Manufacturing process for centrifugal casting of multi-element eutectic high-alloy rolls

A centrifugal casting and manufacturing process technology, applied in the field of metallurgical rolls, can solve the problems of incommensurate wear resistance and heat resistance, troublesome production, transportation and storage, and difficult use by users, and achieves improved casting performance, small solidification temperature range, The effect of dense crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

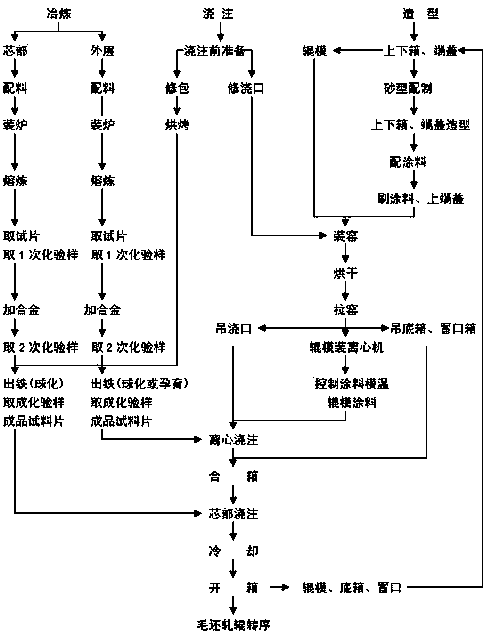

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

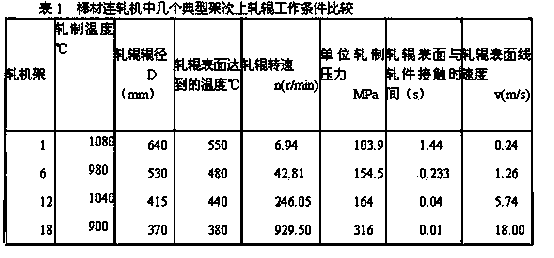

[0018] In the embodiment, refer to the accompanying drawings for the specific process steps. The product of the embodiment has the effect of significantly improving the life of the roll after being used in a bar factory of a company: the sixteenth rolling mill for three-wire splitting (the splitting stage, called K3 on site On the rolling mill), the steel passing through a single groove reaches 1366 tons. However, in this bar production line, the steel passing capacity of ordinary rolls in the same position in a single groove is only 300-400 tons (average 370 tons), which improves the life of the rolls by more than 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com