Hard PVC material composition, and preparation method and use thereof

A PVC material and composition technology, applied in the field of material processing, can solve the problems of insufficient hardness and high cost of rigid PVC materials, and achieve the effect of achieving both hardness, cold resistance and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

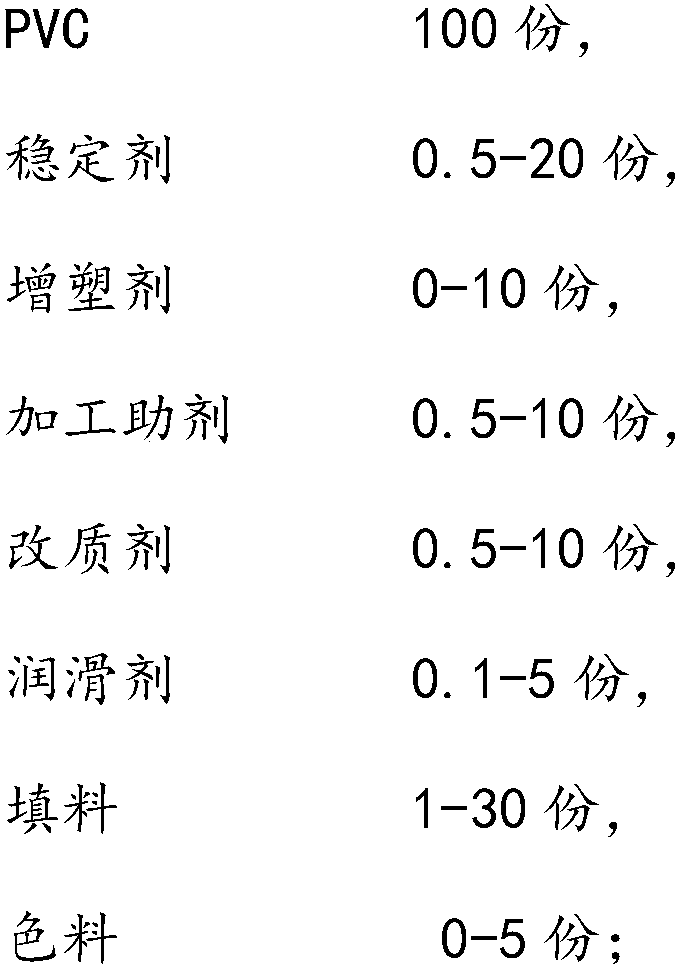

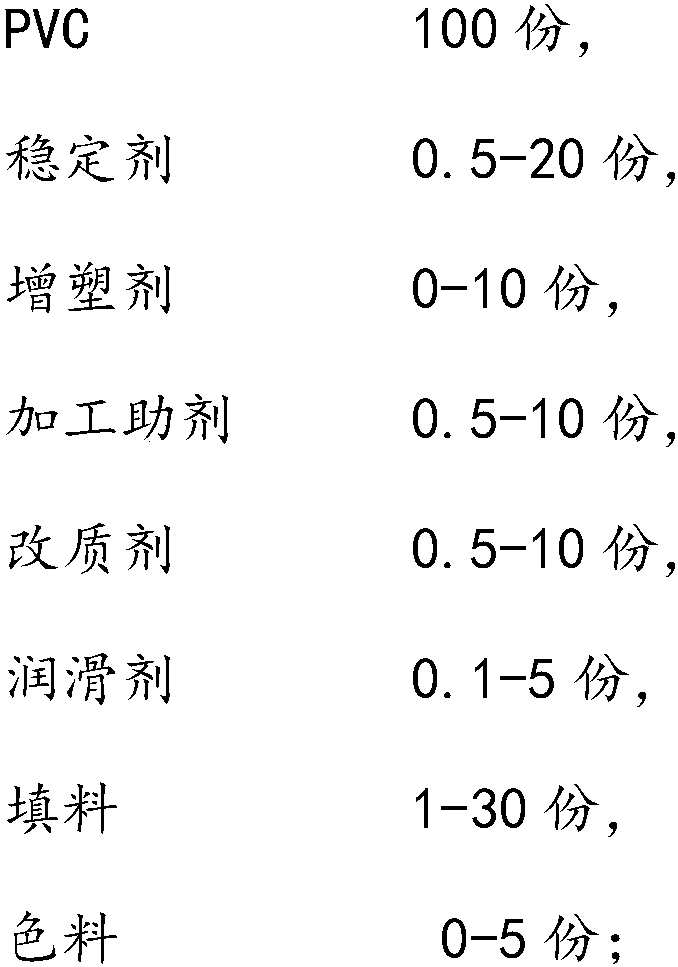

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the rigid PVC material composition that the embodiment of the present invention provides comprises the following steps:

[0034] Mixing the PVC, stabilizer, processing aid, modifier, lubricant, filler, and colorant to obtain a mixed material;

[0035] The mixed material is extruded after shearing and pre-plasticizing in a screw extruder, the extruded material is plasticized in an open mill, and then pressed into a tablet by a calender, drawn out by a stretching machine, cooled and shaped, and rolled, that is Obtain the rigid PVC material composition.

[0036] In the above-mentioned preparation method: the equipment used for mixing is a thermal mixer, and the mixing time is 5-10min; the screw extruder is a planetary screw extruder, and the temperature of the screw extruder is 150-180° C.; The melting temperature is 130-160°C. In this preparation method, the equipment and parameters adopted are all screened by the inventor based on the formula ...

Embodiment 1

[0040] Embodiment 1 provides a kind of rigid PVC material composition and its preparation method, application, specifically:

[0041] Take various raw materials according to the mass parts shown in Table 1;

[0042] Fully mix PVC, heat stabilizer, plasticizer, processing aid, modifier, lubricant, filler and colorant in a hot mixer for 5-10 minutes to obtain a mixed material;

[0043] The mixed material is extruded through a planetary screw extruder at a temperature of 150-180°C, sheared and pre-plasticized, and further plasticized in an open mill at a temperature of 130-160°C, then pressed into a tablet by a calender, and drawn out by a stretching machine. , cooling and shaping, and winding to obtain a PVC hard material composition.

[0044] The PVC hard material composition provided in this embodiment can be used to prepare cooling tower packing.

[0045] Embodiments 2-7 respectively provide a rigid PVC material composition and its preparation method and use. The preparatio...

Embodiment 8

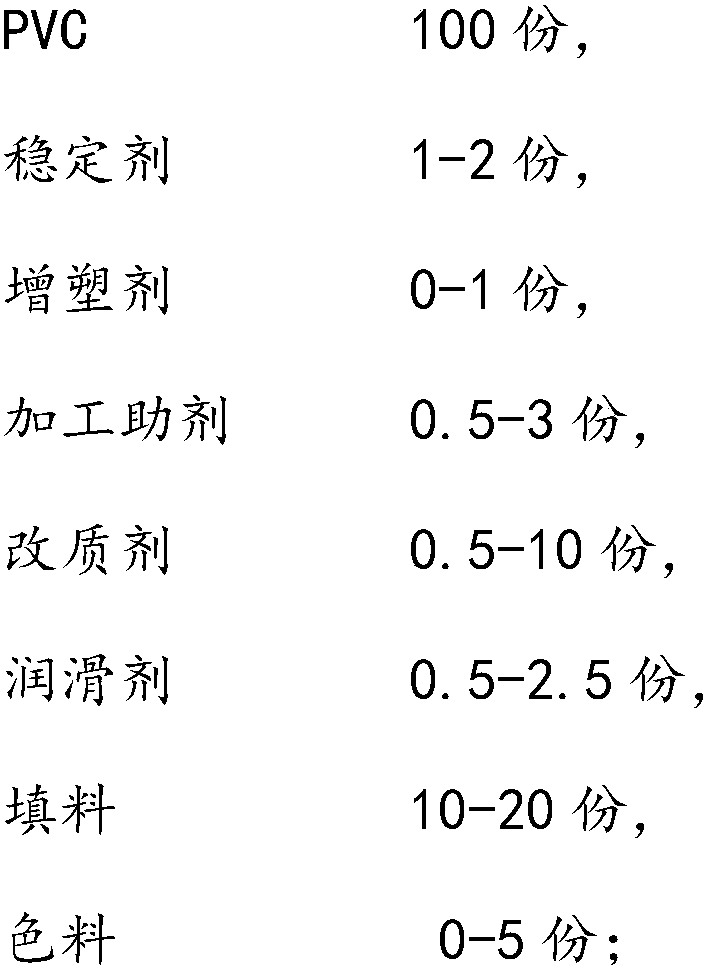

[0049] Embodiment 8 and Embodiment 9 are variations of Embodiment 1, and the only difference lies in the raw material formula of the rigid PVC material composition, as shown in Table 2 below.

[0050] Table 2

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com