Preparation method of hydrogel sensing material and hydrogel sensor

A sensing material, hydrogel technology, applied in the field of intelligent soft materials, can solve the problems of loss of elasticity and conductivity, limited use temperature, poor anti-ultraviolet performance, etc., and achieve high strength, high toughness, excellent frost resistance, ultra- The effect of strong UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

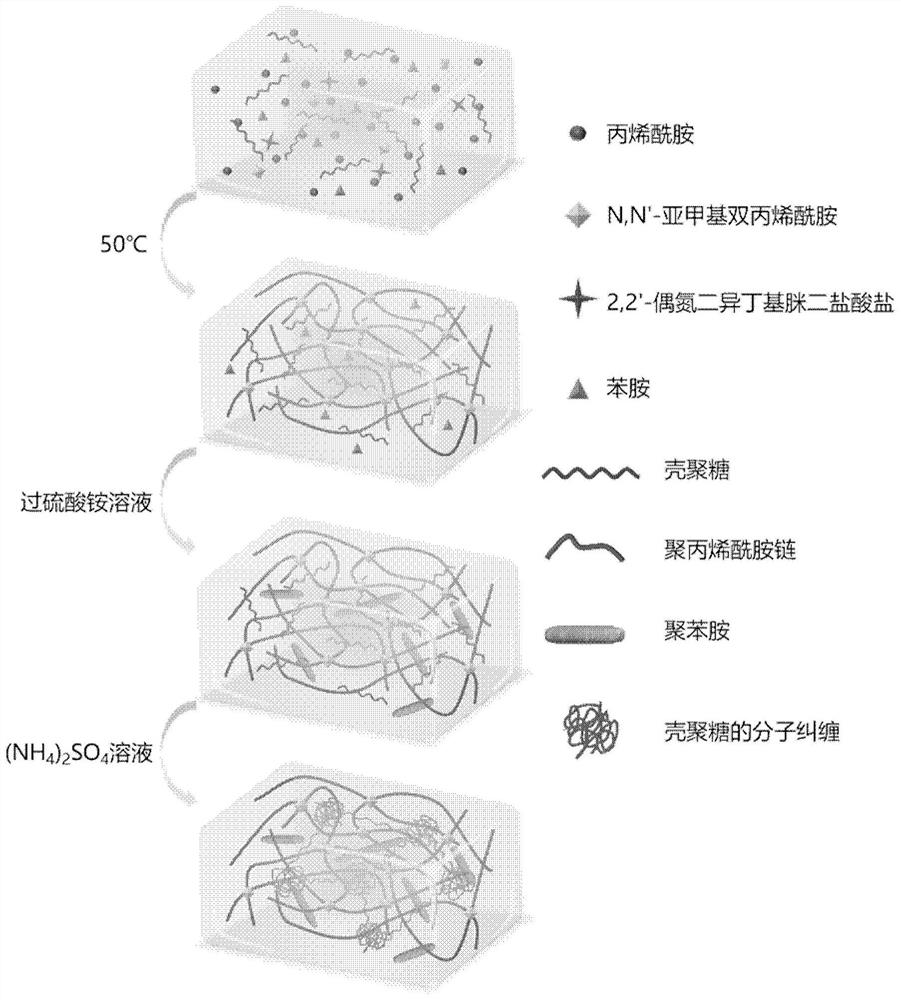

[0035] An aspect of the embodiments of the present disclosure provides a method for preparing a hydrogel sensing material, comprising:

[0036] Step (1) adding chitosan to hydrochloric acid to form a transparent solution under stirring in a water bath;

[0037] Step (2) After the transparent solution returns to room temperature, add acrylamide, N,N'-methylenebis(acrylamide), 2,2'-azobis(2-methylpropionamidine) dihydrochloride and aniline, and stirred to dissolve;

[0038] Step (3) Degas the stirred and dissolved solution by ultrasonic cleaning, then pour it into a mold, put the mold into a constant temperature box, use N,N'-methylenebis(acrylamide) as a crosslinking agent, 2,2'-Azobis(2-methylpropionamidine) dihydrochloride is used as a thermal initiator for free radical polymerization of acrylamide monomers in a thermostat to generate polyacrylamide composite hydrogels;

[0039] Step (4) immersing the polyacrylamide composite hydrogel in the ammonium persulfate solution, tr...

Embodiment 1

[0058] (1) Add 0.3g of chitosan to 10mL of clear water to form a transparent solution under stirring in a water bath at 55°C.

[0059] (2) After the transparent solution returns to room temperature, add 1.42g acrylamide, 10.79mg N, N'-methylenebis(acrylamide), 5.42mg 2,2'-azobis(2-methylpropionamidine) ) dihydrochloride and 250 μL aniline, and stir well to dissolve.

[0060] (3) The above solution was degassed by ultrasonic cleaning for 2 minutes, and then poured into a mold consisting of two glass plates separated by a 1 mm silicone gasket. Using N, N'-methylenebis(acrylamide) as crosslinking agent, 2,2'-azobis(2-methylpropionamidine) dihydrochloride as the thermal initiator of acrylamide monomer free The base polymerization reaction was carried out in a constant temperature box at 57°C for 12 hours to form a polyacrylamide composite hydrogel.

[0061] (4) Immerse the polyacrylamide composite hydrogel in an excess of 0.5 mol / L ammonium persulfate solution, trigger the in si...

Embodiment 2

[0064] (1) Add 0.5 g of chitosan to 10 mL of 0.5 mol / L hydrochloric acid to form a transparent solution under stirring in a water bath at 60°C.

[0065] (2) After the transparent solution returns to room temperature, add 2.13g acrylamide, 16.19mg N, N'-methylenebis(acrylamide), 8.14mg 2,2'-azobis(2-methylpropionamidine) ) dihydrochloride and 750 μL aniline, and stir well to dissolve.

[0066] (3) The above solution was degassed by ultrasonic cleaning for 5 minutes, and then poured into a mold consisting of two glass plates separated by a 2 mm silicone gasket. Free radicals of aniline monomers with N,N'-methylenebis(acrylamide) as crosslinking agent and 2,2'-azobis(2-methylpropionamidine) dihydrochloride as thermal initiator The polymerization reaction was carried out in a thermostat at 50° C. for 12 hours to generate a polyacrylamide composite hydrogel.

[0067] (4) The polyacrylamide composite hydrogel was immersed in an excess of 1 mol / L ammonium persulfate solution, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com