Hollow brick production method utilizing furnace slag to enhancing anti-freezing performance

A hollow brick and slag technology, used in applications, household appliances, clay products, etc., can solve the problems of green body peeling, affecting appearance and durability, and achieve the improvement of anti-freezing performance, improve anti-freezing performance, and promote solid-phase reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

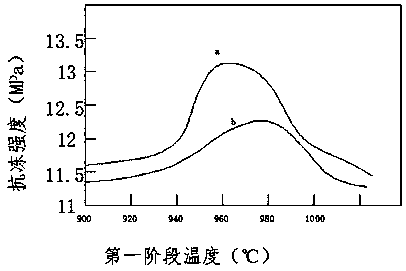

Image

Examples

Embodiment 1

[0022] A method for preparing hollow bricks using slag to enhance frost resistance, comprising the following steps:

[0023] (1) Gneiss, slag and iron ore powder are added to the grinder for crushing and grinding, and then sieved to obtain a premix, and the mixing mass ratio of the gneiss, slag and iron ore powder is 10: 80:1.2, the grinding process is to mix gneiss, slag and iron ore powder, then add glycerin with 30% of the mass of slag, grind for 2 hours, and then add an organic acid solution with 0.5% of the mass of glycerol , continue to grind for 2 hours, then rotate to evaporate and dry, filter, and dry to obtain that, the organic acid solution is selected from one of C1-C18 organic carboxylic acids, wherein the organic carboxylic acid solution is 1.5% by mass fraction Oxalic acid solution, by adding a certain amount of glycerol and organic carboxylic acid as grinding aids when grinding gneiss, slag and iron ore powder, can greatly improve the grinding effect and promot...

Embodiment 2

[0030] A method for preparing hollow bricks using slag to enhance frost resistance, comprising the following steps:

[0031] (1) Gneiss, slag and iron ore powder are added in the grinder and crushed and ground, and then sieved to obtain a premix, and the mixing mass ratio of the gneiss, slag and iron ore powder is 15: 80:1.2, the grinding process is to mix gneiss, slag and iron ore powder, then add glycerin with 30% of the mass of slag, grind for 2 hours, and then add an organic acid solution with 0.5% of the mass of glycerol , continue to grind for 2 hours, then rotate to evaporate and dry, filter, and dry to obtain that, the organic acid solution is selected from one of C1-C18 organic carboxylic acids, wherein the organic carboxylic acid solution is 1.5% by mass fraction Oxalic acid solution, by adding a certain amount of glycerol and organic carboxylic acid as grinding aids when grinding gneiss, slag and iron ore powder, can greatly improve the grinding effect and promote t...

Embodiment 3

[0038] A method for preparing hollow bricks using slag to enhance frost resistance, comprising the following steps:

[0039] (1) Gneiss, slag and iron ore powder are added in the grinder for crushing and grinding, and then sieved to obtain a premix, and the mixing mass ratio of the gneiss, slag and iron ore powder is 12: 80:1.2, the grinding process is to mix gneiss, slag and iron ore powder, then add glycerin with 30% of the mass of slag, grind for 2 hours, and then add an organic acid solution with 0.5% of the mass of glycerol , continue to grind for 2 hours, then rotate to evaporate and dry, filter, and dry to obtain that, the organic acid solution is selected from one of C1-C18 organic carboxylic acids, wherein the organic carboxylic acid solution is 1.5% by mass fraction Oxalic acid solution, by adding a certain amount of glycerol and organic carboxylic acid as grinding aids when grinding gneiss, slag and iron ore powder, can greatly improve the grinding effect and promot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com