Forging forming method for TA15 titanium alloy forge piece with high strength and high tenacity

A titanium alloy, high toughness technology, applied in the field of forging and forming of TA15 titanium alloy forgings, can solve the problems of weak strengthening effect, unqualified strength of forgings, unqualified tensile strength, etc., achieve parameter optimization, improve strength and toughness level, improve The effect of service performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

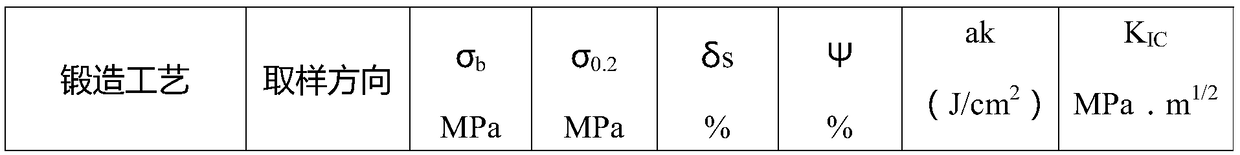

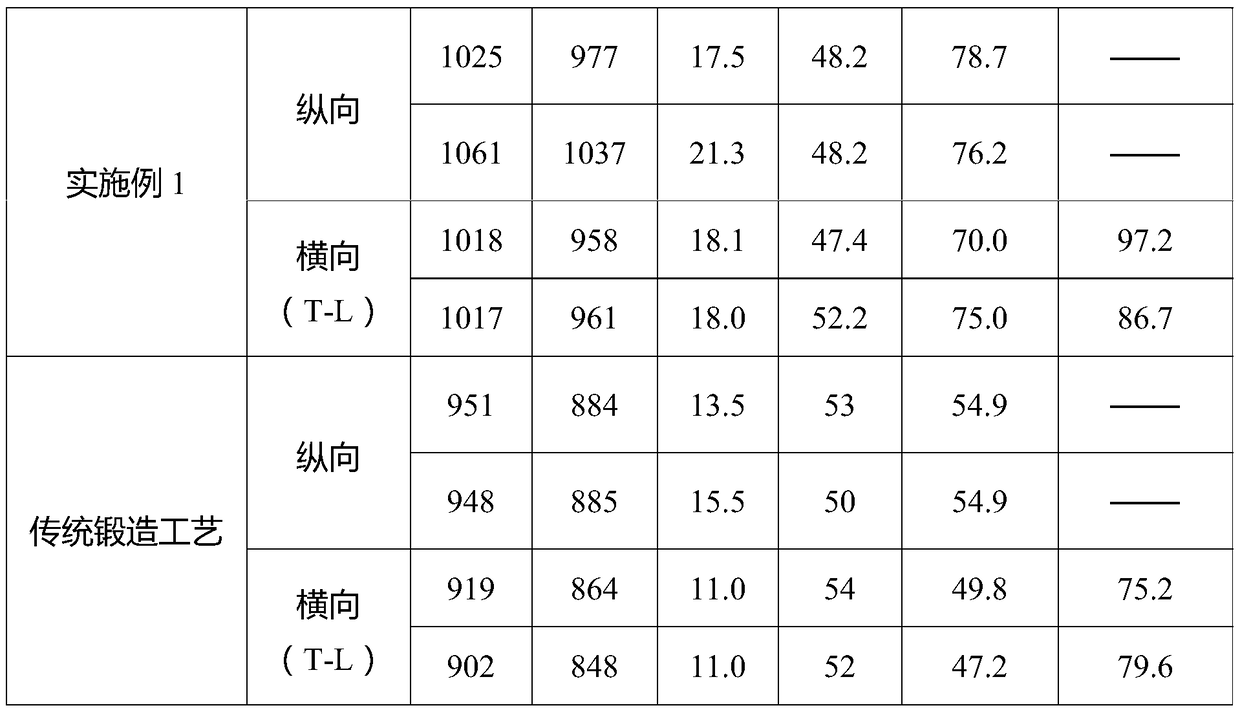

Examples

Embodiment 1

[0034] A method for forging and forming a TA15 titanium alloy forging with high strength and high toughness, comprising the following steps:

[0035] 1. Free forging billet

[0036] Step 1, preheating and heat preservation of the billet: Spray the TA15 titanium alloy φ300mm bar material cut according to the process specification with protective lubricant, and place it in a resistance furnace with a maximum temperature deviation of no more than ±10°C in the effective working area for preheating. heat temperature T β -35°C, calculate the holding time after the furnace temperature reaches the preheating temperature, the heating coefficient η is 0.8, the holding time is 240min, and the preheated billet is obtained after holding the heat.

[0037] Step 2, free forging: take the preheated billet out of the furnace and make billet on the free forging fast forging machine. The forging hammer of the fast forging machine needs to be preheated to 300°C in advance, and the deformation of...

Embodiment 2

[0047] A method for forging and forming a TA15 titanium alloy forging with high strength and high toughness, comprising the following steps:

[0048] 1. Free forging billet

[0049] Step 1, preheating and heat preservation of the billet: preheat the TA15 titanium alloy φ350mm rod obtained by blanking according to the process specification, and place it in a resistance furnace with a maximum temperature deviation of not more than ±10°C in the effective working area, and the preheating temperature is T β -45°C, calculate the holding time after the furnace temperature reaches the preheating temperature, the heating coefficient η is 0.6, the holding time is 210min, and the preheated billet is obtained after holding the heat.

[0050] Step 2, free forging: take the preheated billet out of the furnace and make billet on the free forging fast forging machine. The forging hammer of the fast forging machine needs to be preheated to 250°C in advance, and the deformation of single fire f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com