Fireproof heat insulation coating and preparation method thereof

A heat-insulating coating and refractory fiber technology, applied in the field of coatings, can solve the problems of substrates and pipelines that are not suitable for different shapes, and achieve the effects of low density, easy operation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

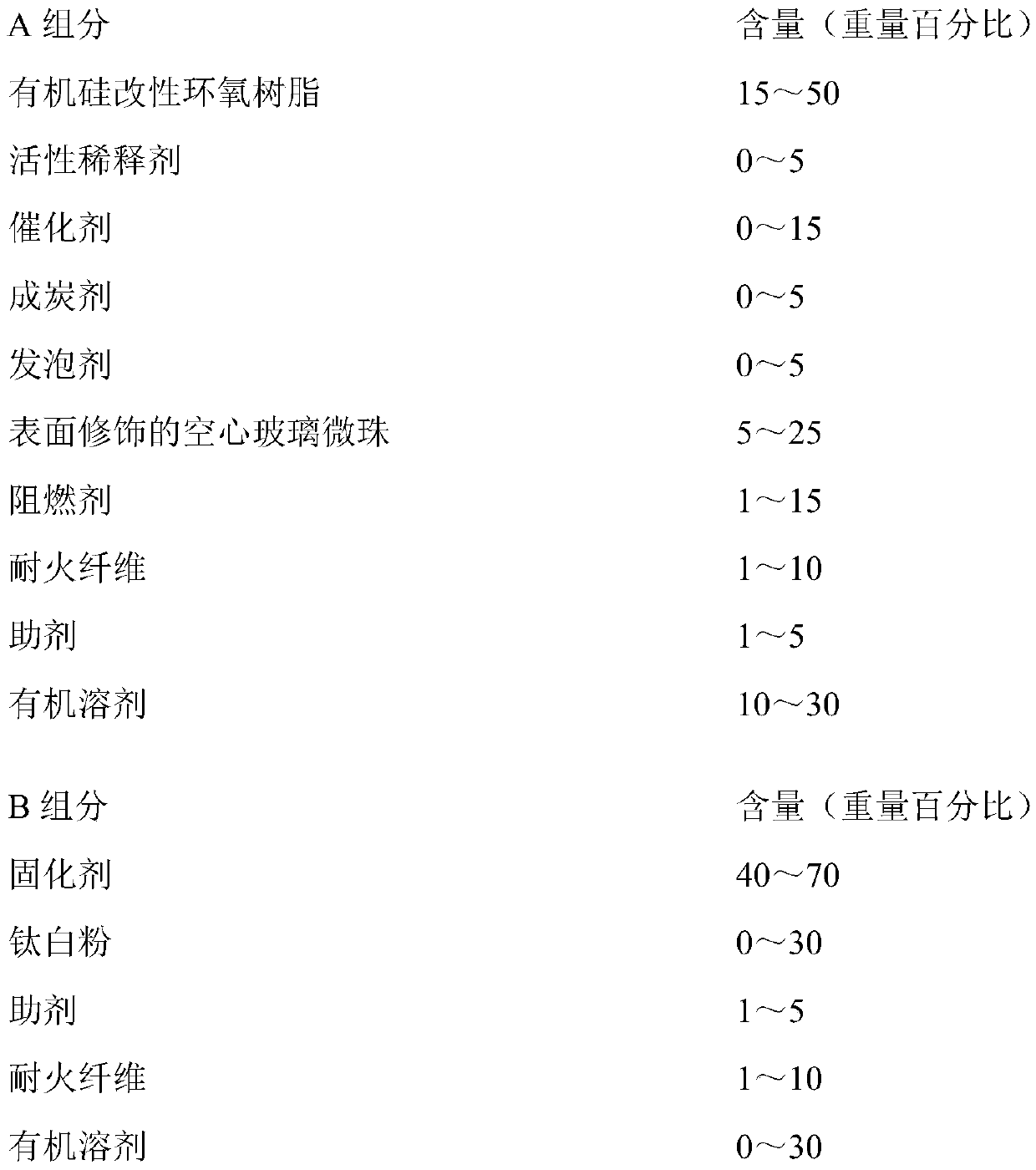

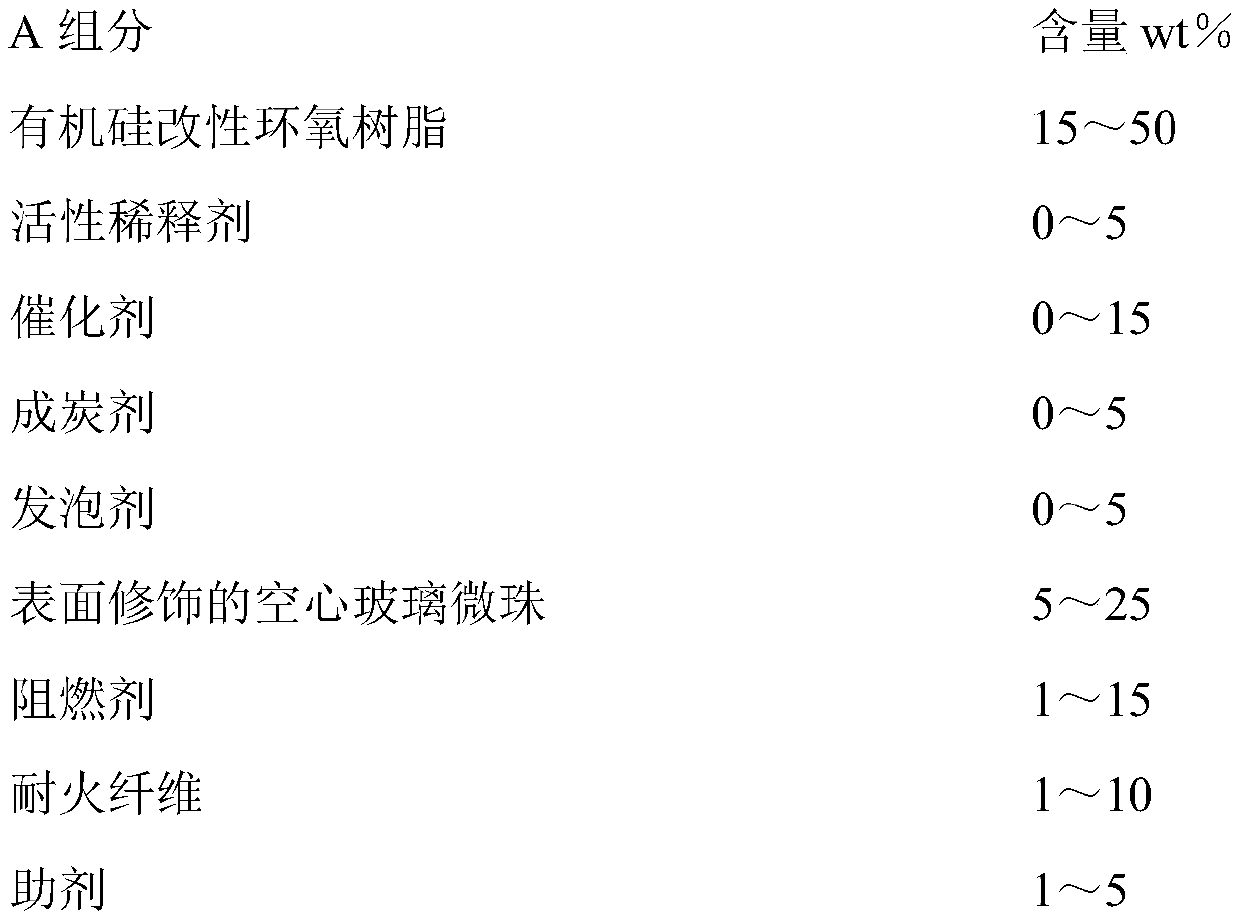

Method used

Image

Examples

Embodiment 1

[0039] Preparation method:

[0040] (1) Add 200g of E44 epoxy resin, 100g of hydroxyl-terminated polysiloxane, and 2g of KH560 into the reaction kettle under stirring, raise the temperature to 180°C, add 10g of dibutyltin dilaurate dropwise, and react for 2 hours. material to obtain silicone-modified epoxy resin.

[0041] (2) Preparation of surface-modified hollow glass microspheres: Wash 10 g of hollow microspheres three times with absolute ethanol, filter, place in a 5% ethanol solution of silane coupling agent KH560, stir at a low speed, and rotate at 100 ~200r / min, disperse for 3h and then filter.

[0042] (3) Preparation of component A: disperse the prepared 40g of silicone-modified epoxy resin and 5g of polyalcohol glycidyl ether in 14g of xylene under a high-speed mixer with a rotation speed of 600-700r / min, and after the dispersion is uniform, Add 6g of ammonium polyphosphate, 3g of melamine, 3g of pentaerythritol, and 5g of triethyl phosphate, and after dispersing e...

Embodiment 2

[0051] Preparation method:

[0052] (1) Add 100g of E51 epoxy resin, 10g of hydroxyl-terminated polysiloxane, and 5g of KH570 into the reaction kettle under stirring, raise the temperature to 200°C, add 1g of dibutyltin dilaurate dropwise, and react for 4 hours. material to obtain silicone-modified epoxy resin.

[0053] (2) Preparation of surface-modified hollow glass microspheres: 15 g of hollow microspheres were washed 3 times with absolute ethanol, filtered, placed in an ethanol solution of 5% silane coupling agent KH560, stirred at a low speed, and rotated at 100 ~200r / min, disperse for 3h and then filter.

[0054] (3) Preparation of component A: disperse the prepared 15g of silicone modified epoxy resin and 5g of n-butyl glycidyl ether in 20g of xylene under a high-speed mixer with a rotation speed of 600-700r / min, and wait for the dispersion to be uniform , add 9g of ammonium polyphosphate, 6g of melamine phosphate, 5g of melamine, 5g of pentaerythritol, and 5g of trii...

Embodiment 3

[0064] Preparation method:

[0065] (1) Add 100g of E51 epoxy resin, 10g of hydroxyl-terminated polysiloxane HPDMS, and 5g of KH560 into the reaction kettle under stirring, raise the temperature to 200°C, add 1g of dibutyltin dilaurate dropwise, and react for 4 hours. Discharging obtains modified epoxy resin.

[0066] (2) Preparation of surface-modified hollow glass microspheres: 15 g of hollow microspheres were washed 3 times with absolute ethanol, filtered, placed in an ethanol solution of 5% silane coupling agent KH560, stirred at a low speed, and rotated at 100 ~200r / min, disperse for 3h and then filter.

[0067] (3) Preparation of component A: Disperse 50g of the prepared silicone-modified epoxy resin in 23g of xylene under a high-speed mixer with a rotation speed of 600-700r / min. After the dispersion is uniform, add 2g of trimethylolpropane Triacrylate, 1g magnesium hydroxide, 2g ammonium octamolybdate, after uniform dispersion, use a three-roll mill to grind to a fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com