Thermoplastic polyurethane and use thereof

A technology of thermoplastic polyurethane and polyurethane, which is applied in the field of thermoplastic polyurethane, can solve the problems of hard polyurethane film, inability to balance moisture permeability and water pressure resistance, reduce elasticity and softness, etc., and achieve the effect of both heat resistance and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] thermoplastic polyurethane 1

[0041] The formulation of Polyurethane 1 is as follows:

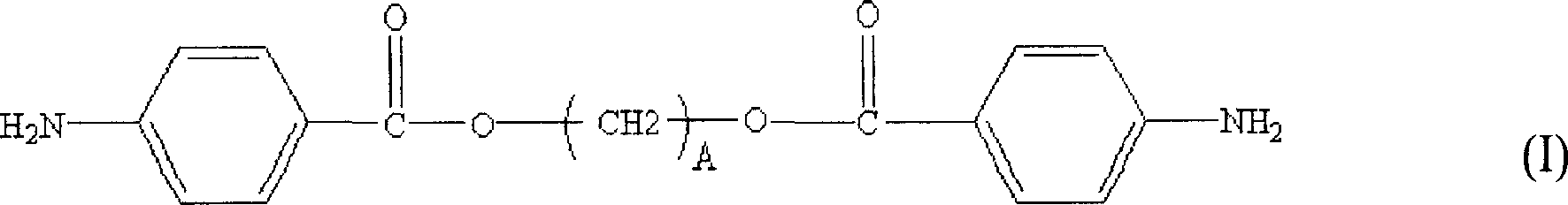

[0042] EO / PO copolymer (A) accounts for 43.3wt% of total raw material; MDI (purchased from Nipponpolyurethane) accounts for 27.5wt% of total raw material; PTMO (purchased from Formosa Plastics Asahi Company, molecular weight is 1000) accounts for 20.1wt% of total raw material 1,4-BG (purchased from BASF company) accounts for 7.0wt% of total raw material; Aromatic diamine accounts for 0.37wt% of total raw material, and all the other are catalyst (T-12) as shown in table 1; Antioxidant ( 1010), anti-ultraviolet agent (Q-287) and anti-sticking agent (PSFLOW 7501) and other auxiliary materials.

[0043] The preparation steps of polyurethane 1 are as follows:

[0044] (a) Melt the required amount of EO / PO, MDI, PTMO, and 1,4-BG according to the above formula and pump them into the working tank; (refer to the feed rate shown in Table 1)

[0045] (b) Stir the EO / PO copolymer, MDI, PTMO...

Embodiment 2

[0048] thermoplastic polyurethane 2

[0049] The formulation of Polyurethane 2 is as follows:

[0050] EO / PO(A) accounts for 52.7wt% of the total raw materials; MDI accounts for 26.2wt% of the total raw materials; PTMO accounts for 12.5wt% of the total raw materials; 1,4-BG accounts for 7.0wt% of the total raw materials; 0.37wt% of the raw material, and the rest are auxiliary materials such as catalyst, antioxidant, antiultraviolet agent and antisticking agent.

[0051] The preparation steps of polyurethane 2 are as follows:

[0052] The polyurethane 2 of the present invention was prepared by the same steps as in Example 1 with the raw materials of the above formula.

[0053] The results of various physical property tests of the polyurethane 2 prepared in this example are as follows: the melting point is 165° C.; the melting point index (at 210° C.) MI=26.

Embodiment 3

[0054] thermoplastic polyurethane 3

[0055] The formula of polyurethane 3 is as follows:

[0056] EO / PO(A) accounts for 52.2wt% of the total raw materials; MDI accounts for 25.9wt% of the total raw materials; PTMO accounts for 12.3wt% of the total raw materials; 1,4-BG accounts for 7.0wt% of the total raw materials; 0.37wt% of the raw material, and the rest are auxiliary materials such as catalyst, antioxidant, anti-ultraviolet agent and anti-sticking agent. In this embodiment, another anti-sticking agent EBS is further added.

[0057] The preparation steps of polyurethane 3 are as follows:

[0058] The polyurethane 3 of the present invention was prepared by the same steps as in Example 1 with the raw materials of the above formula.

[0059] The results of various physical property tests of the polyurethane 3 prepared in this example are as follows: melting point is 170° C.; melting point index (at 210° C.) MI=40; number average molecular weight Mn=138,000; weight average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com