Resin prepreg constitutive rubber solution and heat dissipation rubber piece and manufacturing method thereof

A technology of prepreg and manufacturing method, which is applied in cooling/ventilation/heating transformation, circuit substrate materials, printed circuit components, etc. Effects of Resin Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

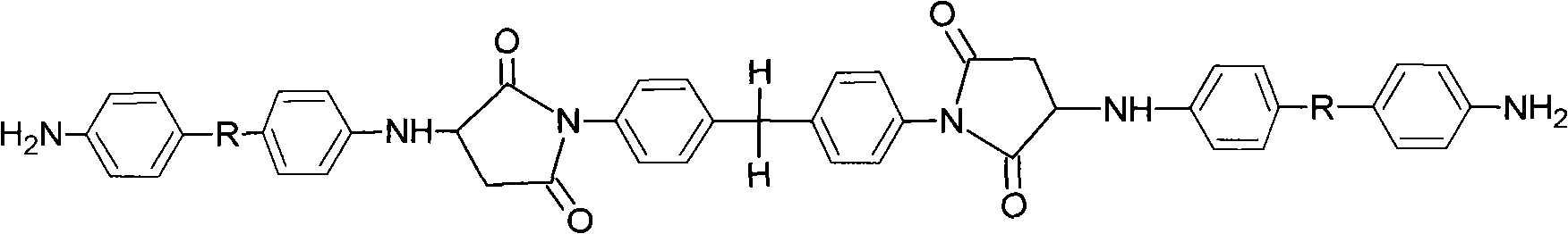

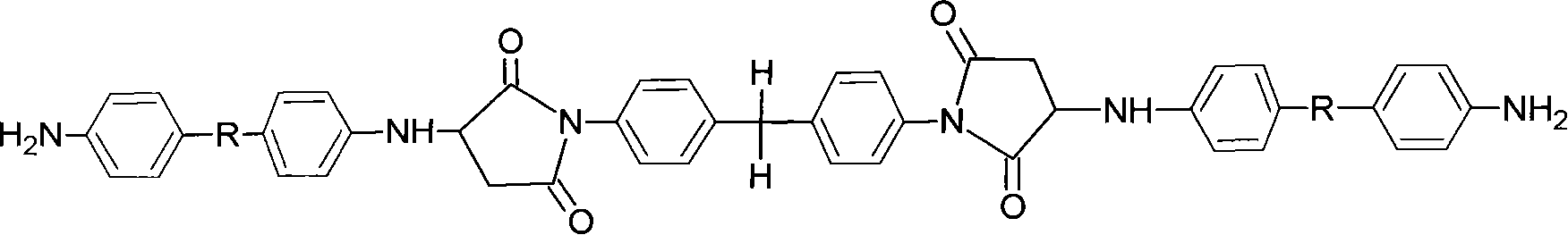

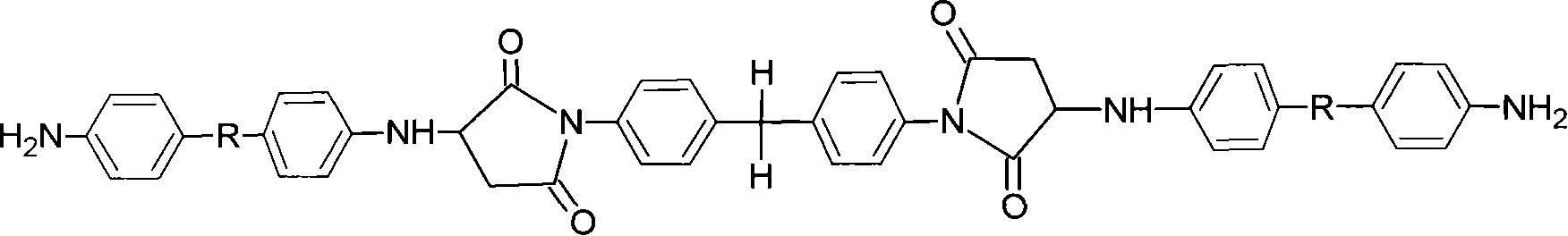

[0017] Please refer to formula (I), the present invention provides a kind of curing agent:

[0018]

[0019] Formula (I)

[0020] where R can be CH 2 , O or SO 2 .

[0021] The main component structure of the hardener contains two structures of imide and amine respectively. Generally speaking, because imide hardener contains imide structure and forms a heterocyclic structure, it has the effect of softening resistance and thermal shock resistance, that is, it has good heat resistance; coupled with an amine functional group at the end, Therefore, the anti-peel strength (peel strength) also conforms to the standard of general use, so the hybrid structure of the above-mentioned hardener can simultaneously have the properties of heat resistance and anti-peeling. In addition, the structure also has many C=O groups, or R can be CH 2 , O or SO 2 The hardener has a certain degree of polarity, which can provide a better dispersion effect for high-concentration inorganic powders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com