Secondary polymerization process of fiber elastic body

A technology of fiber elasticity and secondary polymerization, applied in the direction of fiber type, fiber treatment, improved hand feeling fiber, etc., can solve the problems of easy stiffness of fiber body, achieve simple and ingenious process flow, easy implementation and application, improve elasticity and The effect of softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention provides a secondary polymerization process of fiber elastic body. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

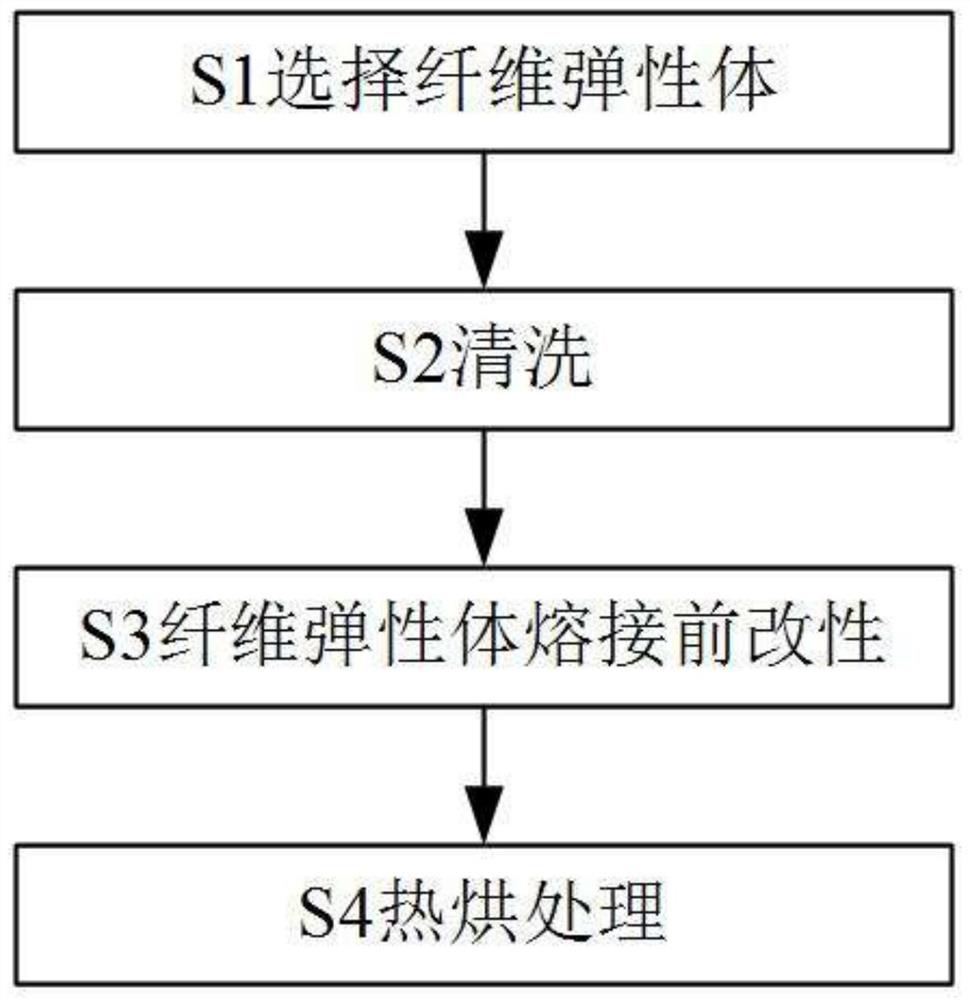

[0034] Fiber elastomer secondary polymerization process, such as figure 1 shown, including the following steps:

[0035] Choose a fiber elastomer,

[0036] A fibrous elastic body made of heat-melt fibers and elastic polyester fibers laminated in a net is used.

[0037] Among them, the melting point of the hot-melt fiber is less than or equal to 110°C, and the fiber elastic body adopts the process in CN104805600B, and the hot-melt fiber and the elastic polyester fiber are mixed with long and short fibers and then hot-melt formed.

[0038] The fiber elastic body obtained by this process is relatively fluffy and has a certain degree of elasticity, but it meets the high elastic recovery requirements of cushions and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com