Production process of high-strength and high-toughness as-cast ductile cast iron

A technology for ductile iron and production process, which is applied in the field of production process of as-cast high-strength and high-toughness ductile iron, can solve the problems of complex processing process and high production cost, and achieve the effects of simple process, low production cost and small ball diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1), material selection

[0036] Pig iron, low carbon steel and nodular cast iron are selected as smelting raw materials;

[0037] Wherein, the mass content of C in the pig iron is 4%, the mass content of Si is 1%, the mass content of Mn is 0.23%, the mass content of P≤0.05%, and the mass content of S≤0.04%;

[0038] The mass content of C in the low carbon steel is 0.2%, the mass content of Si is 0.35%, the mass content of Mn is 0.45%, the mass content of P is ≤0.03%, and the mass content of S is ≤0.03%;

[0039] The mass content of C in the ductile iron return charge is 3.45%, the mass content of Si is 2.85%, the mass content of Mn is 0.3%, the mass content of P is ≤0.04%, and the mass content of S is ≤0.03%;

[0040] (2) Ingredients

[0041] Raw material ratio: 500kg of pig iron, 374.5kg of low carbon steel, 100kg of ductile iron return charge, 8kg of 99% electrolytic copper; wherein the mass content of Mn in ferromanganese alloy is 64.5%, the mass content of Si is ...

Embodiment 2

[0051] (1), material selection

[0052] Pig iron, low carbon steel and nodular cast iron are selected as smelting raw materials;

[0053] Wherein, the mass content of C in pig iron is 4.3%, the mass content of Si is 0.78%, the mass content of Mn is 0.45%, the mass content of P≤0.05%, and the mass content of S≤0.04%;

[0054] The mass content of C in the low carbon steel is 0.4%, the mass content of Si is 0.25%, the mass content of Mn is 0.6%, the mass content of P≤0.03%, and the mass content of S≤0.03%;

[0055] The mass content of C in the ductile iron return charge is 3.9%, the mass content of Si is 2.6%, the mass content of Mn is 0.5%, the mass content of P is ≤0.04%, and the mass content of S is ≤0.03%;

[0056] (2) Ingredients

[0057] Raw material ratio: 562.5kg of pig iron, 200kg of low carbon steel, 195kg of ductile iron return charge, 3kg of 99.99% electrolytic copper; among them, the mass content of Mn in ferromanganese alloy is 65.5%, the mass content of Si is 1.2...

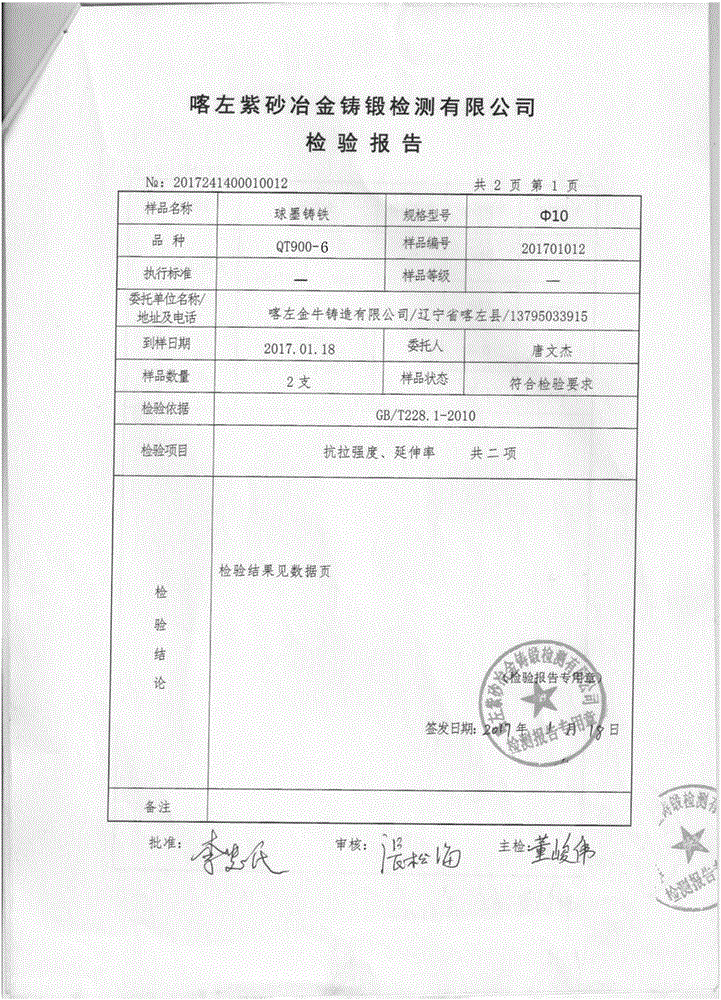

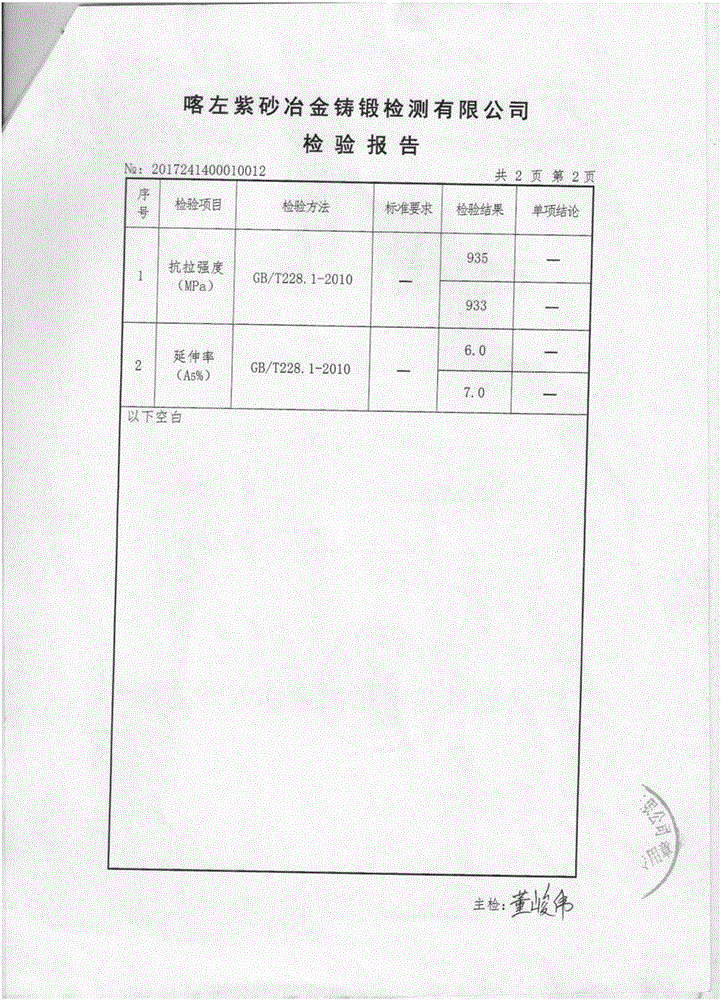

Embodiment 3

[0067] (1), material selection

[0068] The Q10 pig iron, low carbon steel and ductile iron produced by Benxi Iron and Steel Co., Ltd. are selected as smelting raw materials;

[0069] Wherein, the mass content of C in pig iron is 4.2%, the mass content of Si is 0.85%, the mass content of Mn is 0.3%, the mass content of P≤0.05%, and the mass content of S≤0.04%;

[0070] The mass content of C in the low carbon steel is 0.3%, the mass content of Si is 0.3%, the mass content of Mn is 0.5%, the mass content of P is ≤0.03%, and the mass content of S is ≤0.03%;

[0071] The mass content of C in the ductile iron return charge is 3.5%, the mass content of Si is 2.7%, the mass content of Mn is 0.4%, the mass content of P is ≤0.04%, and the mass content of S is ≤0.03%;

[0072] (2) Ingredients

[0073] Raw material ratio: 662kg of pig iron, 210kg of low carbon steel, 105kg of ductile iron return charge, 4kg of 99.9% electrolytic copper;

[0074] The mass content of Mn in the ferromang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com