Patents

Literature

41results about How to "High strength and high toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

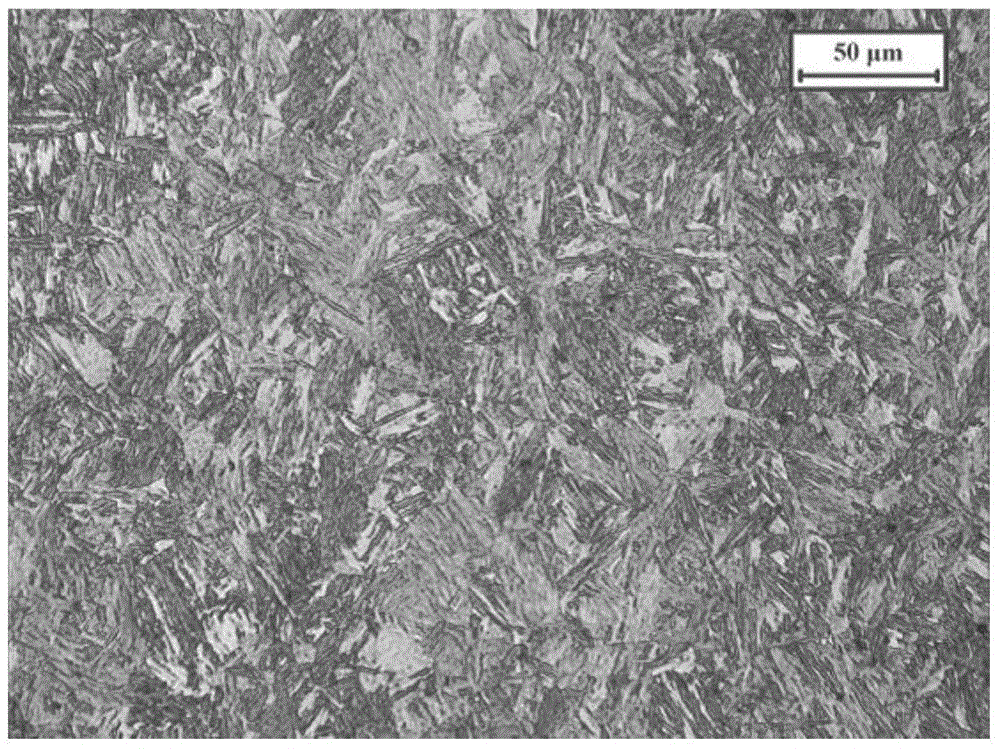

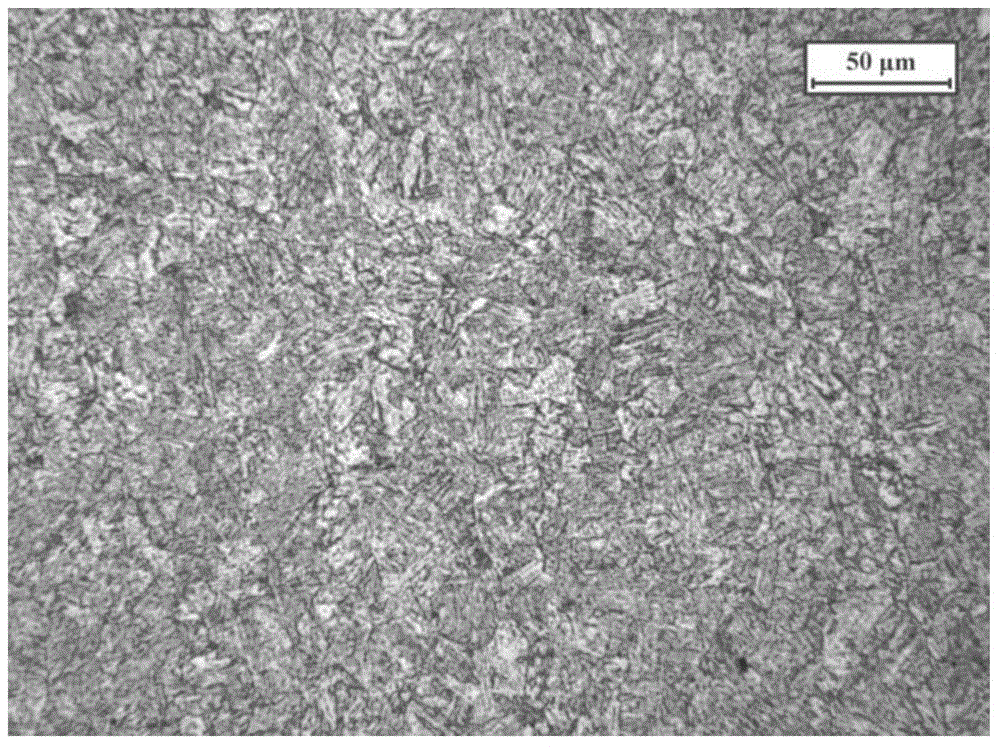

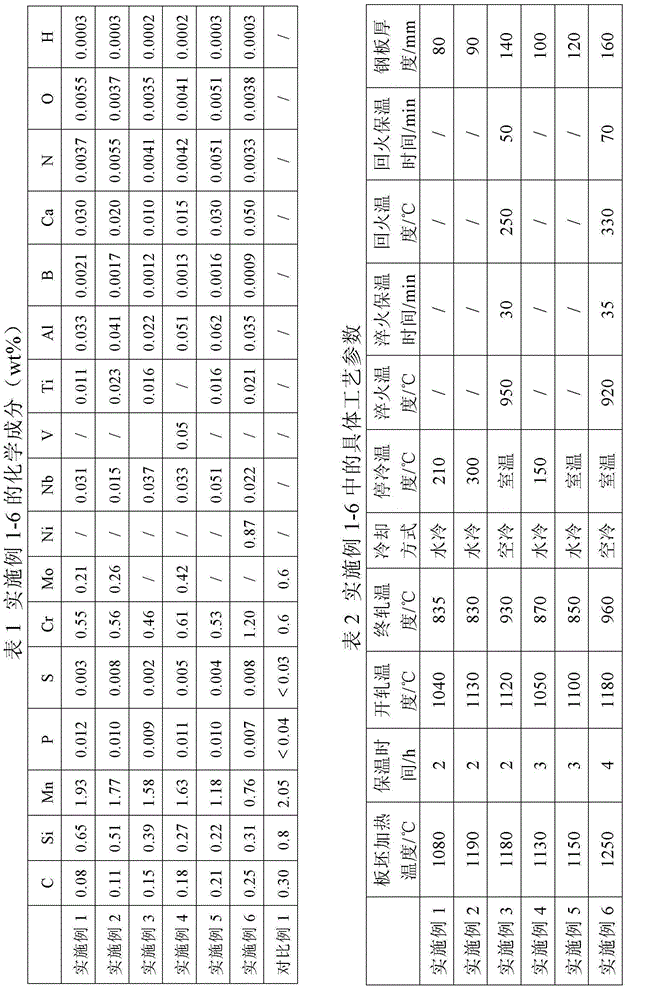

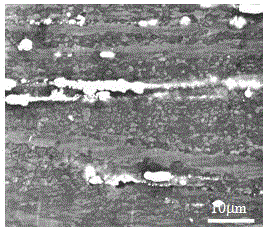

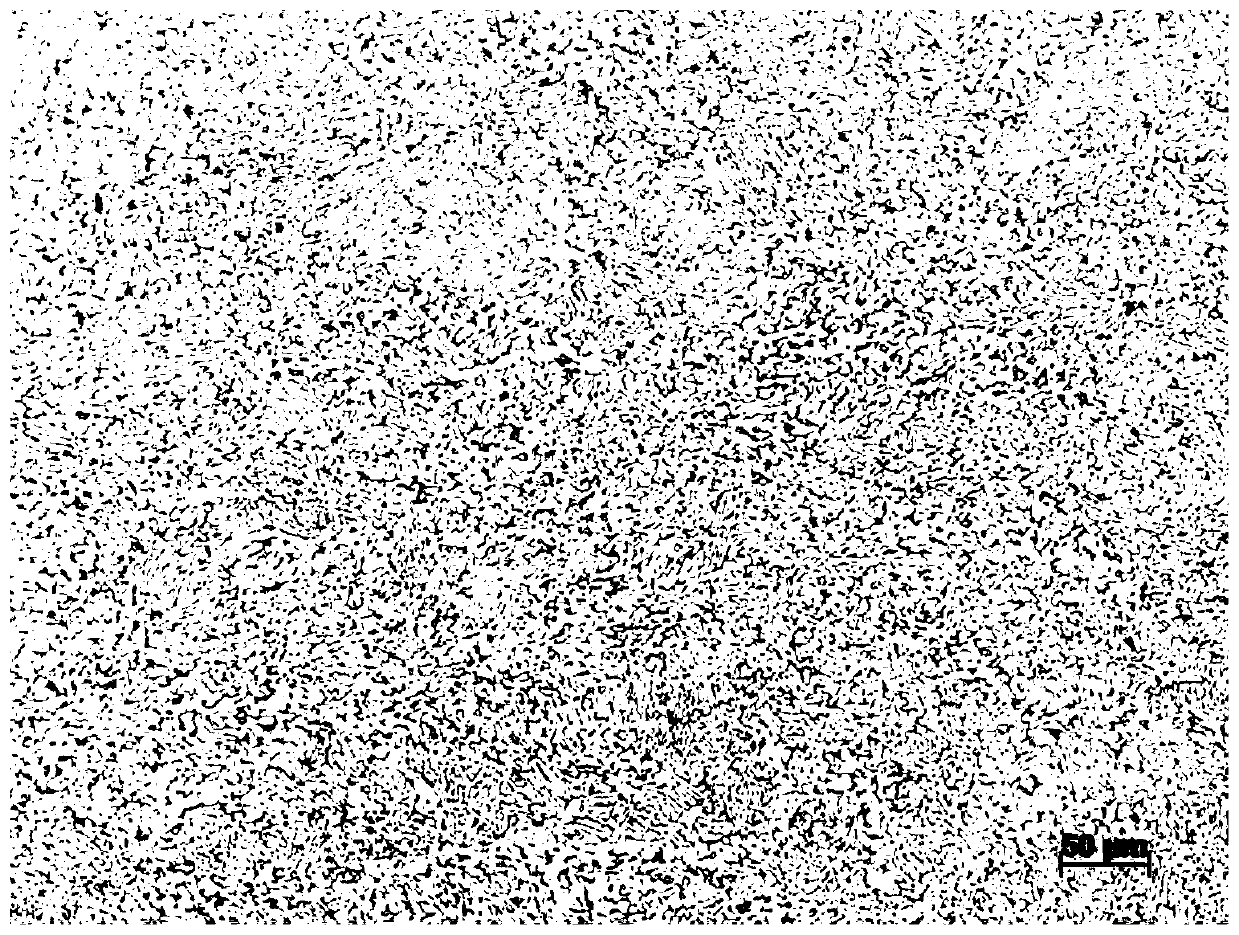

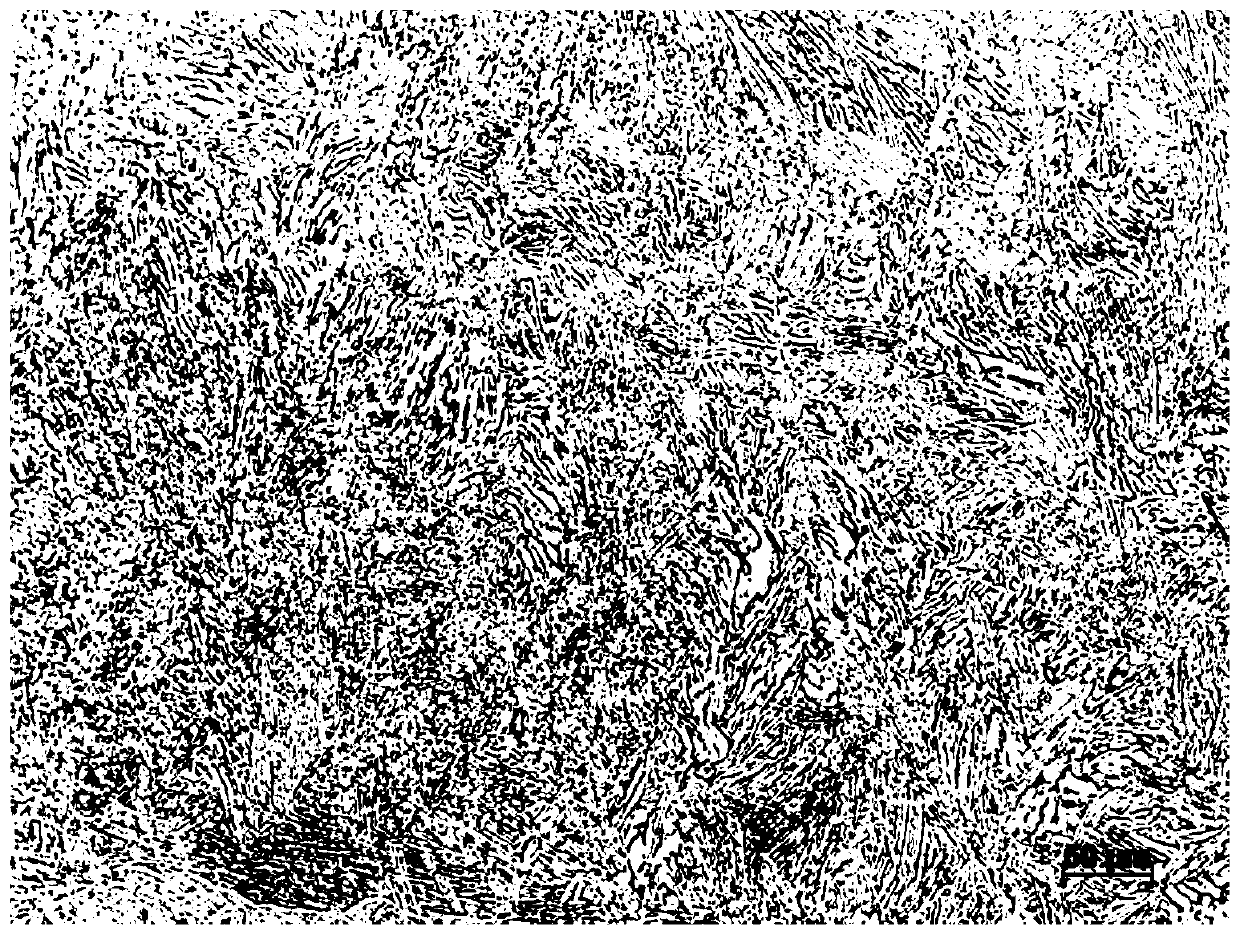

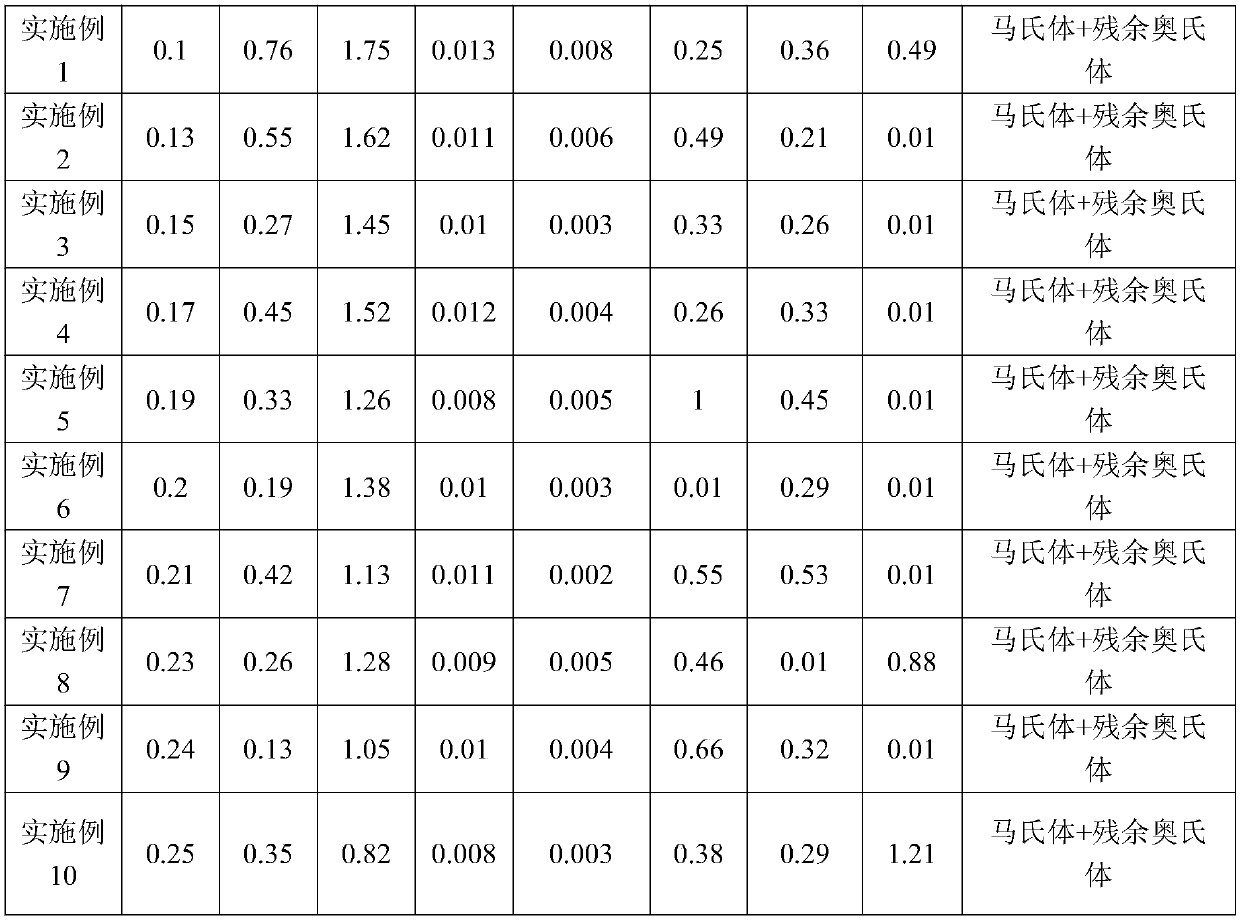

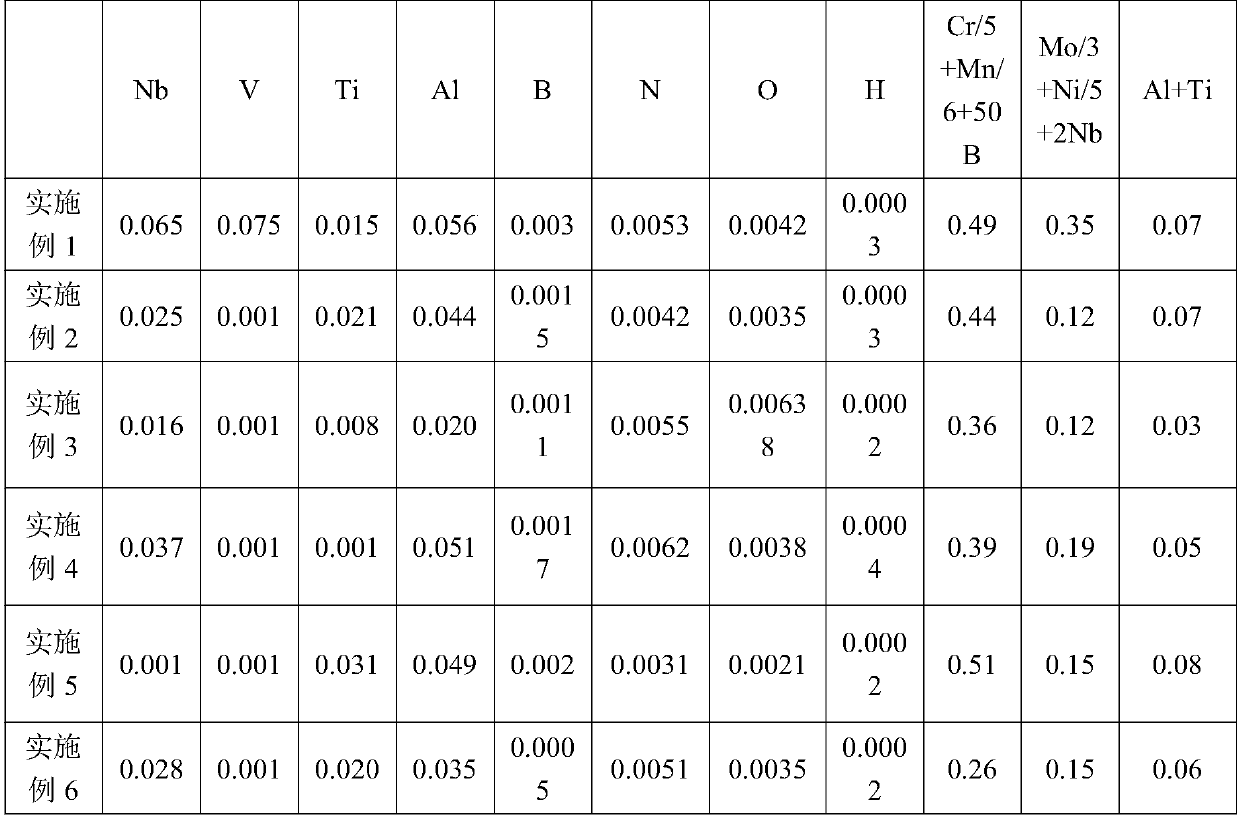

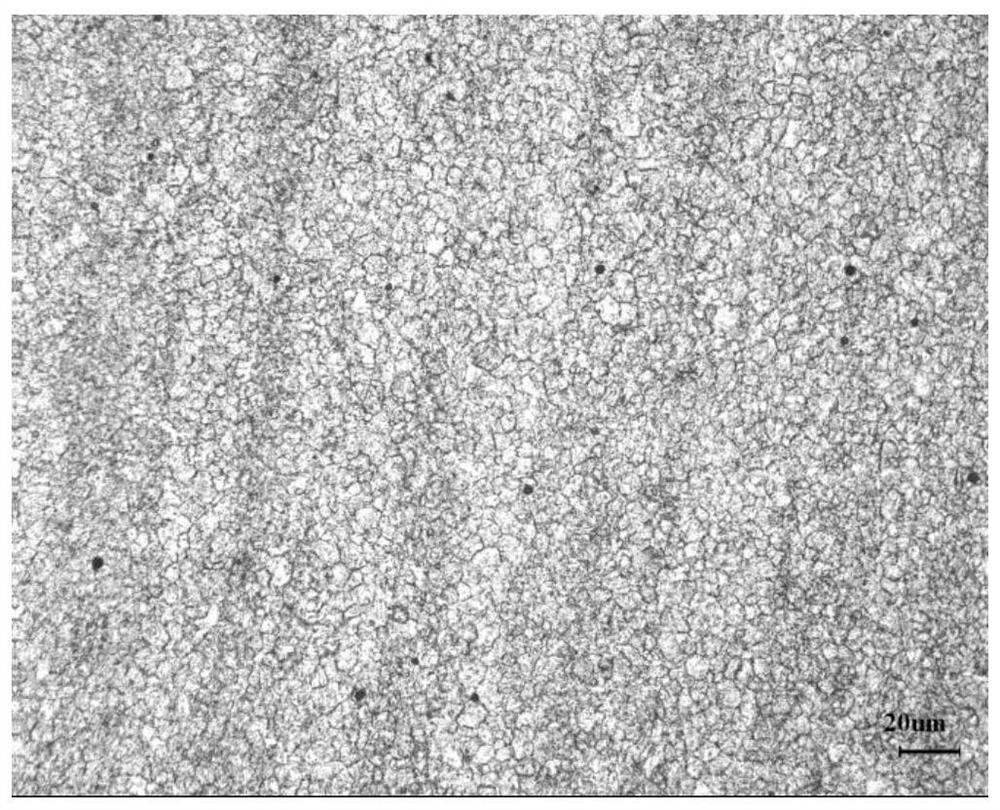

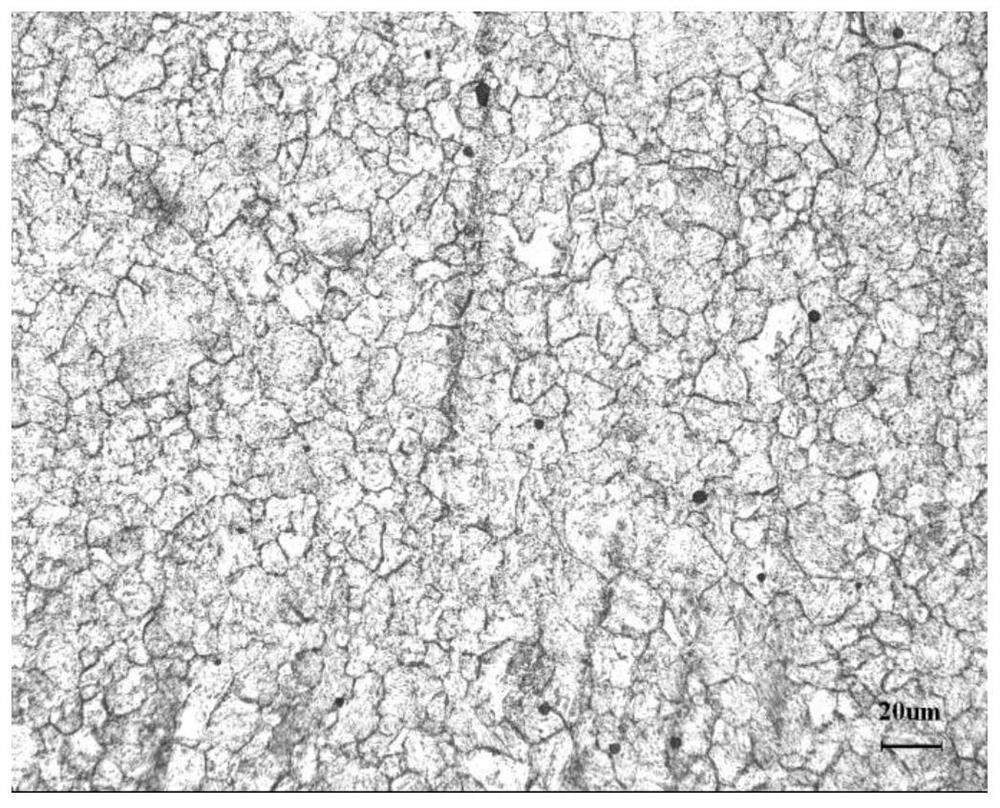

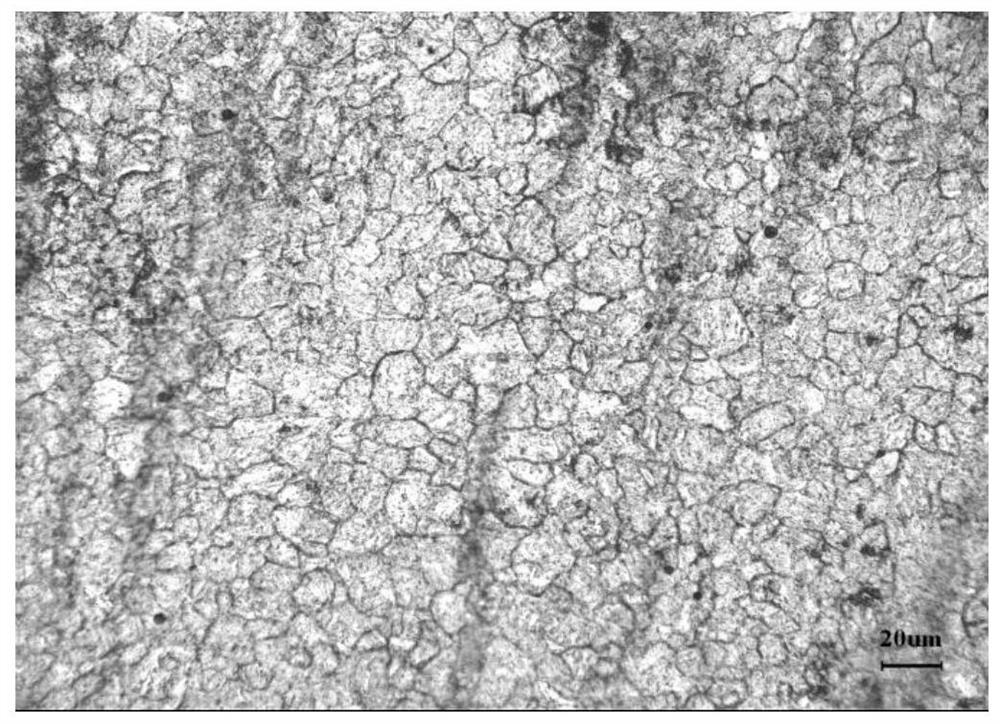

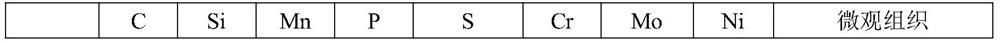

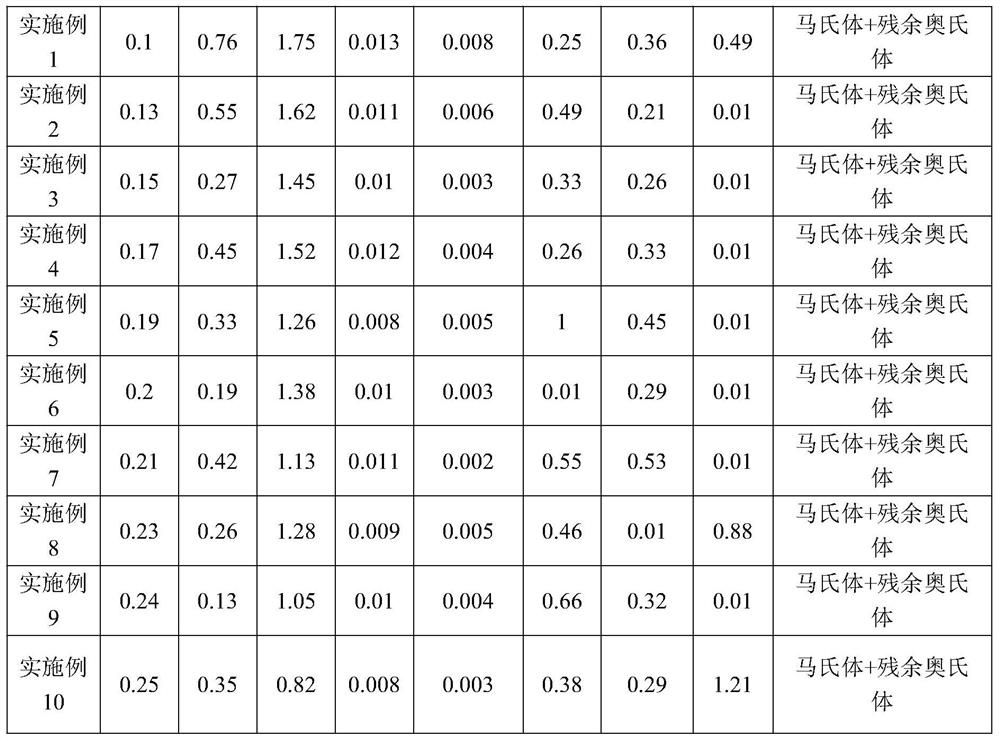

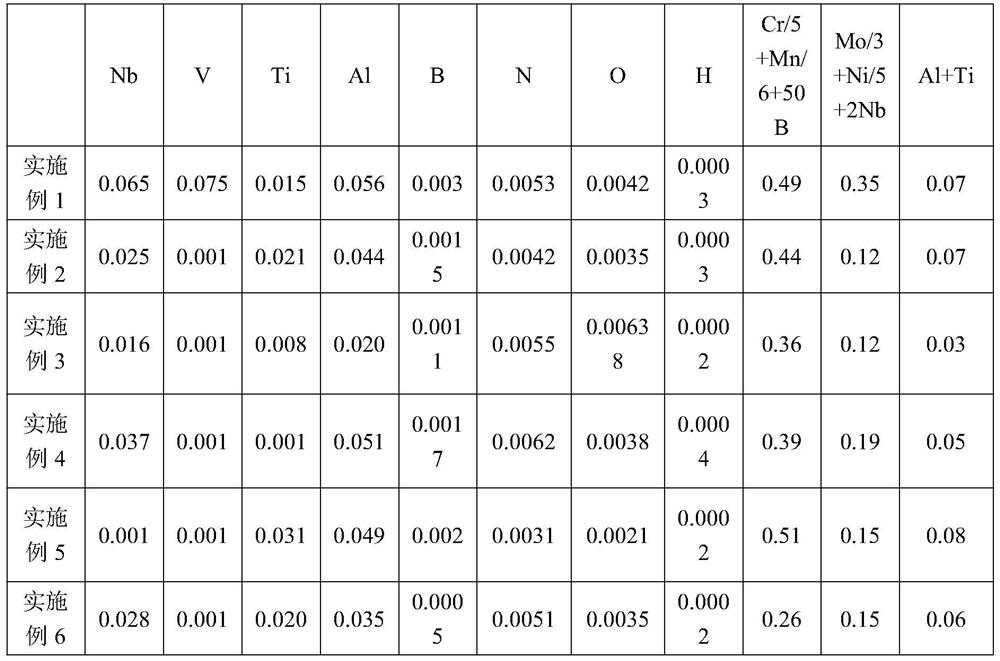

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

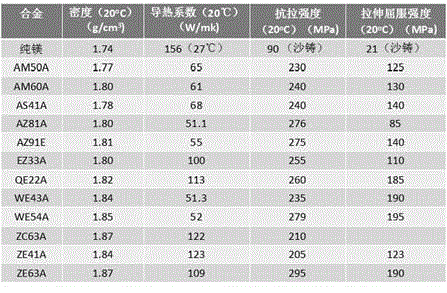

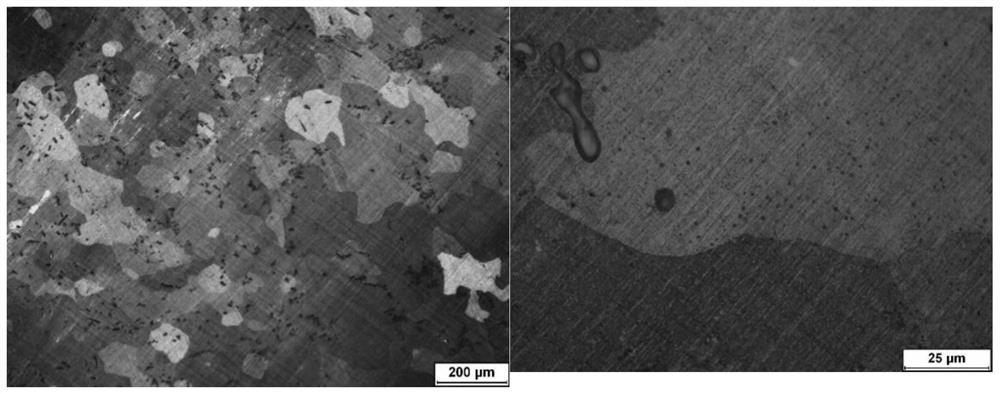

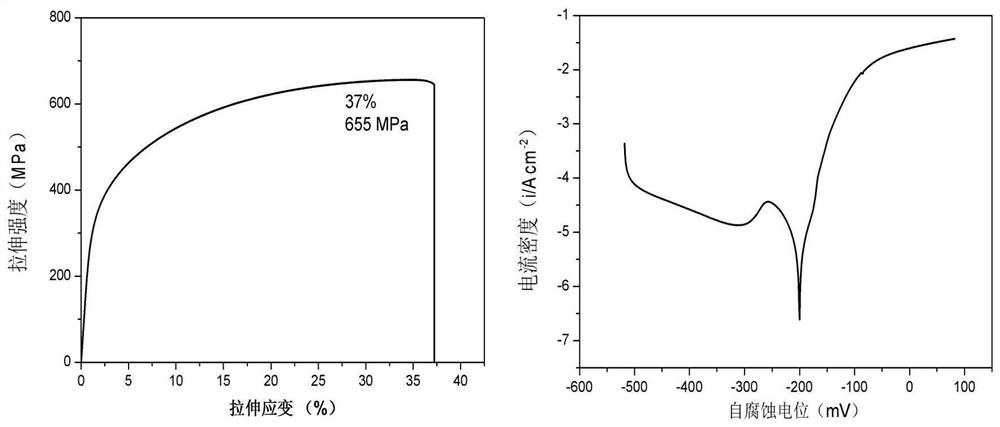

Low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy and preparation method thereof

The invention discloses a low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy and a preparation method thereof. The low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy comprises, by mass, 0.5-3% of Zn, 0.1-0.5% of Ca, 0.1-0.5% of La, 0.1-0.4% of Mn and the balance Mg and unavoidable impurities. The preparation method comprises 1, preparing a magnesium alloy cast ingot, 2, preparing an extruded blank, and 3, carrying out extrusion deformation treatment to obtain the low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy. The low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy has thermal conductivity of 125-140W.(m.k)<-1>, tensile strength of 330-360MPa, yield strength of 310-330MPa and an elongation percentage of 15-35%.

Owner:BAOSHAN IRON & STEEL CO LTD

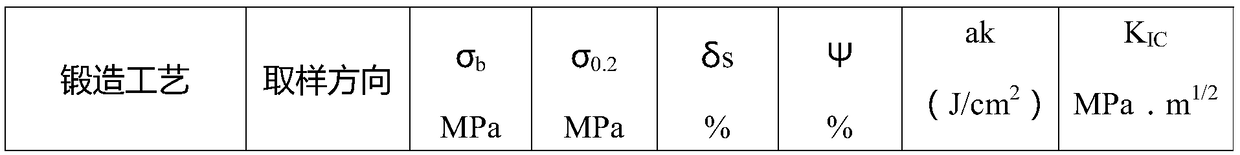

Forging forming method for TA15 titanium alloy forge piece with high strength and high tenacity

PendingCN109226622AHigh strengthHigh strength and high toughnessMetal-working apparatusHigh intensityMaterials processing

The invention belongs to the technical field of material machining, and particularly discloses a forging forming method for a TA15 titanium alloy forge piece with high strength and high tenacity. Themethod comprises the following steps of 1, freely forging a blank, wherein the black is preheated under the temperature of Tbeta-30-Tbeta-50 DEG C for heat preservation; free forging is performed after the blank is discharged out of a furnace; 2, performing die forging, wherein the blank is preheated under the temperature of Tbeta-30-Tbeta-50 DEG C for heat preservation; die forging is performed after the blank is discharged out of the furnace; the blank is preheated under the temperature of Tbeta-10-Tbeta-30 DEG C for heat preservation; final-heating-number die forging is performed after theblank is discharged; 3, performing thermal treatment. The TA15 titanium alloy forge piece with high strength and high tenacity can be obtained through the method. The forging forming method can obtainthe TA15 titanium alloy forge piece with high strength, high plasticity, high tenacity and high impact matching, is widely used for an airplane body component, the service performance of an airplaneis improved, and the service life of the airplane is prolonged.

Owner:XIAN TRIANGLE AVIATION TECH

High-strength and high-toughness aluminum alloy material for pressure casting

The invention discloses a high-strength and high-toughness aluminum alloy material for pressure casting. According to the high-strength and high-toughness aluminum alloy material for pressure casting,composition proportions of Si, Ti, Sr, Cu, Fe, Mn, Mg, Zn and Cr are adjusted reasonably, a rare earth element formed by mixing lanthanum and cerium is added, a pressure casting aluminum alloy with the good mechanical property and decay resistance can be obtained, the high-strength, high-toughness, wear-resisting and corrosion-resisting aluminum alloy pressure casting can be prepared, and the service life of the aluminum alloy material is prolonged. By means of the high-strength and high-toughness aluminum alloy material for pressure casting, the higher tensile strength, endurance strength and elongation percentage can be obtained.

Owner:浙江诺达信汽车配件有限公司

High-strength high-toughness spring steel wire and preparation process thereof

InactiveCN108179355AHigh strengthHigh strength and high toughnessFurnace typesHeat treatment furnacesWire rodStress relief

The invention discloses a high-strength high-toughness spring steel wire and a preparation process thereof. The spring steel wire is prepared from the following raw materials in percentage by mass: 96.2-97% of Fe, 0.5-0.6% of C, 1.2-1.6% of Si, 0.6-0.8% of Mn, 0.6-0.8% of Cr, less than or equal to 0.015% of P, less than or equal to 0.015% of S and the balance of nonmetal impurities. The steel wireobtained by performing wire-drawing and processing on a wire rod is subjected to quenching tempering treatment to obtain the high-strength high-toughness spring steel wire; the spring steel wire prepared by the preparation process is subjected to cold-coiling and forming, stress-relief tempering treatment, surface shot blasting and pressing to obtain a spring with high permissible stress, and thespring can be used as an inner spring and a torsion bar structural member of an automobile clutch transmission device; and precious metal does not need to add into steel billets and dosage of alloy elements is small, and therefore, the steel billets are easily obtained, the cost is low and the energy consumption is little.

Owner:中钢集团郑州金属制品研究院股份有限公司

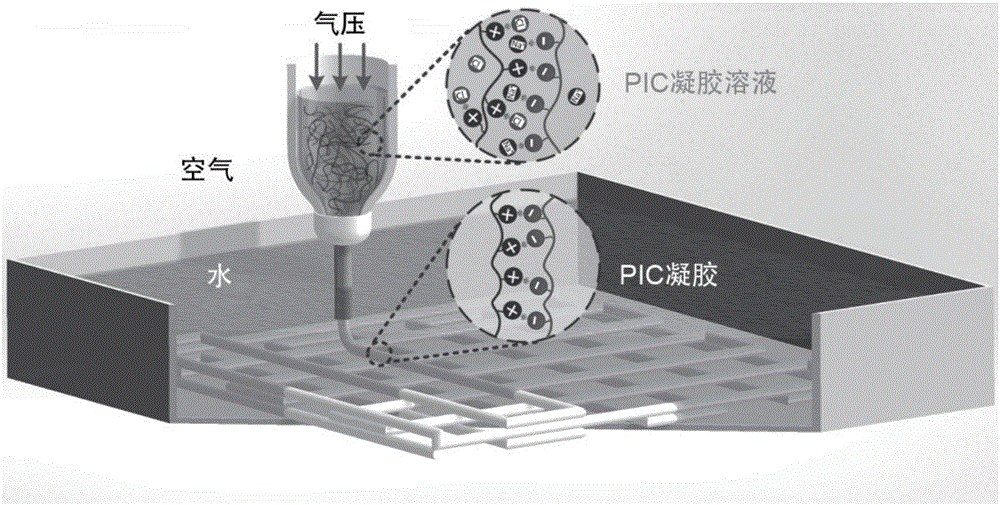

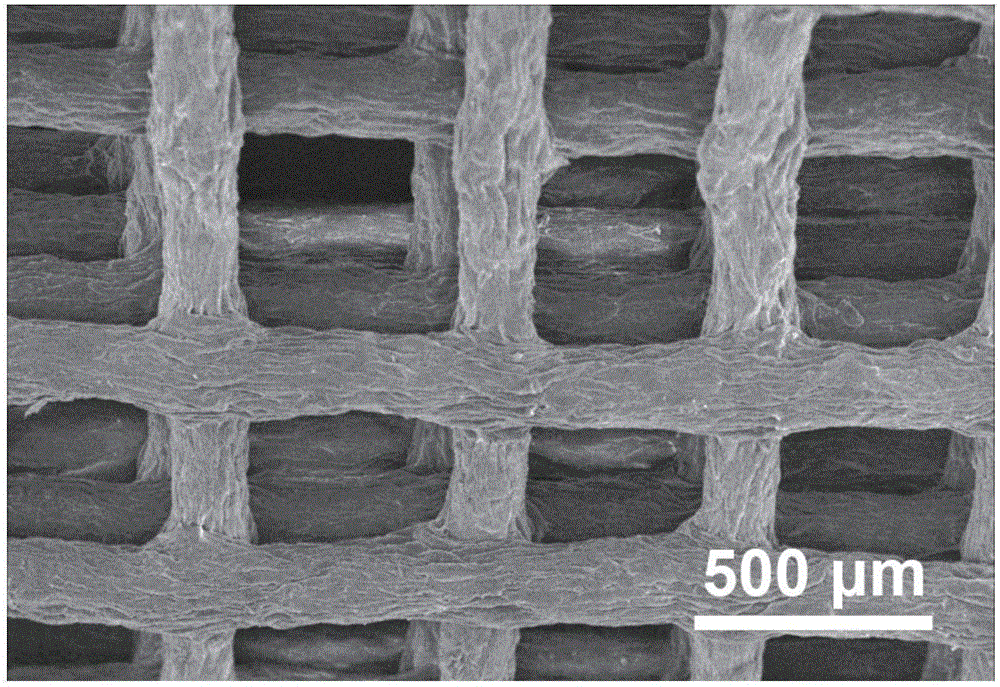

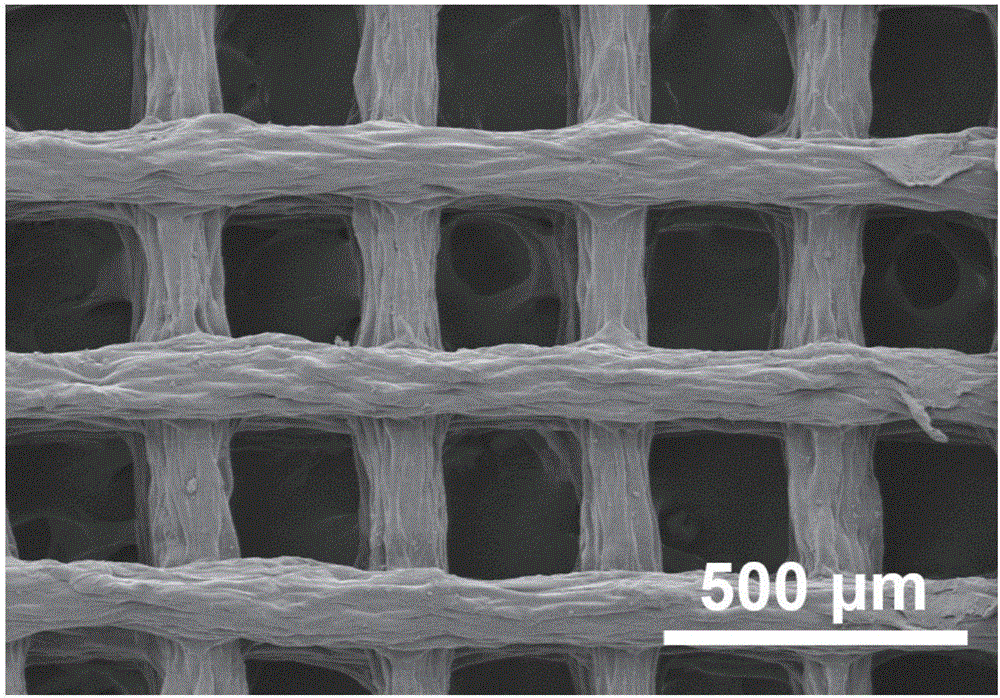

Method for preparing high-strength and high-toughness poly-ion hydrogel support through 3D printing

ActiveCN106267366AHigh strengthImprove toughnessAdditive manufacturing apparatusProsthesisCross-linkPolymer science

The invention discloses a method for preparing a high-strength and high-toughness poly-ion hydrogel support through 3D printing. The method includes the steps that an N,N,N-trimethyl-3-(2-methyl allyl acylamino)-1-propyl ammonia chloride solution to which a photoinitiator is added and a sodium p-styrenesulfonate solution are put below an ultraviolet lamp to be irradiated, solutions of two polymers are obtained, and two kinds of polymer powder are obtained after purifying, drying and grinding are completed; the two kinds of polymer powder are prepared into a water solution, the water solution is mixed and stirred, polyion compound precipitates are obtained, collected and dried, and polyion compound powder is obtained; saline is added into the polyion compound powder, the materials are stirred to be uniform, and polyion gel is obtained; a 3D printer is used for extruding the polyion gel in pure water under set printing parameters, and the poly-ion gel support is obtained after soaking and cross-linking forming. According to the method, bio-supports with different micro-structures and macro-appearances can be printed by correcting the printing parameters while it is guaranteed that the support has good mechanical performance.

Owner:ZHEJIANG UNIV

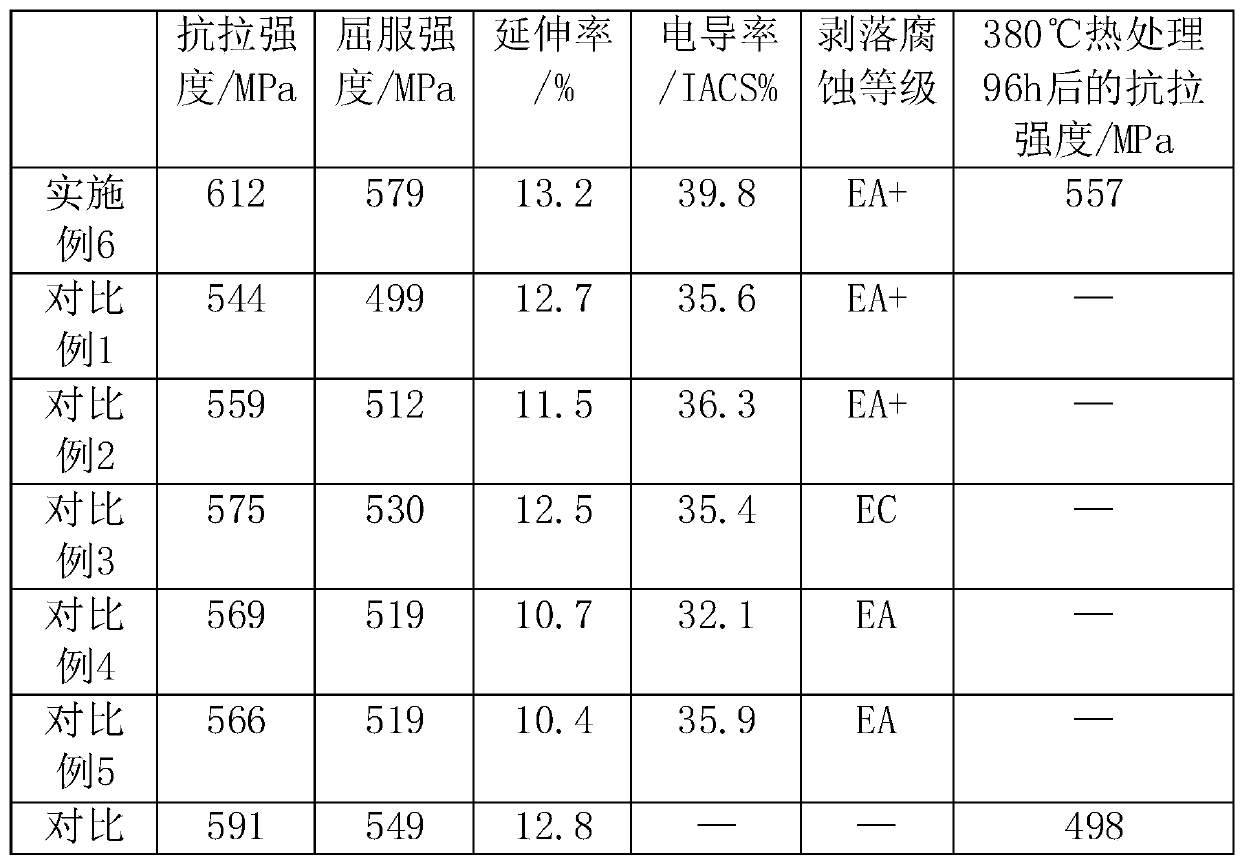

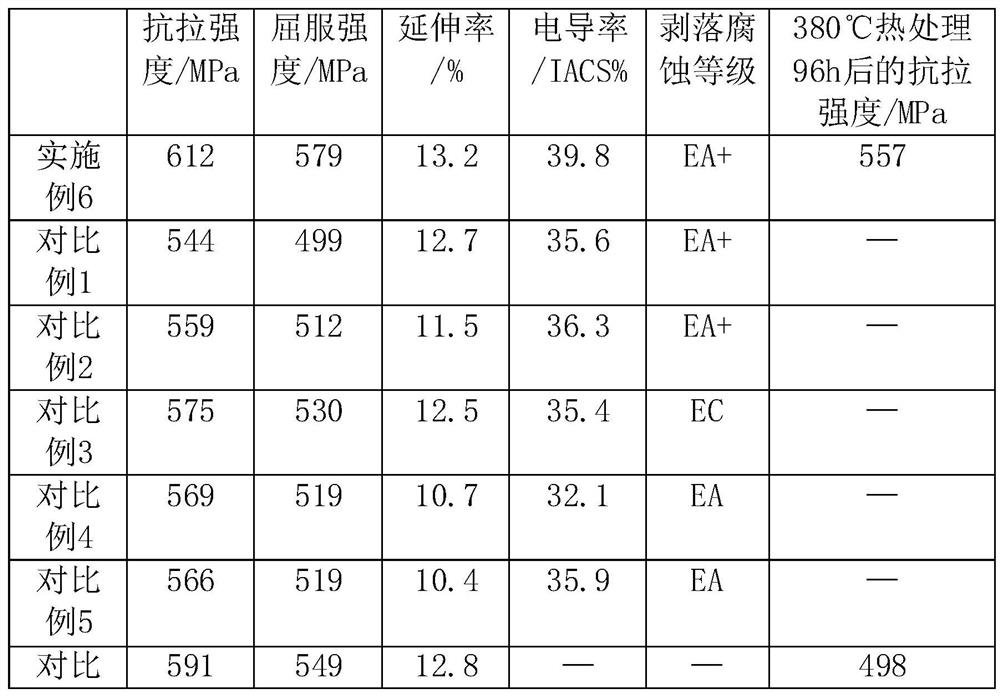

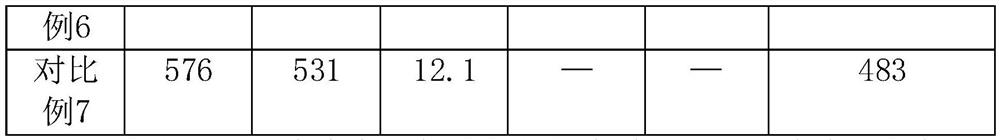

High-strength and high-tenacity aluminum alloy and preparing method thereof

ActiveCN110699575AHigh strengthHigh strength and high toughnessMetal rolling arrangementsCorrosion resistantAluminium alloy

The invention discloses a high-strength and high-tenacity aluminum alloy and a preparing method thereof. The alloy comprises components including, by weight percent, 1.3%-2.06% of Mg, 6.18%-7.1% of Zn, 1.05%-2% of Cu, 0.07%-0.16% of RE, 0.08%-0.15% of Fe, 0.11%-0.23% of Si, 0.04%-0.12% of Zr, 0.01%-0.23% of Ti, 0.01%-0.03% of Cr, 0.1%-0.24% of Mn, 0.07%-0.14% of B, 0.11%-0.27% of Li, 0.28%-0.42% of Ag and the balance Al, wherein RE is one or more mixtures of Yb, Sc, Er, Y, Ce and La. The provided high-strength and high-tenacity aluminum alloy preparing method is simple in process, the obtainedaluminum alloy is high in strength, and tenacity and corrosion resistance are good.

Owner:黄山市龙跃铜业有限公司

Non-quenched and tempered steel and method for manufacturing automobile steering knuckle through non-quenched and tempered steel

InactiveCN111778443AGood mechanical propertiesHigh strength and high toughnessVehicle componentsTemperingManufacturing technology

The invention discloses non-quenched and tempered steel and a method for manufacturing an automobile steering knuckle through the non-quenched and tempered steel. The non-quenched and tempered steel comprises components including, by mass percent, 0.35-0.39% of C, 0.50-0.70% of Si, 1.30-1.55% of Mn, smaller than or equal to 0.015% of P, 0.015-0.060% of S, 0.10-0.30% of Cr, 0.10-0.15% of V, 0.01-0.05% of Al, 0.020-0.035% of Nb, 0.015-0.035% of Ti, 0.015-0.020% of N, smaller than or equal to 0.25% of Ni, smaller than or equal to 0.10% of Mo, smaller than or equal to 0.03% of Sn, smaller than orequal to 0.20% of Cu and the balance Fe and impurities. The free-cutting high-strength high-tenacity microalloying non-quenched and tempered steel is used for replacing 41CrS4 (or 42CrMo) quenched andtempered steel for implementing of the automobile steering knuckle controlled-forging and controlled-cooling manufacturing technology, the quenching and tempering heat treatment procedure is eliminated, the cost is reduced by 10-20%, meanwhile, the steering knuckle cutting machining performance is improved, and the technical level of the steering knuckle reaches the national advanced level.

Owner:SHAANXI AUTOMOBILE GROUP +1

High-strength, high-toughness and low-viscosity modified ECC concrete sound barrier plate and preparation method thereof

ActiveCN106800399AReduce defectsImproves compressive strength and toughnessClimate change adaptationNoise reduction constructionQuartzViscosity

The invention discloses a high-strength, high-toughness and low-viscosity modified ECC concrete sound barrier plate and a preparation method of the sound barrier plate. The sound barrier plate consists of a concrete unit plate and a pottery sand concrete sound absorption layer which covers a sound facing area of the concrete unit plate, wherein the concrete unit plate is prepared from the following components: cement, fly ash, a microbead, silicon ash, quartz sand, a water reducing agent, a PVA fiber, a steel fiber and water at a weight ratio of 1:(0.05-0.15):(0.05-0.15):(0.25-0.35):1.3:(0.05-0.08):(0.005-0.01):(0.2-0.25):(0.20-0.25); the pottery sand concrete sound absorption layer is prepared from the following components: cement, fly ash, a microbead, silicon ash, pottery sand, quartz sand, a water reducing agent, a PVA fiber, a steel fiber and water at a weight ratio of 1:(0.05-0.15):(0.05-0.15):(0.25-0.35):(0.2-0.25):1.3:(0.05-0.08):(0.005-0.01):(0.2-0.25):(0.20-0.25). The modified ECC concrete sound barrier plate is low in viscosity, high in strength and high in toughness, can be used for pouring a sheet concrete sound barrier unit, and overcomes the defects of heavy load and excessive transport and mounting cost.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

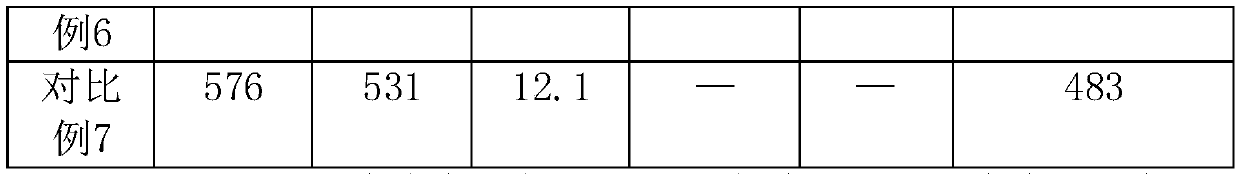

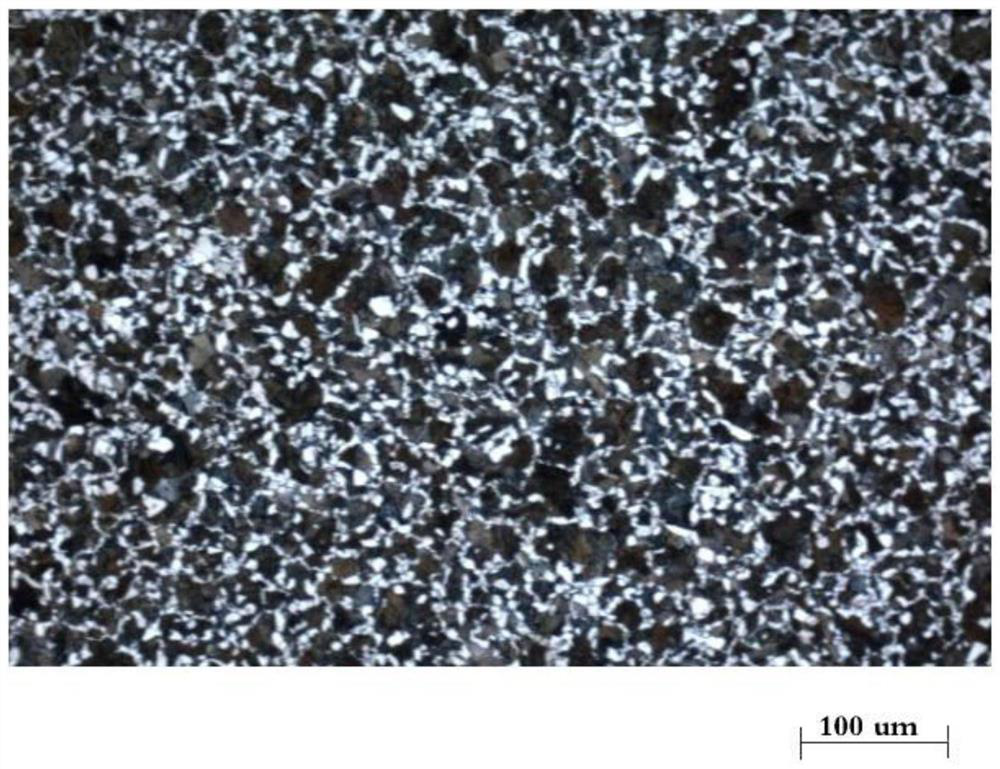

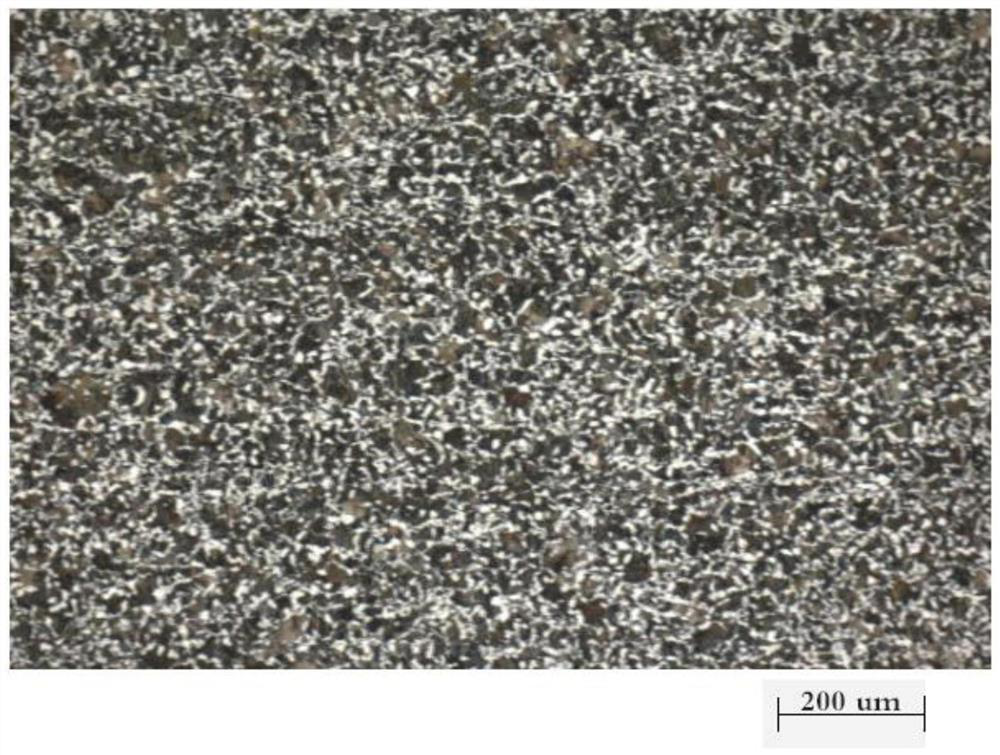

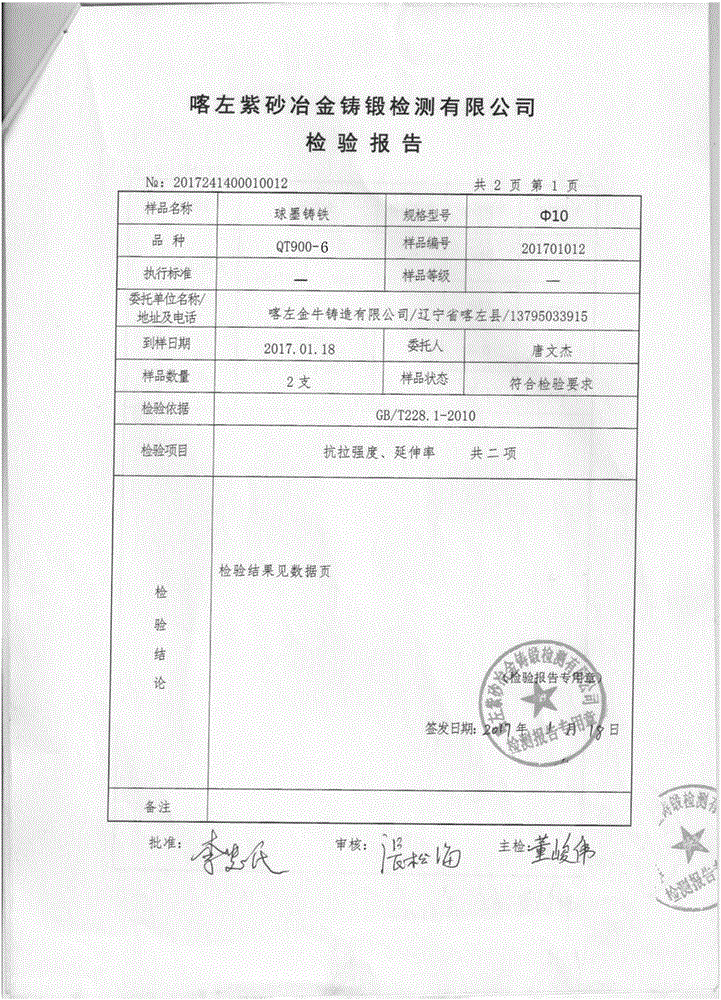

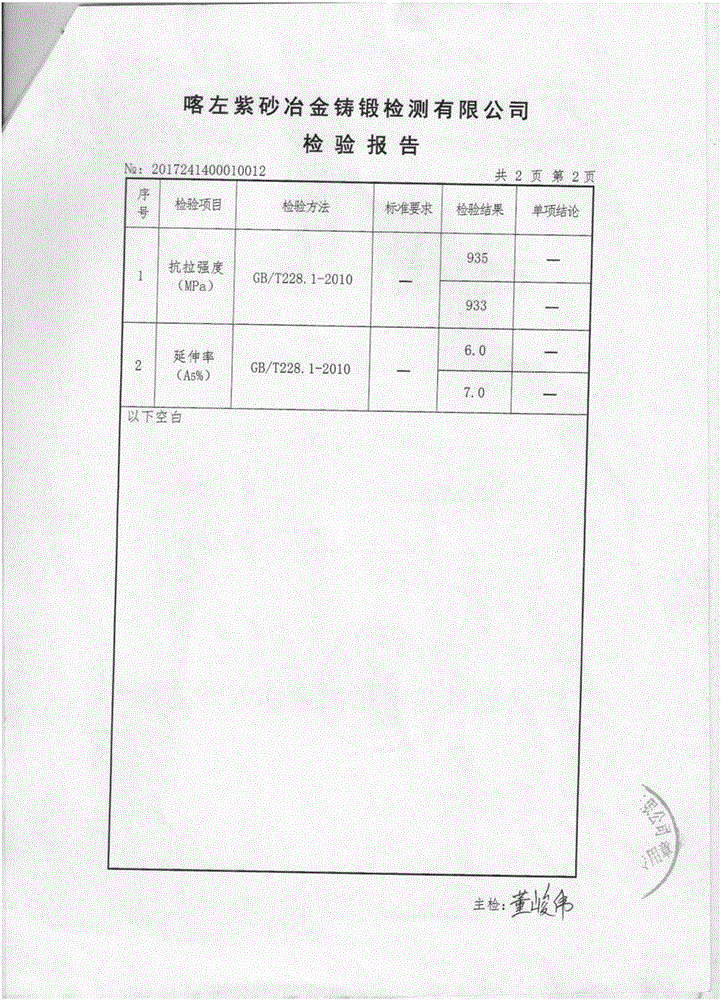

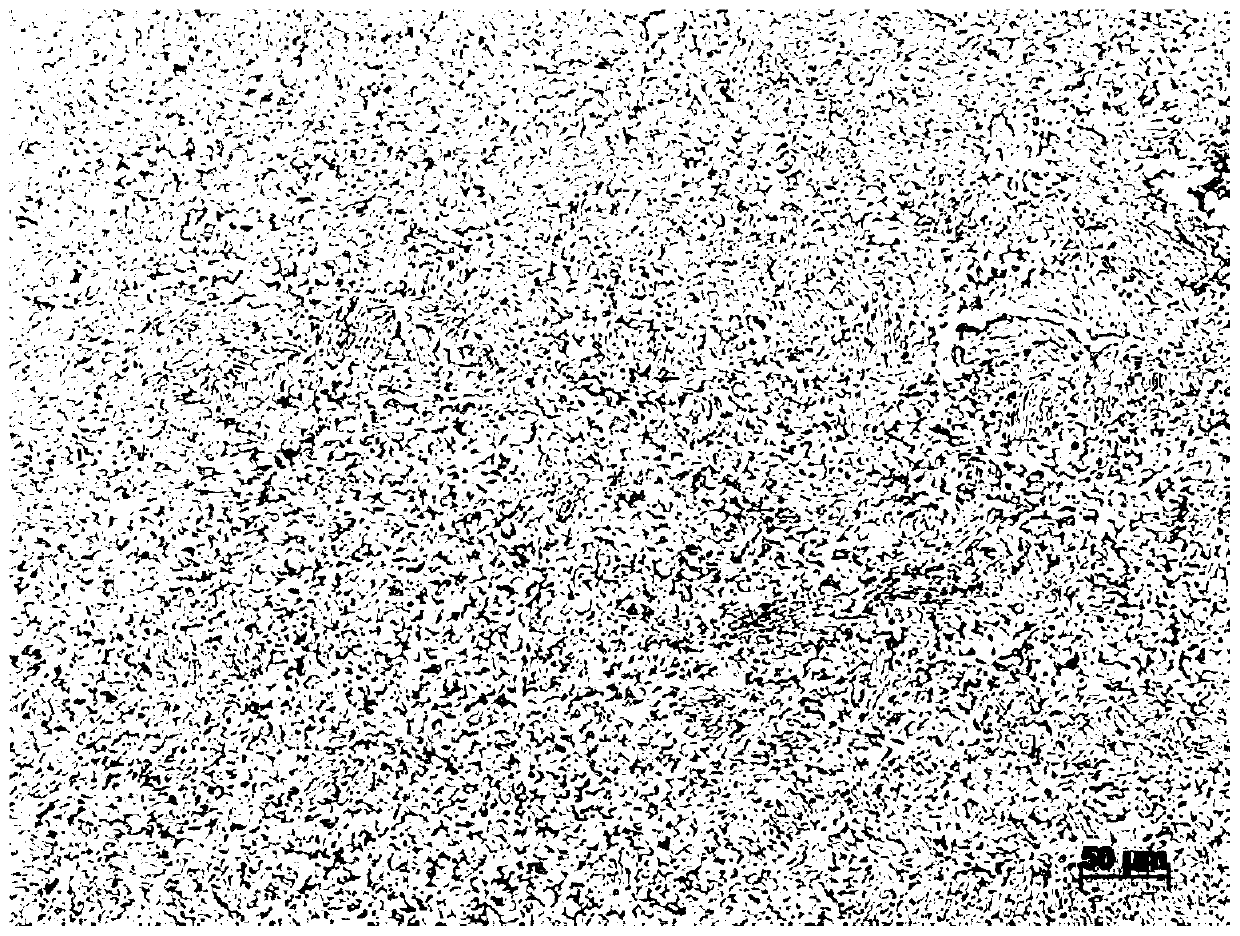

Production process of high-strength and high-toughness as-cast ductile cast iron

The invention discloses a production process of high-strength and high-toughness as-cast ductile cast iron. Raw materials including pig iron, low-carbon steel and ductile cast iron foundry returns are added to a medium-frequency melting furnace and heated to be molten, an efficient carburant, a manganese-iron alloy and a silicon-iron alloy are added to the medium-frequency melting furnace, and the mixture is molten into molten iron; firstly, a spheroidizing ladle is preheated, a spheroidizing agent is added to one side, close to a furnace body, of a dam of the spheroidizing ladle, an inoculant is taken and applied to the surface of the spheroidizing agent in a covering manner, metal nickel and metal titanium are added to the other side, close to the furnace body, of the dam of the spheroidizing ladle, the surface of the spheroidizing agent is covered with a perlite covering agent, part of molten iron is poured into the spheroidizing agent for a reaction, the remaining molten iron is poured into the spheroidizing agent after the reaction is stable, the remaining inoculant is added along with the flow for inoculation, the mixture is stirred sufficiently, a molten iron deslagging agent is added after slagging off, slag is rammed, silicon granules are added, the mixture is covered with the perlite covering agent after inoculation of unstable silicon, and a product is obtained after pouring and air cooling. The production process has the advantages that the process is simple, reasonable and low in production cost, heat treatment is not required, the product elongation is increased, and the mechanical performance of the product is good.

Owner:喀左金牛机电设备科技有限公司 +1

High-strength and high-tenacity titanium alloy tubular product used for oil and gas exploitation and preparation method thereof

ActiveCN109706344AImproves Strength and ToughnessIncrease the rate of the hydrogen evolution reactionDrilling rodsDrilling casingsAlloy elementHigh pressure

The invention relates to a high-strength and high-tenacity titanium alloy tubular product used for oil and gas exploitation and a preparation method thereof. Safe and effective exploitation of oil andgas wells is ensured, and the problems that strength and tenacity of existing titanium alloy pipes cannot meet environment characteristics, such as ultra-large depth and high pressure, of oil and gasfields are mainly solved. Besides Ti, the titanium alloy tubular product is mainly composed of, by mass, 3.8%-5.0% of Al, 2.4%-3.3% of V, 1.3%-1.8% of Fe, 0.4%-0.8% of Nb, 0.3%-1.0% of Ni, smaller than or equal to 0.2% of O, smaller than or equal to 0.04% of C, smaller than or equal to 0.04% of N and smaller than or equal to 0.0135% of H, and one or two of following alloy elements, namely, 0.15%-0.35% of Cr and 0.05%-1.0% of Mo are further added. Meanwhile, the invention further provides the preparation method of the titanium alloy tubular product.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

High-strength and high-toughness wear-resistant composite steel plate and manufacturing method thereof

ActiveCN109835014AImprove performanceImprove refinementFurnace typesMetal rolling arrangementsWear resistantHardness

The invention discloses a high-strength and high-toughness wear-resistant composite steel plate. The composite steel plate comprises a substrate layer and a composite layer compounded to one side or two sides of the substrate layer; and the substrate layer is a carbon steel layer, the composite layer is an ultrahigh-manganese steel layer, and the content of Mn element in the composite layer is 16.00-25.00 wt.%. The invention also discloses a manufacturing method of the high-strength and high-toughness wear-resistant composite steel plate. The manufacturing method comprises the following steps:(1) producing a substrate layer slab and a composite layer slab; (2) assembling the slabs; (3) heating: raising the temperature to 1150-1250 DEG C, and keeping the temperature for 1-3 h; (4) carryingout composite rolling: rolling at an initial rolling temperature of 1120-1220 DEG C and a finishing rolling temperature of 1050-1200 DEG C, and controlling the reduction ratio to be 50% or above; and5) cooling after rolling. The high-strength and high-toughness wear-resistant composite steel plate of the invention has the advantages of high strength and hardness, good toughness, high wear resistance and excellent comprehensive performances.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick-wall high-strength high-toughness oil casing pipe and manufacturing method thereof

The invention discloses a thick-wall high-strength high-toughness oil casing pipe which comprises the chemical elements in percentage by mass: 0.22 to 0.30 percent of C, 0.1 to 0.4 percent of Si, 0.5to 1.2 percent of Mn, 0.8 to 1.3 percent of Cr, 0.6 to 1.2 percent of Mo, 0.02 to 0.06 percent of Nb, 0.2 to 0.3 percent of V, 0.02 to 0.06 percent of Ti, 0.0015 to 0.005 percent of B, 0.01 to 0.05 percent of Al, 0.0005 to 0.005 percent of Ca, and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the thick-wall high-strength high-toughness oil casing pipe. The manufacturing method of the thick-wall high-strength high-toughness oil casing pipe comprises the steps of (1) smelting and continuous casting; (2) perforating and continuous rolling; and(3) adopting heat treatment processes for two times, wherein during heat treatment for the first time, a two-phase region quenching process is adopted, so that austenite formed by dispersed distribution of a two-phase region is quenched so as to form martensite, and other tissues keep as bainite; and during heat treatment for the second time, a process of water quenching and tempering after complete austenitizing is adopted. The thick-wall high-strength high-toughness oil casing pipe provided by the invention is low in cost, has high strength and high toughness at the same time, and can meetthe demand of an oil field on high-performance oil well pipes.

Owner:BAOSHAN IRON & STEEL CO LTD

Stable manufacturing method of high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for pressure vessel

PendingCN112775204AHigh strengthHigh strength and high toughnessFurnace typesHeat treatment furnacesThick plateHeat treated

The invention relates to a stable manufacturing method of an aluminum alloy thick plate, in particular to a stable manufacturing method of a high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for a pressure vessel. The invention aims to solve the problem that the aluminum alloy plate with high strength, high toughness, high allowable stress and high corrosion resistance at the same time is difficult to prepare in the prior art. The manufacturing method comprises the following steps of 1, weighing and smelting; 2, casting; 3, homogenizing annealing treatment; 4, heating; 5, primary hot rolling; 6, secondary hot rolling; 7, solid solution; 8, high-temperature annealing; 9, primary aging; 10, secondary aging; 11, stabilizing heat treatment; 12, stretching; and 13, tertiary aging. The stable manufacturing method is mainly used for stably manufacturing the high-strength, high-toughness and high-allowable-stress aluminum alloy thick plate for the pressure vessel.

Owner:NORTHEAST LIGHT ALLOY CO LTD

High-strength high-toughness flame-retardant polypropylene composite material and preparation method thereof

PendingCN114085458AImprove production efficiencyImprove the qualified rate of finished productsMethacrylateQuinoxaline

The invention discloses a high-strength high-toughness flame-retardant polypropylene composite material which is characterized by being prepared from the following components in parts by weight: 40-60 parts of polypropylene, 15-25 parts of hyperbranched polypropylene, 10-20 parts of hydroxyl-containing polypropylene, 8 to 12 parts of isocyanoethyl methacrylate / 3-(1,1-difluoroallyl)quinoxalin-2-ol / allyltriphenylphosphonium bromide / isopropenylboronic acid pinacol ester copolymer, 0.8 to 1.2 parts of catalyst, 6 to 10 parts of nano boron fiber, 0.1 to 0.5 part of an antioxidant, 1 to 3 parts of a coupling agent, 2 to 5 parts of a compatilizer, 1 to 3 parts of an environment-friendly plasticizer, 0.8 to 1.3 parts of an initiator, 2 to 4 parts of sodium 3-mercapto-1-propanesulfonate and 2 to 5 parts of thermoplastic elastomer SBS. The invention also discloses a preparation method of the high-strength high-toughness flame-retardant polypropylene composite material. The high-strength high-toughness flame-retardant polypropylene composite material disclosed by the invention is high in strength, sufficient in toughness, good in flame retardance, good in ageing resistance and performance stability and long in service lifetime.

Owner:宁波塑之华塑化有限公司

Preparation method of polypropylene nano composite material

ActiveCN102086280BGood modification effectImprove interface strengthHeat deflection temperaturePolypropylene

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

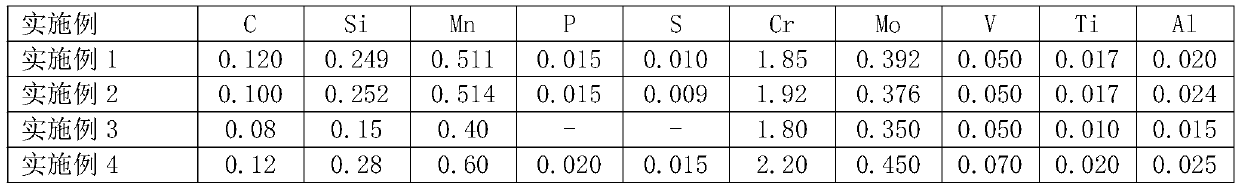

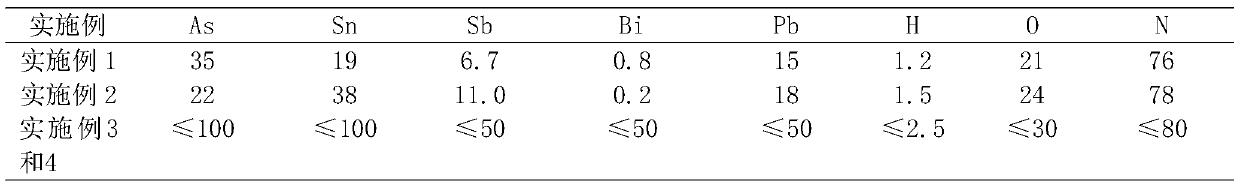

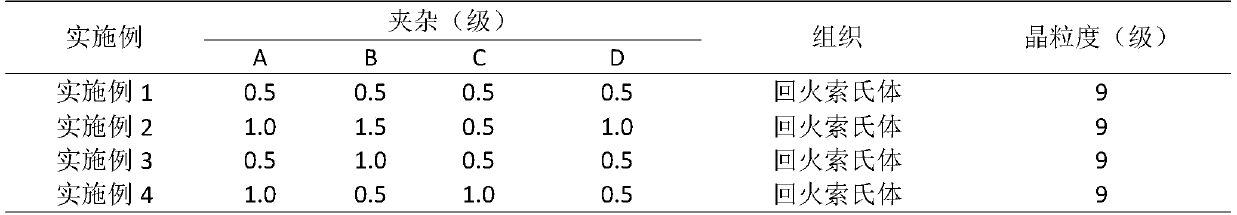

Rare-earth-containing low-carbon high-alloy anticorrosion oil casing steel and preparation process thereof

The invention discloses rare-earth-containing low-carbon high-alloy anticorrosion oil casing steel comprising the following chemical components of, by mass, 0.08%-0.12% of C, 0.15%-0.28% of Si, 0.40%-0.60% of Mn, 1.8%-2.2% of Cr, 0.35%-0.45% of Mo, 0-0.02% of P, 0-0.015% of S, 0.05%-0.07% of V, 0.015%-0.025% of Al and 0.01%-0.02% of RE. A preparation process of the rare-earth-containing low-carbonhigh-alloy anticorrosion oil casing steel is further disclosed. The invention provides a chemical component design method of the high-strength high-toughness H2S / CO2-corrosion-resistant steel for anoil casing, and the material has high hydrogen sulfide corrosion resistance and a match between high strength and high toughness with the reasonable chemical components.

Owner:BAOTOU IRON & STEEL GRP

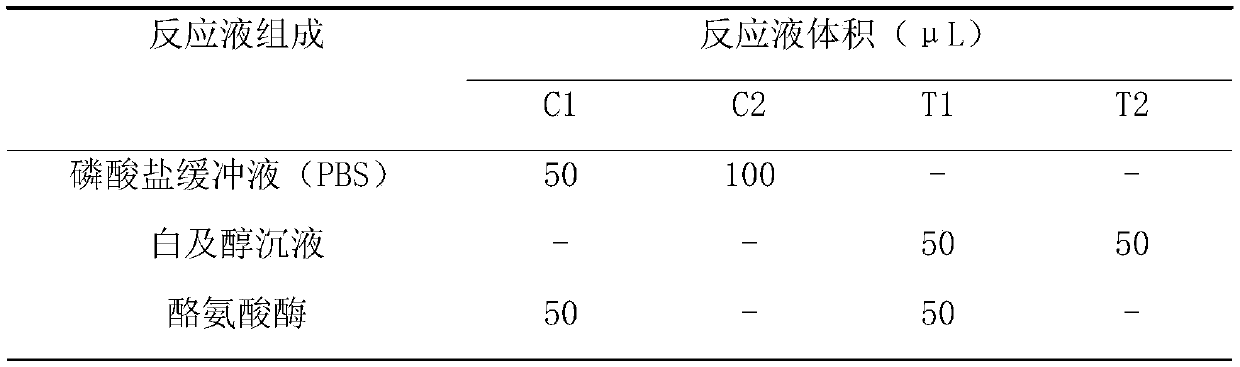

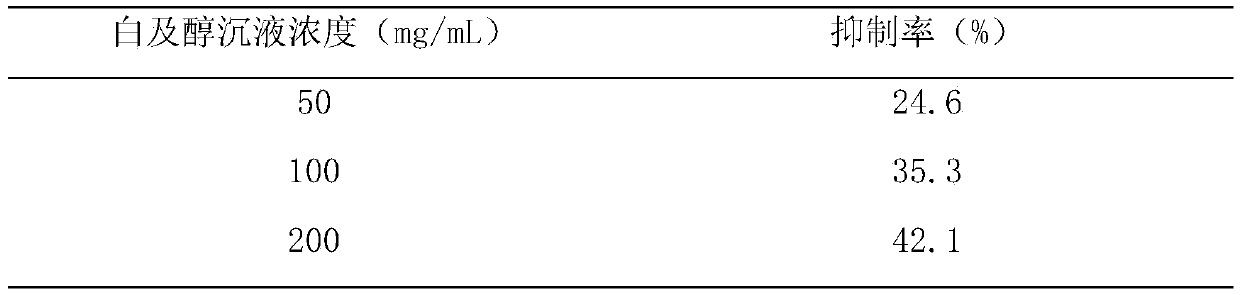

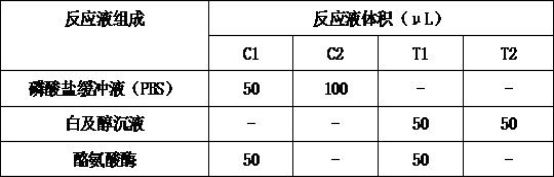

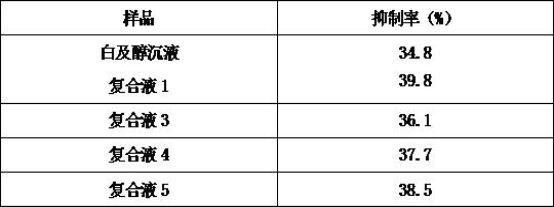

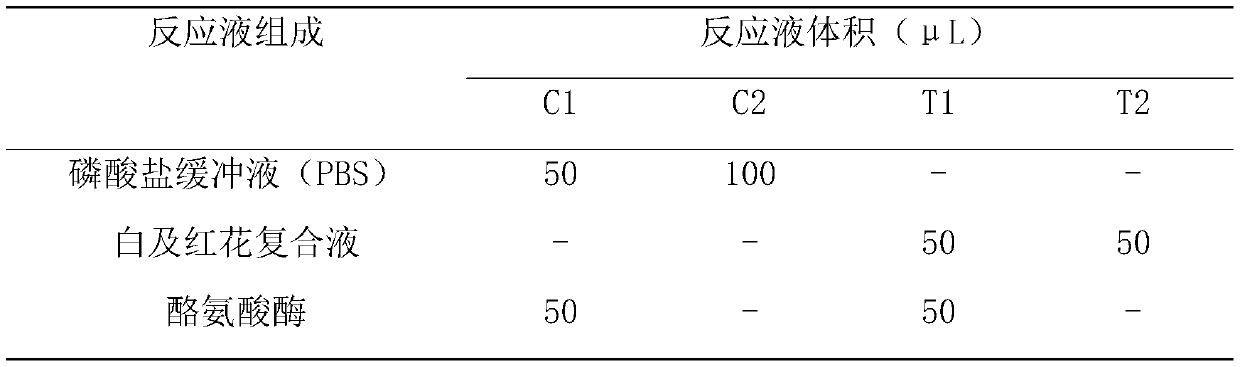

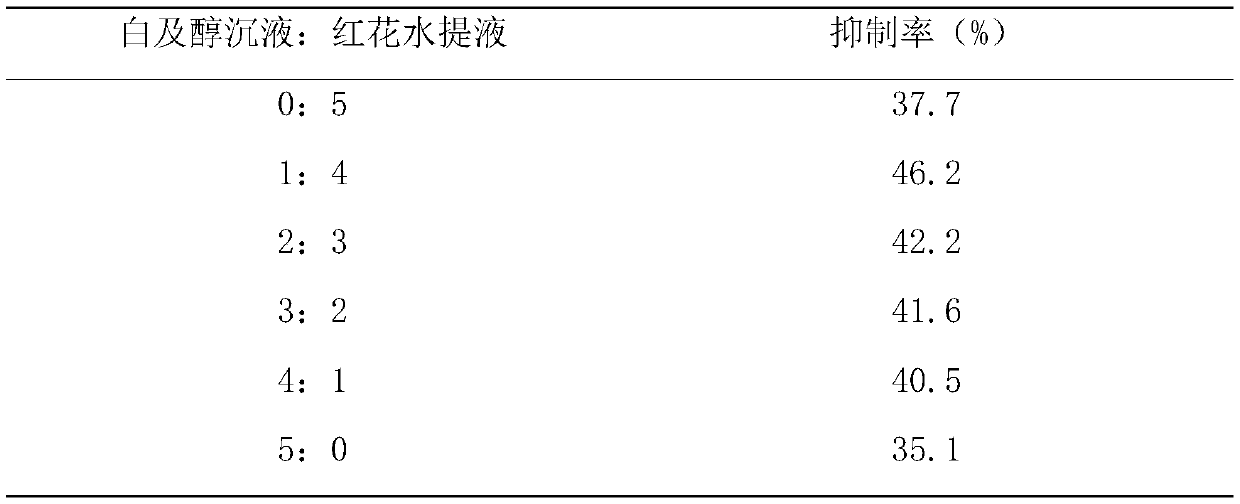

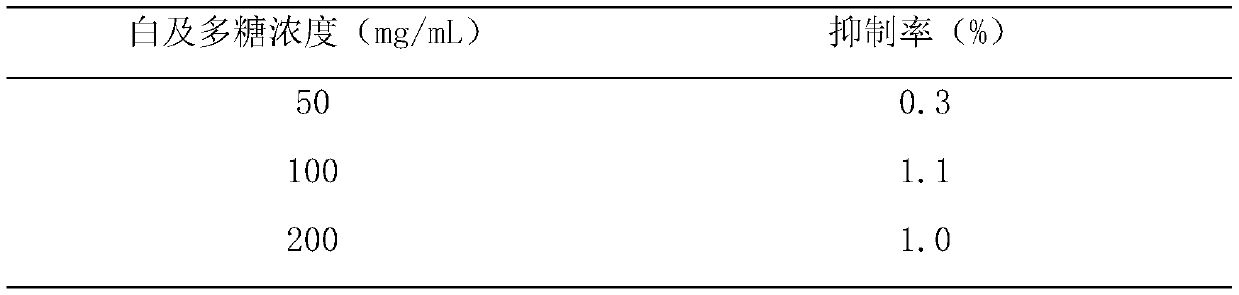

Tear-and-pull type common bletilla tuber whitening facial mask and preparation method thereof

ActiveCN109846720AImprove skin damageSolve the unfavorable factorsCosmetic preparationsToilet preparationsSodium carboxymethylcelluloseChemistry

The invention discloses a tear-and-pull type common bletilla tuber whitening facial mask and a preparation method thereof. The tear-and-pull type common bletilla tuber whitening facial mask consists of the following components in percentage by weight of 1-5% of common bletilla tuber ethanol precipitation fluid, 0.02-0.4% of a whitening reinforcing agent, 0.01-0.05% of sodium hyaluronate, 0.1-0.5%of sodium carboxymethyl cellulose, 0.05-0.5% of allantoin, 10-30% of polyvinyl alcohol, 5-20% of glycerine, 5-20% of butanediol, 0.1-0.6% of methyl hydroxybenzoate and the balance deionized water. According to the prepared tear-and-pull type common bletilla tuber whitening facial mask, the common bletilla tuber ethanol precipitation liquid can effectively restrain tyrosine enzymic activity, can alleviate chloasma and block spots caused by acne, and has the effects of dispelling freckles and whitening skin; and a whitening reinforcing agent namely EDTA-ZnNa and vitamin C can restrain tyrosine enzymic activity and block generation of melanin, so that the tyrosine enzyme inhibition activity of the common bletilla tuber ethanol precipitation liquid can be improved, and the common bletilla tuber ethanol precipitation liquid has the function of being synergistically synergistic; and chitosan and ethylenediamine tetraacetic acid disodium salt can remove heavy metal ions of Pb2+, Hg2+,Ni2+ andthe like on faces, and the damage of skin aging and wrinkles caused by heavy metals can be reduced.

Owner:HUBEI UNIV OF CHINESE MEDICINE

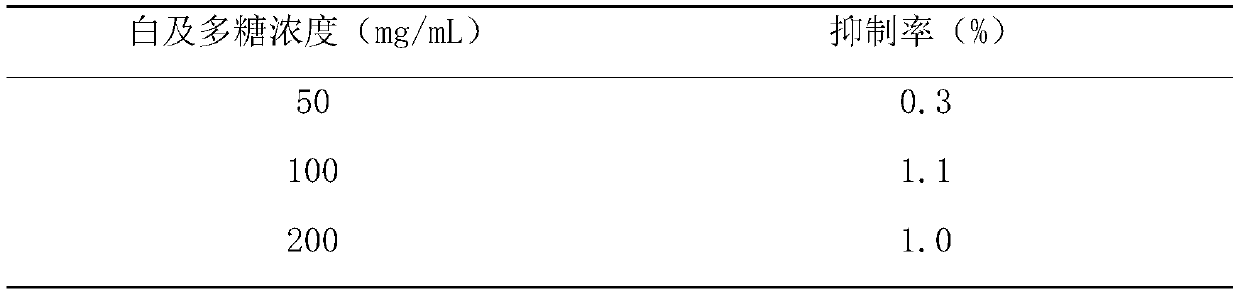

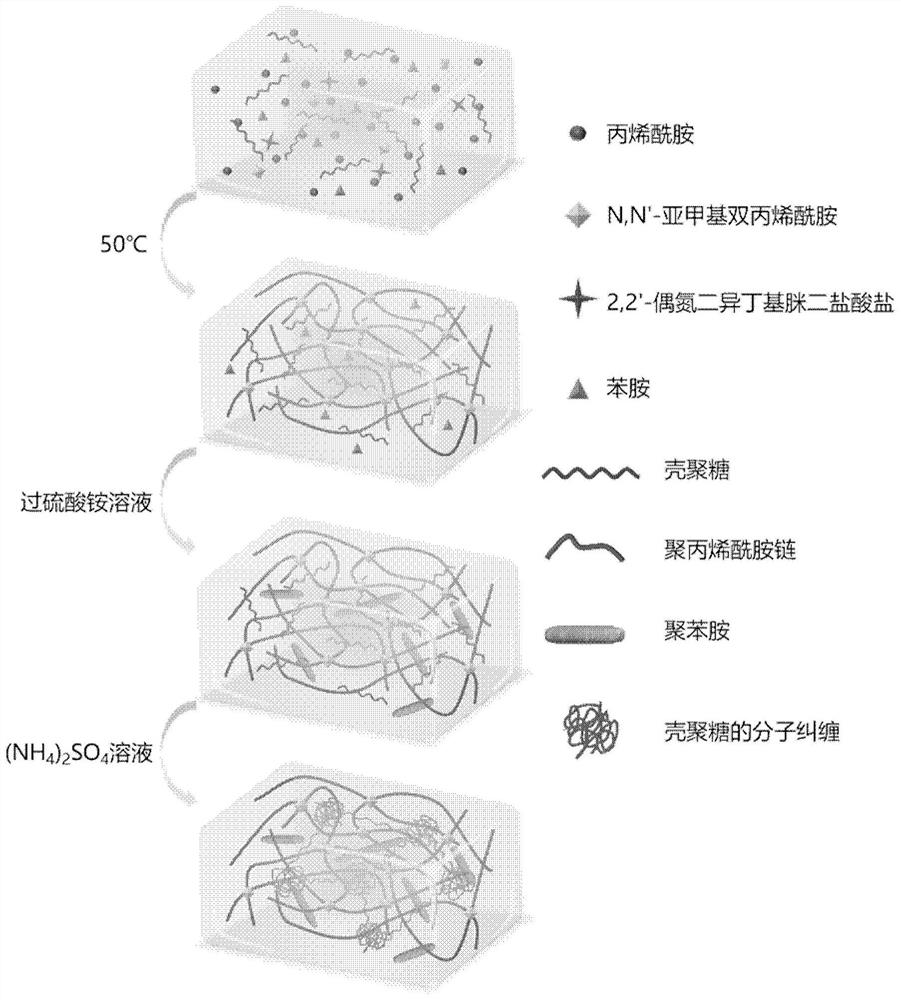

Preparation method of hydrogel sensing material and hydrogel sensor

ActiveCN113429587AGood frost resistanceHigh strength and high toughnessConverting sensor output electrically/magneticallyAmmonium sulfateChemistry

The invention provides a preparation method of a hydrogel sensing material and a hydrogel sensor. The hydrogel sensing material is prepared by the following steps: adding chitosan into hydrochloric acid, stirring in a water bath to form a transparent solution, adding acrylamide, N, N '-methylenebis (acrylamide), 2, 2'-azobis (2-methylpropiamidine) dihydrochloride and aniline after the transparent solution returns to room temperature, stirring and dissolving, carrying out ultrasonic cleaning on the obtained solution for degassing, injecting the polyacrylamide hydrogel into a mold, putting the mold into a constant-temperature box, reacting to generate polyacrylamide composite hydrogel, and immersing the polyacrylamide composite hydrogel into an ammonium persulfate solution to initiate aniline in-situ oxidative polymerization, and finally, immersing the obtained polyaniline / chitosan-polyacrylamide composite hydrogel into an ammonium sulfate solution to obtain the polyaniline / chitosan-polyacrylamide ion-covalent dual-network hydrogel. The prepared polyaniline / chitosan-polyacrylamide ion-covalent dual-network hydrogel can be directly used as a hydrogel sensor.

Owner:UNIV OF SCI & TECH OF CHINA

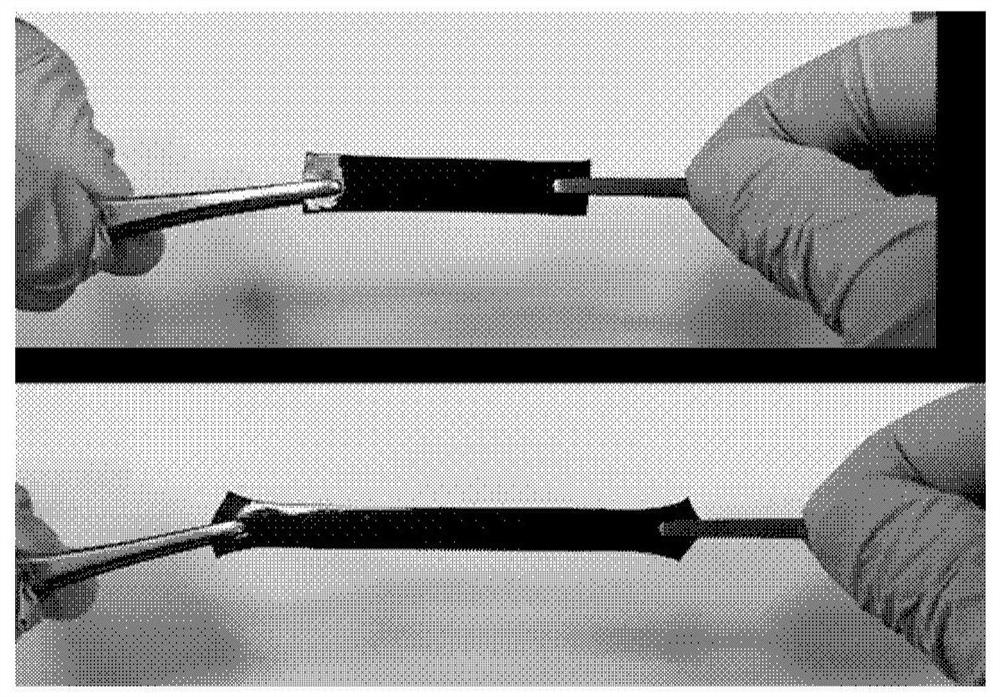

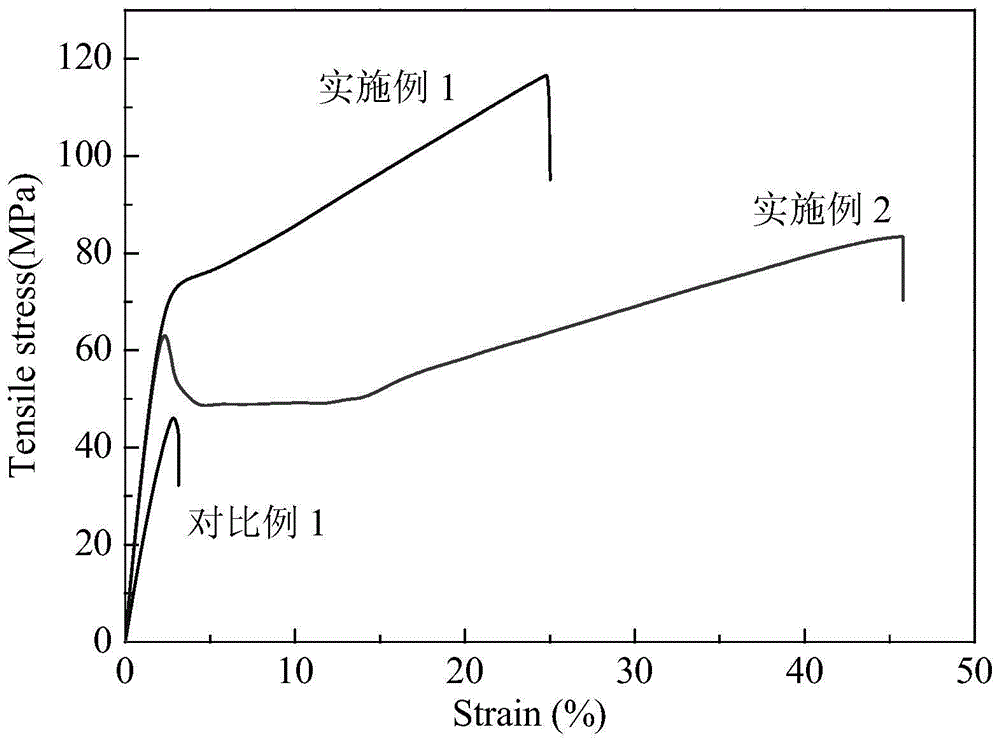

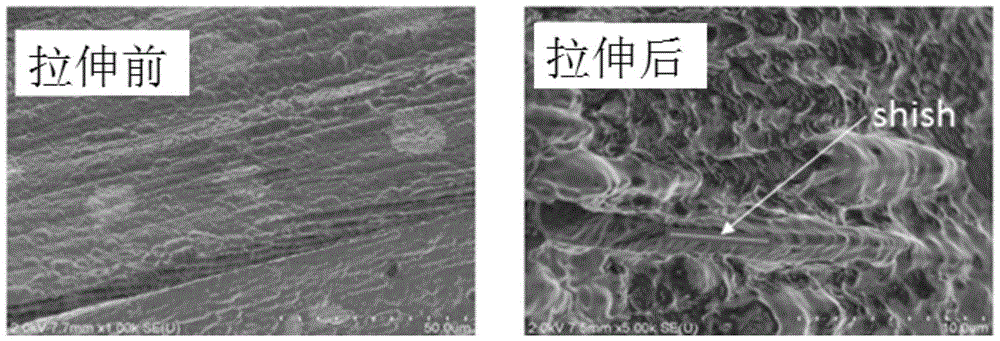

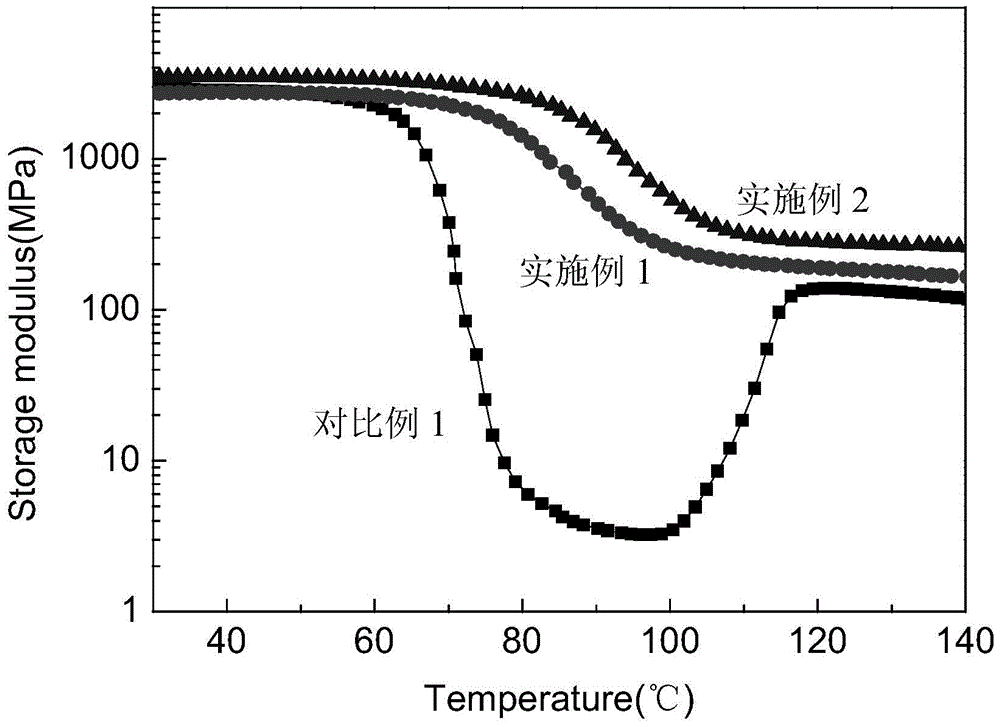

A kind of preparation method of high-strength and high-toughness heat-resistant polylactic acid base film material

A disclosed preparation method for a high-strength high-toughness heatproof polylactic-acid-based membrane material comprises the following steps: firstly performing melt blending on polylactic acid and an amide compound, then forming a sheet material with the thickness of 0.1-3 mm, then stretching the sheet material at a temperature higher than the polylactic acid glass-transition temperature by 0-50 DEG C, and cooling to room temperature, so as to obtain the high-strength high-toughness heatproof polylactic-acid-based membrane material. The method is simple and easy for industrialization, and the obtained polylactic acid material is high in polylactic acid content, and possesses the tensile strength of 135 MPa or more, the breaking elongation of 55% and the heat-resistant temperature of 140 DEG C or more.

Owner:JIANGNAN UNIV

High-strength and high-toughness copper-zinc alloy wire material and preparation method thereof

The invention discloses a high-strength and high-toughness copper-zinc alloy wire material and a preparation method thereof, and relates to the technical field of copper-zinc alloys, and the high-strength and high-toughness copper-zinc alloy wire material comprises the following raw material components in percentage by weight: 2wt%-4wt% of zinc, 0.01 wt%-0.03 wt% of rare earth elements and the balance of copper. The high-strength and high-toughness copper-zinc alloy wire material is reasonable in proportion of copper, zinc and rare earth elements in the raw material components, low in gas content, few in inclusions, uniform in structure component, free of macroscopic and microcosmic defects such as copper and zinc enrichment and the like, high in corrosion resistance, high in strength and high in toughness.

Owner:无锡市蓝格林金属材料科技有限公司

A kind of high-strength high-toughness aluminum alloy and preparation method thereof

ActiveCN110699575BHigh strengthHigh strength and high toughnessMetal rolling arrangementsUltimate tensile strengthToughness

Owner:黄山市龙跃铜业有限公司

A tear-off whitening and whitening mask and its preparation method

ActiveCN109846720BInhibitory activityReduce dark spotsCosmetic preparationsToilet preparationsPolyvinyl alcoholGlycerol

The invention discloses a tear-off whitening and whitening mask and a preparation method thereof. The tear-off whitening and whitening mask is composed of the following components in percentage by weight: whitening and alcohol precipitation 1-5%, whitening enhancer 0.02‑0.4%, sodium hyaluronate 0.01‑0.05%, sodium carboxymethylcellulose 0.1‑0.5%, allantoin 0.05‑0.5%, polyvinyl alcohol 10‑30%, glycerin 5‑20%, butylene glycol 5‑20%, methyl paraben 0.1‑0.6%, and the balance is deionized water. The peeling type whitening and whitening facial mask prepared by the present invention can effectively inhibit the activity of tyrosinase, reduce the dark spots caused by chloasma and acne, and have the functions of removing freckles, whitening and moisturizing; whitening enhancer B Sodium zinc diamine tetraacetate and vitamin C can inhibit the activity of tyrosinase and block the production of melanin, and can improve the inhibitory activity of tyrosinase by Baijiol precipitation solution, and have synergistic functions; chitosan and B Disodium diamine tetraacetate can remove Pb from the face 2+ , Hg 2+ 、Ni 2+ and other heavy metal ions, reducing the harm caused by heavy metals to skin aging and wrinkles.

Owner:HUBEI UNIV OF CHINESE MEDICINE

Iron powder electrode deposited metal with high strength and high toughness

InactiveCN101693327BHigh strengthHigh strength and high toughnessWelding/cutting media/materialsSoldering mediaIron powderShrinkage rate

The invention belongs to the technical field of welding materials, and specifically introduces an iron powder electrode deposited metal with high strength and high toughness. Ingredients in mass percent include C 0.030 to 0.080, Mn 0.80 to 1.80, Si 0.20 to 0.50, Ni 2.30 to 3.50, Cr 0.10 to 0.25, Mo 0.10 to 0.25, Ti 0.010 to 0.040, S less than or equal to 0.010, P less than or equal to 0.016, the balance of Fe. By using the deposited metal for welding 10CrNi3MoV steels and 10CrNi4MoV steels, the technology is good, yield strength of welded joints is more than 600MPa, elongation percentage is more than 16%, section shrinkage rate is greater than 50%, impact energy under minus 50 DEG C is more than 34J; proportion of welding seam structure acicular ferrite is over 90%; deposition efficiency can be over 130%.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-strength and high-toughness titanium alloy pipe for oil and gas development and preparation method thereof

ActiveCN109706344BHigh strengthHigh strength and high toughnessDrilling rodsDrilling casingsTitanium alloyComponents of crude oil

The invention relates to a high-strength and high-toughness titanium alloy pipe for oil and gas development and a preparation method thereof, so as to ensure the safe and effective exploitation of oil and gas wells, and mainly solve the problem that the strength and toughness of existing titanium alloy pipes cannot meet the requirements of ultra-deep and high-pressure oil and gas wells. environmental characteristics. Except for Ti, the titanium alloy pipe is mainly composed of the following components by mass percentage, Al: 3.8-5.0%, V: 2.4-3.3%, Fe: 1.3-1.8%, Nb: 0.4-0.8%, Ni: 0.3-1.0 %, O ≤ 0.2%, C ≤ 0.04%, N ≤ 0.04%, H ≤ 0.0135%, also add one or two of the following alloying elements, Cr: 0.15-0.35%, Mo: 0.05-1.0%. At the same time, the present invention also provides a method for preparing the above-mentioned titanium alloy tube.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A tear-off type traditional Chinese medicine whitening mask and preparation method thereof

ActiveCN109745274BReduce dark spotsInhibits tyrosinase activityCosmetic preparationsToilet preparationsMorinPolyvinyl alcohol

The invention discloses a tearing-type traditional Chinese medicine whitening facial mask and a preparation method thereof. The tearing-type traditional Chinese medicine whitening facial mask is prepared from, by weight, 1-4% of an alcohol precipitate of rhizoma bletillae, 1-4% of a water extract of flos carthami, 0.05-0.3% of a whitening enhancer, 0.01-0.05% of sodium hyaluronate, 0.1-0.5% of sodium carboxymethyl cellulose, 0.05-0.5% of allantoin, 10-30% of polyvinyl alcohol, 5-20% of glycerin, 5-20% of butanediol, 0.1-0.6% of methylparaben and the balance deionized water. The alcohol precipitate of rhizoma bletillae and the water extract of flos carthami in the prepared tearing-type traditional Chinese medicine whitening facial mask can effectively inhibit the activity of tyrosinase andreduce melasma and black spots caused by acne; the whitening enhancer EDTA-Zn and a morin-zinc complex can inhibit the activity of tyrosinase and block the production of melanin, the inhibitory activity of the alcohol precipitate of rhizoma bletillae and the water extract of flos carthami to tyrosinase can be improved, and a synergistic function is achieved. Chitosan and morin can remove heavy metal ions such as Pb2+, Hg2+ and Ni2+ from the face and reduce the damage of skin aging and wrinkles caused by the heavy metals.

Owner:湖北润康医疗科技有限公司

A high-strength, high-toughness and wear-resistant composite steel plate and its manufacturing method

ActiveCN109835014BImprove performanceImprove refinementFurnace typesMetal rolling arrangementsHardnessHigh wear resistance

The invention discloses a high-strength, high-toughness and wear-resistant composite steel plate, which includes a substrate layer and a composite layer composited on one or both sides of the substrate layer; the substrate layer is a carbon steel layer, and the composite layer is ultra-high manganese. Steel layer, the content of Mn element in the composite layer is 16.00-25.00wt.%. In addition, the invention also discloses a method for manufacturing the above-mentioned high-strength, high-toughness and wear-resistant composite steel plate, which includes the steps: (1) preparing the base layer slab and the composite layer slab; (2) assembling the slab; (3) heating: The heating temperature is 1150~1250℃, and the heat preservation is 1~3 hours; (4) Composite rolling: the opening rolling temperature is 1120~1220℃, the final rolling temperature is 1050~1200℃, and the control reduction rate is ≥50%; (5) Cool after rolling. The high-strength, high-toughness and wear-resistant composite steel plate of the present invention not only has high hardness, but also has high wear resistance and high toughness, and the steel plate has excellent comprehensive properties.

Owner:BAOSHAN IRON & STEEL CO LTD

A high-strength, high-toughness, corrosion-resistant, lead-free, arsenic-free brass alloy and preparation method thereof

The invention relates to the technical field of nonferrous metals, in particular to a high-strength, high-toughness, corrosion-resistant, lead-free, arsenic-free brass alloy and a preparation method thereof. The lead-free and arsenic-free brass alloy of the present invention comprises 59-70% of Cu, 20-33% of Zn, 4-5% of Al and 2-5% of Fe in terms of mass percentage, excluding As and Pb. The brass alloy of the invention is free of arsenic and lead, has high strength, high toughness and good corrosion resistance, and can replace lead brass and arsenic brass.

Owner:SHENZHEN RES INST OF XIAMEN UNIV

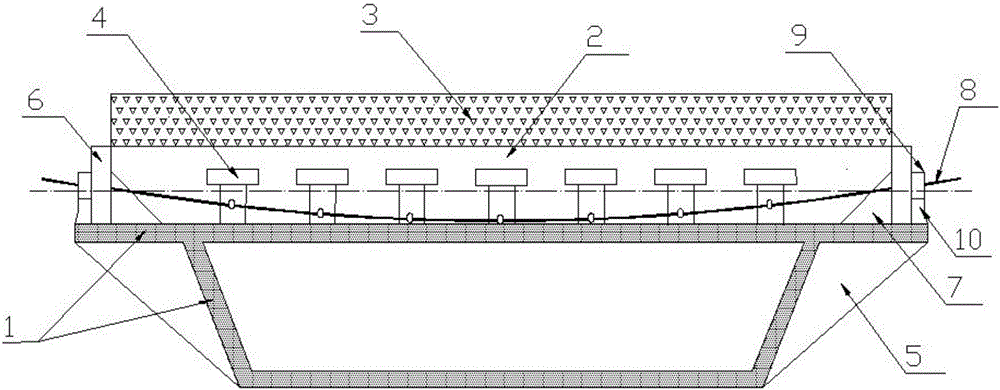

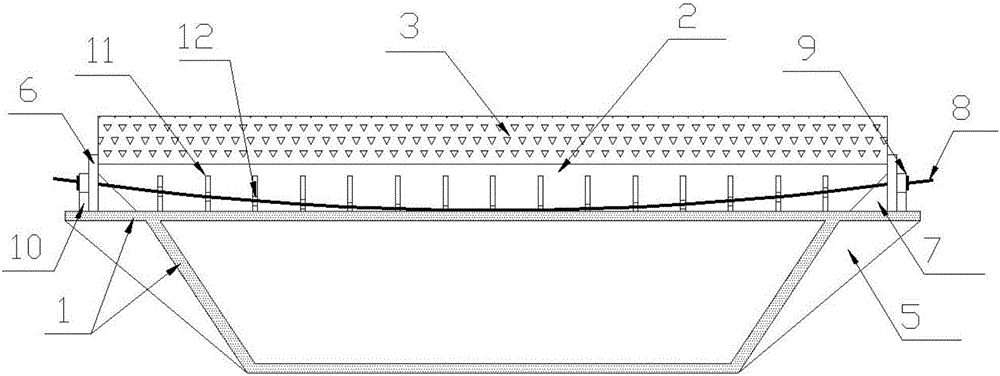

A kind of bridge deck pavement method

ActiveCN104562888BReduce diseaseExtended service lifeTemporary pavingsBridge structural detailsSheet steelPre stress

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com