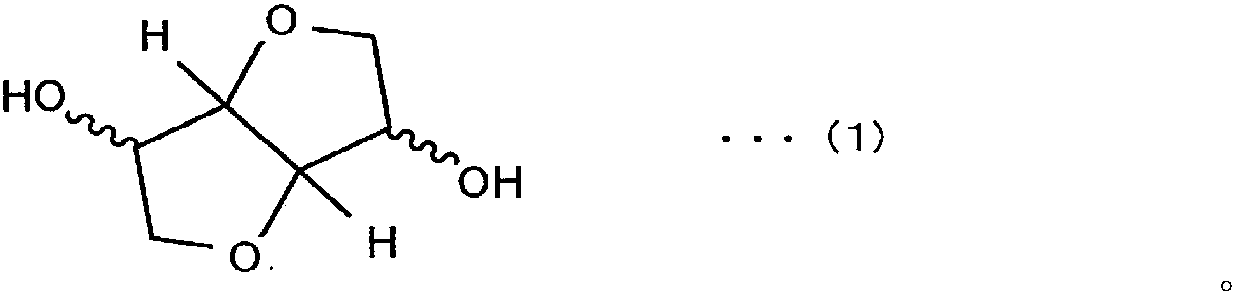

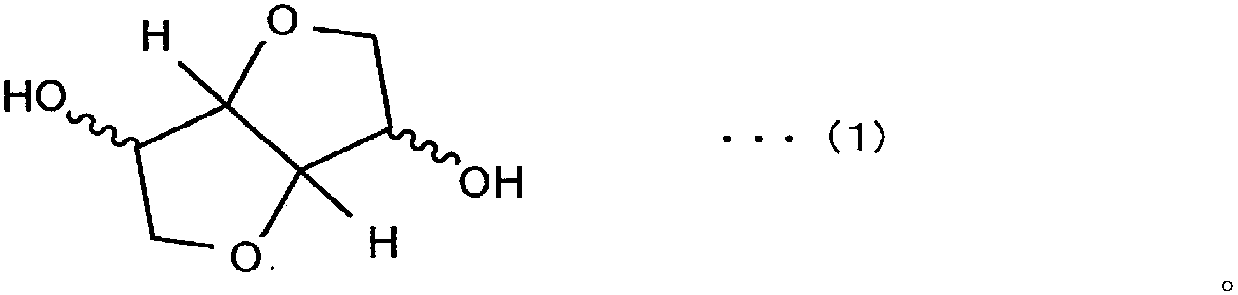

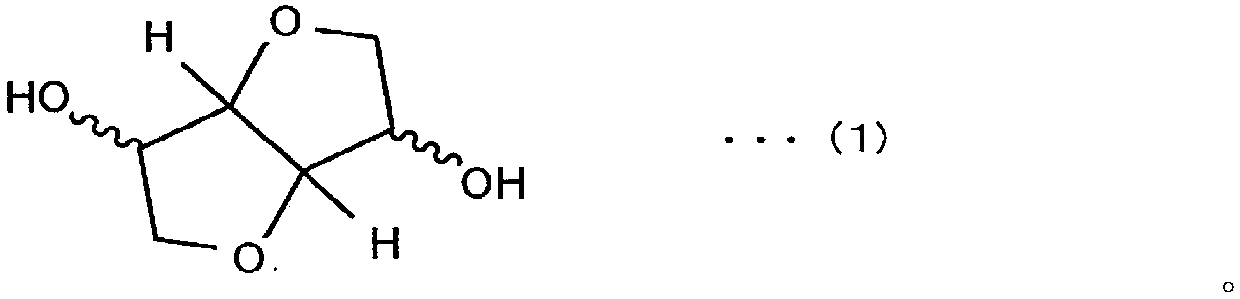

Polycarbonate resin composition, method for producing same, and molded object

A technology of polycarbonate resin and manufacturing method, applied in the field of polycarbonate resin composition, can solve the problems of unfavorable environment, high melt viscosity, no increase in polymerization degree, etc., and achieve the effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0248] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to the following examples unless the gist is exceeded.

manufacture example 1-1

[0292] The polycarbonate resin was polymerized using a continuous polymerization apparatus consisting of three vertical stirring reactors and one horizontal stirring reactor and a twin-screw extruder. Specifically, firstly, ISB, CHDM and DPC are melted in a tank respectively, and ISB is 35.2 kg / hr, CHDM is 14.9 kg / hr, and DPC is 74.5 kg / hr (by molar ratio, ISB / CHDM / DPC= 0.700 / 0.300 / 1.010) was continuously supplied to the first vertical stirring reactor. Simultaneously, an aqueous solution of calcium acetate monohydrate was supplied to the first vertical stirring reactor so that the amount of calcium acetate monohydrate added as a catalyst was 1.5 μmol relative to 1 mol of the total dihydroxy compound. The reaction temperature, internal pressure, and residence time of each reactor were set as the first vertical stirred reactor: 190°C, 25kPa, 90 minutes, the second vertical stirred reactor: 195°C, 10kPa, 45 minutes, and the third vertical stirred reactor. Type stirred reactor: ...

manufacture example 1-2

[0297] Regarding the supply amount of each raw material to the reactor, ISB is 25.4 kg / hr, CHDM is 25.0 kg / hr, and DPC is 74.8 kg / hr (ISB / CHDM / DPC=0.500 / 0.500 / 1.006 in molar ratio), Calcium acetate monohydrate is 1.5 μ mol with respect to 1 mol of all dihydroxy compounds, and the reduced viscosity of the obtained polycarbonate resin is changed from 0.60 dL / g to 0.63 dL / g. 1 A resin was prepared in the same manner to obtain a polycarbonate resin having a molar ratio of ISB / CHDM of 50 / 50 mol%. 0.65 weight ppm of phosphorous acid (0.24 weight ppm in terms of phosphorus atoms) was added as a catalyst deactivator to the polycarbonate resin. In addition, phosphorous acid was added as follows. Prepare the masterbatch that coats and mixes the ethanol solution of phosphorous acid on the pellet of the polycarbonate resin obtained in Production Example 1-2, from the side of the first exhaust port of the extruder (the Resin supply port side) The masterbatch is supplied so that it may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com