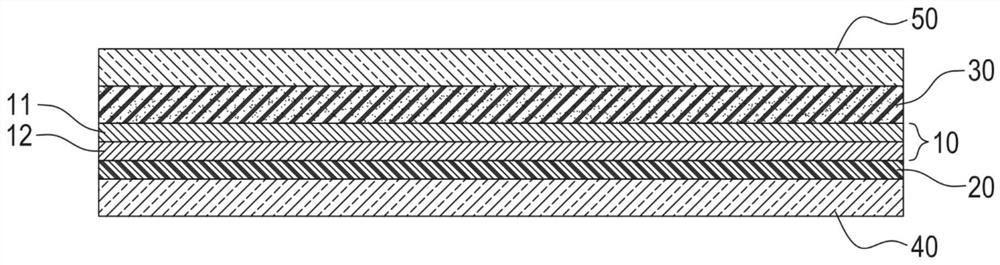

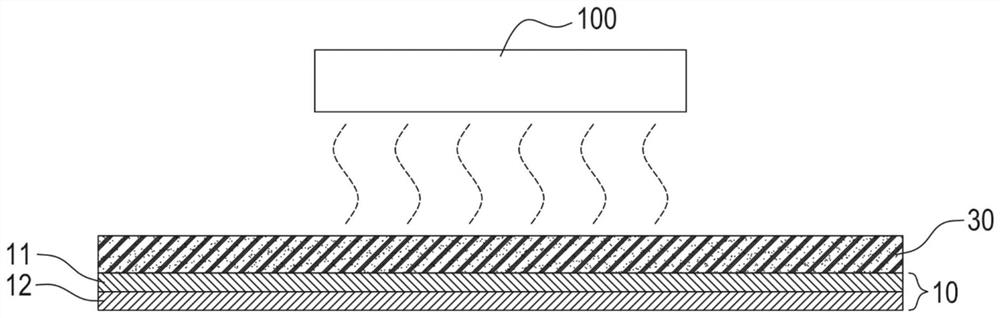

EMI shielding film and method of manufacturing the same

A technology of anti-electromagnetic interference and production method, which is applied in the direction of film/sheet adhesives, electrical components, conductive adhesives, etc., can solve the problems of electromagnetic wave shielding ability and thermal conductivity cannot be improved, and achieve flatness, Both flexibility and bending resistance, heat resistance, and adhesive strength are combined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

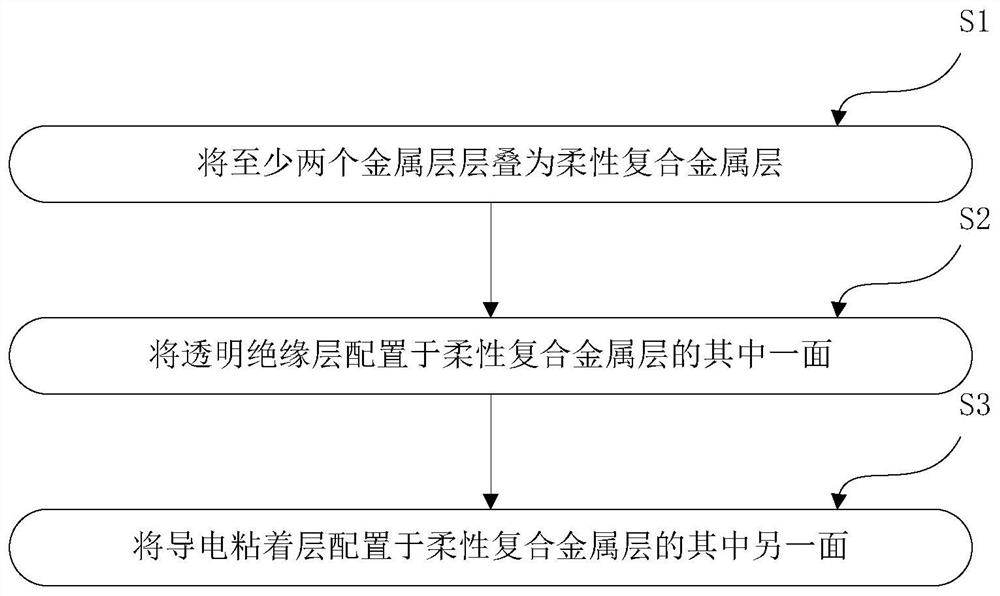

Method used

Image

Examples

Embodiment 1

[0060] Prepare the acrylate solution first, mix 12.5 grams of polyalkylacrylate compound and 22.5 grams of ethyl acetate (EAC) at room temperature, use a 300 ml three-port glass reactor, and stir evenly with a stirrer with 2 impellers. After stirring for two hours, add 35.0 grams of dibasic acid ester solution, 25 g of solvent (toluene), 3 grams of nickel particle powder (more than 50% of the particle size is 5-10 μm), and 2 parts by weight of dispersant , PEDOT:PSS with a concentration of 1 to 2.5% and 0.5 grams, kept stirring at room temperature for eight hours and then allowed to stand for one hour, and then added EAC or toluene as needed to adjust the viscosity to control the viscosity of the conductive adhesive composition at 30cps~ 50cps. The ingredients are shown in Table 1. After production, the resin composition is coated on the flexible composite metal layer at room temperature by Die Coater mold coating method. After coating, the surface is dried by heating. The he...

Embodiment 2

[0062] Resin composition 2 was prepared in the same manner as in Example 1, except that the amount of polyalkylacrylate compound in the acrylate solution was adjusted to 10 g and the weight of EAC to 25 g, as shown in Table 1.

Embodiment 3

[0064]Resin composition 3 was prepared in the same manner as in Example 1, except that the amount of polyalkylacrylate compound in the acrylate solution was adjusted to 14 grams and the weight of EAC to 21 grams, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com