Heavy duty pneumatic tire

A technology for pneumatic tires and heavy loads, applied in the field of pneumatic tires for heavy loads, can solve the problems of deterioration of tire durability, deterioration of heat resistance, etc., and achieve the effect of taking into account both tar resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 17

[0101] Example 17 has the same specifications as Example 14 except that two groove bends (a fourth groove bend and a fifth groove bend) are provided in the central horizontal groove 14 .

Embodiment 18

[0102] Example 18 has the same specifications as Example 17 except that the center transverse groove 14 is a lug groove in which the third straight line 14g of the center transverse groove 14 is not inclined with respect to the tire width direction.

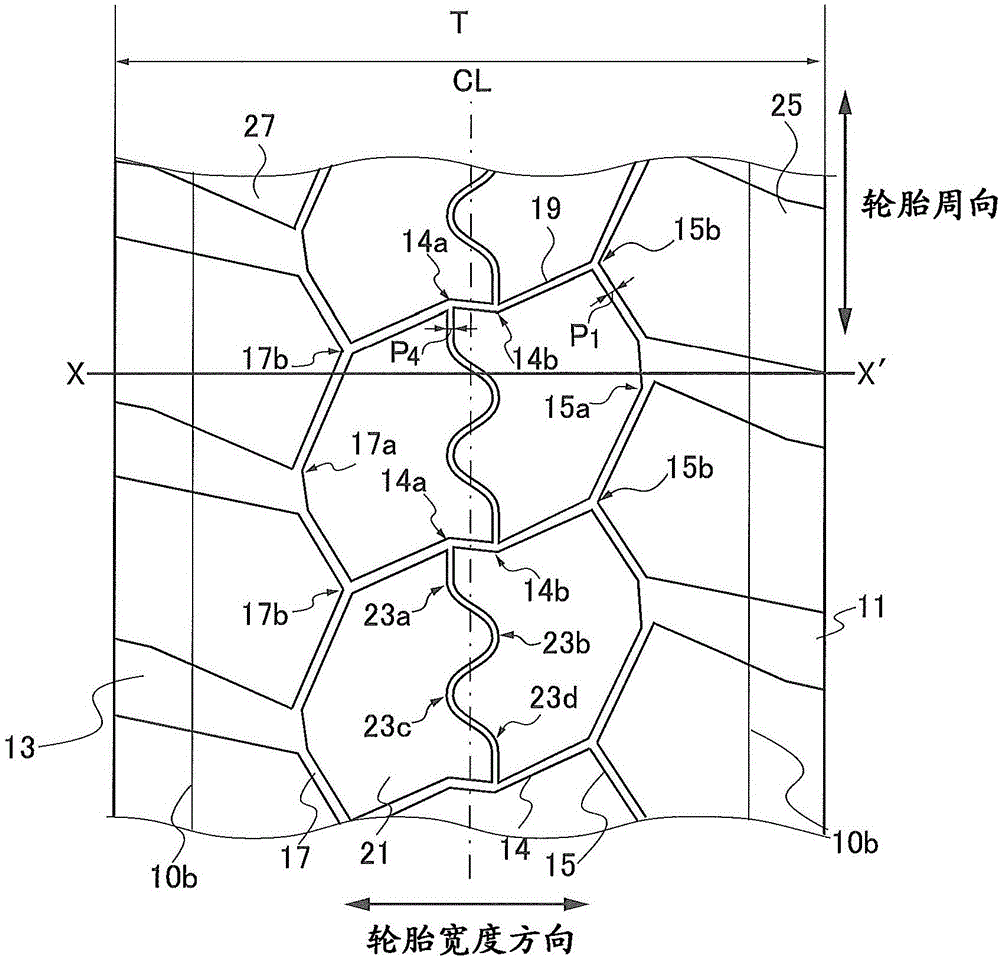

[0103] The tread pattern of the conventional example uses Figure 6 Tread pattern shown. Figure 6 It is a figure which shows the tread pattern of a conventional example. Figure 6 The shown tread pattern includes shoulder lateral grooves 110 , a pair of circumferential main grooves 112 , a central lateral groove 114 , and a central block 116 . The shoulder transverse grooves 110, the pair of circumferential main grooves 112, the central transverse groove 114, and the central block 116 have the same structures as the shoulder transverse grooves 11, 13, the pair of circumferential main grooves 15, 17, the central transverse groove 14, and the central block 21, respectively. , but the groove width of the shoulder transverse groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com