Patents

Literature

60results about How to "Dense crystal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of starch type film-forming agent for glass fiber wetting agent

InactiveCN102304188ALow thermal decomposition temperatureReduce carbon residueFermentationGlass fiberFiltration

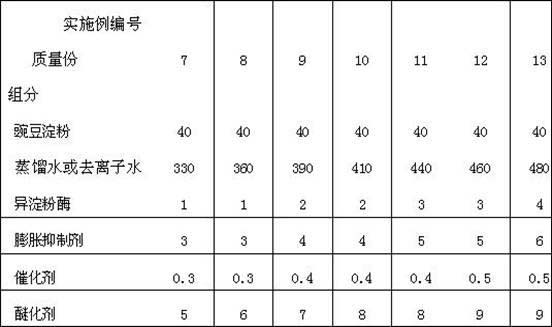

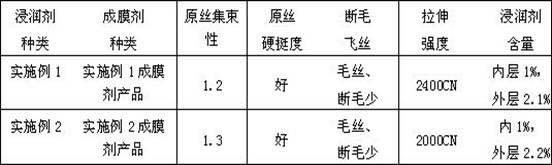

The invention discloses a preparation method of a starch type film-forming agent for a glass fiber wetting agent, which is characterized by comprising the following steps: feeding 40 mass parts of pea starch into a reaction vessel, adding 300-500 mass parts of water, heating to 75-90 DEG C while stirring, carrying out gelation reaction for 0.5-2 hours, and then cooling to 35-50 DEG C; adjusting the pH value to 4-6.5, adding 1-4 mass parts of isoamylase, reacting for 6-30 hours, and then heating to 75-90 DEG C to carry out enzyme inactivation for 5-30 minutes; cooling to 30-55 DEG C, adding 3-6 mass parts of expansion inhibitor, and keeping the temperature for 10-20 minutes; and adding 0.3-0.5 mass part of catalyst and 4-10 mass parts of etherifying agent, reacting for 10-24 hours, adjusting the pH value to 6-8, cooling to room temperature, then carrying out vacuum filtration, and drying the solid to obtain the film-forming agent product. The product is used for a glass fiber wetting agent, and has the characteristics of good film forming performance, convenient post treatment process and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

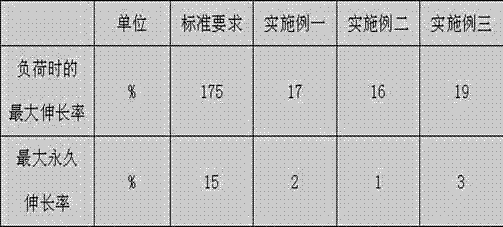

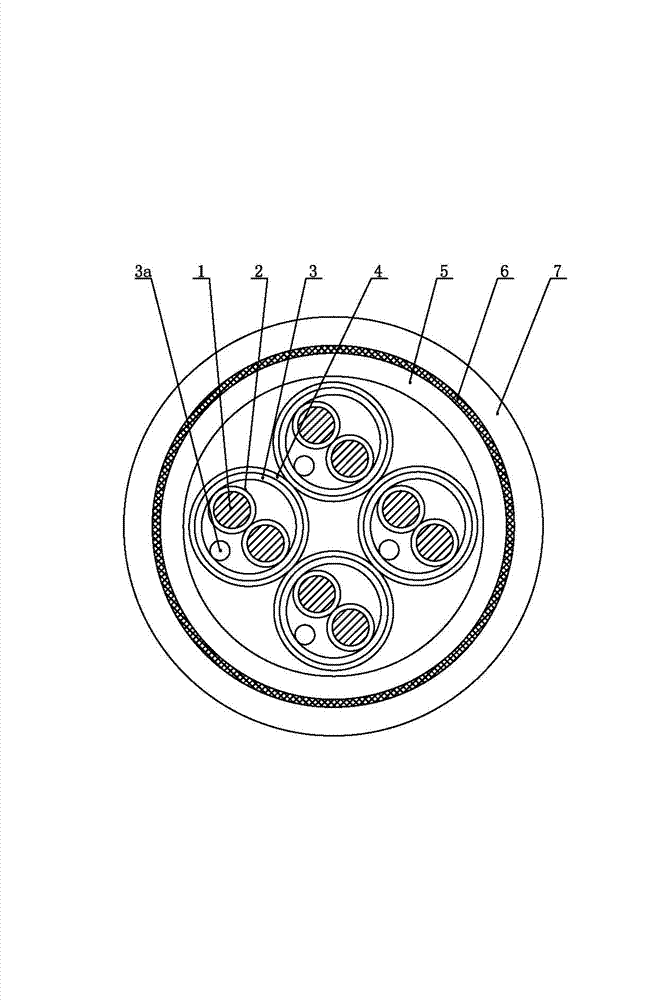

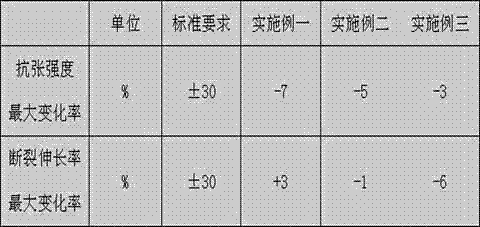

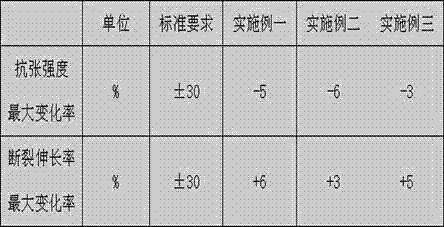

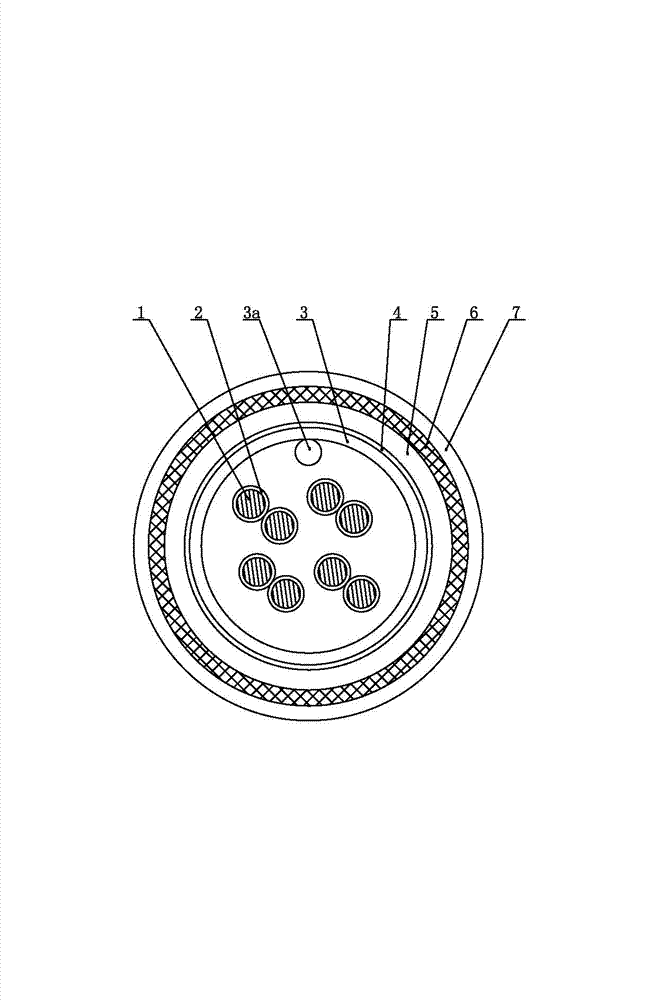

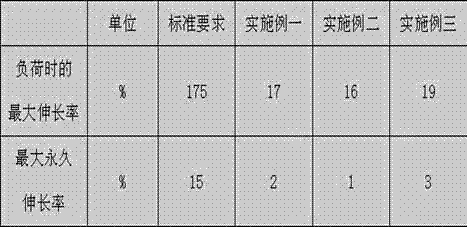

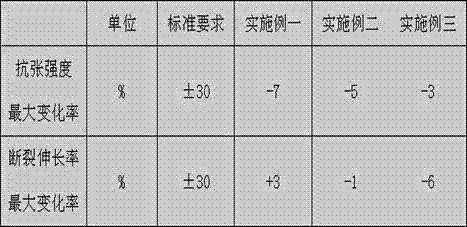

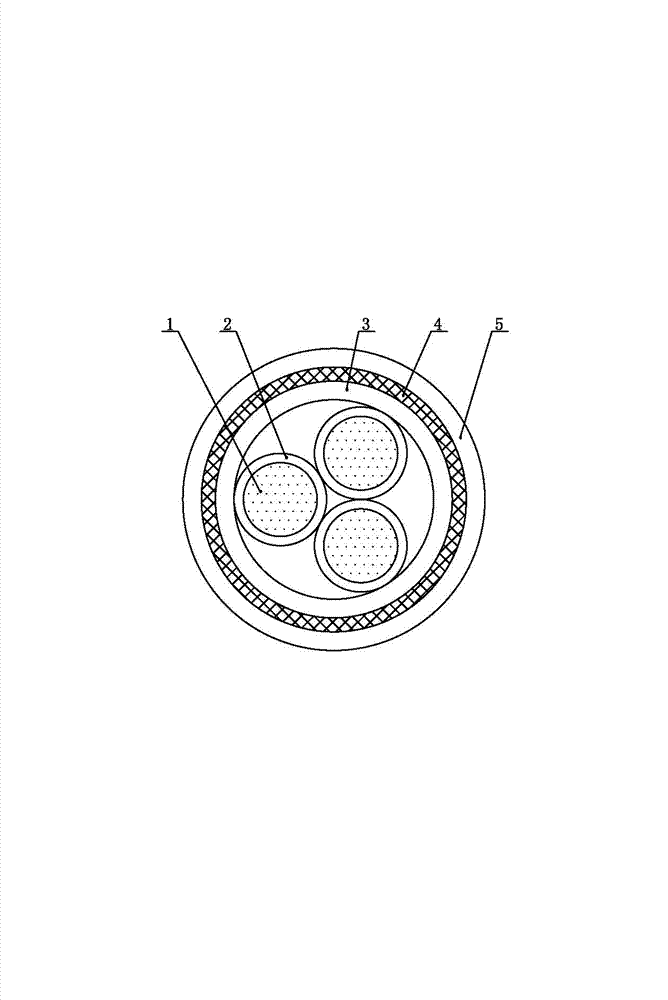

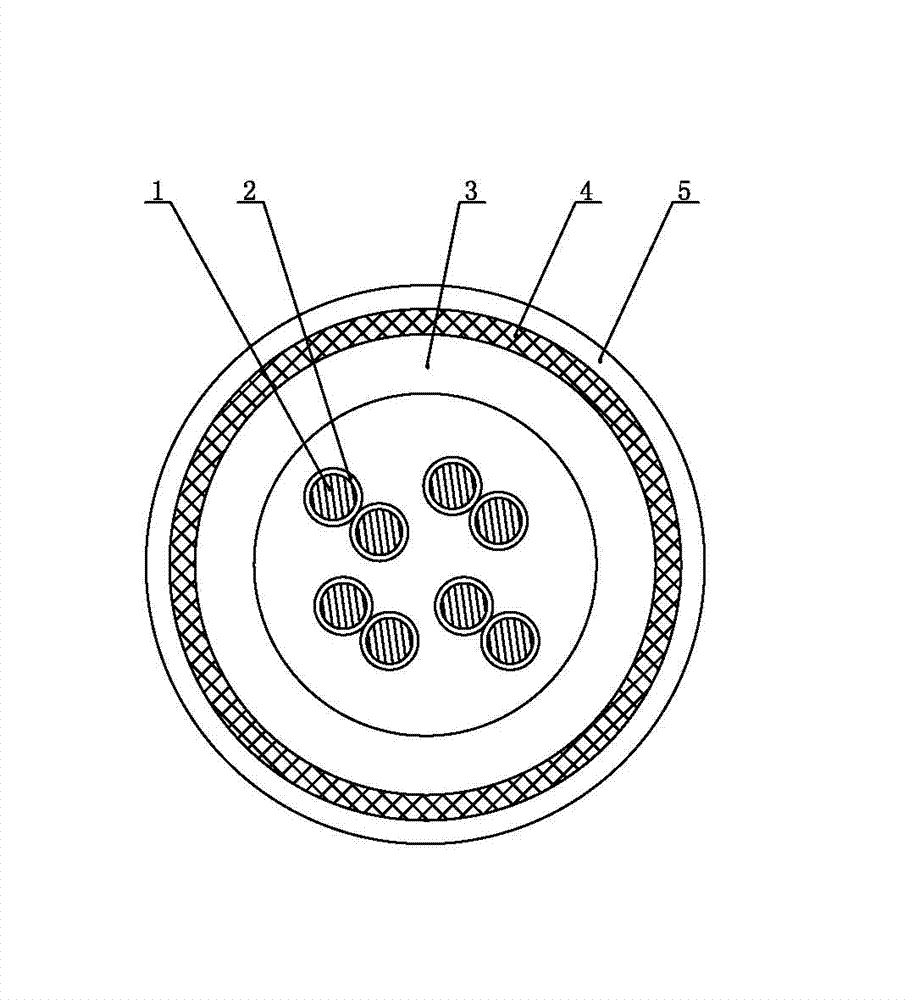

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

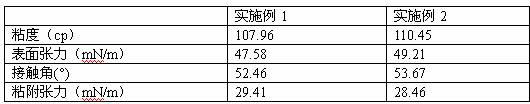

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

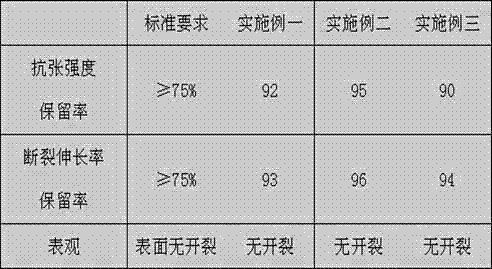

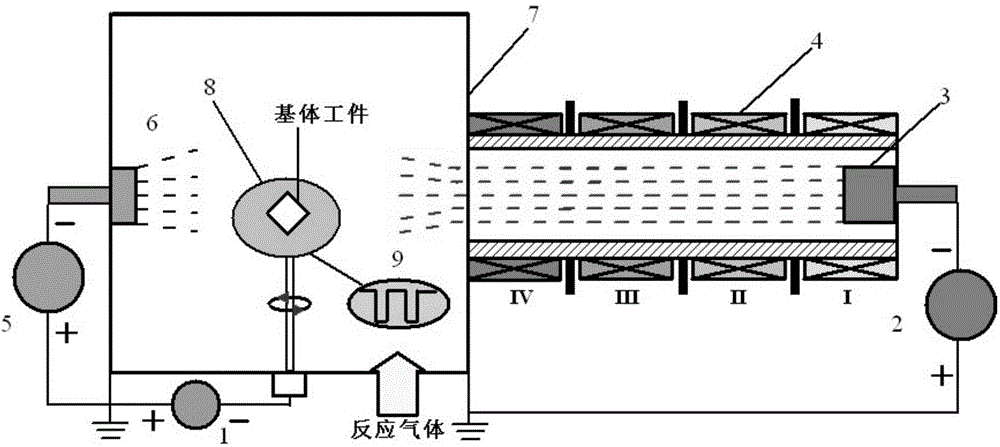

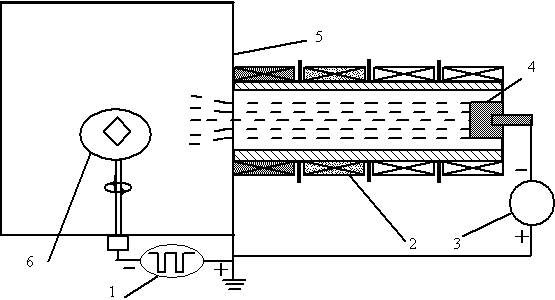

Combined method of arc ion plating and twin target bipolar high-power pulsed magnetron sputtering

InactiveCN105803411AEfficient transmissionGuaranteed film deposition rateVacuum evaporation coatingSputtering coatingPlasma energyFilm-coated tablet

Owner:魏永强

Antifouling wear-resisting coating for metal surface and preparation method thereof

ActiveCN107033642AShort curing timeImprove water resistanceFireproof paintsAntifouling/underwater paintsLithiumPotassium silicate

The invention discloses an antifouling wear-resisting coating for a metal surface and a preparation method thereof. The invention aims to provide the antifouling wear-resisting coating for the metal surface, which is easy to clean, excellent in wear resistance and high in hardness. The technical scheme is that the antifouling wear-resisting coating is prepared from, by weight percent, 3.2-9.6% of high modulus potassium silicate, 2.4-3.6% of lithium silicate, 3.2-4.8% of silica sol, 1.6-2.4% of aluminum oxide sol, 1.6-2.4% of nanometer zirconia, 0.8-1.2% of silicon triphosphate, and the balance being water. The coating is prepared by weighing the components respectively and uniformly mixing and stirring the components. The antifouling wear-resisting coating belongs to the technical field of coatings.

Owner:GUANGZHOU SYSMYK NEW MATERIAL TECH CO LTD

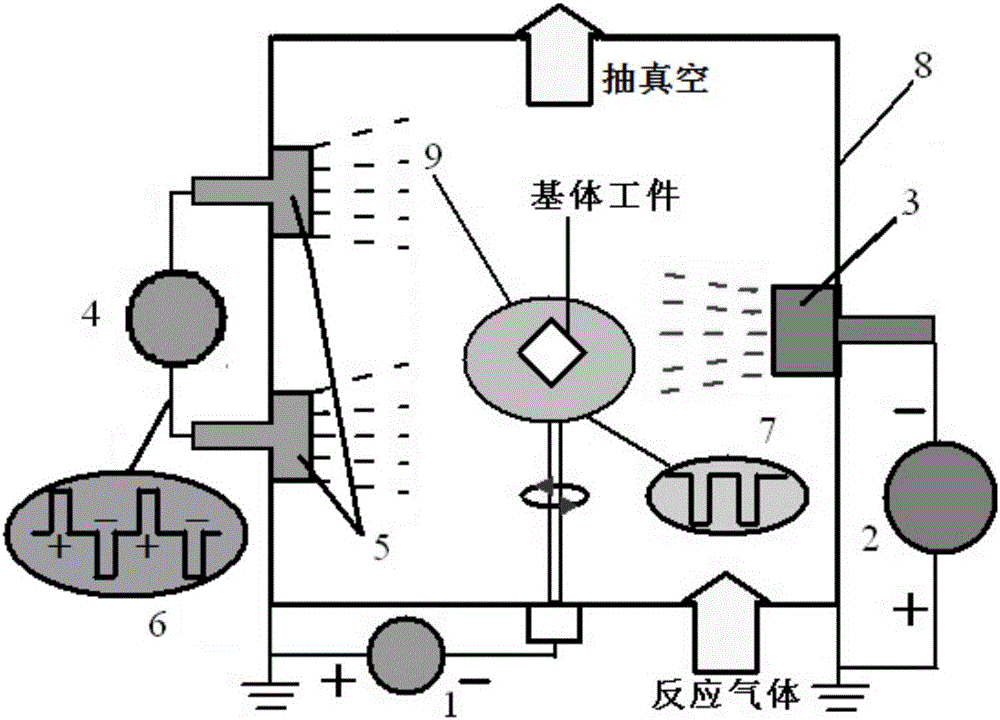

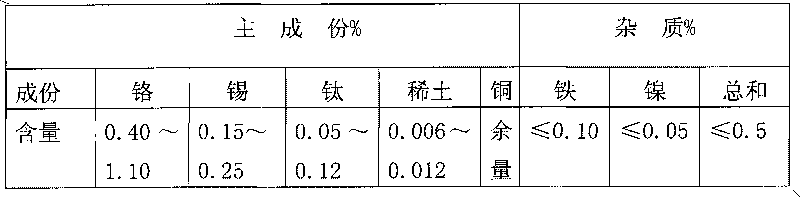

Chromium bronze alloy material and preparation method thereof

The invention discloses a chromium bronze alloy material and a preparation method thereof. The chromium bronze alloy material consists of chromium, tin, titanium, 0.006 to 0.012 percent of rare earth and 98.518 to 99.394 percent of copper. The preparation method for the chromium bronze alloy material comprises the manufacturing steps of batching, smelting, casting, extruding, stretching, straightening and finished product inspection and detection. Through the chromium bronze alloy material and the preparation method thereof, the prepared chromium bronze alloy material has good elastic recovery capability and smaller grain size; and because of the adoption of an advanced process method in the process, the quality of the chromium bronze alloy material is greatly improved, and meanwhile the service life of processing equipment is prolonged.

Owner:甘肃大鑫铜业有限责任公司

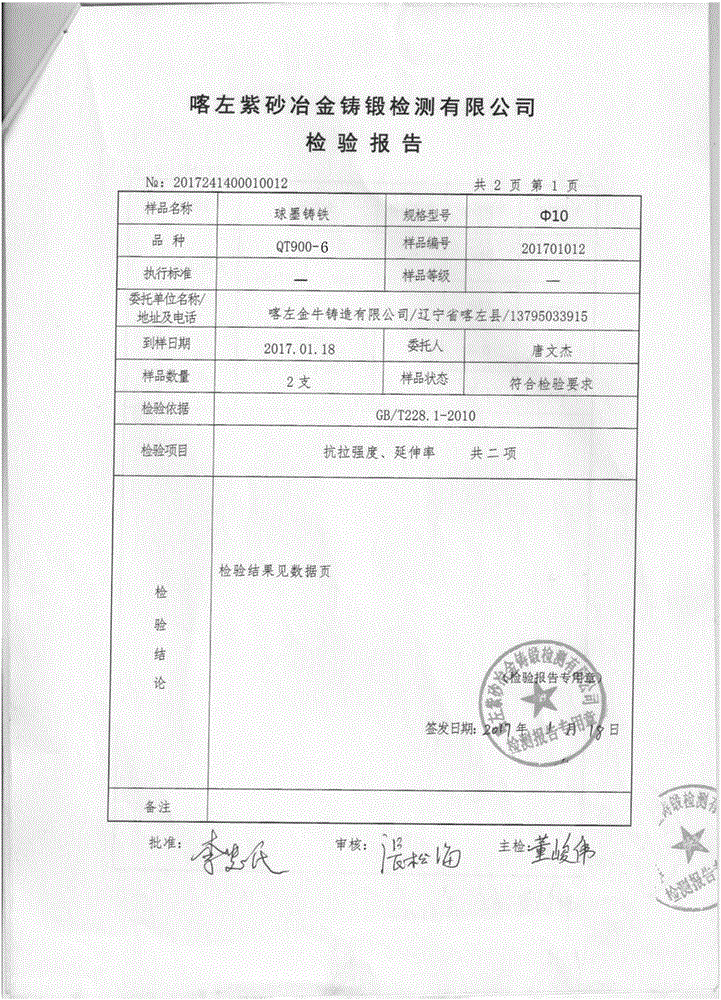

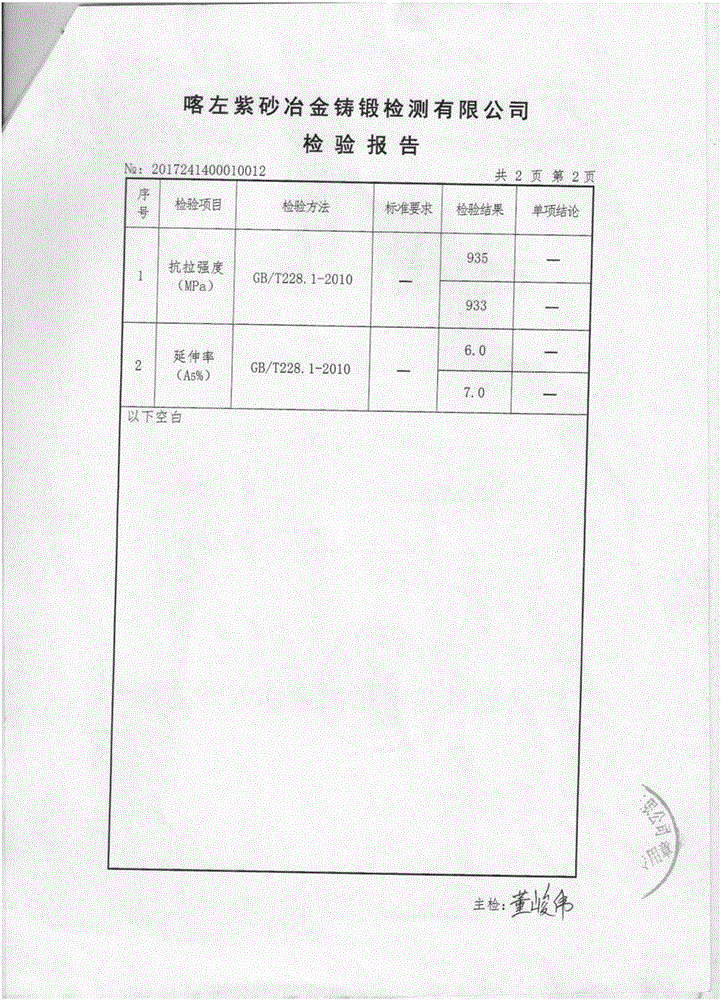

Production process of high-strength and high-toughness as-cast ductile cast iron

The invention discloses a production process of high-strength and high-toughness as-cast ductile cast iron. Raw materials including pig iron, low-carbon steel and ductile cast iron foundry returns are added to a medium-frequency melting furnace and heated to be molten, an efficient carburant, a manganese-iron alloy and a silicon-iron alloy are added to the medium-frequency melting furnace, and the mixture is molten into molten iron; firstly, a spheroidizing ladle is preheated, a spheroidizing agent is added to one side, close to a furnace body, of a dam of the spheroidizing ladle, an inoculant is taken and applied to the surface of the spheroidizing agent in a covering manner, metal nickel and metal titanium are added to the other side, close to the furnace body, of the dam of the spheroidizing ladle, the surface of the spheroidizing agent is covered with a perlite covering agent, part of molten iron is poured into the spheroidizing agent for a reaction, the remaining molten iron is poured into the spheroidizing agent after the reaction is stable, the remaining inoculant is added along with the flow for inoculation, the mixture is stirred sufficiently, a molten iron deslagging agent is added after slagging off, slag is rammed, silicon granules are added, the mixture is covered with the perlite covering agent after inoculation of unstable silicon, and a product is obtained after pouring and air cooling. The production process has the advantages that the process is simple, reasonable and low in production cost, heat treatment is not required, the product elongation is increased, and the mechanical performance of the product is good.

Owner:喀左金牛机电设备科技有限公司 +1

Multi-stage magnetic field arc ion plating and radio-frequency magnetron sputtering composite deposition method

PendingCN104975263AReduce Large Particle DefectsGuaranteed normal transmissionVacuum evaporation coatingSputtering coatingSemiconductor materialsRadio frequency magnetron sputtering

The invention provides a multi-stage magnetic field arc ion plating and radio-frequency magnetron sputtering composite deposition method and belongs to the technical field of material surface processing. The method aims to solve the problem that low-melting-point pure metal or multicomponent alloy materials and non-metal materials, such as graphite are large in particle in traditional arc ion plating, breaking through the limitations that semiconductor materials and insulating materials can not be used, the ionization rate and thin film deposition efficiency of traditional magnetron sputtering are low and high- melting-point targets are difficult to ionize, and eliminating the limitations of an original method in the aspect of use of the targets. The composite deposition method includes the steps that 1, a workpiece to be plated is placed on a sample table in a vacuum room, and a relative power source is powered on; 2, a thin film is deposited, wherein when the vacuum degree in the vacuum room is smaller than 10-4Pa, work gas is introduced, gas pressure is adjusted, a plating power source is powered on, and energy of a composite plasma is adjusted through a grid bias power supply. By means of a multi-stage magnetic field straight tube magnetic filter device, the defect of large particles is overcome, transmission efficiency of arc plasmas is guaranteed, and required process parameters are set for thin film deposition.

Owner:魏永强

Marine independent screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969048AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesUltraviolet lightsEngineering

The invention relates to a marine independent screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, a copper foil polyester composite belt screening layer is lapped at the periphery of each group of stranded wire pair, copper foil surfaces are inward, tin-plating stranded steel drainage wires are arranged on the inner sides of the copper foil polyester composite belt screening layers, penetrate through the full length of each stranded pair and cling together with the copper foil surfaces; and a polyester belt is lapped at the periphery of each copper foil polyester composite belt screening layer to form a stranded group; and the all stranded groups are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, an inner protecting bush is extruded at the periphery of the cable core, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The independent screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

Marine integral screening instrument cable capable of whitening and resisting ultraviolet and manufacturing method thereof

InactiveCN102969056AExcellent light aging performanceGood physical and mechanical propertiesRubber insulatorsInsulated cablesCopper foilScreening instrument

The invention relates to a marine integral screening instrument cable capable of whitening and resisting ultraviolet and a manufacturing method thereof. Whitening and ultraviolet-resisting ethylene propylene rubber insulation layers are extruded at the peripheries of tin-plating annealing stranded copper conductors to form insulation wire cores, every two insulation wire cores are stranded to form a stranded wire pair, the all stranded wire pairs are stranded rightwards according to the 16-24 times of stranded node ratio to form a cable core, a copper foil polyester composite belt screening layer is lapped at the periphery of the cable core, a copper foil surface is inward, a tin-plating stranded steel drainage wire is arranged on the inner side of the copper foil polyester composite belt screening layer, penetrates through the full length of each stranded pair and clings together with the copper foil surface; and a polyester belt is lapped at the periphery of the copper foil polyester composite belt screening layer, an inner protecting bush is extruded at the periphery of the polyester belt, a copper alloy wire knitting armor layer covers the periphery of the inner protecting bush, and an outer protecting bush is extruded at the periphery of the copper alloy wire knitting armor layer. The integral screening instrument cable has the advantages that the color of an insulation layer is white, the mechanical property is good, the performance of resisting aging caused by ultraviolet light is excellent, and the service life is long.

Owner:JIANGSU YUANYANG DONGZE CABLE

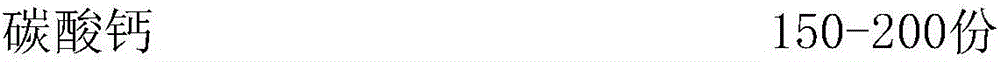

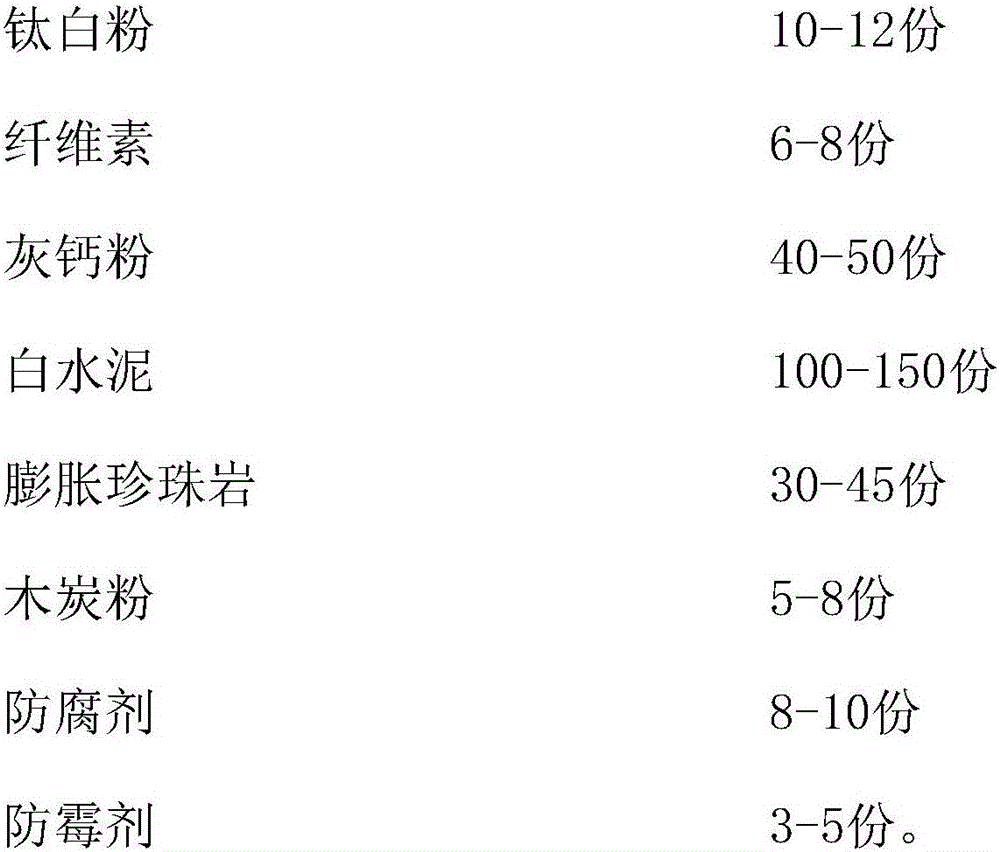

Inner wall putty with antibacterial and odor removing effects and preparation method thereof

The invention discloses inner wall putty with antibacterial and odor removing effects and a preparation method of the inner wall putty with the antibacterial and odor removing effects. The inner wall putty is prepared from the following components calculated in parts by weight: 150 to 200 parts of calcium carbonate, 10 to 12 parts of titanium dioxide, 6 to 8 parts of cellulose, 40 to 50 parts of ash calcium powder, 100 to 150 parts of white cement, 30 to 45 parts of expanded perlite, 5 to 8 parts of charcoal dust, 8 to 10 parts of preservatives and 3 to 5 parts of mould inhibitors. The inner wall putty disclosed by the invention has the advantages of being high in strength, anti-cracking, good in insulation performance, high in flexibility and the like, and is capable of carrying out sterilization and removing odors, and further can adjust the indoor humidity to improve indoor air environment. In addition, the invention further provides the preparation method of the inner wall putty with the antibacterial and odor removing effects. The inner wall putty prepared by the preparation method is small in particle size and easy to mix and does not drop dregs and peel off and has no expansion while meeting dampness and water.

Owner:ZHONGSHAN MOORE CHEM IND CO LTD

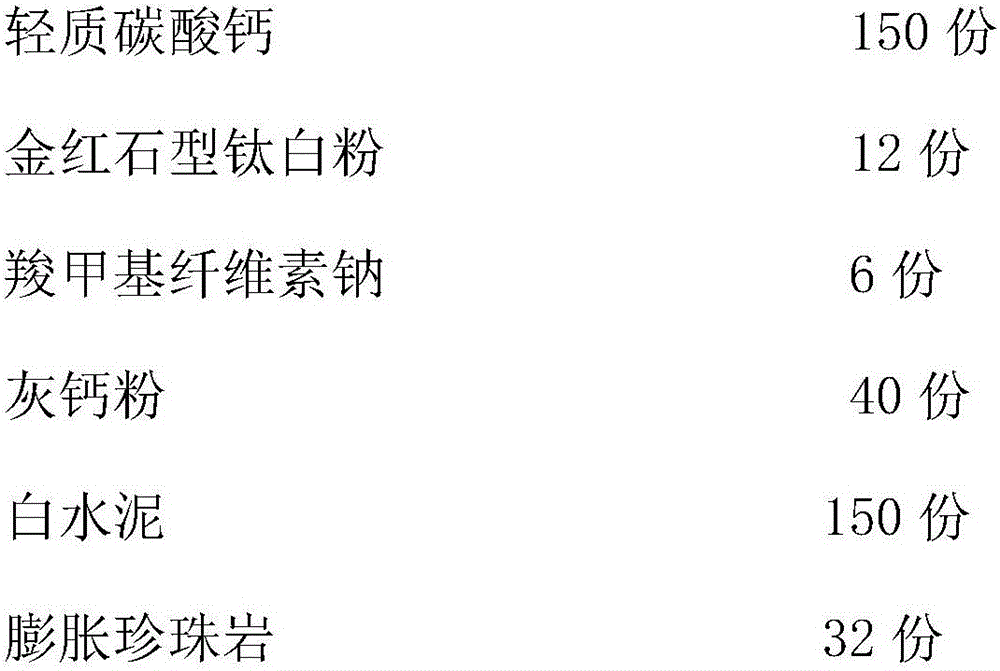

Equiaxed beta-Si3N4+TiN+O'-Sialon multiphase ceramic material and preparation method thereof

The invention discloses an equiaxed beta-Si3N4+TiN+O'-Sialon multiphase ceramic material and a preparation method thereof. According to the invention, TiO2 sol is introduced as a Si powder nitriding catalyst, and a nano-TiN enhancement phase is produced in situ; a Re2O3-Al2O3-SiO2 sintering aid is introduced for promoting densification of Si3N4 sintering, such that equiaxed beta-Si3N4 grains are formed, and O'-Sialon is produced. The beta-Si3N4+TiN+O'-Sialon multiphase ceramic material provided by the invention has excellent mechanical performance, high-temperature performance, oxidation resistance and corrosion resistance.

Owner:吉林长玉特陶新材料技术股份有限公司

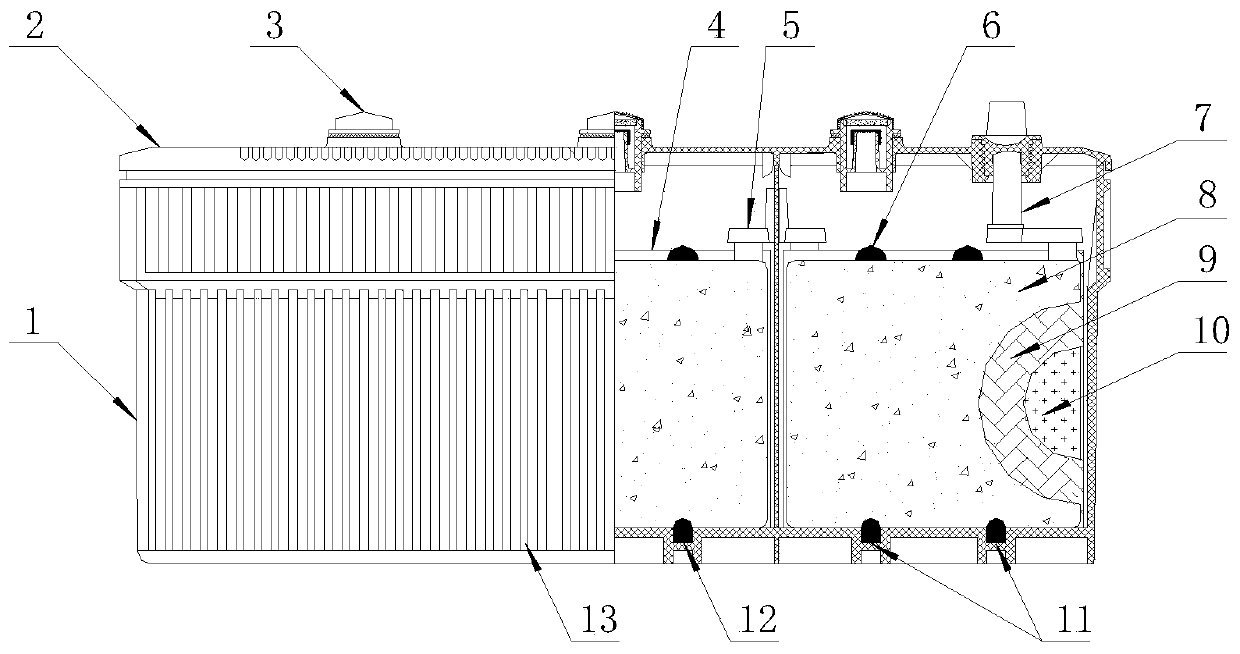

Novel commercial vehicle lead-acid storage battery with long service life

ActiveCN111129613AImprove vibration resistanceAvoid destructionFinal product manufactureSmall-sized cells cases/jacketsElectrolytic agentBusbar

The invention discloses a novel commercial vehicle lead-acid storage battery with a long service life. The storage battery comprises a storage battery groove, a storage battery cover, a safety valve,pole groups and an electrolyte. Two glue remaining grooves are arranged in a bottom of an inner cavity of each grid of the storage battery groove. When the storage battery is assembled, a first hot melt glue is injected into the glue remaining grooves firstly, then the pole groups are installed, and each pole group is fixed to the bottom of the storage battery groove through the first hot melt glue; each pole group comprises a negative plate, an AGM partition plate, a positive plate, a busbar and a pole column; assembly pressure of each pole group is 35-45 kPa, two second hot melt glues are added to an upper part of each pole group; and the negative plate, the AGM partition plate and the positive plate are fixed by the second hot melt glues, and the electrolyte is adsorbed in the negativeplate, the AGM partition plate and the positive plate. The hot melt glue is used for bonding each pole group in the storage battery groove, and the hot melt glue added at the upper part of each pole group is used for fixing the positive plate, the negative plate and the AGM partition plate so that up-and-down movement between pole plates in a vibration process of the storage battery is prevented,and vibration resistance of the storage battery is enhanced.

Owner:陕西凌云蓄电池有限公司

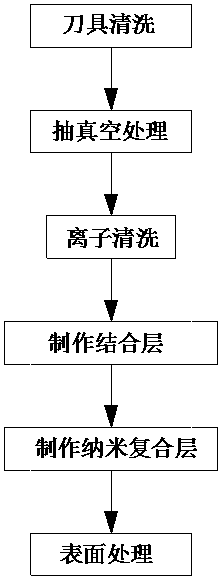

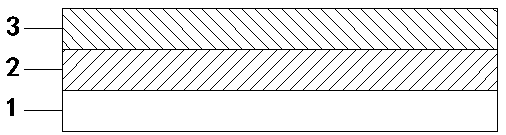

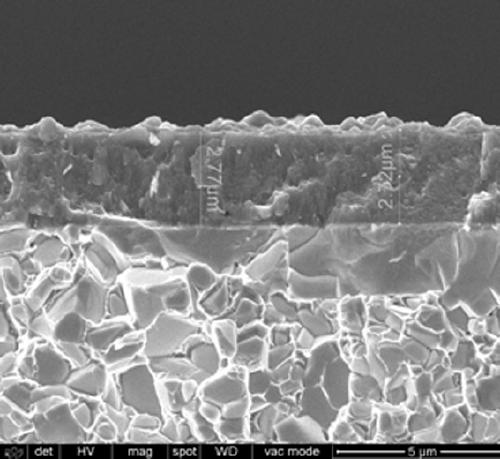

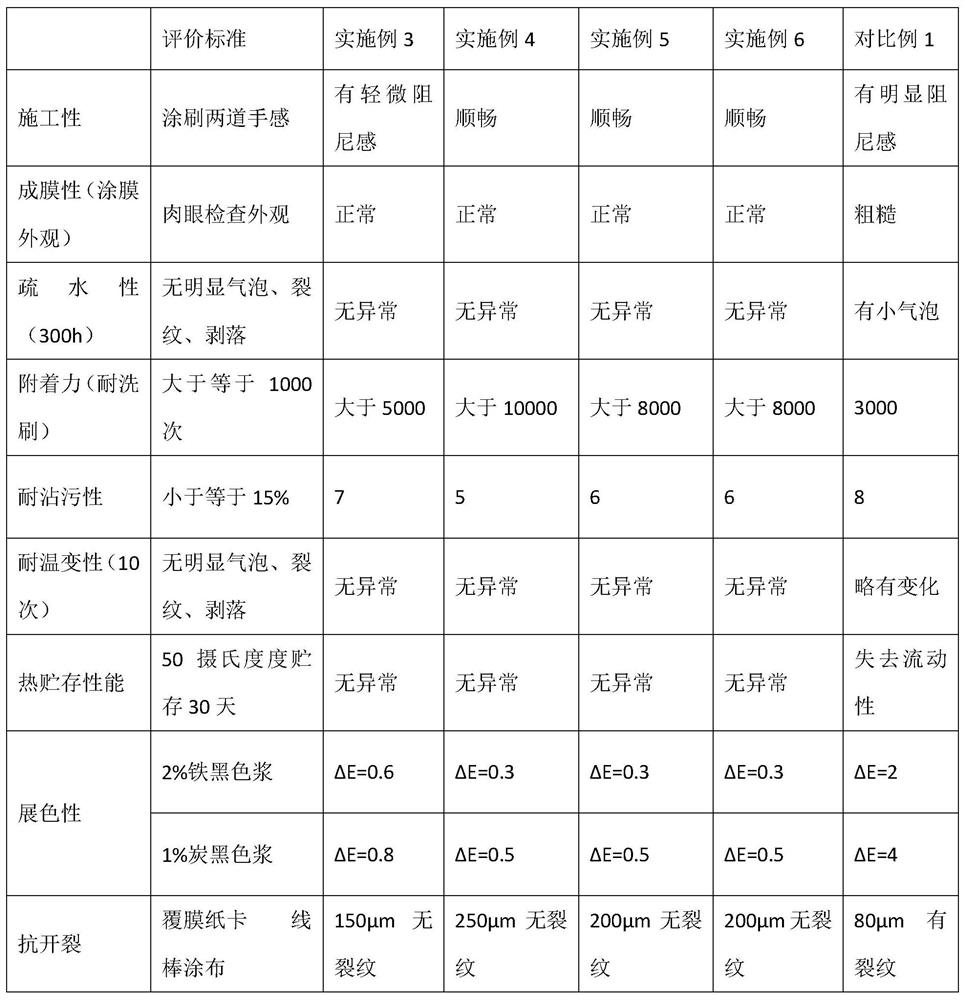

Superhard nanometer composite cutter and manufacturing method and application thereof

InactiveCN110257779AReduce wearReduce cutting heat generationVacuum evaporation coatingSputtering coatingPower flowNitrogen

The invention discloses a superhard nanometer composite cutter and a manufacturing method and application thereof. The method comprises the following steps: 1) cutter washing, namely, keeping the surface of a cutter base body dry and clean; 2) vacuumizing treatment, namely, assembling the cutter base body on a rotating frame of a film coating device; positioning the rotating frame in a closed film coating device which is prepared through a Cr target material and an AlCr target material; vacuumizing a vacuum chamber; starting a heater for increasing the temperature; and controlling the temperature in the film coating device to be 420-550 DEG C; 3) ionic washing, namely, charging argon into the vacuum chamber; performing glow washing on the surface of the cutter base body; and closing argon; 4) preparing of a combination coating, namely, opening the Cr target material and electric arc; controlling the current of the electric arc to be 400-800A; and charging nitrogen to deposit a CrN combination coating on the surface of the cutter base body; and 5) preparing of a nanometer composite coating, namely, closing the Cr target material; opening the AlCr target material; controlling the electric arc current to be 400-800A; and depositing the AlCrN nanometer composite coating on the surface of the CrN combination coating.

Owner:TECHMART SHENZHEN LTD

Polyvinyl alcohol modified water-resistant gypsum-polyamide 6 composite material and preparation method thereof

The invention discloses a polyvinyl alcohol modified water-resistant gypsum-polyamide 6 composite material and a preparation process of the composite material. The preparation process is characterized by comprising the following steps: mixing a polyvinyl alcohol solution, a barium chloride solution and a sodium methylsilanolate solution so as to obtain a composite glue solution; adding the composite glue solution into gypsum powder, and uniformly stirring so as to obtain water-resistant gypsum; adding ethanol into a coupling agent for diluting, adding the water-resistant gypsum into a high-speed mixer, spraying the diluted coupling agent into the gypsum by adopting an atomization method, and performing vacuum drying so as to obtain coupling modified water-resistant gypsum; adding distilled water into polyvinylpyrrolidone so as to obtain a surfactant solution; adding multiwalled carbon nanotubes, stirring, performing ultrasonic treatment in an ultrasonic cell disruption system, and centrifuging so as to carbon nanotube dispersion; drying polyamide, adding the polyamide into the high-speed mixer, spraying white oil onto the surface of polyamide 6 under spray conditions, and mixing at a high speed; and adding the previous obtained materials, mixing at the high speed, adding the materials into a twin-screw extruder for granulating, drying, thereby obtaining the composite material.

Owner:阜阳三环水泥制品有限公司

Preparation method of inorganic mineral material modified inorganic silicon resin

InactiveCN112724718AGood compatibilityImprove film formationAntifouling/underwater paintsPaints with biocidesEmulsionHydrophobe

The invention discloses a preparation method of inorganic mineral material modified inorganic silicon resin, which comprises the following steps: putting a silica sol solution with the pH value of 8-11 into a reaction kettle, heating to 50-80 DEG C, and continuously stirring; dropwise adding a hydrophilic organic silicon monomer accounting for 1.5%-3% of the mass of the silica sol solution, keeping the temperature in the step S1 unchanged, and reacting for 3-4 hours to finish copolymerization; reducing the temperature to 50-60 DEG C, dropwise adding 1-3% of hydrophobic organic silicon monomer, reacting for 5-6 hours, and finishing copolymerization again; adding flaky or acicular inorganic mineral powder accounting for 5%-20% of the mass of the silica sol solution into the resin obtained in the step S3, increasing the rotating speed to 500-1000 revolutions per minute, and continuously reacting for 1-2 hours; and through the arrangement, the nano inorganic silicon resin prepared by the method has good film-forming property and hydrophobicity, can be used for preparing a pure inorganic building coating, and can also be compounded with a common emulsion to produce an inorganic building coating meeting industrial standard provisions.

Owner:济南百士多高分子化工技术有限公司

Whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and manufacturing method thereof

InactiveCN102969064AExcellent light aging performanceGood physical and mechanical propertiesPower cablesCable/conductor manufactureCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof ethylene-propylene rubber insulation power cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; a plurality of insulation wire cores are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 parts of TAIC, 0.5-0.8 parts of DCP (Dicumyl Peroxide), 0.3 -0.6 part of Ager MB, 0.1-0.2 parts of anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid; 1-1.5 parts of a rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of ultraviolet absorbent UV-326, and 0.1-0.3 parts of coupling agent A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

Fabrication technology of wear-resistant hammer

Provided is a fabrication technology of a wear-resistant hammer. The hammer is composed of two materials, a hammer handle is made of low carbon alloy steel, a hammer head is made of high-chromium iron, an upper part of a prepared hammer handle is placed in a slag bath of a water-cooling crystallizer, and a lower part of the hammer handle is located at the bottom of the crystallizer. The method comprises the following steps: (1) slag is melted into liquid state, and (2) liquid-state slag is cast into the hammer head. According to the fabrication technology of the wear-resistant hammer, product metal purity and product combined strength are high, crystal structure is compact, and technical process is stable and easy to control.

Owner:江苏亚洲气体设备有限公司

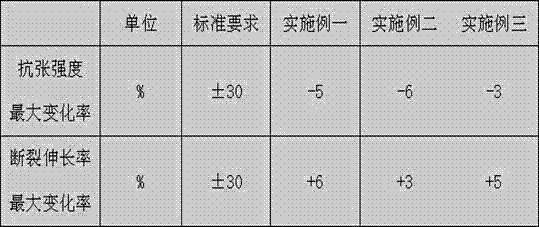

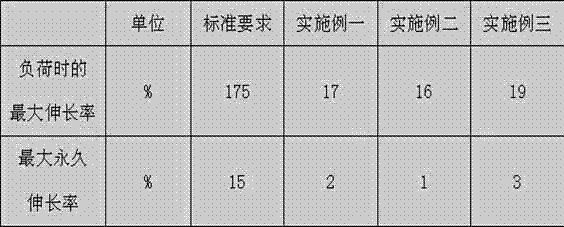

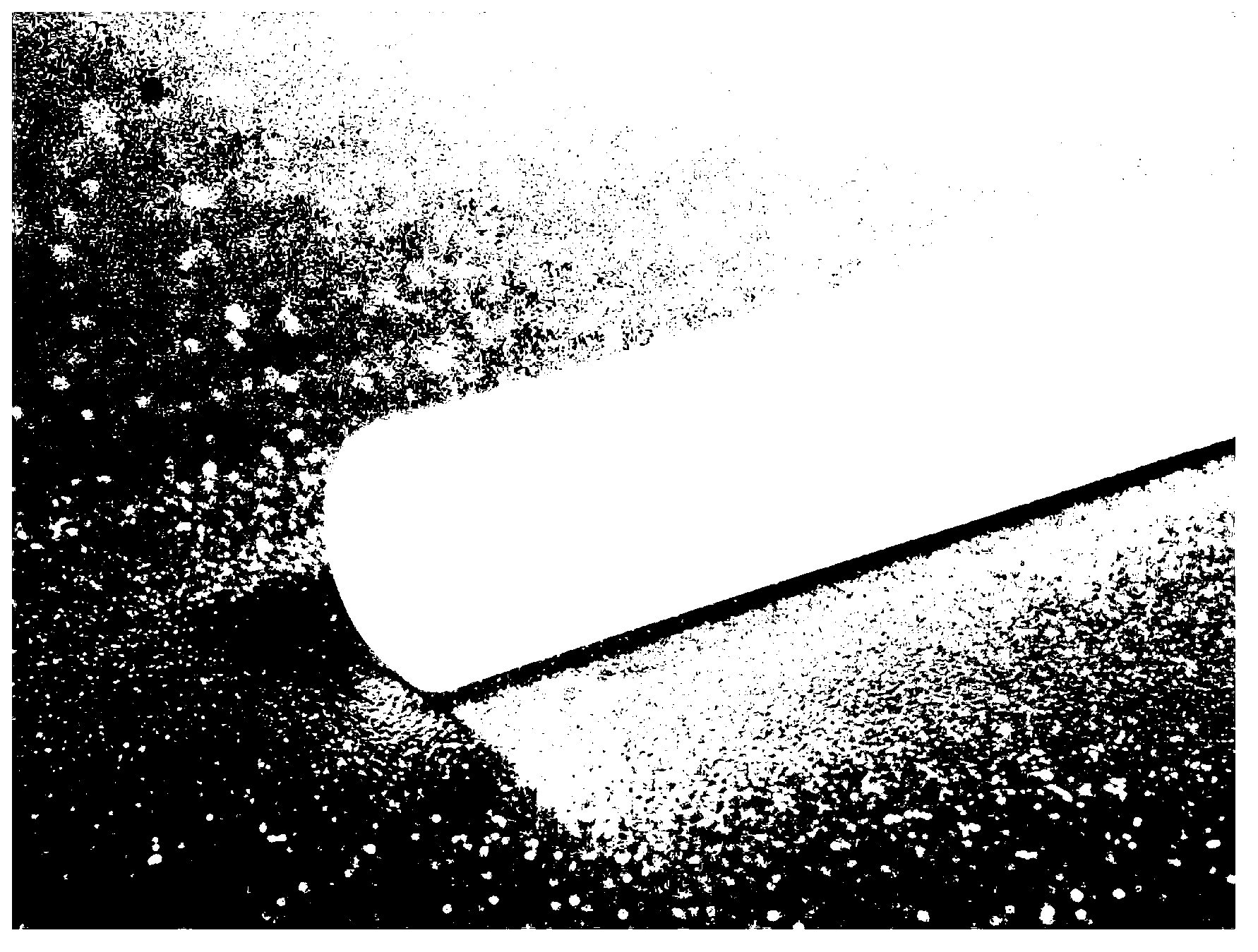

Preparation method of high-hardness Cu-SiC nanometer compound plating layer and special device thereof

InactiveCN101717977BHigh content of nanoparticlesEvenly distributedElectrolytic coatingsNanoparticleCrystal structure

Owner:HUAIHAI INST OF TECH

Insulating positioning ceramic kit material and preparation process thereof

The invention discloses an insulating positioning ceramic kit material and a preparation process thereof, and relates to the technical field of ceramic materials. The insulating positioning ceramic kit material disclosed by the invention is prepared from the following raw materials in parts by weight: 40-70 parts of zirconium oxide, 10-20 parts of aluminum oxide fiber, 5-10 parts of copper oxide,5-10 parts of iron oxide, 5-10 parts of yttrium oxide, 2-5 parts of niobium diselenide, 2-5 parts of graphite, 0.5-1 part of water glass and 0.1-0.5 part of defoaming agent, wherein the defoaming agent is polydimethylsiloxane. In addition, the invention also provides a preparation method of the insulation positioning ceramic kit material. The insulating positioning ceramic kit material disclosed by the invention is non-conductive and non-magnetic, has high strength, high toughness and high wear resistance, is not easy to deform, wear and break when working under a high-temperature condition, prolongs the service life of a positioning ceramic kit, and is simple in preparation process and relatively low in processing cost.

Owner:HUNAN PROVINCE XINHUA COUNTY LINHAI CERAMICS CO LTD

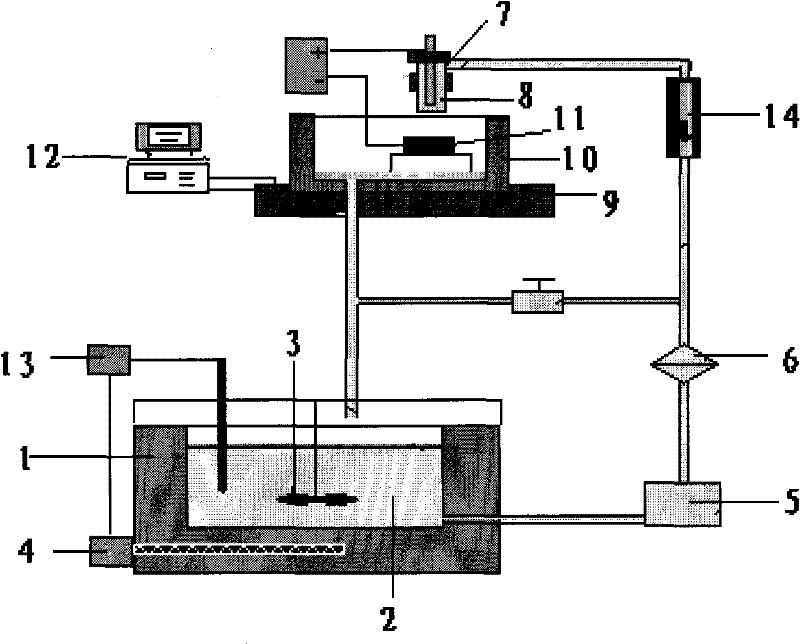

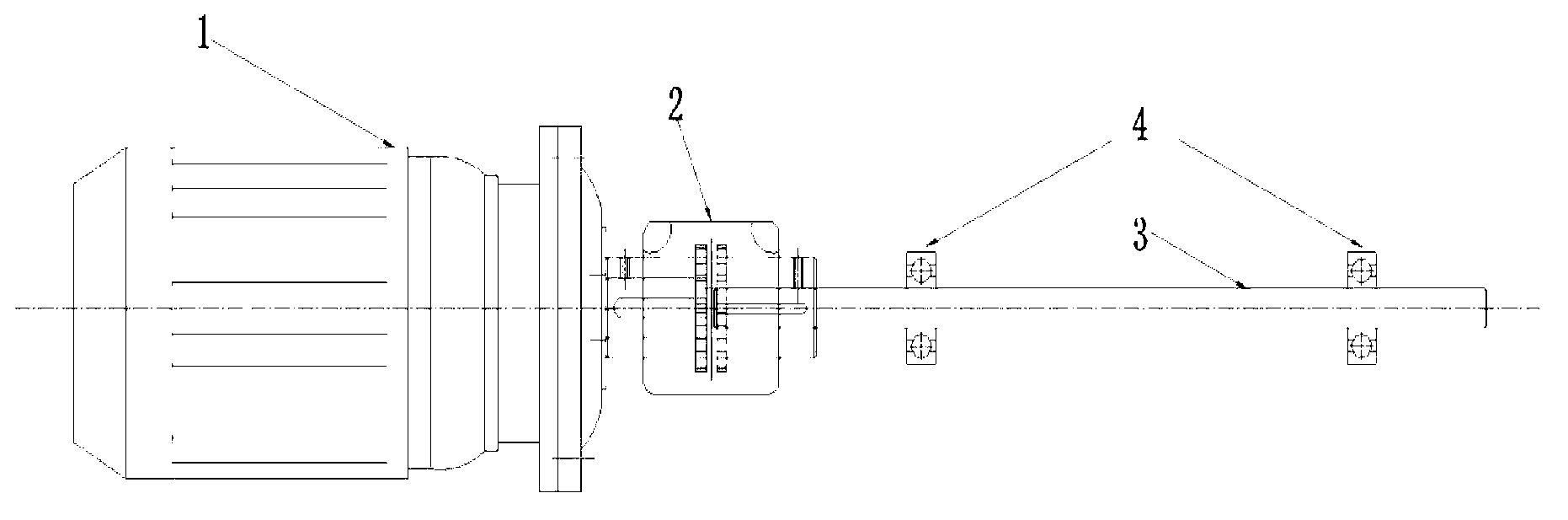

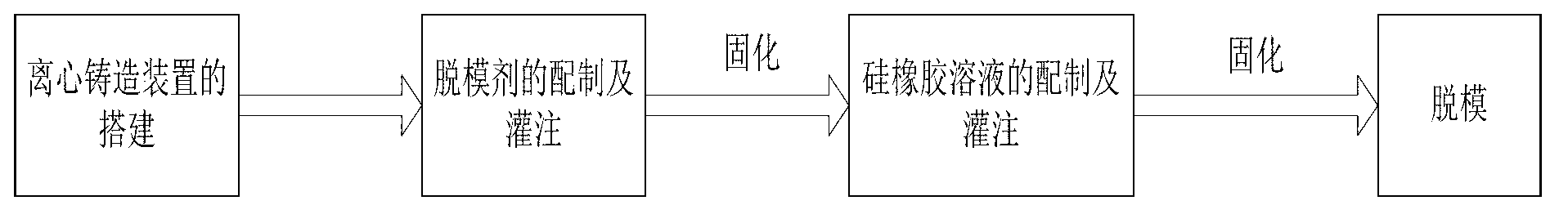

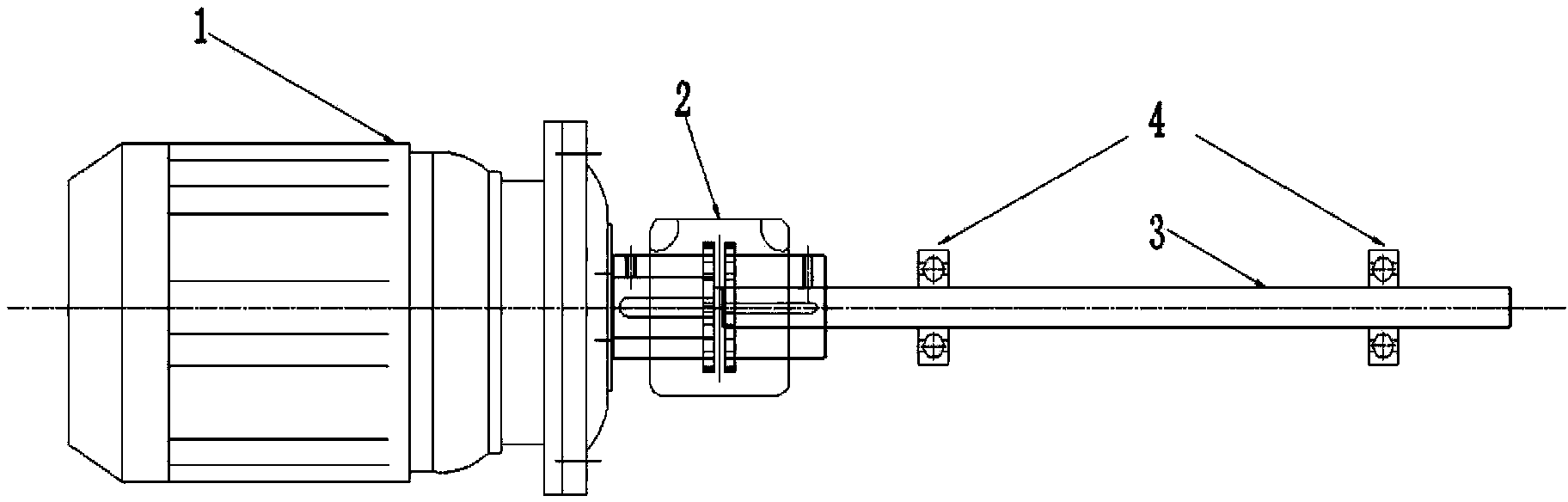

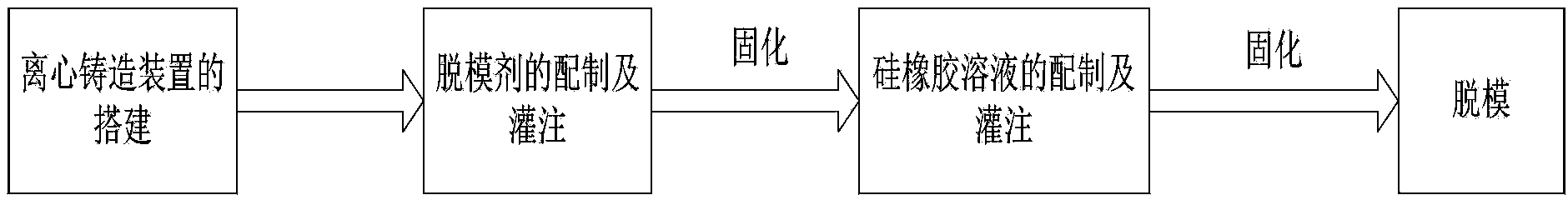

Improvement method for centrifugal casting silicon tube

The invention relates to an improvement method for a centrifugal casting silicon tube. The improvement method for the centrifugal casting silicon tube comprises the steps of (1) constructing a centrifugal casting device comprising a motor, a coupler, a stainless steel precise tube for casting and molding and a bearing; (2) preparing a mold release, immersing granulous gelatin with certain quantity in purified water for 5 hours, putting a container for containing the gelatin into a water bath after the gelatin fully absorbs moisture and expands, and heating until the gelatin is dissolved completely; (3) pouring the mold release; (4) preparing an RTV (room temperature vulcanization) silicon solution; (5) pouring and curing the silicon solution, namely, pouring a certain amount of silicon mixed solution after volume defoaming into the stainless steel precise tube, and under room temperature, driving the stainless steel tube by the high-speed rotation of the motor until the mixed solution is cured; and (6) demolding, and taking out the molded silicon tube after the cured gelatin is dissolved at the temperature of 35 DEG C. According to the invention, the problem of demolding of silicon tube machining is solved well, and the required silicon tube is manufactured effectively.

Owner:UNIV OF SCI & TECH OF CHINA

Environment-friendly glass fiber-magnesium cement board and preparation method thereof

The invention relates to an environment-friendly glass fiber-magnesium cement board and a preparation method thereof. The environment-friendly glass fiber-magnesium cement board comprises, by weight, 20 to 30% of MgO, 20 to 30% of MgCl2, 0.1 to 0.5% of a composite water reducer, 30 to 50% of fly ash, 1.2 to 2% of an exciting agent, 6 to 10% of wood chip and 6 to 10% of perlite. According to the invention, the water reducer and exciting agent are used in combination to excite activity of fly ash, so the strength of the whole board is improved, and in particular, later strength of the board is improved by nearly 20%; the concept of a four-component gelling system is provided for the first time, and the complex four-component gelling system SiO2-MgO-MgCl2-H2O exists in the process of hydration of magnesium cement; formation of novel crystal phases provides sufficient mechanical support; eventual addition of fly ash enables silicon-containing mine dregs to pose decisive influence on the strength of the fireproof board; disadvantages of original boards are overcome, an interior crystal structure is more compact, and the prepared board has the advantages of high strength, no overflowing of brine water, warping resistance, good resistance to freezing and thawing, etc.; and the preparation method is a green technology with development prospects.

Owner:SCFM MATERIAL TECH SHANGHAI

Whitening ultraviolet-proof non-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969042AExcellent light aging performanceGood physical and mechanical propertiesInsulated cablesCable/conductor manufactureCopper conductorInsulation layer

The invention relates to a whitening ultraviolet-proof non-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a 0.35-2.5mm<2> tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted groups; all the twisted groups are stranded to the right to form a cable core; and then an inner lining layer is extruded, a copper alloy wire weaving armor layer is coated, and an outer sheath is extruded successively. The insulation layer is prepared from the following raw material components: 12 parts of Keltan5508, 8 parts of Keltan21, 0.4-0.6 parts of TAIC, 0.5-0.8 parts of DCP (Dicumyl Peroxide), 0.3 -0.6 parts of Ager MB, 0.1-0.2 parts of an anti-aging agent 2246, 0.8-1.2 parts of oxidation zinc, 0.1-0.3 parts of stearic acid, 1-1.5 parts of a rutile-type titanium dioxide, 10-12 parts of lightweight calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of 38# cylinder oil, 2-3 parts of vapor-phase-method hydrated silica, 0.05-0.1 parts of UV-326, and 0.1-0.3 parts of A-174. The insulation layer of the cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

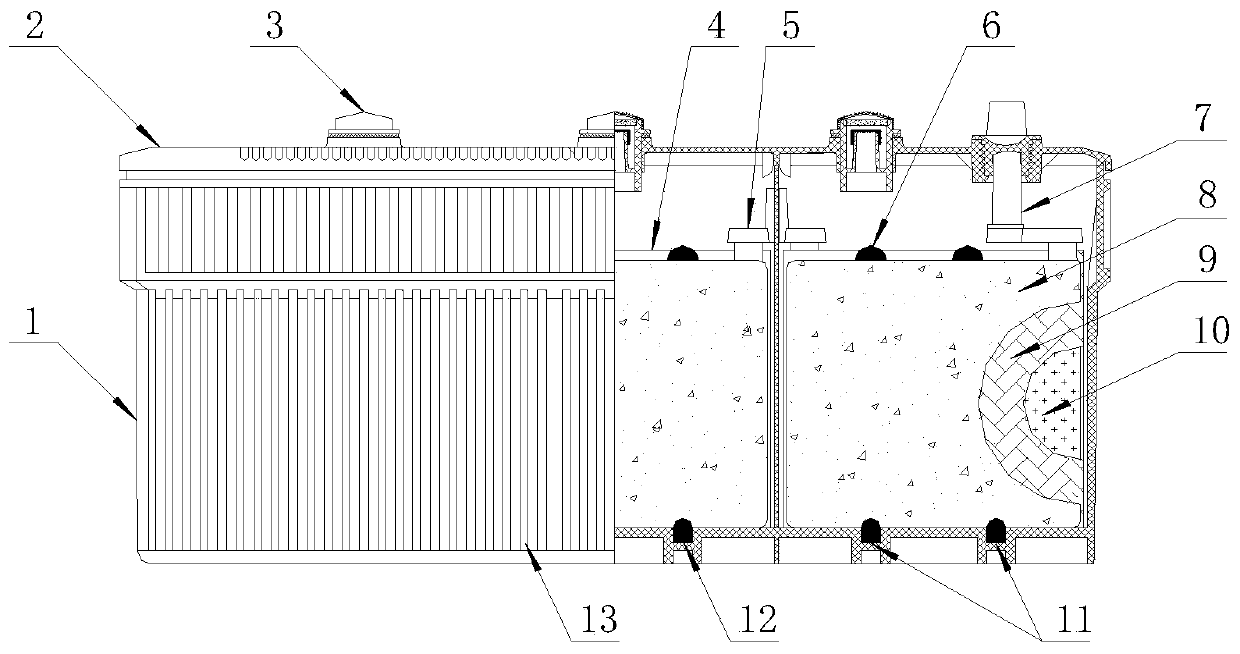

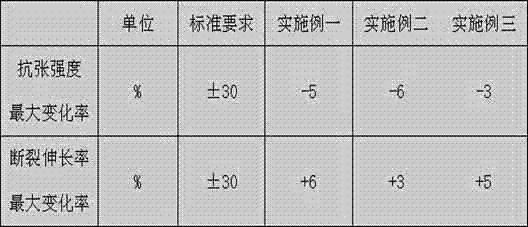

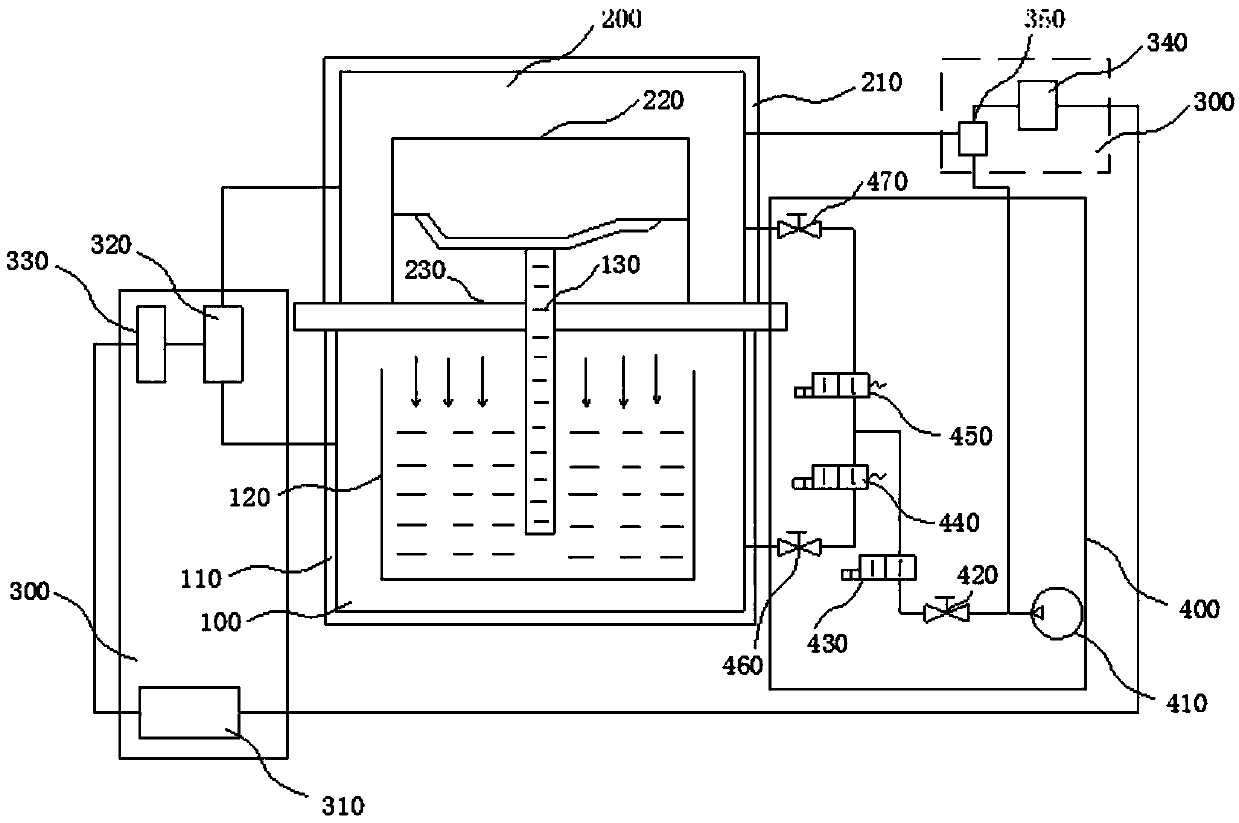

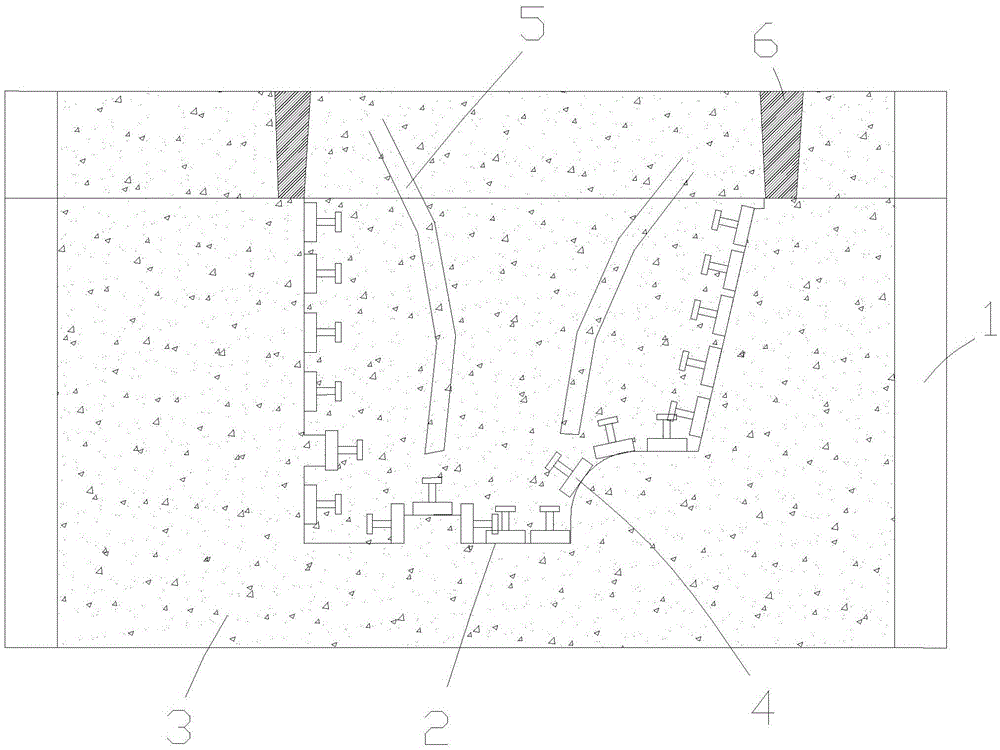

Counter-pressure casting control system for aluminum alloy hubs

The invention discloses a counter-pressure casting control system for aluminum alloy hubs. The system comprises a lower furnace chamber, an upper furnace chamber, an electrical control module and an air intake and exhaust control module. Stable air intake is performed on the upper furnace chamber and the lower furnace chamber simultaneously by the aid of an air pump and a flow regulating valve inthe system, an electrical valve positioner is controlled by the aid of a programmable logic controller (PLC), then a pneumatic proportional regulating valve is controlled, air exhaust of the upper furnace chamber is realized, the high-pressure field and the differential pressure are formed in the upper furnace chamber and the lower furnace chamber, the dendrite feeding effect is improved by the aid of the pressure field, the mechanical properties of castings are effectively improved, the castings have the good adherence to a cavity under the effect of the pressure field, the cooling speed is higher, and the crystal structure is denser; under the effect of the pressure field, the solubility of hydrogen in molten aluminum is effectively increased, separation of the hydrogen as gas pinholes during solidification of the castings is restrained, and the pinholes are reduced obviously; and the counter pressure is formed by the pressure field in the cavity, spraying spattering during filling of molten metal is restrained, and the stable filing effect is better.

Owner:东风精密铸造安徽有限公司

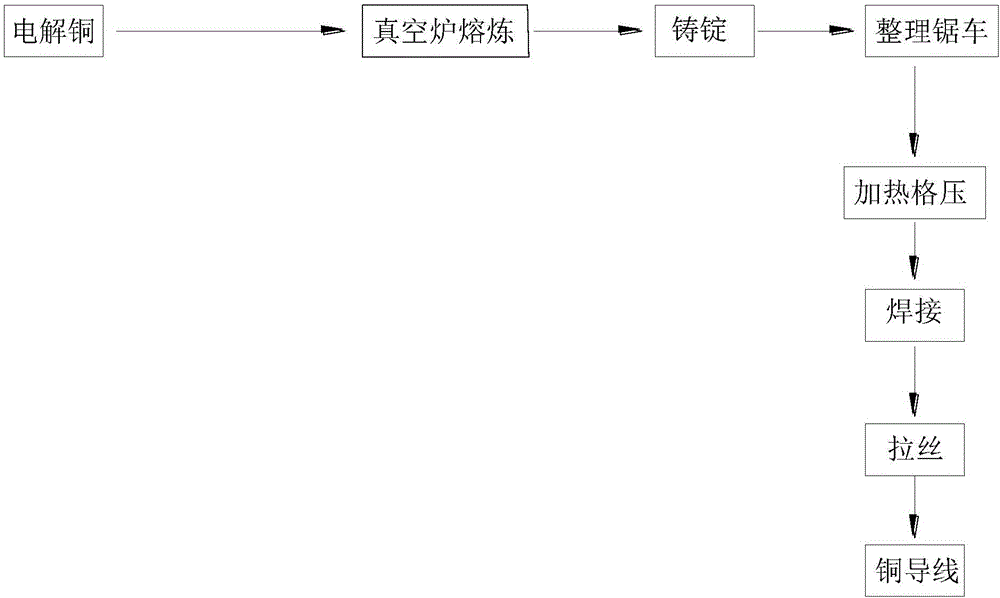

Novel high-conductivity silver-free copper alloy material

The invention discloses a novel high-conductivity silver-free copper alloy material which comprises, in weight percentage, 0.5%-1% of manganese, 0.01%-0.05% of cerium, 0.01%-0.05% of lanthanum, 0.002%-0.005% of lithium and the rest copper. The material has the advantages that the material is low in resistance and high in conductivity and reaches or closes to conductivity of silver. A silver-free copper alloy is a new energy-saving material of copper for electrical engineering and a new essential advanced function material in the field of future military industries and equipment manufacturing industries, and the silver-free copper alloy can replace the silver to use in part fields such as spaceflight, aviation, navigation, submarine and naval ship manufacturing, military equipment light weight, high-end electrical engineering, high-end electric products, energy-saving transformers and motors, wind energy, solar energy, electricity vehicles, new-energy electric vehicles or superconductivity.

Owner:何国良 +1

Improvement method for centrifugal casting silicon tube

InactiveCN103057023BSolve the demoulding problemEfficient manufacturingCoatingsTubular articlesWater bathsVulcanization

The invention relates to an improvement method for a centrifugal casting silicon tube. The improvement method for the centrifugal casting silicon tube comprises the steps of (1) constructing a centrifugal casting device comprising a motor, a coupler, a stainless steel precise tube for casting and molding and a bearing; (2) preparing a mold release, immersing granulous gelatin with certain quantity in purified water for 5 hours, putting a container for containing the gelatin into a water bath after the gelatin fully absorbs moisture and expands, and heating until the gelatin is dissolved completely; (3) pouring the mold release; (4) preparing an RTV (room temperature vulcanization) silicon solution; (5) pouring and curing the silicon solution, namely, pouring a certain amount of silicon mixed solution after volume defoaming into the stainless steel precise tube, and under room temperature, driving the stainless steel tube by the high-speed rotation of the motor until the mixed solution is cured; and (6) demolding, and taking out the molded silicon tube after the cured gelatin is dissolved at the temperature of 35 DEG C. According to the invention, the problem of demolding of silicon tube machining is solved well, and the required silicon tube is manufactured effectively.

Owner:UNIV OF SCI & TECH OF CHINA

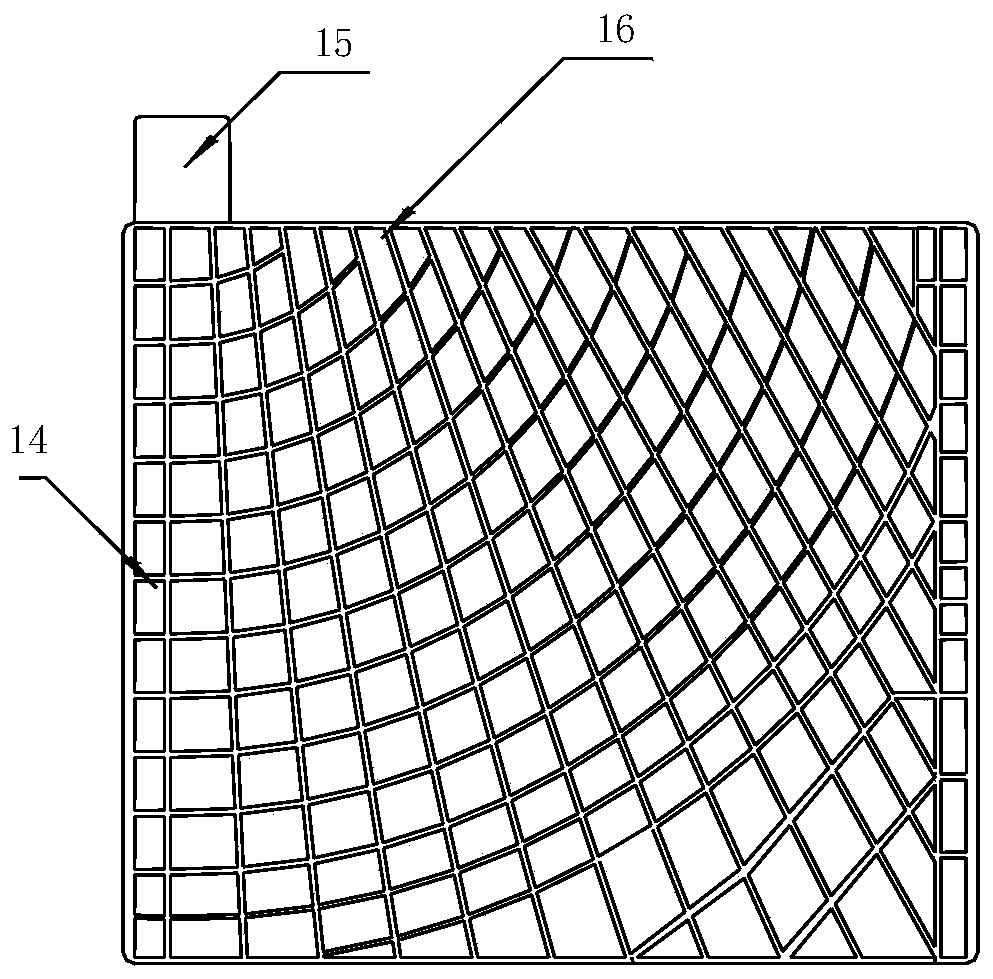

The structure of the upper box for casting refrigerator inner tank mold based on v-method

ActiveCN104525857BReduce casting defectsImprove product qualityFoundry mouldsFoundry coresDry sandCasting mold

The invention discloses an upper box structure for a refrigerator inner liner mold on the basis of V-process casting. The upper box structure is characterized by comprising a vacuum sand box, wherein a convex-mold model is formed in the vacuum sand box; gaps between the concave-mold model and the vacuum sand box are filled with dry sand; cold iron blocks are arranged on the inner wall of the concave-mold model and are uniformly distributed on the inner wall of the concave-mold model; a negative-pressure pipeline is arranged in an inner cavity of the concave-mold model; a part between the negative-pressure pipeline and the inner wall of the concave-mold model is filled with dry sand; and the two sides of the upper end of the concave-mold model are provided with casting system models. The upper box structure disclosed by the invention is simple in structure and reasonable in design; by adoption of the upper box structure, the casting defects of a casting piece is reduced, the production quality of a casting piece product is greatly improved, and the qualification rate of the casting piece product is greatly increased.

Owner:CHUZHOU JINNUO INDAL

Continuous casting and continuous punching technology for grid

PendingCN113351645AExtended penetration corrosion resistanceLong cycle lifeWork treatment devicesMetal rolling arrangementsPunchingThin slab

The invention relates to the technical field of storage battery grid manufacturing, and discloses a continuous casting and continuous punching technology for a grid. The continuous casting and continuous punching technology for the grid is characterized by comprising the following steps: conducting proportioning according to the components of the grid, and separately preheating tin, aluminum, calcium, antimony and lead at 200 DEG C for 0.5-1.5 hours; and heating and melting the preheated lead by using a crucible resistance furnace. By adding the alloy elements of antimony, calcium and the like and adopting a cast rolling technology, compared with a grid formed by direct casting, the continuous casting and continuous punching technology for the grid has the advantages that a casting blank is firstly cast, then the casting blank is calendered to form a thin plate, then the grid is finally formed through technologies of punching and the like, rolling passes are correspondingly increased after a rough rolling process is added, a reasonable rolling process where the thick blank is subjected to multi-pass rolling is formed, the thickness ratio of a raw material to a finished product is increased, and the total compression ratio in the rolling process is increased, so that improvement of the internal metal structure of the finished product, grain refinement and the compactness of the crystal structure are facilitated, thus the mechanical performance of the product is improved, the penetration corrosion resistance of the grid is improved, and the cycle life is prolonged.

Owner:山东久力新能源集团有限公司

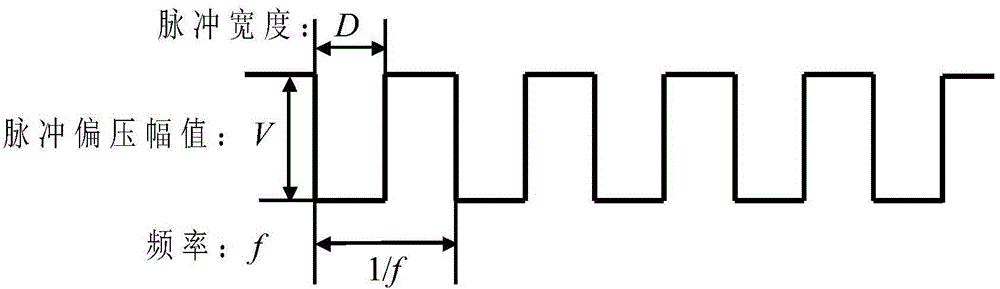

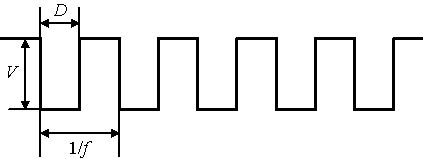

Arc ion plating method combined with multi-stage magnetic field straight tube magnetic filtering and pulse bias

ActiveCN103276362BIncrease the areaImprove mechanical propertiesVacuum evaporation coatingSputtering coatingSingle stageStraight tube

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

The metal mold process of casting refrigerator liner mold casting billet based on v-method

ActiveCN104525855BHigh degree of mechanizationReduce labor intensityFoundry mouldsMoulding machinesCasting defectMetal mold

Owner:CHUZHOU JINNUO INDAL

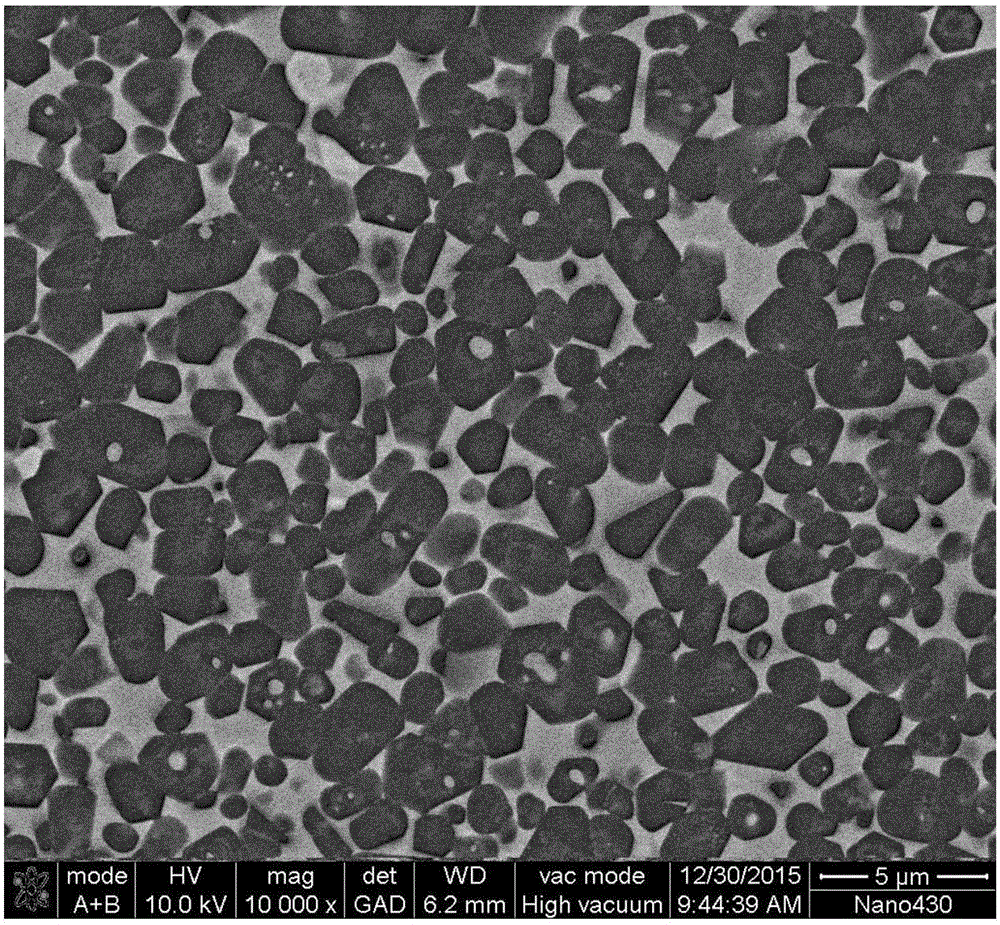

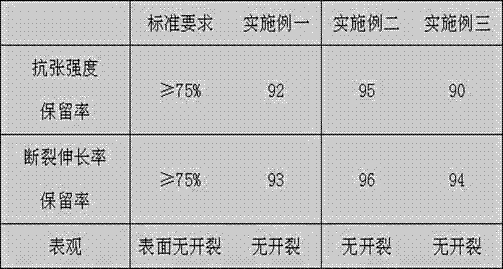

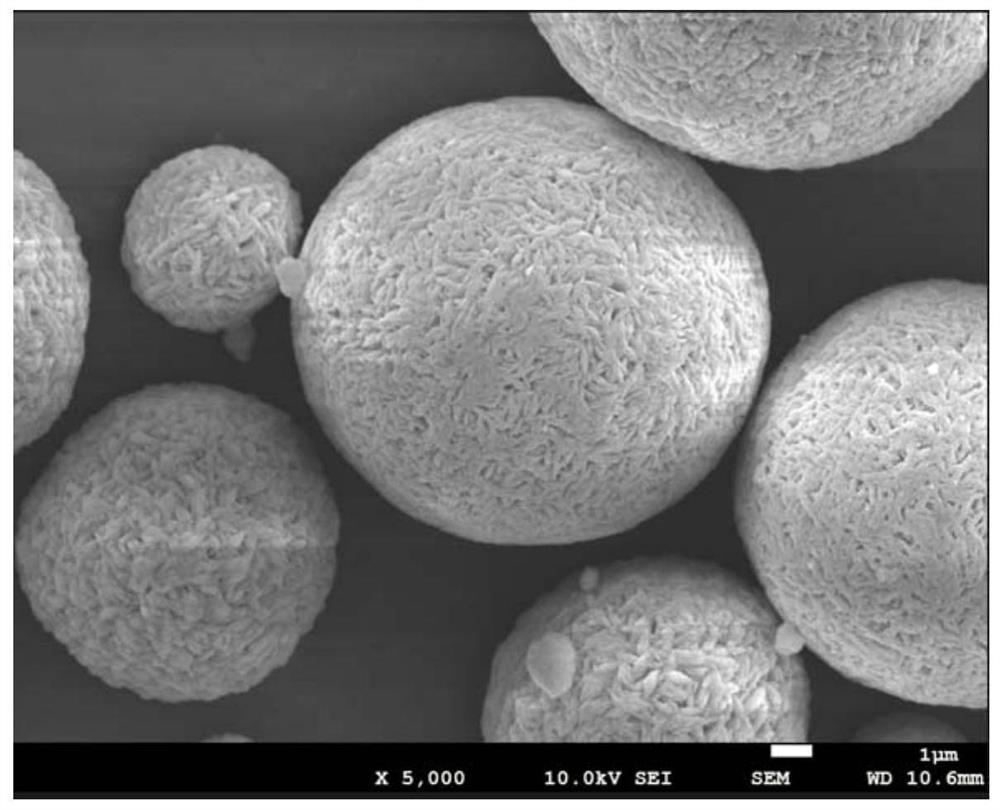

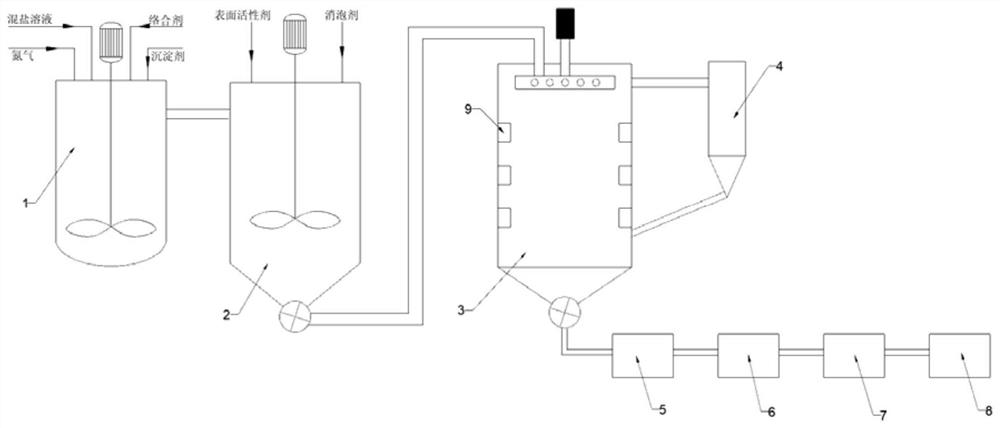

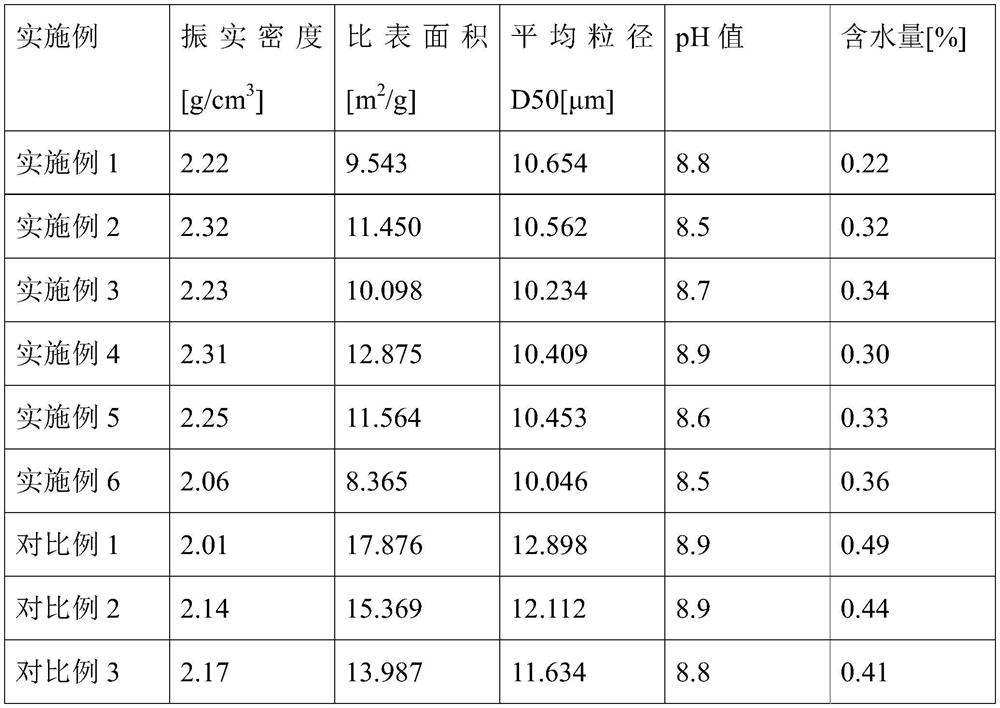

High-nickel quaternary precursor material as well as preparation method and preparation system thereof

PendingCN112225262AReduce surface tensionDense crystal structureSecondary cellsPositive electrodesDefoaming AgentsActive agent

The invention provides a high-nickel quaternary precursor material as well as a preparation method and a preparation system thereof. The preparation method comprises the steps of mixing and reacting amixed salt solution, a complexing agent and a precipitator to obtain mixed slurry, and mixing the mixed slurry with a surfactant and a defoaming agent to obtain a precursor solution; and carrying outspray granulation on the precursor solution to obtain the quaternary precursor material. By adding the surfactant and the defoaming agent into the mixed slurry, crystal nucleus particles can be further formed, the surfactant reduces the surface tension among the particles, and dense crystal form particles can be formed. Meanwhile, gas is mixed in the stirring process of the mixed slurry, and thedefoaming agent is beneficial to rapid discharge of the gas, so that the mixed slurry system is more uniform, and the uniformity of particle element components is ensured.

Owner:中科(马鞍山)新材料科创园有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com