Rare-earth-containing low-carbon high-alloy anticorrosion oil casing steel and preparation process thereof

A preparation process and a technology for corrosion oil, applied in the metallurgical field, can solve the problems of low economic benefit and investment ratio, insufficient anti-SSC performance, large one-time investment, etc., and achieve the effects of good economic benefit, good promotion value and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

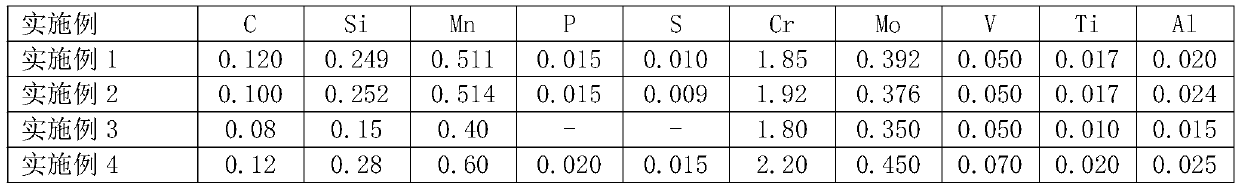

[0016] The manufacturing process of the material is: electric furnace smelting→alloy addition→rare earth treatment→blank casting. The chemical composition of each example is shown in Table 1.

[0017] Each embodiment composition of table 1 (mass percentage / %)

[0018]

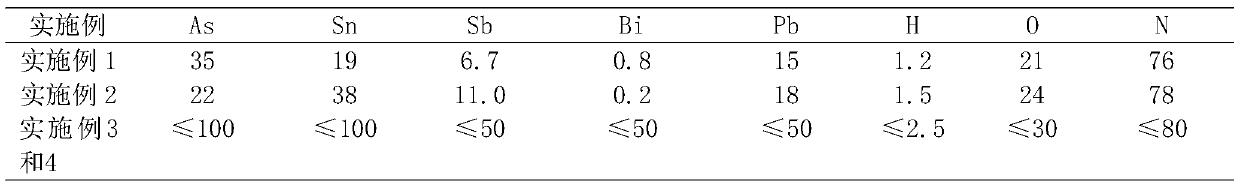

[0019] Table 2 five harmful elements and gas content (ppm)

[0020]

[0021] The rolling process is: billet→heating→rolling→slow cooling. The starting temperature of the round billet rolling is 1200-1250°C; the final rolling temperature is above 930°C.

[0022] The heat treatment process is: quenching + tempering, the quenching temperature is 1030°C ± 10°C, and the heat preservation is 70-80 minutes; the tempering temperature is 740°C ± 10°C, and the heat preservation is 90-100 minutes.

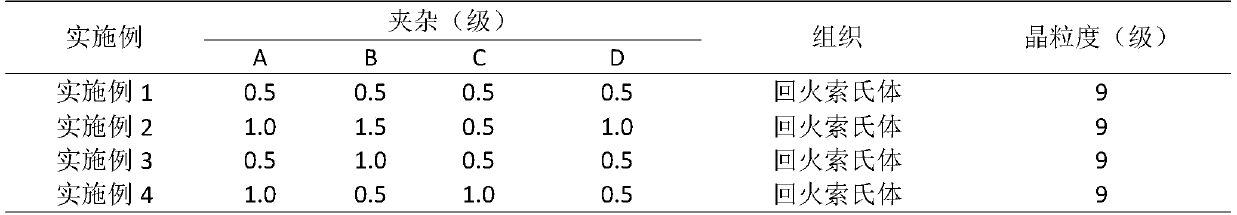

[0023] The metallographic structure inspection results after heat treatment are shown in Table 3, and the mechanical properties after heat treatment are shown in Table 4.

[0024] Metallographic structure of each embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com