Polycarbonate resin composition and molded article of same

A technology of polycarbonate resin and composition, which is applied in the field of polycarbonate resin composition, can solve unknown problems and achieve the effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0254] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to the following examples unless the gist is exceeded.

[0255] [Evaluation method]

[0256] Hereinafter, evaluation of the physical properties or characteristics of the polycarbonate resin (A), polyrotaxane (B) and the resin composition was performed by the following methods.

[0257] (1) Determination of elongation at break

[0258]Using STROGRAPH (model name VG10E) manufactured by Toyo Seiki Co., Ltd., the elongation at breaking point was measured at a tensile speed of 50 mm / min at a room temperature of 23°C. It should be noted that the larger the value of elongation at break, the better the mechanical strength, and in the present invention, it is judged that the value is 12% or more to be excellent in mechanical strength.

[0259] (2) Total light transmittance

[0260] The pellets of the polycarbonate resin composition were dried at 90°...

manufacture example 1

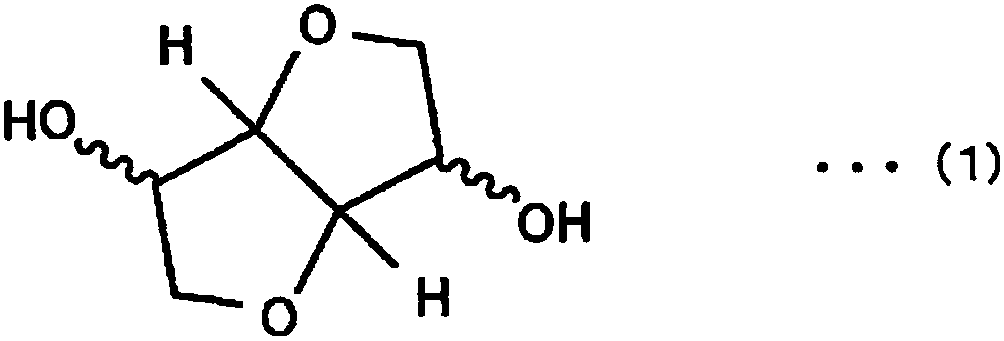

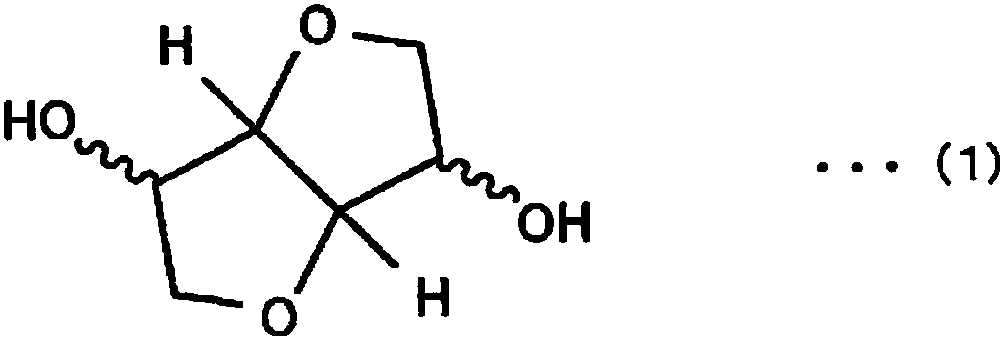

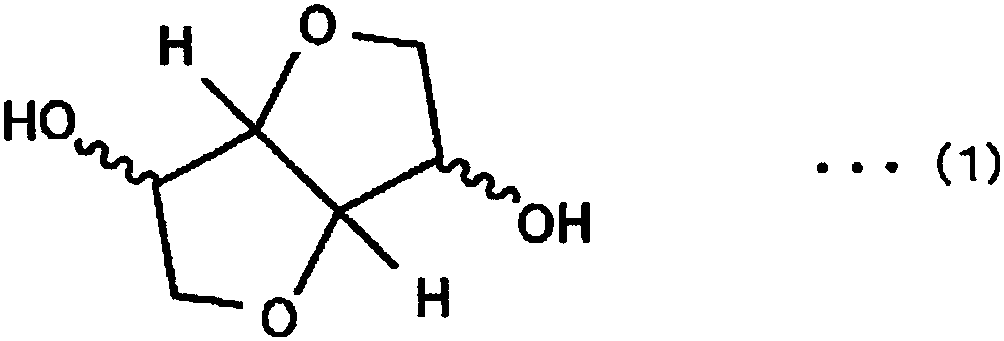

[0302] The polycarbonate resin was polymerized using a continuous polymerization equipment consisting of 3 vertical stirred reactors and 1 horizontal stirred reactor and a twin-screw extruder. Specifically, firstly, ISB, CHDM and DPC are melted in a tank respectively, and ISB is 35.2 kg / hr, CHDM is 14.9 kg / hr, and DPC is 74.5 kg / hr (by molar ratio, ISB / CHDM / DPC= 0.700 / 0.300 / 1.010) was continuously supplied to the first vertical stirring reactor. Simultaneously, an aqueous solution of calcium acetate monohydrate was supplied to the first vertical stirring reactor so that the amount of calcium acetate monohydrate added as a catalyst was 1.5 μmol relative to 1 mol of the total dihydroxy compound. The reaction temperature, internal pressure, and residence time of each reactor were set as the first vertical stirred reactor: 190°C, 25kPa, 90 minutes, the second vertical stirred reactor: 195°C, 10kPa, 45 minutes, and the third vertical stirred reactor. Type stirred reactor: 210°C, 3...

Embodiment 1

[0310] Using a torque rheometer (LABO PLASTOMILL) 4C150-01 manufactured by Toyo Seiki Co., Ltd., 47.5 g of the copolycarbonate resin obtained in Production Example 1 and 2.5 g of SeRM Super Polymer SH2400P as a polyrotaxane were carried out at 240° C. Mix for 10 minutes (refer to Table 1 for the mixing ratio).

[0311] After drying the obtained kneaded resin in a vacuum dryer at 90° C. for 5 hours, it was heated at 200° C. for 10 hours using a hot press made by Toyo Seiki Co., Ltd. (Mini Test Press (200×200 mm) model MP-2FH). Hot pressing was carried out within 1 minute to obtain a composite composite composition pressboard of copolycarbonate and polyrotaxane with a thickness of 0.5 mm. The total light transmittance of the obtained pressed board was evaluated, and the test piece for the tensile test was punched out, and the amount of stretch was evaluated by the tensile test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com