Preparation method of inorganic mineral material modified inorganic silicon resin

A technology of inorganic mineral materials and inorganic silicone resins, which can be applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., and can solve the problems of excessive film formation, poor storage stability, and poor compatibility of potassium silicate inorganic coatings and other problems, to achieve the effect of improving film forming and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

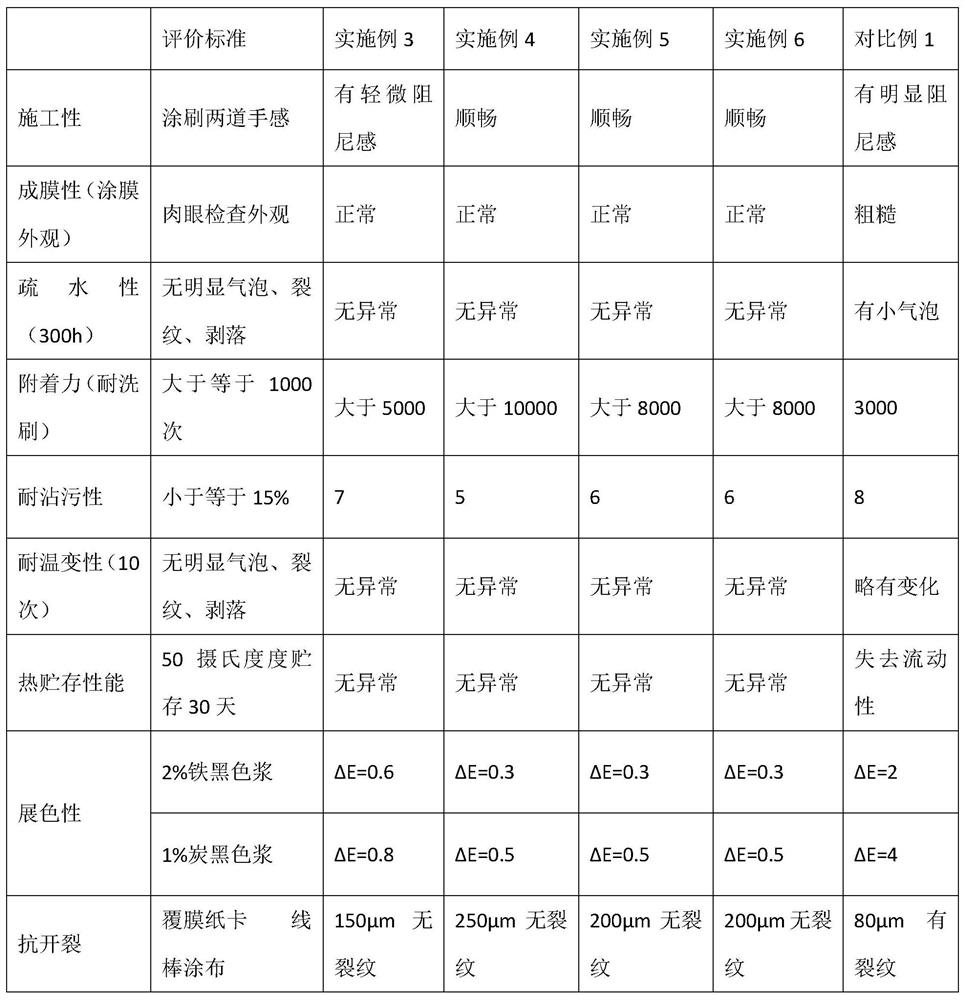

Examples

Embodiment 1

[0034] Embodiment 1: a kind of preparation method of inorganic mineral material modified inorganic silicone resin, comprises the following steps:

[0035] S1. Place the silica sol solution with a pH value of 8-11 in the reaction kettle and heat up to 50-80°C; the silica sol solution is selected from the LS-30 silica sol solution of Zhejiang Yuda Chemical Co., Ltd., SiO 2 The content is 30%; continue to stir, and the speed is 60-80 rpm;

[0036] S2. Add dropwise 1.5%-3% of the mass of the silica sol solution with a hydrophilic organosilicon monomer; the hydrophilic organosilicon monomer is γ-glycidyl etheroxypropyltrimethoxysilane and or γ-form Acryloyloxytrimethoxysilane; keep the temperature in S1 constant, and react for 3-4h to complete the copolymerization;

[0037] S3. Lower the temperature to 50-60°C, add 1-3% hydrophobic silicone monomer dropwise; the hydrophobic silicone monomer is methyltrioxysilane and or isobutyltrioxysilane; Increase to 80-120 rpm, react for 5-6h,...

Embodiment 2

[0039] Embodiment 2: An inorganic mineral material modified inorganic silicone resin. It is prepared by the method of Example 1. When in use, building emulsion can be added as a film-forming substance to improve film-forming properties, and one or more of titanium dioxide, kaolin and heavy calcium carbonate can be added as pigments and fillers.

Embodiment 3

[0040] Embodiment 3: A kind of nano inorganic silicone resin modified by organosilicon monomer, prepared by the following method:

[0041] S1. Place the silica sol solution with a pH value of 8-11 in the reaction kettle and heat up to 50-80°C; the silica sol solution is selected from the LS-30 silica sol solution of Zhejiang Yuda Chemical Co., Ltd., SiO 2 The content is 30%; continue to stir, and the speed is 60-80 rpm;

[0042] S2, drop the hydrophilic organosilicon monomer of 1.5% of the mass of the silica sol solution; the hydrophilic organosilicon monomer is γ-glycidyl etheroxypropyltrimethoxysilane; keep the temperature in S1 constant , the reaction is 3-4h to complete the copolymerization;

[0043] S3. Lower the temperature to 50-60°C, add 1% hydrophobic silicone monomer dropwise; the hydrophobic silicone monomer is methyltrioxysilane; increase the rotation speed to 80-120 rpm, and react for 5-6 hours , to complete the copolymerization again;

[0044] S4, adding 5% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com