Novel high-conductivity silver-free copper alloy material

A silver-copper alloy and high-conductivity technology, which is applied in the field of new materials of high-conductivity silver-free copper alloys, can solve the problem of undensified copper crystal structure, and achieve the effects of compact crystal structure, low resistance and low resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A new material of high-conductivity silver-free copper alloy is composed of the following components by weight: 0.5% manganese, 0.01% cerium, 0.01% lanthanum, 0.002% lithium, and the rest is copper.

Embodiment 2

[0029] A new material of a high-conductivity silver-free copper alloy consisting of the following components by weight:

[0030] 1% manganese, 0.05% cerium, 0.05% lanthanum, 0.005% lithium, and the rest is copper.

Embodiment 3

[0032] A new material of a high-conductivity silver-free copper alloy consisting of the following components by weight:

[0033] 0.7% manganese, 0.03% cerium, 0.03% lanthanum, 0.003% lithium, and the rest is copper.

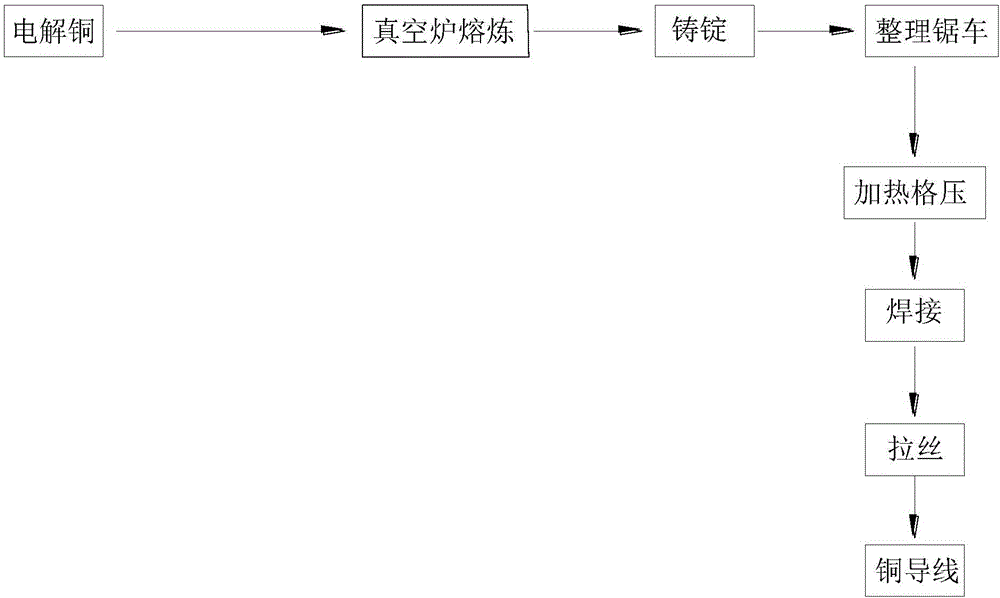

[0034] Another aspect of the present invention also discloses a method for preparing a high-conductivity silver-free copper alloy, comprising the following steps:

[0035] S1, select electrolytic copper with copper content of 99.99% as copper raw material;

[0036] S2, when the vacuum degree is -1P through the vacuum melting furnace, fill with argon to -0.6 to -0.3P;

[0037] S3, the copper is gradually melted after the moisture and residual gas in the heating furnace and the raw material are released;

[0038] S4, in the molten state of copper at 1150-1200 degrees, add 0.5-1% element manganese, 0.01-0.05% rare earth elements cerium and lanthanum, and 0.002%-0.005% lithium element. and other trace scattered elements, so as to completely remove impurities from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com