High and low temperature resistance and engine diesel oil resistance ultra-low pressure variation rubber material and preparation method thereof

A technology of high and low temperature resistant rubber materials, applied in the field of ultra-low pressure variable rubber materials and its preparation, can solve the problems of low heat resistance, poor compression permanent deformation, etc., to improve heat resistance, prolong service life, heat resistance The effect that balances cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

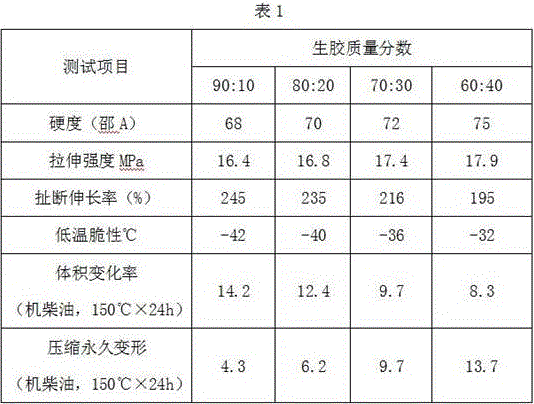

[0025] The 26-type nitrile rubber and the 40-type nitrile rubber are respectively 90:10, 80:20, 70:30 and 60:40 according to the ratio of parts by mass, and are masticated for a certain period of time in an open mill. After several times, until the Mooney viscosity value of the mixed rubber is ML 1+4 In the range of 40~60.

[0026] The masterbatch after mastication is moved into the internal mixer, the mass parts of the masterbatch are calculated as 100 parts, 30~80 parts of semi-reinforcing carbon black, 0~25 parts of high wear-resistant granular carbon black and 2~5 parts 2 parts of process additives are added to the internal mixer, and mixed evenly under high temperature and high shear conditions, wherein the rotor speed of the internal mixer is controlled at 50~120r / min, and the mixing time is at least 2 minutes; then add DOS softening plasticizer 6 ~15 parts, 0.7 parts of chemical anti-aging agent 4010NA and 1.5-5 parts of other anti-aging agents, 5 parts of active agent...

Embodiment 2

[0035] The preparation method of the high and low temperature resistant, engine diesel resistant ultra-low pressure variable nitrile rubber material of the present embodiment is the same as 1, and the difference is that the type and weight of the added plasticizer are different.

Embodiment 3

[0037] The preparation method of the high and low temperature resistant, engine diesel resistant ultra-low pressure variable nitrile rubber material of this embodiment is the same as 1, the difference lies in the type and proportion of the added anti-aging agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com