Superhard nanometer composite cutter and manufacturing method and application thereof

A nano-composite and manufacturing method technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of harsh cutting conditions, reduced processing efficiency, rough coating surface, etc., to achieve arc spot dispersion , Improve the processing performance, the effect of compact crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

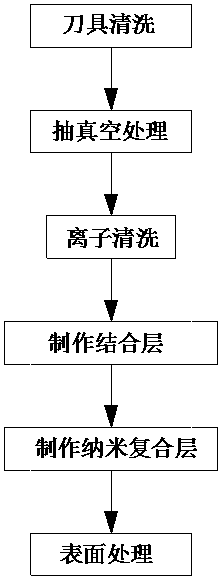

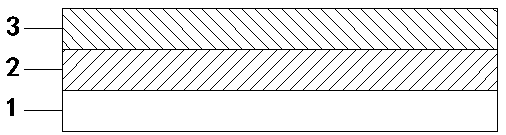

Method used

Image

Examples

experiment example

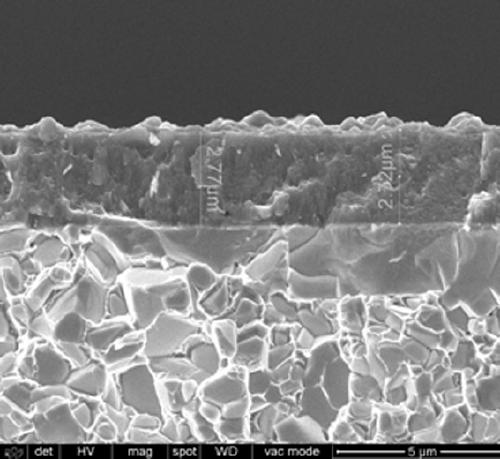

[0049] Experimental object: the new AlCrN nanocomposite coating in this example was selected for a comparative experiment with the existing traditional AlCrN nanocomposite coating.

[0050] Experimental method: The Vickers hardness of the new AlCrN nanocomposite coating and the AlCrN nanocomposite coating were tested respectively and the results were recorded.

[0051] The following table shows the test results of the new AlCrN nanocomposite coating and AlCrN nanocomposite coating:

[0052]

[0053] It can be seen from the above table that the novel AlCrN nanocomposite coating of the present invention has higher hardness than the existing AlCrN nanocomposite coating, so the novel AlCrN surface layer has high coating hardness and good wear resistance during use, and is suitable for many A high hardness metal material.

[0054] The beneficial effect of the present invention is that: due to the combination of high-temperature deposition and splitting arc used in the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com