Colored composition, colored cured film, and display element

A coloring composition, colorant technology, applied in optical components, chemical instruments and methods, naphthalene dicarboxamide dyes/phthalimide dyes, etc., can solve problems such as heat resistance or solvent resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0321] Hereinafter, an Example is given and the embodiment of this invention is demonstrated more concretely. However, the present invention is not limited to the following examples.

[0322]

Synthetic example 1

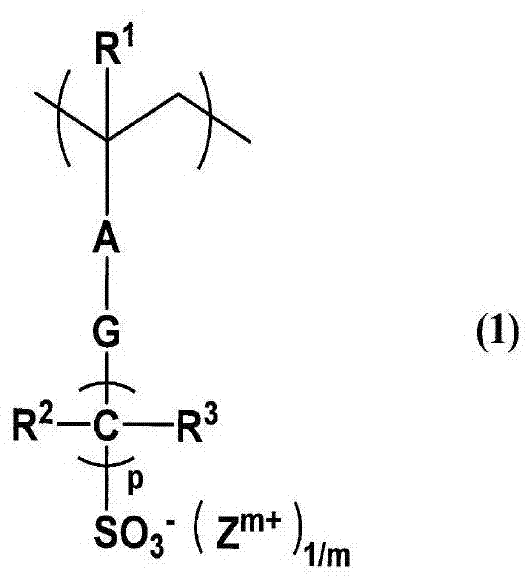

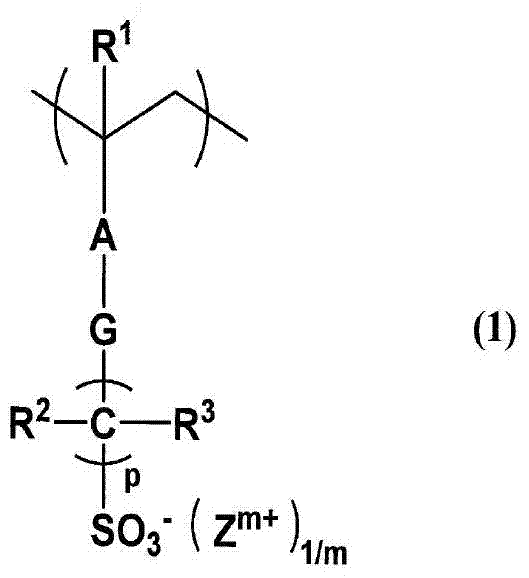

[0324] [Synthesis of Monomer (1)]

[0325] Monomer (1) was synthesized using the following procedure according to the following scheme.

[0326]

[0327] Install a stirrer, a thermometer, a dropping funnel, and a reflux cooling tube in a 300mL four-necked flask with a stirrer, put 100g of water, 14g of sodium dithionite (0.080 mol), and 12.1g of triethylamine (0.12 mol) . Thereafter, a solution obtained by dissolving 9.56 g (0.040 mol) of 5-bromo-4,4,5,5-tetrafluoropentan-1-ol in 80 g of acetonitrile was added dropwise from the dropping funnel over 15 minutes while stirring. . Thereafter, it was heated in an oil bath and reacted at an internal temperature of 60° C. for 5 hours under a nitrogen stream. After the reaction was completed, it was cooled to 25° C., and after standing for 15 minutes, the reaction liquid separated into two layers. The organic layer was separated, and 100 g of acetonitrile was further added to the water layer. The organic layer was separated, co...

Synthetic example 2

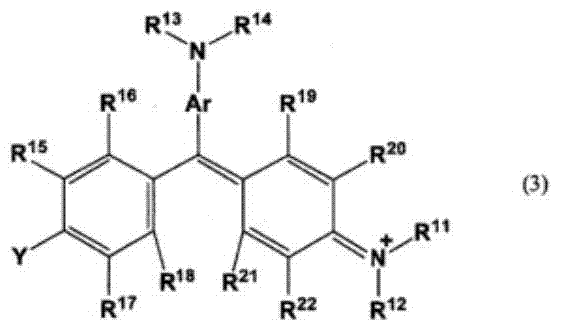

[0338] [Synthesis of Monomer (2)]

[0339] According to the following scheme, the monomer (2) was synthesized by the following procedure.

[0340]

[0341] A thermometer and a dropping funnel were attached to a 300 mL three-necked flask with a stirring bar, and 23.0 g of methacryloyl chloride (0.220 mol) and 160 mL of methylene chloride were added and uniformly dissolved in a nitrogen atmosphere. This solution was cooled to 0° C., 30.4 g (0.300 mol) of triethylamine was added, and the mixture was further stirred. Next, after adding 34.4 g (0.200 mol) of 2-iodoethanol dropwise over 30 minutes, the reaction solution was heated up to room temperature and stirred for 2 hours. Thereafter, the reaction solution was poured into 300 mL of saturated ammonium chloride aqueous solution, the organic layer was separated, and the aqueous layer was extracted twice with 200 mL of dichloromethane. It was combined with the organic layer, washed sequentially with 500 g of saturated aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com