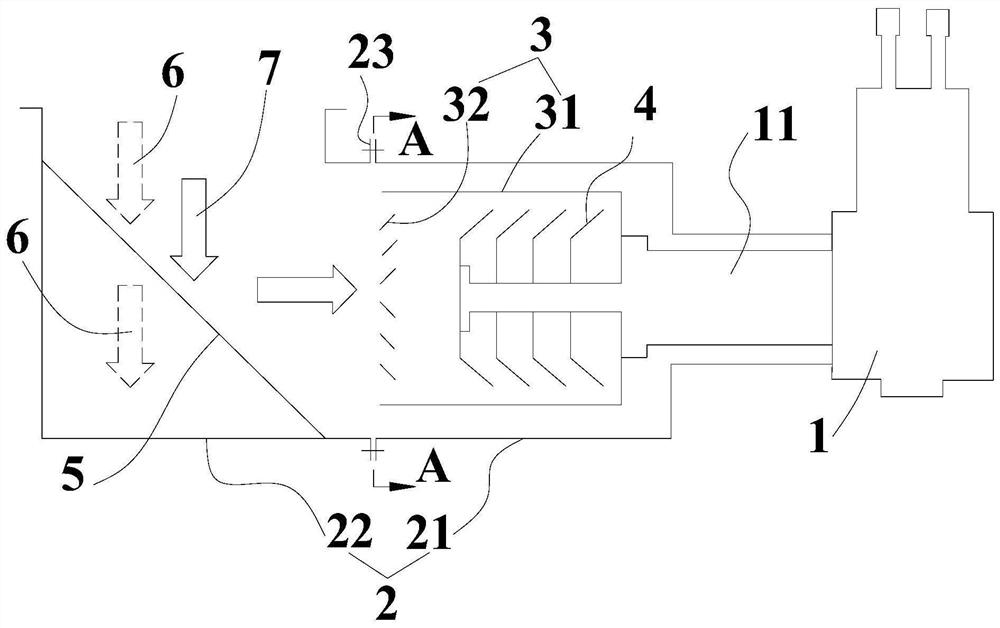

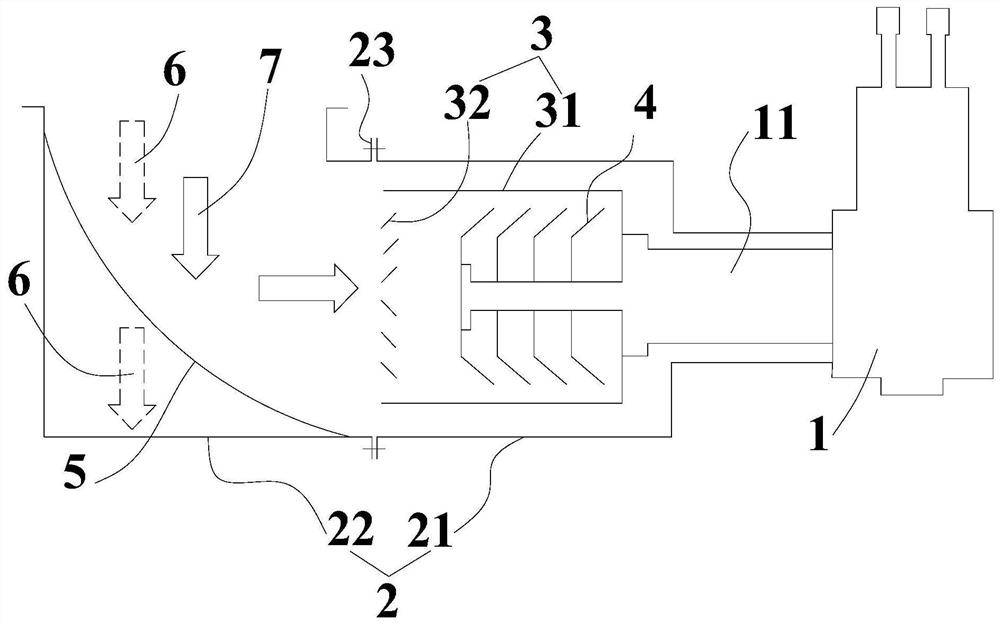

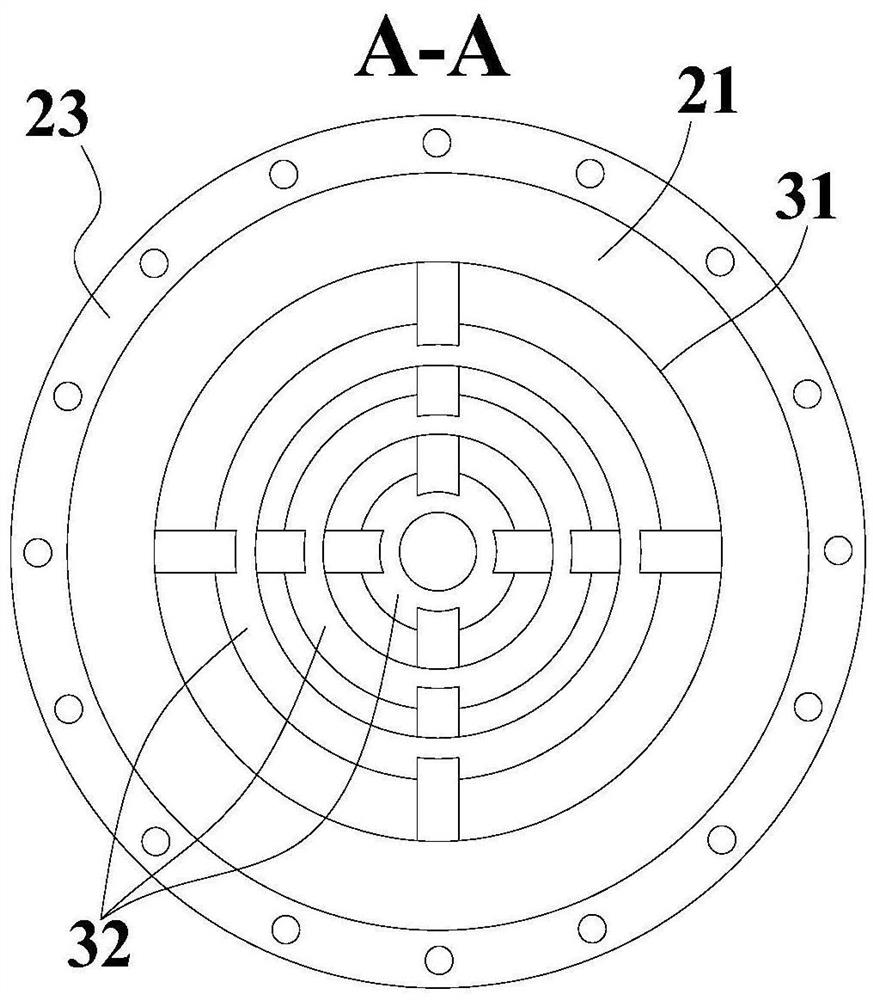

High Pumping Speed Cryopump Resistant to Thermal Radiation

ActiveCN112392687BAchieve the purpose of separationReduce receptionPositive displacement pump componentsPumpsEngineeringCold plate

The invention relates to the field of vacuum equipment, in particular to a heat-radiation-resistant high pumping speed cryogenic pump, which includes a refrigerator, a casing is installed on the refrigerator, and a cold head of the refrigerator is located in the casing; the cold head is provided with a first-stage Cold plate, secondary cold plate; the opening of the shell is provided with a front baffle, the heat radiation entering from the opening of the shell can pass through the front baffle and hit the shell to be reflected and absorbed, from the shell The gas entering through the opening of the body can be guided to the primary cold plate and the secondary cold plate by the front baffle. The advantage of the present invention is that: through the front baffle structure of this solution, the purpose of heat radiation and separation of gas molecules can be basically realized, thereby greatly reducing the heat radiation received by the cold plate of the cryopump, and because the gas movement channel is relatively smooth, Higher gas pumping speed can be achieved, so as to take into account the heat radiation resistance and high pumping speed.

Owner:VACREE TECH

Polycarbonate resin composition and molded article thereof

ActiveCN108603018BHigh transparencyTaking into account the substance contentPolymer sciencePolyrotaxane

An object of the present invention is to provide a polycarbonate resin composition, a method for producing the same, and a molded article of the polycarbonate resin composition that can balance impact resistance at a high level. The present invention relates to a polycarbonate resin composition containing a polycarbonate resin (A) and a polyrotaxane (B), a method for producing the same, and a molded article of the resin composition. The polycarbonate resin (A) Contains a structural unit derived from a compound represented by formula (1).

Owner:MITSUBISHI CHEM CORP

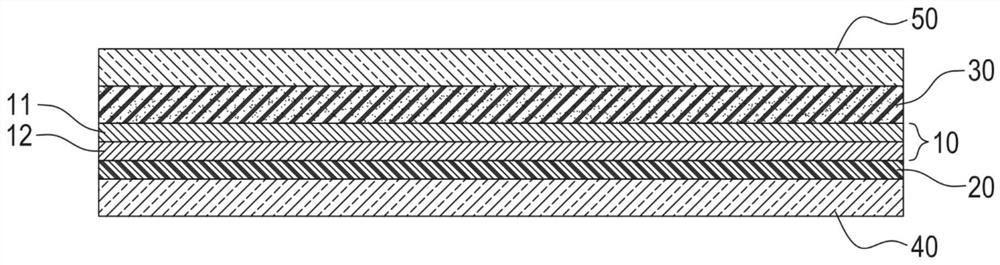

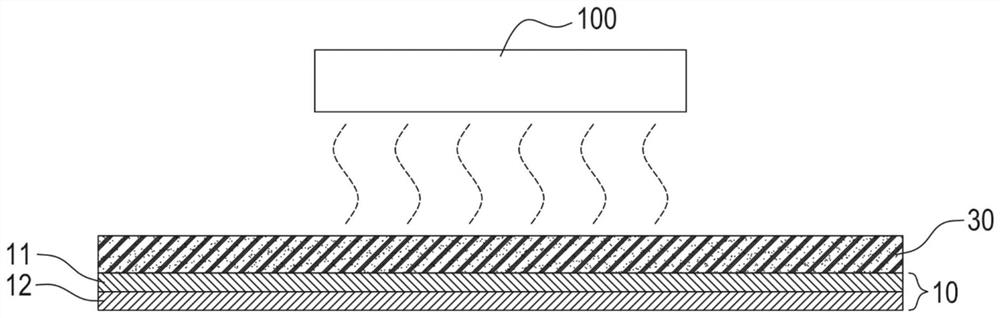

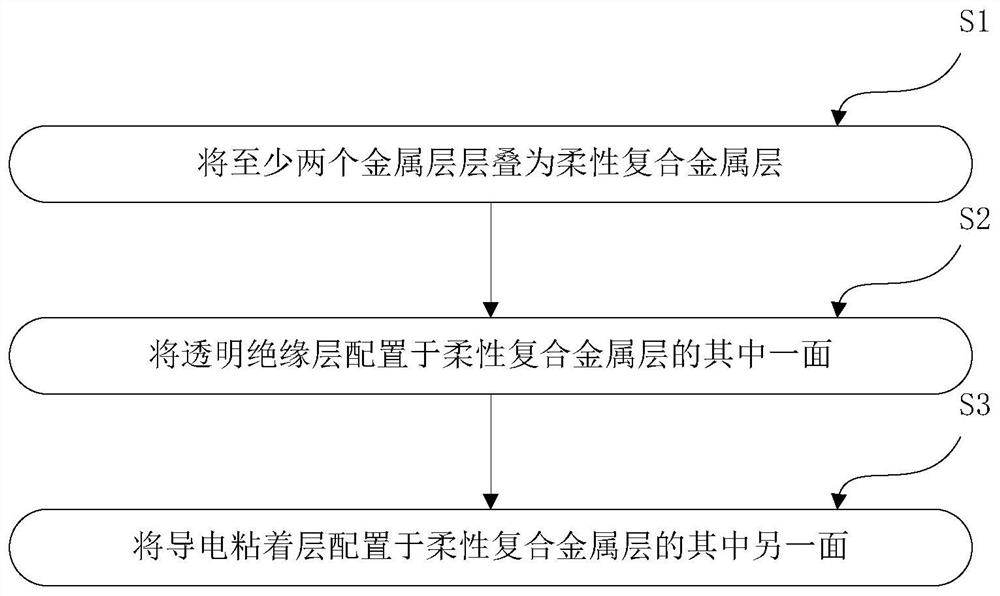

EMI shielding film and method of manufacturing the same

PendingCN113973488AAdhesion will not change significantlyNo need to worry about adhesive strengthMagnetic/electric field screeningFilm/foil adhesivesPolymer scienceThin membrane

An EMI shielding film includes a flexible composite metal layer, a transparent insulating layer, and a conductive adhesive layer. The conductive adhesive layer is formed by removing a solvent from a conductive adhesive composition. The conductive adhesive composition includes an acrylate solution, a divalent acid ester solution, a plurality of conductive particles, and the solvent. The present disclosure further includes a method of manufacturing the EMI shielding film.

Owner:NANOBIT TECH

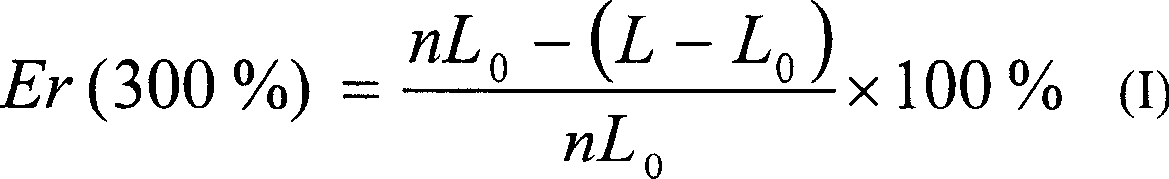

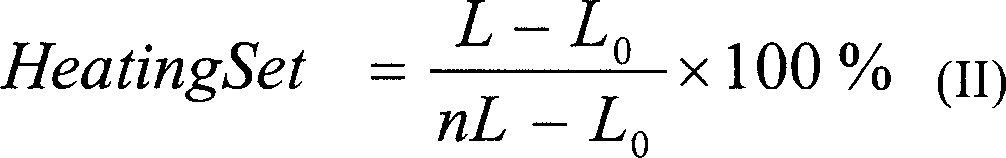

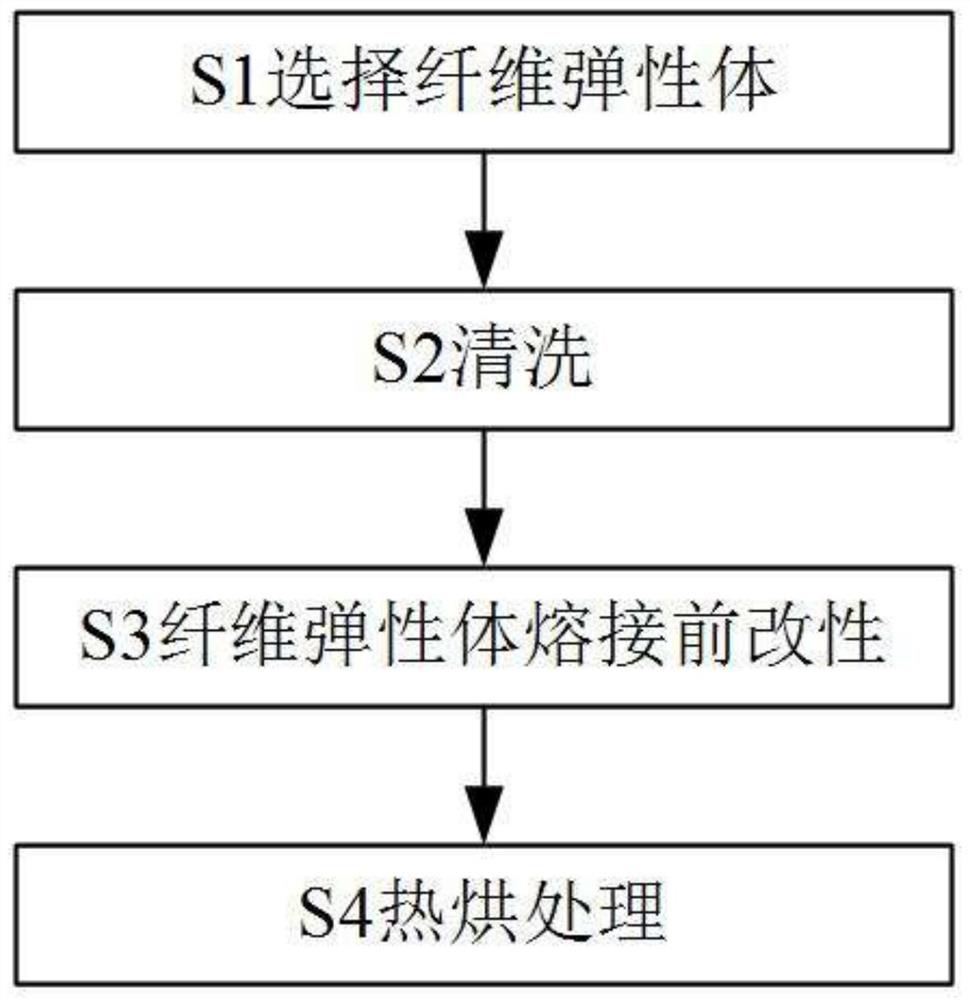

Secondary polymerization process of fiber elastic body

The invention discloses a fiber elastomer secondary polymerization process, which comprises the following steps: adopting a fiber elastomer layered by hot-melt fibers and elastic polyester fibers in a net; and performing penetrating deep cleaning on the fiber elastomer by spraying or soaking ; The fiber elastomer after deep cleaning is modified by spraying the modified solution, and the modified solution includes at least softener and chain extender; the sprayed fiber elastomer is heated by a hot air blower to obtain secondary polymerization Fiber Elastomer. The invention can improve the elasticity and softness of the fiber elastic body through the secondary polymerization process, meet the elastic recovery and softness requirements of cushions, mattresses and other cushion bodies, and has excellent fatigue resistance. By modifying the fiber elastomer before welding, it can take into account both heat setting and heat resistance, and the welding surface can be effectively protected, while the rigidity of the welding can be prevented, and the elasticity of the matrix will not be lost. The technological process is concise and ingenious, and is easy to implement and popularize.

Owner:海安腾昱智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com