Preparation method of self-lubricating PAI (polyamide-imide) enameled wire paint

A technology of polyamide-imide and enameled wire varnish, which is applied in the direction of coating to achieve the effect of both heat resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

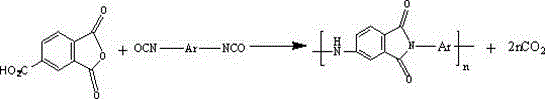

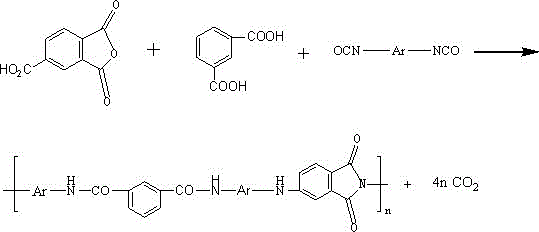

Method used

Image

Examples

Embodiment 1

[0017] The first step: Put 2503 grams of diphenylmethane diisocyanate, 1537 grams of trimellitic anhydride, and 332 grams of isophthalic acid into a 40-liter reactor equipped with a stirring device and a reflux condensing device, and the molar ratio is 1:0.8 :0.2, add solvent methylpyrrolidone (NMP) 15302 grams, the mass ratio of raw material and solvent is 1:3.5. Raise from room temperature to 70-80°C, keep warm for 1-2 hours, then raise the temperature by 15--25°C per hour to make the reaction run smoothly, raise the temperature to 190°C, keep warm for 1-2 hours, the system gradually becomes transparent , in orange, to obtain a low-viscosity polyamide-imide (PAI) prepolymer solution;

[0018] Step 2: Take 10kg of the low-viscosity polyamideimide (PAI) prepolymer solution and 2kg of nano-scale polytetrafluoroethylene (PTFE) powder in the first step, and grind and disperse them in a nano-scale ball mill. The grinding and dispersing time is 4- After 5 hours, a dispersion liqui...

Embodiment 2

[0021] 2503 grams of diphenylmethane diisocyanate, 1729 grams of trimellitic anhydride, and 166 grams of isophthalic acid were put into a 40-liter reactor equipped with a stirring device and a reflux condensing device, and the molar ratio was 1:0.9:0.1. The solvent methylpyrrolidone (NMP) is 15393 grams, and the mass ratio of raw material to solvent is 1:3.5. All the other operations are the same as in Example 1.

[0022] Test items Comparative example Example 1 Example 2 Conductor diameter / mm 0.101 0.101 0.102 Enameled wire outer diameter / mm 0.120 0.121 0.119 surface smooth without bright spots smooth without bright spots smooth without bright spots dynamic friction coefficient 0.092042 0.043793 0.046143 Thermal shock (Test temperature 280±5°C, 30min, round rod diameter 2D) No cracking under test conditions (310±5°C, 30min, round rod diameter 2D) no cracking under test conditions (310±5°C, 30min, round rod diameter 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com