Lightning protection composite material surface film as well as preparation method and application thereof

A composite material and composite material board technology, which is applied to the surface film of lightning strike protection composite material and its preparation and application fields, can solve the problems of internal instrument damage and failure, composite material damage, complex process, etc., and achieves both heat resistance and economy. The effect of improving the heat resistance is obvious, and the modification effect is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

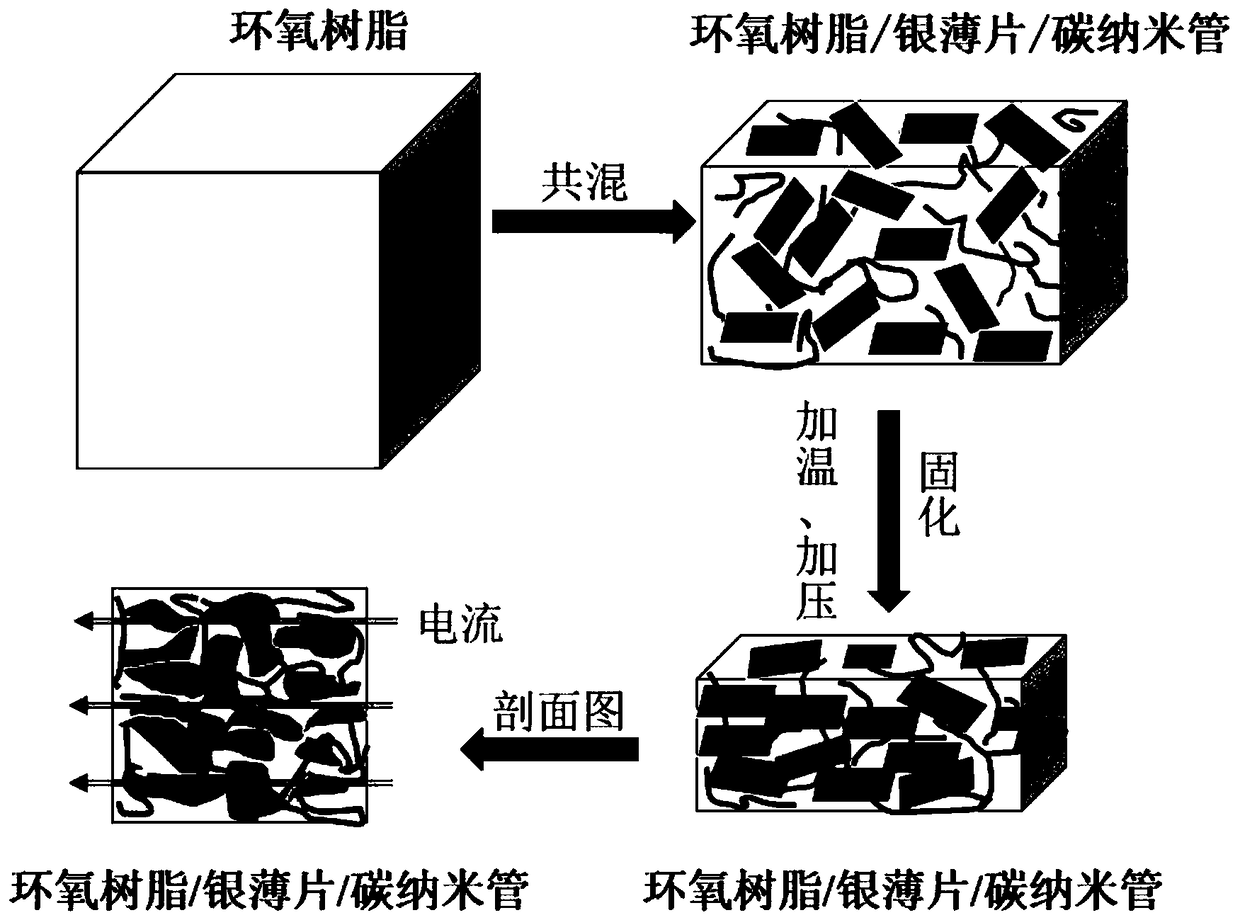

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: a kind of anti-lightning strike composite material surface film of the present invention, it is by the epoxy resin of 75~100 parts, 25~60 parts of silver flakes, the carbon nano material of 2~10 parts, 10-15 parts of toughening modifier, 10-20 parts of heat-resistant modifier, 10-30 parts of curing agent, 1-5 parts of UV stabilizer and carrier.

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the epoxy resin is made of N,N,N',N'-tetra(oxiranylmethyl)-1,3-xylylene amine , naphthyl novolac epoxy resin One or two of them in any proportion. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the size of the micron silver flakes is 5-15 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com