Inner wall putty with antibacterial and odor removing effects and preparation method thereof

A technology for interior wall putty and deodorization, applied in the direction of filling slurry, etc., can solve the problems of lack of indoor environment influence of interior wall putty, achieve the effects of inhibiting growth and reproduction, improving surface gloss and surface smoothness, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

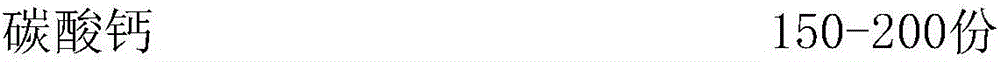

[0028] An antibacterial and deodorizing interior wall putty is prepared from the following components in parts by weight:

[0029]

[0030]

[0031] Among them, the fineness particle diameter of calcium carbonate is 400-500 mesh, the fineness particle diameter of titanium dioxide is 500-1000 mesh, the fineness particle diameter of cellulose is 800-1000 mesh, the fineness particle diameter of ash calcium powder is 400-500 mesh, the fineness particle size of white cement is 300-400 mesh, the fineness particle size of expanded perlite is 600-800 mesh, and the fineness particle size of charcoal is 300-500 mesh;

[0032] The preparation method of this interior wall putty comprises the steps:

[0033] 1) Grinding calcium carbonate to 400-500 mesh, titanium dioxide to 500-1000 mesh, cellulose to 800-1000 mesh, ash calcium powder to 400-500 mesh, white cement to 300-400 mesh, The expanded perlite is ground to 600-800 mesh, and the charcoal is ground to 300-500 mesh;

[0034] 2...

Embodiment 2

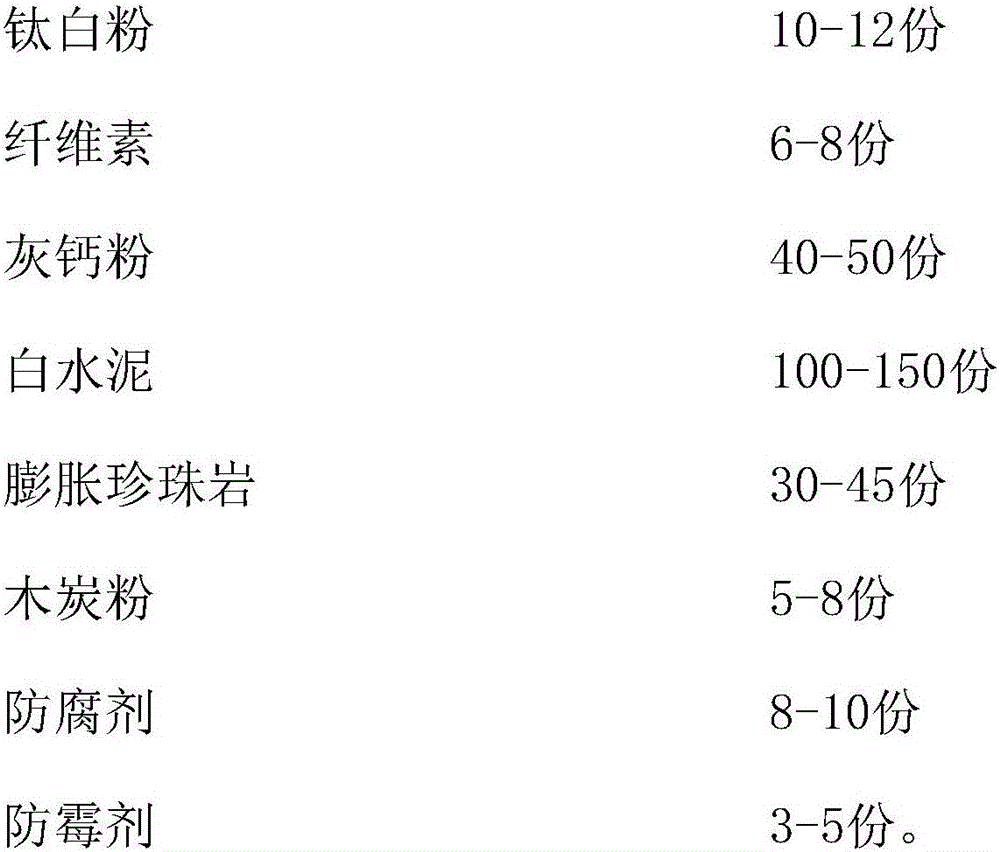

[0038] An antibacterial and deodorizing interior wall putty is prepared from the following components in parts by weight:

[0039]

[0040] Among them, the fineness particle diameter of calcium carbonate is 400-500 mesh, the fineness particle diameter of titanium dioxide is 500-1000 mesh, the fineness particle diameter of cellulose is 800-1000 mesh, the fineness particle diameter of ash calcium powder is 400-500 mesh, the fineness particle size of white cement is 300-400 mesh, the fineness particle size of expanded perlite is 600-800 mesh, and the fineness particle size of charcoal is 300-500 mesh;

[0041] The preparation method of this interior wall putty comprises the steps:

[0042] 1) Grinding calcium carbonate to 400-500 mesh, titanium dioxide to 500-1000 mesh, cellulose to 800-1000 mesh, ash calcium powder to 400-500 mesh, white cement to 300-400 mesh, The expanded perlite is ground to 600-800 mesh, and the charcoal is ground to 300-500 mesh;

[0043] 2) According ...

Embodiment 3

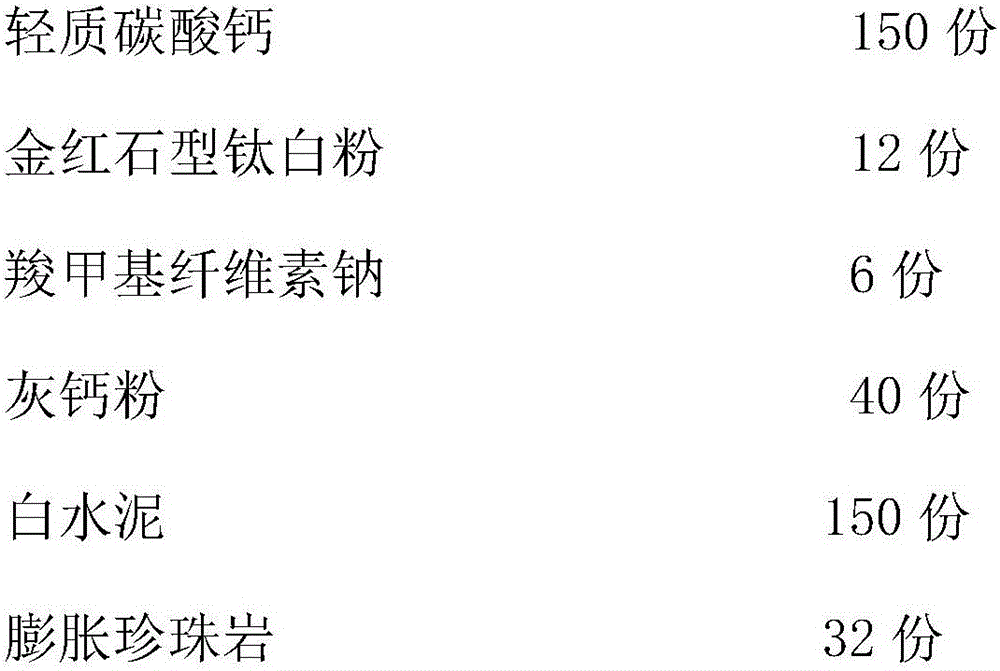

[0047] An antibacterial and deodorizing interior wall putty is prepared from the following components in parts by weight:

[0048]

[0049] Among them, the fineness particle diameter of calcium carbonate is 400-500 mesh, the fineness particle diameter of titanium dioxide is 500-1000 mesh, the fineness particle diameter of cellulose is 800-1000 mesh, the fineness particle diameter of ash calcium powder is 400-500 mesh, the fineness particle size of white cement is 300-400 mesh, the fineness particle size of expanded perlite is 600-800 mesh, and the fineness particle size of charcoal is 300-500 mesh;

[0050] The preparation method of this interior wall putty comprises the steps:

[0051] 1) Grinding calcium carbonate to 400-500 mesh, titanium dioxide to 500-1000 mesh, cellulose to 800-1000 mesh, ash calcium powder to 400-500 mesh, white cement to 300-400 mesh, The expanded perlite is ground to 600-800 mesh, and the charcoal is ground to 300-500 mesh;

[0052] 2) According ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com