Patents

Literature

32results about How to "Improve sintering density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrocondution slurry for chip component termination electrode

InactiveCN102842353AReduce thicknessImprove adhesion strengthNon-conductive material with dispersed conductive materialMetallurgySlurry

The invention provides electrocondution slurry used for a chip component termination electrode. The electrocondution slurry comprise the following components in percentage by weight: 45-75% of silver powder, 2-10% of glass powder, 20-50% of organic carriers and 0-3% of inorganic additives. The chip component termination electrode manufactured by the electrocondution slurry can reduce thickness of a silver layer obviously, thus reducing manufacturing cost of a chip component obviously.

Owner:廖晓峰

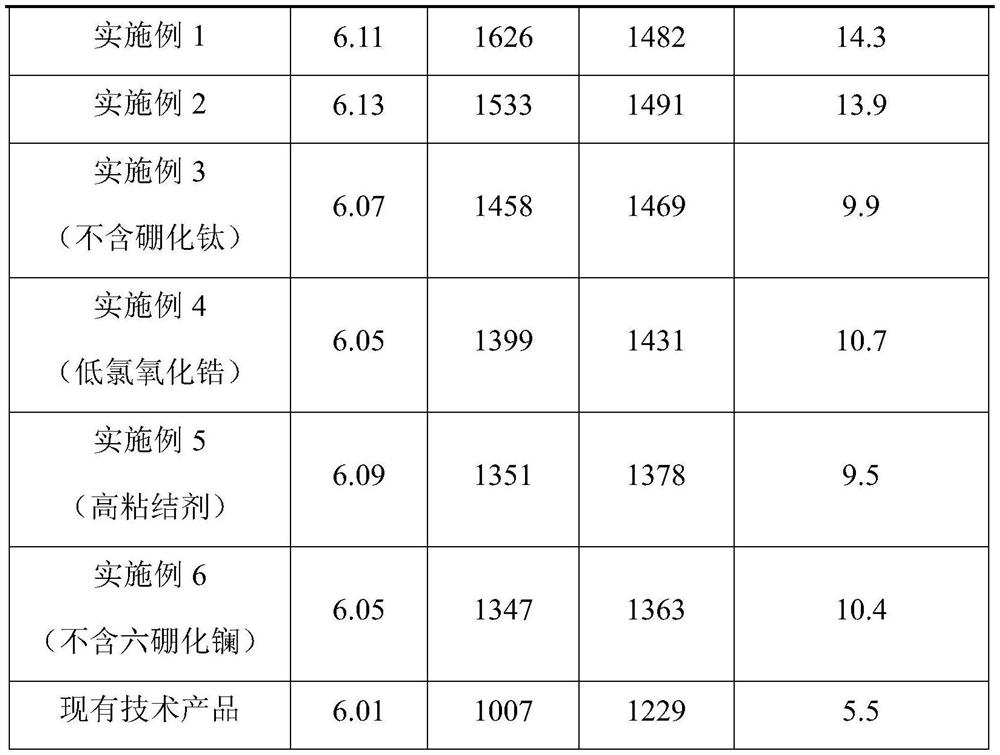

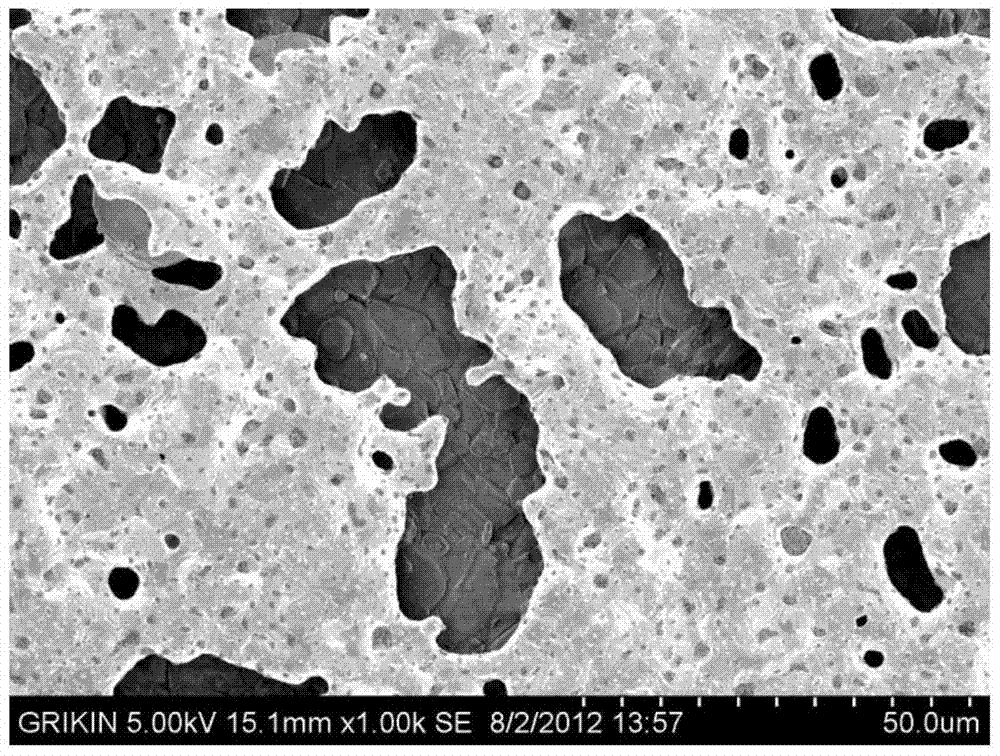

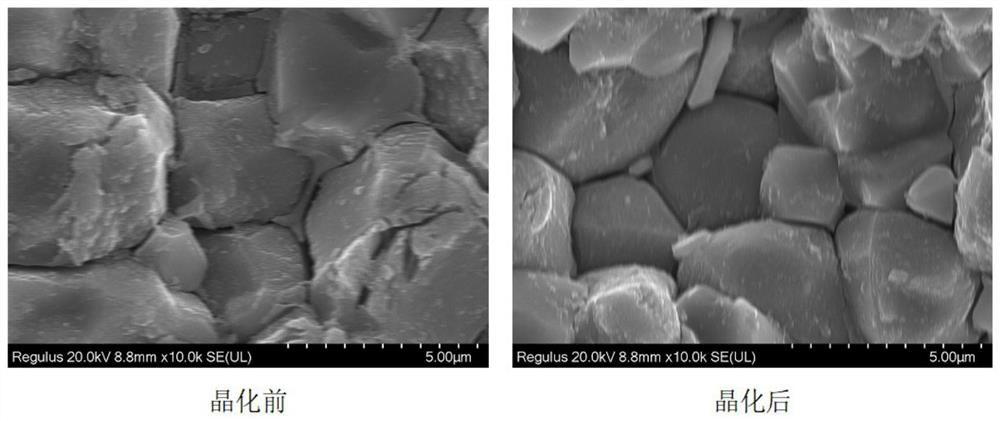

Zirconia-based ceramic back plate, preparation method and application thereof

ActiveCN112723885ANo VOCReduce porosityTelephone set constructionsHeat stabilityZirconium oxychloride

The invention provides a zirconia-based ceramic back plate, a preparation method and application thereof. According to the invention, zirconia, zirconium oxychloride and lanthanum hexaboride are used as initial raw materials, a green body is obtained through uniform mixing, hydrolysis, drying and ultrahigh-pressure isostatic cool pressing pretreatment in the presence of a binder, and is free of organic volatilization, low in porosity and free of density gradient, and the blank is subjected to presintering, slicing and secondary sintering treatment to obtain a zirconia ceramic back plate, wherein the zirconia ceramic back plate obtained after the blank is sintered is good in sintering density, high in strength and high in wear resistance and has high toughness, strength and hardness and excellent wear resistance and heat stability.

Owner:HUNAN KOSEN NEW MATERIAL

High-compactness boiling-resistant solar aluminum paste

InactiveCN103106948AHigh bulk densityImprove sintering densityNon-conductive material with dispersed conductive materialSemiconductor devicesCelluloseBack surface field

The invention provides high-compactness boiling-resistant solar aluminum paste. The high-compactness boiling-resistant solar aluminum paste is characterized by comprising, by weight, 75-78% of spherical aluminum powder, 20-25% of organic binding agents, 1-2% of glass powder, and 0.1-0.2% of boron carbide micro powder, wherein the spherical aluminum powder comprises, by weight, 10-20% of spherical aluminum powder of 7-8 micrometers, 10-20% of spherical aluminum powder of 6-7 micrometers, 40-60% of spherical aluminum powder of 5-6 micrometers and 10-20% of spherical aluminum powder of 1-2 micrometers. The organic binding agents comprise, by weight, 94.5% of mixed solvent, 2% of low grade ethyl cellulose, 4% of high grade of ethyl cellulose and 0.5% of hydrogenated castor oil. Through adjustment and optimization of a formula, boiling-resistant performance of an aluminum back surface field is significantly improved.

Owner:NANTONG RELIANCE SOLAR TECH

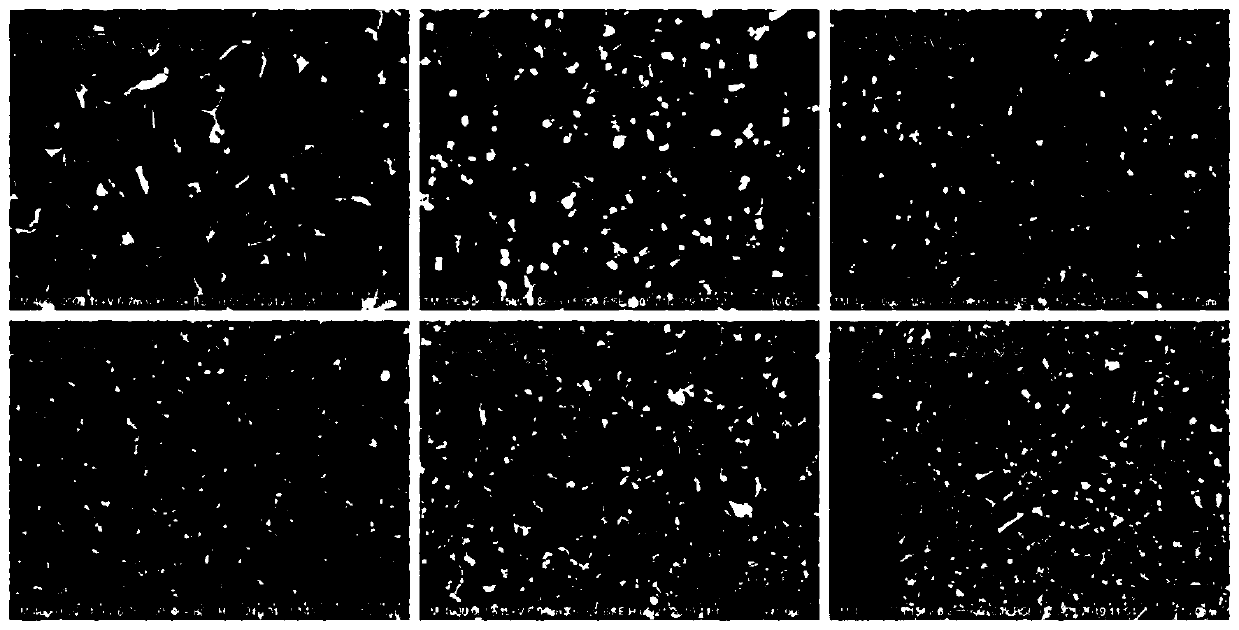

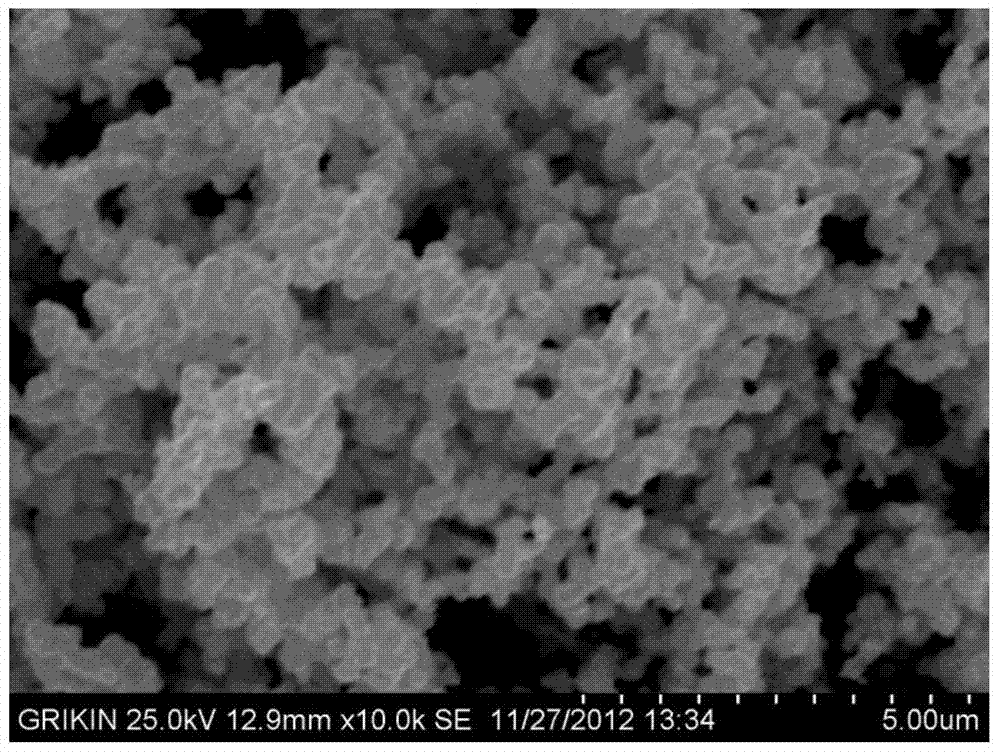

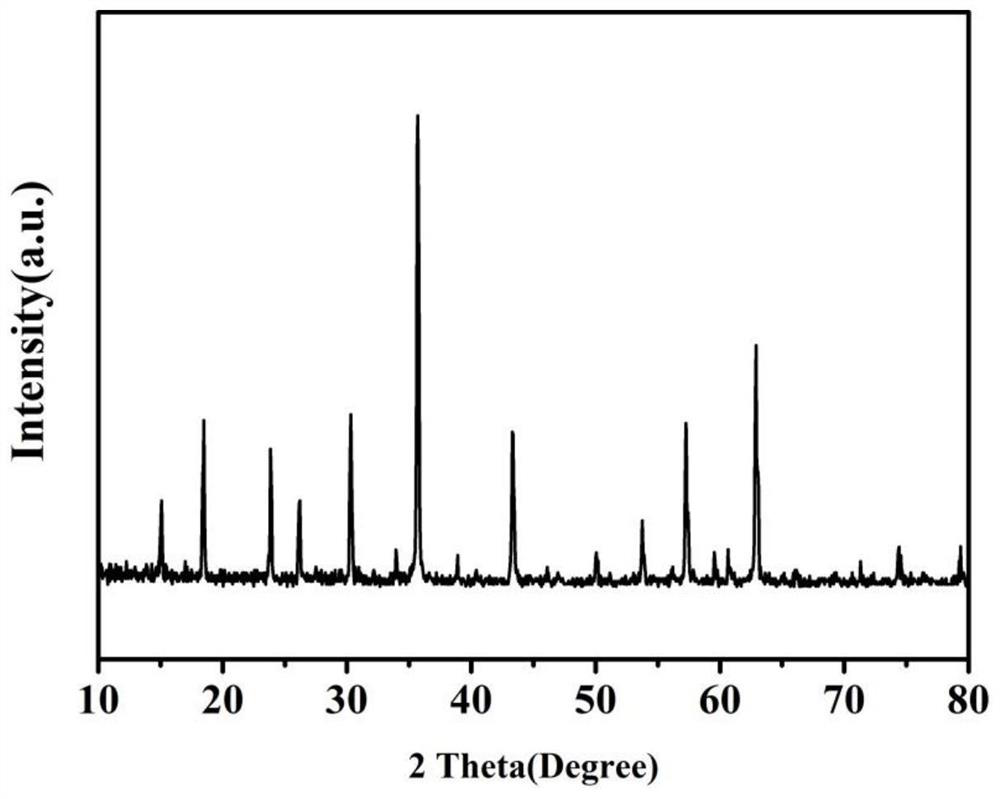

Method for improving sintering compactness of un-bonded phase tungsten carbide hard alloy

The invention discloses a method for improving sintering compactness of an un-bonded phase tungsten carbide hard alloy. The method comprises preparation of activated tungsten carbide powder and die pressing sintering, wherein the preparation of the activated tungsten carbide powder comprises the following steps of: putting tungsten carbide powder into an active solution, performing ultrasonic activation treatment for 30 to 40 minutes at normal temperature, washing after the activation is finished, drying for 3 to 6 hours at the temperature of between 150 and 180 DEG C, and thus obtaining the activated tungsten carbide powder, wherein the particle diameter of the tungsten carbide is 1 to 3 microns, and the active solution is an aqueous solution of hydrofluoric acid, ammonium fluoride and nitric acid. According to the method, the sintering compactness of the un-bonded phase tungsten carbide hard alloy can be improved by the activation treatment, the prepared un-bonded phase tungsten carbide hard alloy is small in tissues, the hardness of the alloy is HV1900-2200, and the fracture toughness of the alloy is 7-12MPam<1 / 2>.

Owner:HEFEI UNIV OF TECH

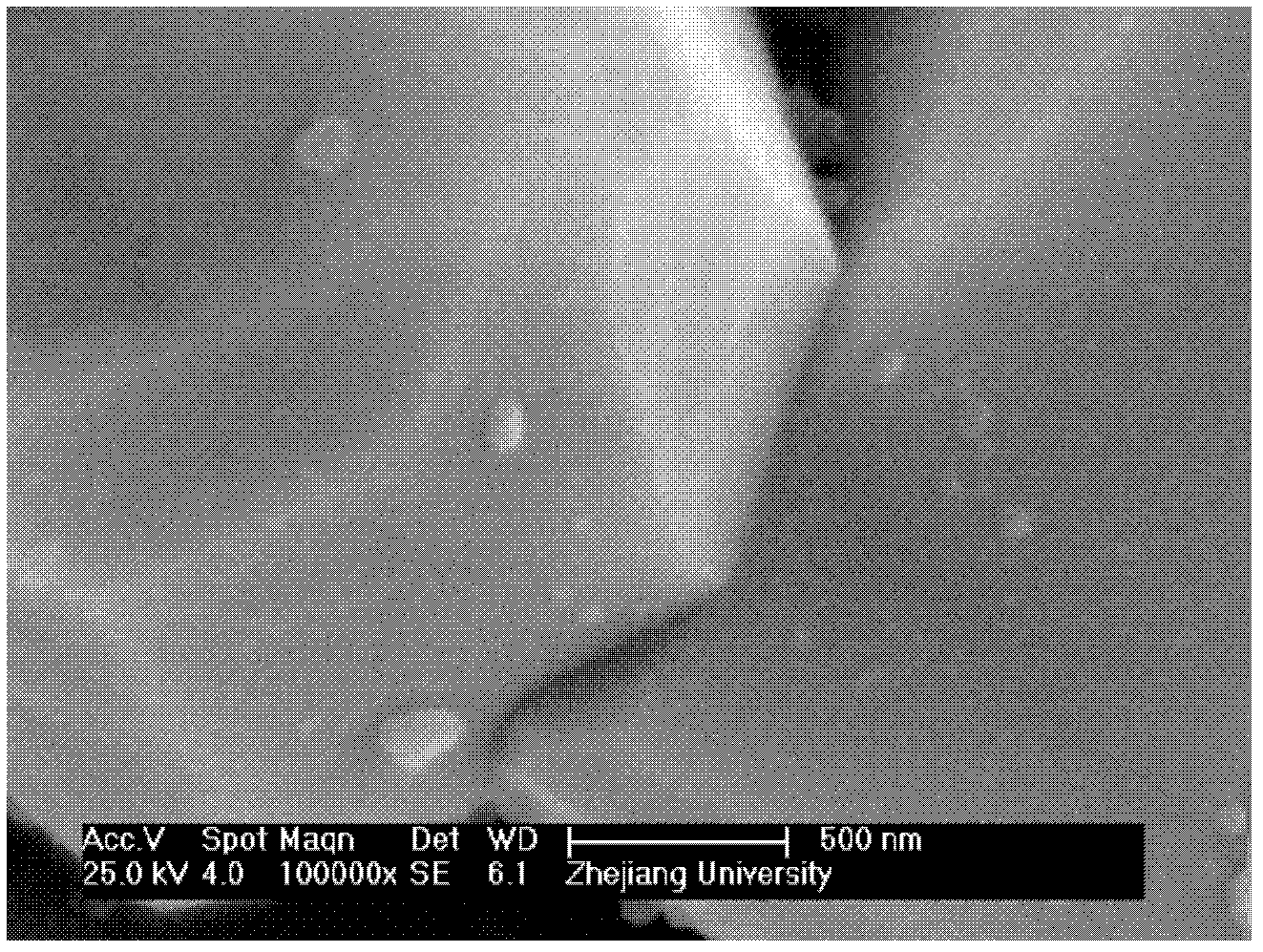

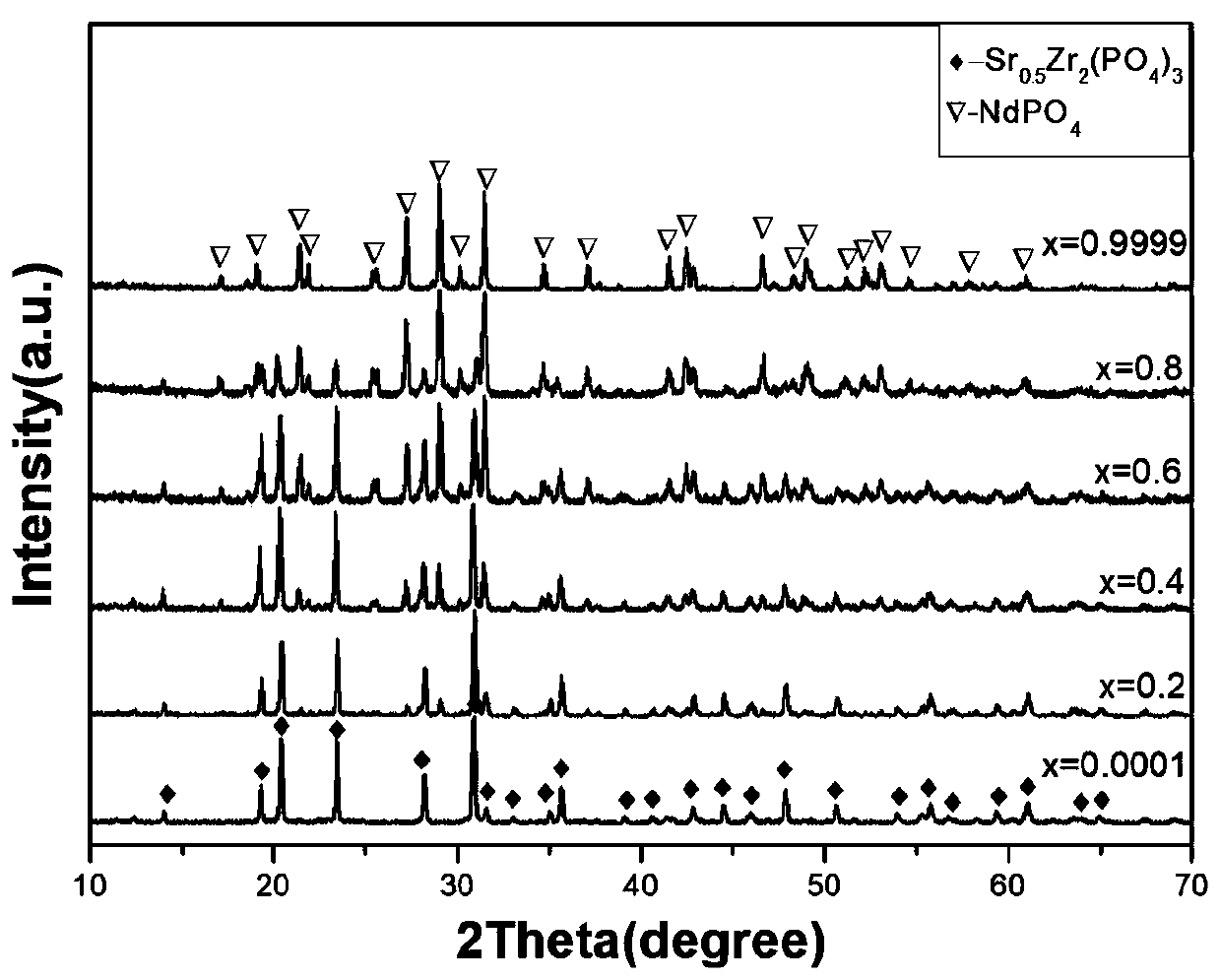

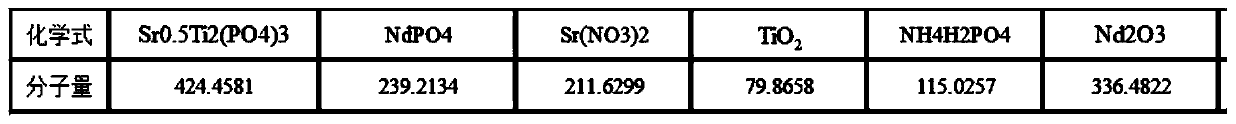

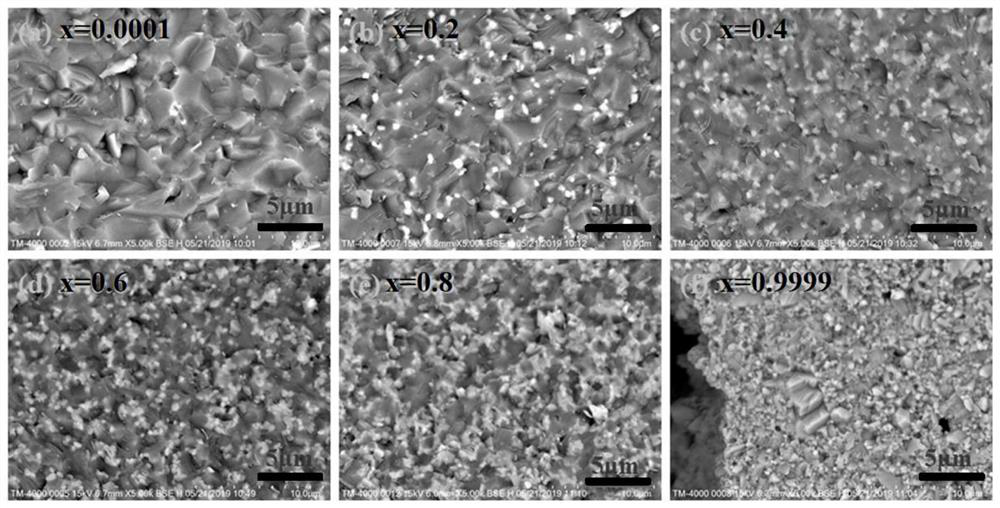

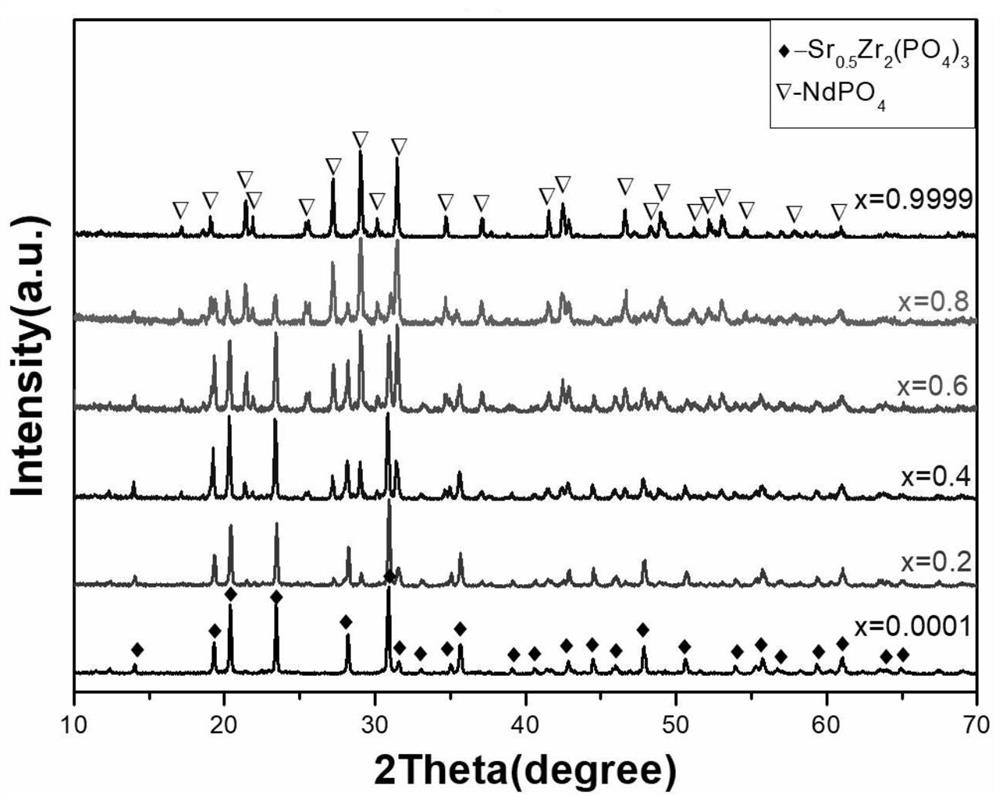

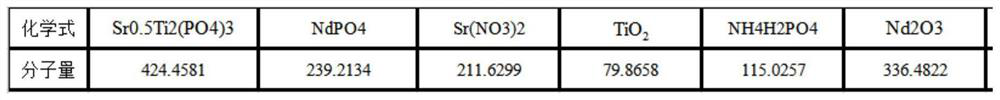

Preparation method of novel phosphate composite ceramic solidified body material

The invention discloses a preparation method of a novel phosphate composite ceramic solidified body material, which comprises the following steps: mixing raw materials, presintering to obtain a precursor, adding a sintering aid into the precursor, and carrying out mechanical activation, molding and sintering to obtain the novel phosphate composite ceramic solidified body material; wherein a phosphorus source in the raw materials is ammonium dihydrogen phosphate or phosphorus pentoxide; the raw materials of elements A, B, Ln and An in the raw materials are one selected from nitrate, metal alkoxide or oxide; A is a +1 or +2 valent element, B is a +4 valent element, Ln is a +3 or +4 valent lanthanide, and An is a +3 or +4 valent actinide. The NZP type ceramic and the monazite ceramic in the novel phosphate composite ceramic solidified body prepared by the invention are solidified body materials with excellent chemical stability, so that the phosphate composite ceramic solidified body is large in waste packaging capacity and good in stability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

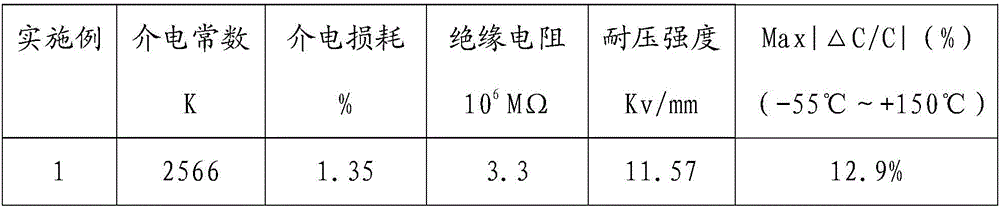

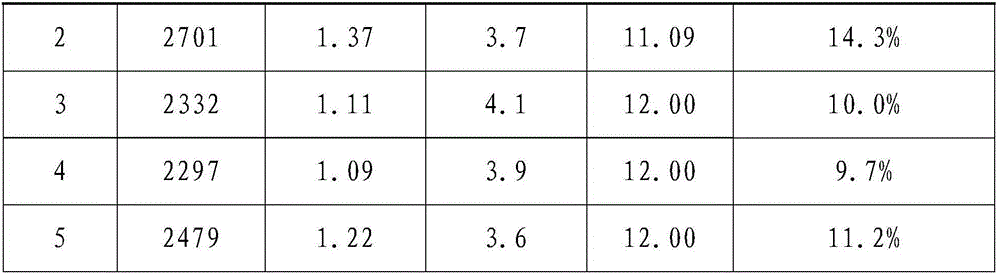

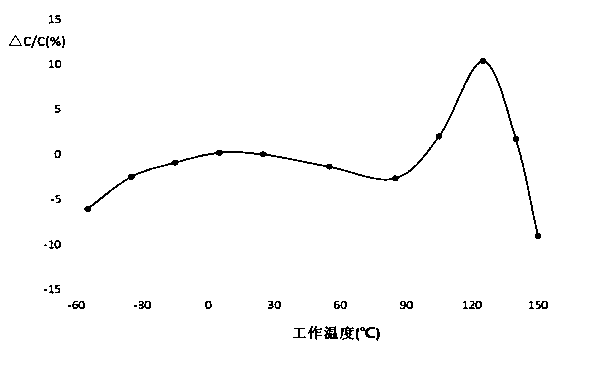

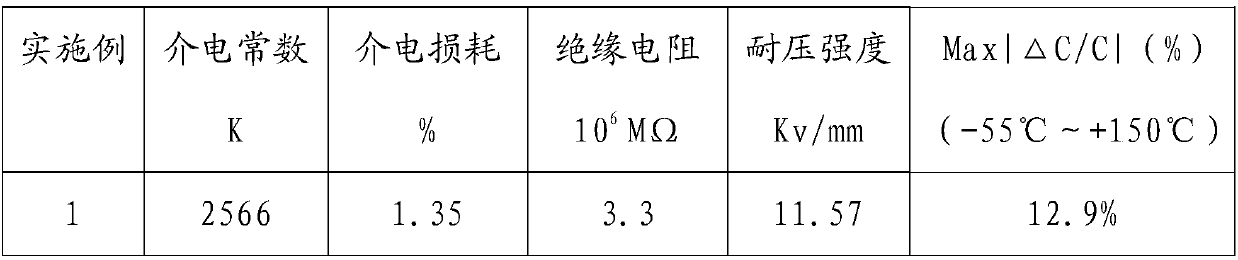

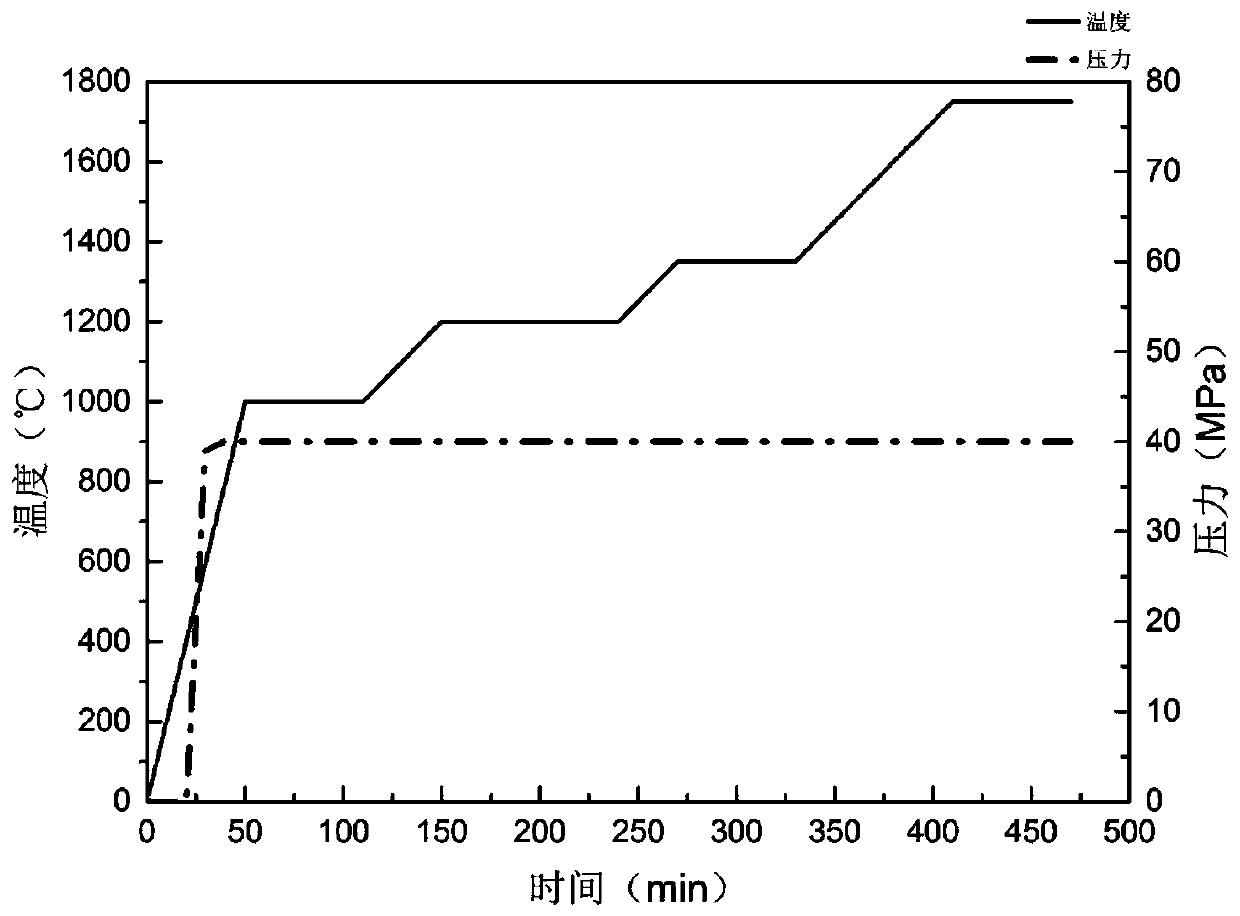

High-temperature X8R type ceramic-capacitor dielectric material and preparation method thereof

ActiveCN106348748AHigh curie temperatureExtended operating temperature rangeFixed capacitor dielectricRare-earth elementBarium titanate

The invention belongs to the technical field of ceramic-capacitor dielectric materials and particularly relates to a high-temperature X8R type ceramic-capacitor dielectric material. The high-temperature X8R type ceramic-capacitor dielectric material is characterized in that a co-fusion content of barium titanate and sodium bismuth titanate barium is taken as the main material, a co-fusion content of niobium manganese and oxide of A, a silicon lithium co-fusion content, a barium metaborate co-fusion content and Re2O3 are added, the element A is one or more of cobalt, nickel, zinc, bismuth and the like, and the element Re is one or more of rare-earth elements of praseodymium, samarium, gadolinium, dysprosium and the like. A capacitor made from the high-temperature X8R type ceramic-capacitor dielectric material is high in dielectric constant and high-temperature stability, medium-temperature sintering can be realized since the high-temperature X8R type ceramic-capacitor dielectric material can be matched with a medium and low-temperature sintered 30Pd-70Ag inner electrode in production of a multilayer ceramic dielectric fixed capacitor, application in high-temperature environment is realized, and high industrial prospects and industrial application value are achieved.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

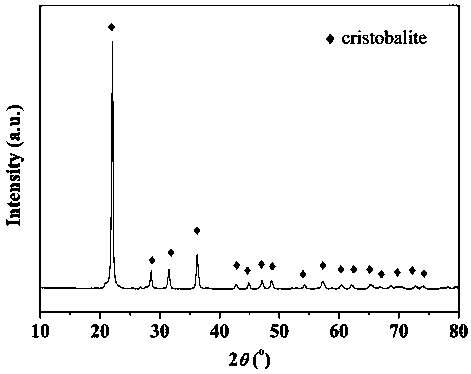

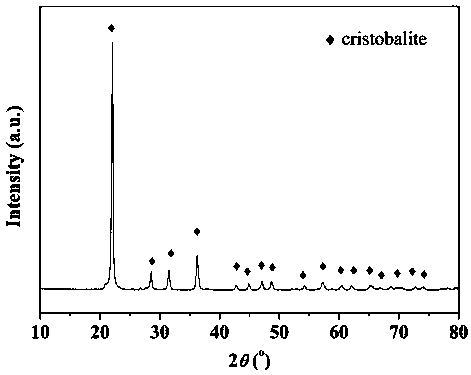

Ultralow dielectric constant microwave dielectric ceramic material and preparation method thereof

ActiveCN108455979AImprove sintering densityImprove compactnessTemperature coefficientLow-k dielectric

The invention discloses an ultralow dielectric constant microwave dielectric ceramic material. The material is prepared by sintering, by mass, 93-95% of fused silica powder, 2-4% of nanometer silica powder, 0.5-2.5% of CaF2 and 0.5-2.5% of MnO2, and the principal phase of the ultralow dielectric constant microwave dielectric ceramic material is crystalline state SiO2. The invention further discloses a preparation method of the ultralow dielectric constant microwave dielectric ceramic material. The method comprises the steps that S1, CaF2 and MnO2 powder are ground and mixed; S2, the fused silica powder and the nanometer silica powder are mixed, the CaF2 and MnO2 mixed powder obtained in step 1 is added, and wet process ball milling is performed to obtain a mixture; S3, the mixture obtainedin step 2 is dried, granulation and pressing are performed to obtain a perform body, and the perform body is sintered to obtain the ceramic material. The ultralow dielectric constant microwave dielectric ceramic material is wide in raw material source, the preparation method is simple and convenient to implement, practical application and production are facilitated, the obtained ceramic materialis low in dielectric constant, the temperature coefficient of resonance frequency approaches to zero, and the ultralow dielectric constant microwave dielectric ceramic material can be widely applied to manufacturing microwave devices such as a microwave substrate and a missile radome.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

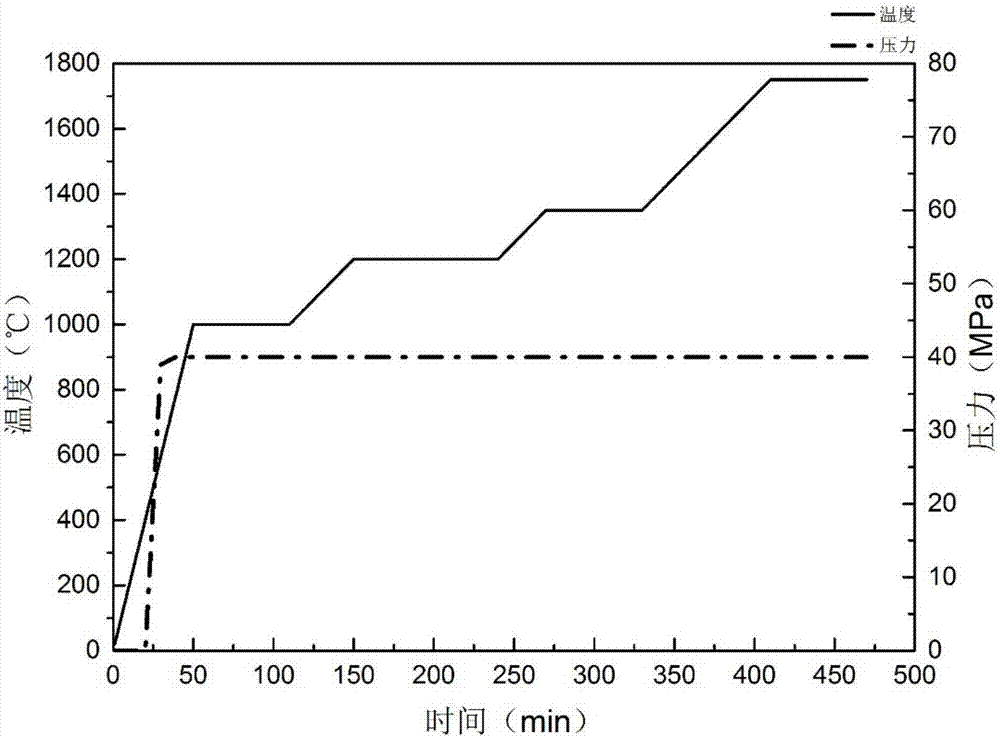

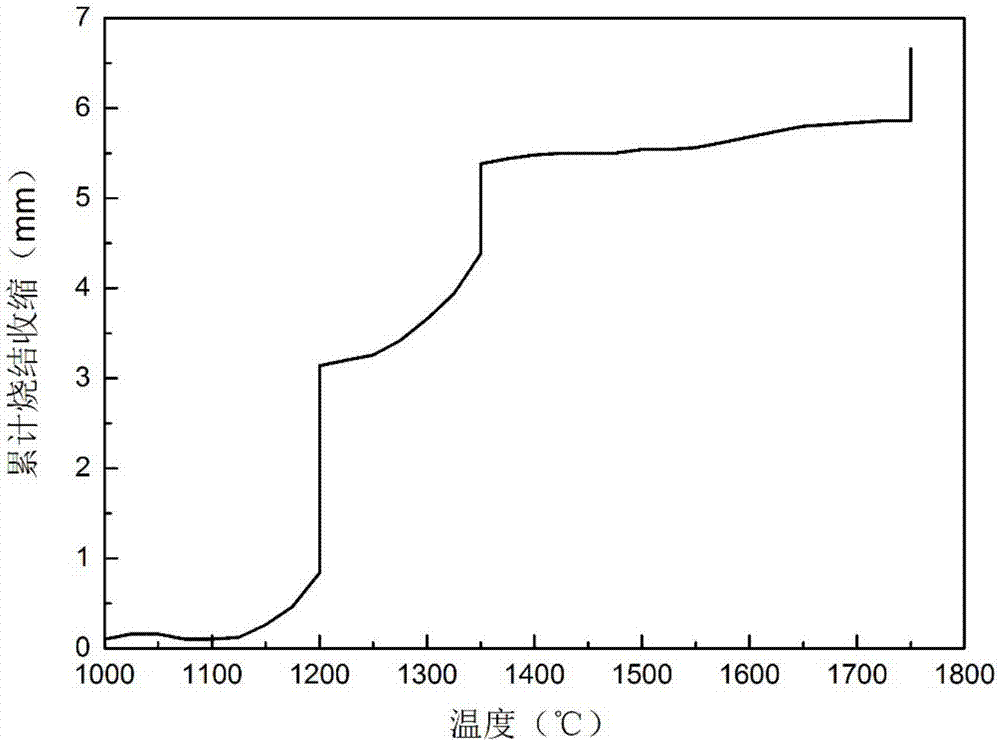

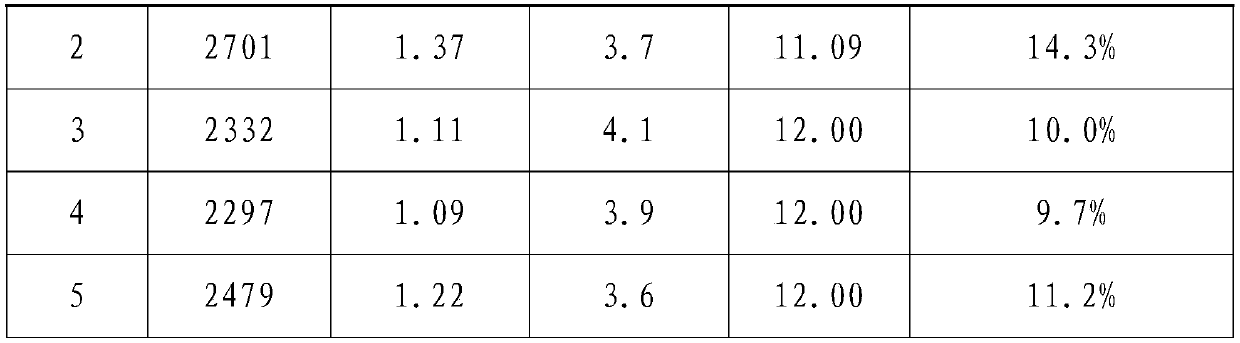

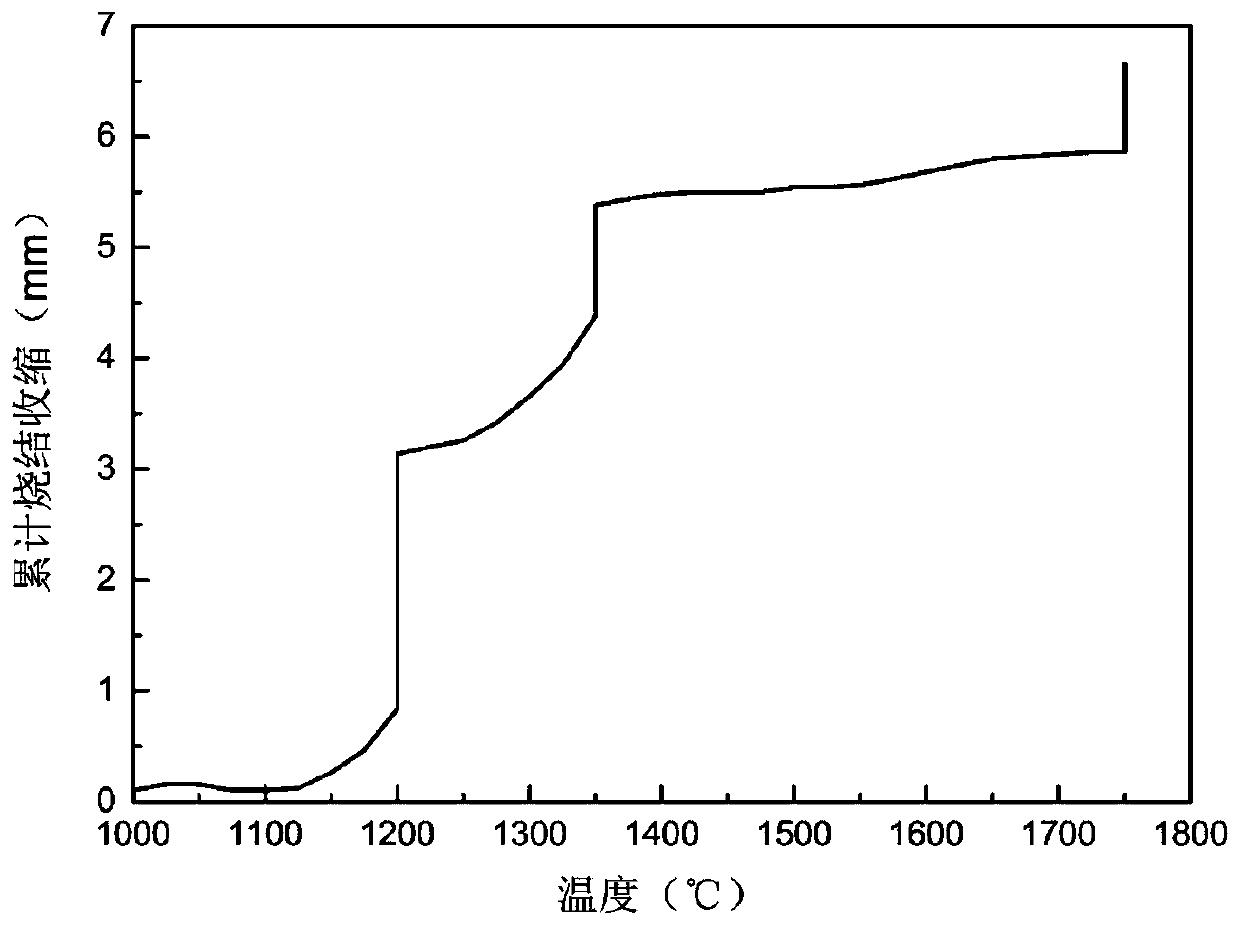

Low-temperature sintering method of ultra-high-temperature ceramic

InactiveCN107879743AReduce the possibilityReduce sintering processBorideUltra-high-temperature ceramics

The invention relates to a low-temperature sintering method of ultra-high-temperature ceramic, belonging to the technical field of preparation of compact ceramics. The ultra-high-temperature ceramic is a material capable of maintaining chemical stability in a high temperature environment (with a temperature higher than 2000 DEG C) and mainly contains certain high-melting-point transition metal compounds such as boride and carbide, and low-temperature sintering is carried out at 1650-1750 DEG C. The ultra-high-temperature ceramic prepared by virtue of the method is high in density.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

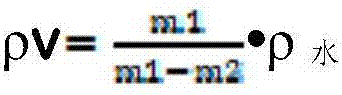

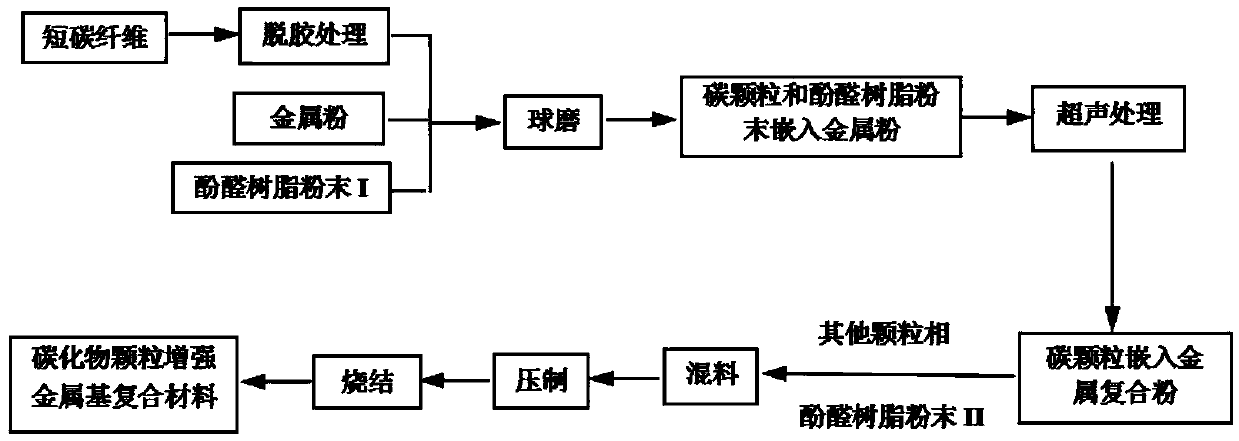

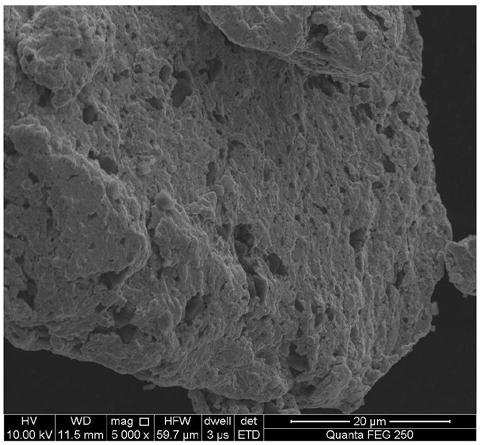

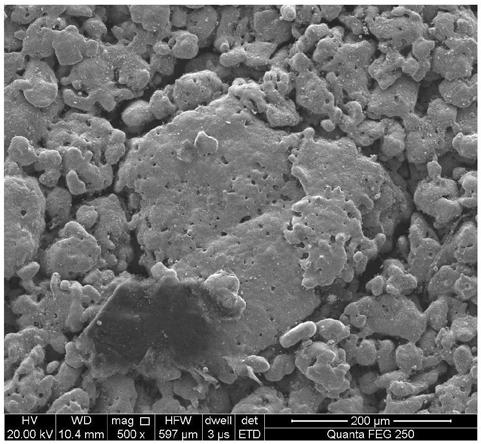

Preparation method for carbon particle reinforced metal base composite materials

The invention relates to a preparation method for carbon particle reinforced metal base composite materials, and belongs to the technical field of metal material preparation. Carbon parcel and phenolic resin uniform-embedded metal powder is obtained through high energy of degummed short carbon fibers and phenolic resin powder, is ultrasonically processed and dried to obtain surface carbon removedand carbon and phenolic resin powder embedded metal powder, and is mixed with the phenolic resin powder and other components for pressing and sintering to obtain the carbon particle reinforced metal base composite materials. The preparation method successfully solves the problem of loose interface sintering of the carbon particle embedded metal powder in the sintering process; under the precondition of realizing compact sintering of the metal powder, the mechanical performance and the wear resistance of the designed and prepared metal composite materials are greatly improved; the preparation process is simple; and the cost is low.

Owner:CENT SOUTH UNIV

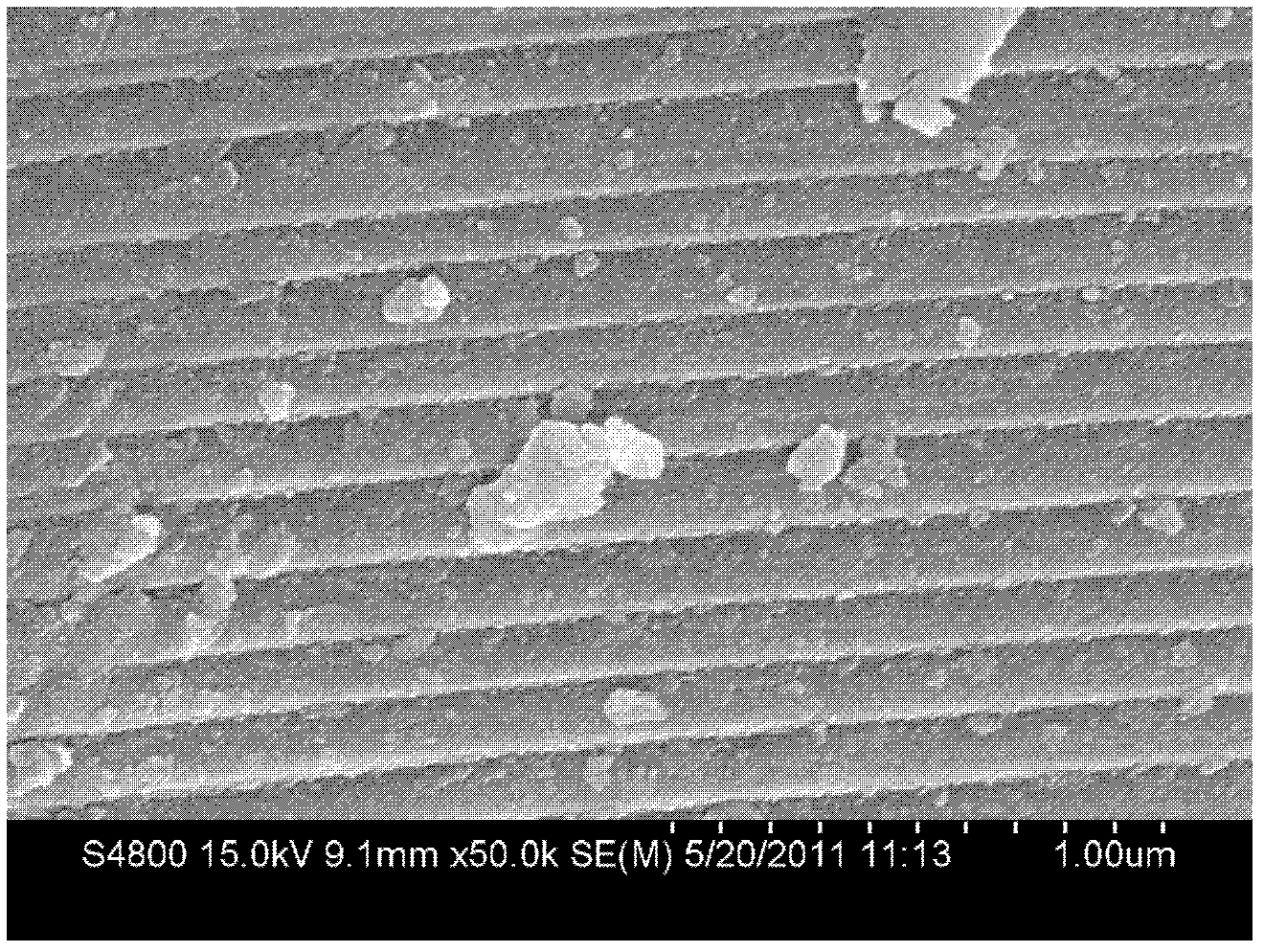

Aluminum-silicon alloy graphite composite heat conduction material and preparation method and application thereof

ActiveCN111636006AHigh thermal conductivityImprove thermal conductivityThermal dilatationSilicon alloy

The invention provides an aluminum-silicon alloy graphite composite heat conduction material, and a preparation method and an application thereof, the aluminum-silicon alloy graphite composite heat conduction material is prepared by mixing aluminum-silicon alloy powder with graphite packing and then performing hot pressed sintering for the obtained mixture under a vacuum condition; and in the material, the graphite packing is evenly dispersed in an aluminum-silicon alloy matrix. The material provided by the invention has relatively higher heat conductivity, relatively higher compactness, relatively higher effective strength and a relatively lower coefficient of thermal expansion, and can be used for manufacturing high-power electronic devices so as to solve a difficult problem of heat conduction of the high-power electronic devices.

Owner:HONG KONG PRODUCTIVITY COUNCIL

High-performance low-temperature-sintering laminated chip varistor material

InactiveCN109796202AReasonable proportionImprove sintering densityVaristor coresElectronic materialsCapacitor

The invention relates to a high-stability low-temperature-sintering laminated chip varistor material and belongs to the technical field of electronic materials. The high-stability low-temperature-sintering laminated chip varistor material has the advantages that by adding Ta2O5 and BBSZ glass into a ZnO-Bi2O3-based low-temperature-sintering varistor material and using a liquid phase sintering mechanism to accelerate a mass transfer process, the sintering compactness of the material is further increased, and the sintering temperature of the material is lowered; a chip varistor produced by the material through a laminated chip capacitor production process has a high-stability voltage-sensitive feature and is low in sintering temperature (850-925 DEG C), high in nonlinear coefficient (not smaller than 86.26), small in leakage currents and promising in application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

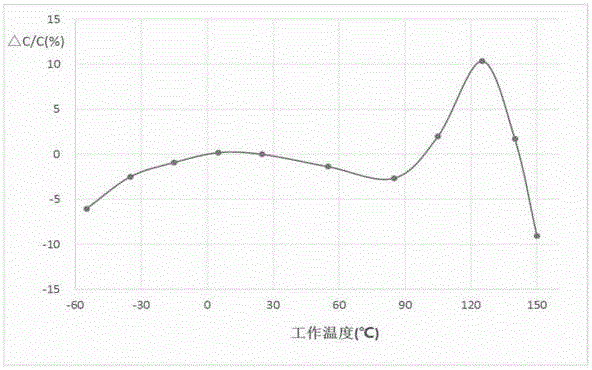

Doped modified SrTiO3-based high-pressure ceramic capacitor material with negative temperature coefficient

InactiveCN102115324AHigh dielectric constantImprove sintering densityFixed capacitor dielectricStrontium titanateCapacitance

The invention provides a doped modified ceramic capacitor material for equalizing the voltages of a zinc oxide arrester, in particular to a high-pressure ceramic capacitor material prepared from 80-84 percent of SrTiO3, 8-10 percent of BiO8, 0.5-2 percent of TiO2, 0.1-1 percent of MnO2, 4-8 percent of YO4 and 3-5 percent of MgTiO3. By adopting the formula, solid volume limit in SrTiO3 crystal lattices can be increased, a strong peak shifting and broadening action is generated, and the capacitor temperature characteristics are improved. Meanwhile, the electric constant is increased to 2500, the dielectric loss is smaller than 0.0001, the change rate of the high-temperature stability capacity along with temperature is smaller than 10 percent, and the lightning-protection and voltage-equalizing actions are excellent.

Owner:费金华

Preparing method for magnesium synthetic material

The invention discloses a preparing method for a magnesium synthetic material. The preparing method comprises the following steps that light roasting magnesium calcium powder is subjected to sufficient fine grinding, light roasting calcium magnesium fine powder is obtained, and in addition, iron oxide red is subjected to sufficient fine grinding; the obtained fine powder and finely ground iron oxide red are subjected to co-grinding, and activated nano calcium carbonate is evenly added in the co-grinding process; water is added in the co-grinding fine powder, the mixture is placed in a rolling machine to be subjected to stirring and wheel rolling, stirring is uniform, and the press heating temperature is larger than or equal to 40 DEG C; wet powder is added in a ball pressing machine to be compacted, and ball blanks are manufactured in the ball pressing process; the obtained ball blanks are naturally dried; and the obtained dry blanks are placed in a kiln to be fired, the firing temperature ranges from 1,600 DEG C to 1,700 DEG C, heat preservation is conducted for 2-6 h, and the magnesium synthetic material is obtained. According to the preparing method, the magnesium synthetic material can be manufactured at the relatively low firing temperature and the short firing time, coal consumption is effectively reduced, the production cost is controlled, sufficient sintering of the magnesium synthetic material is guaranteed as well, and the firing compactness of the magnesium synthetic material is improved.

Owner:北京利尔高温材料股份有限公司

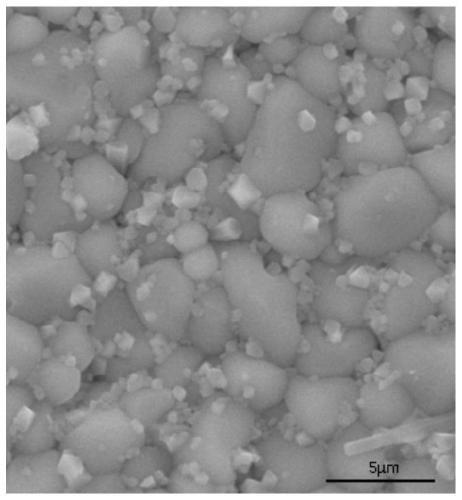

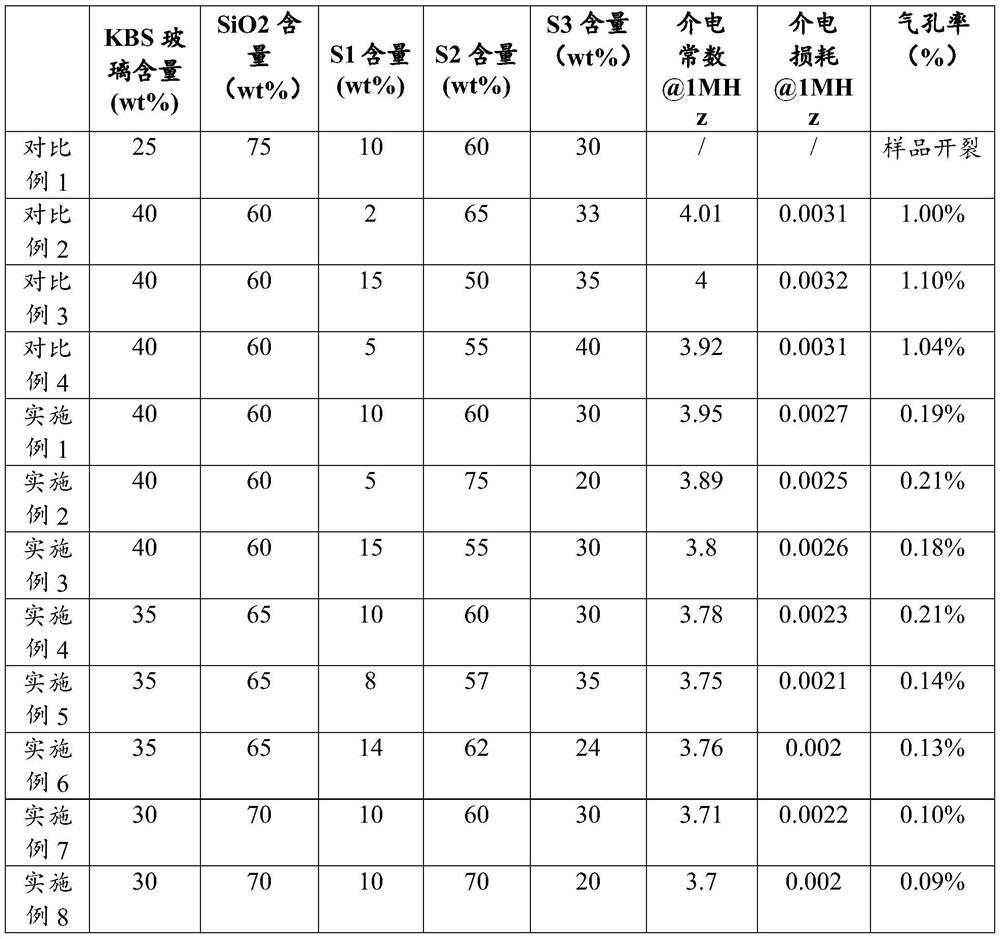

LTCC ceramic material as well as preparation method and application thereof

The invention discloses an LTCC ceramic material as well as a preparation method and application thereof. The LTCC ceramic material disclosed by the invention comprises the following components in percentage by mass: 30 to 40 percent of KBS glass powder and 60 to 70 percent of spherical SiO2. By adding the spherical SiO2, the dielectric constant of the LTCC is effectively reduced, so that the dielectric constant of the material is as low as 3.7, and the dielectric loss is as low as 0.2%; the sphericity degree of the spherical SiO2 is greater than or equal to 98%, and the spherical SiO2 is graded by SiO2 with three particle sizes, so that the sintering compactness of the material is improved, and the porosity of a sintered ceramic body is as low as 0.09%. The LTCC ceramic material disclosed by the invention has the advantages of ultralow dielectric constant, low loss and good compactness, and is suitable for the fields of high-frequency communication and radio frequency.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

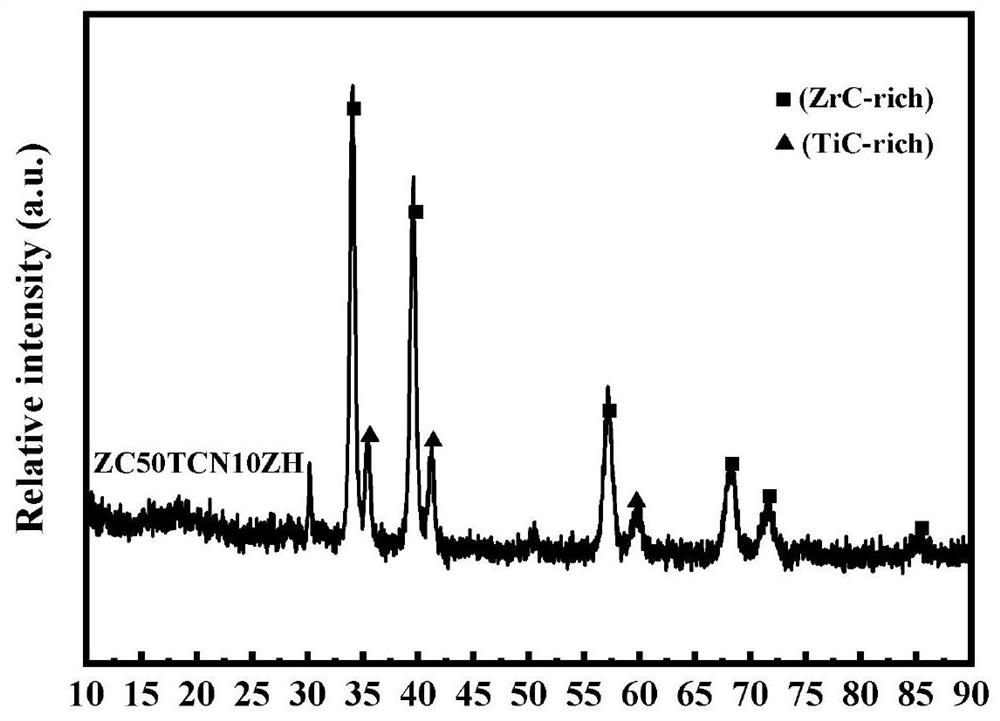

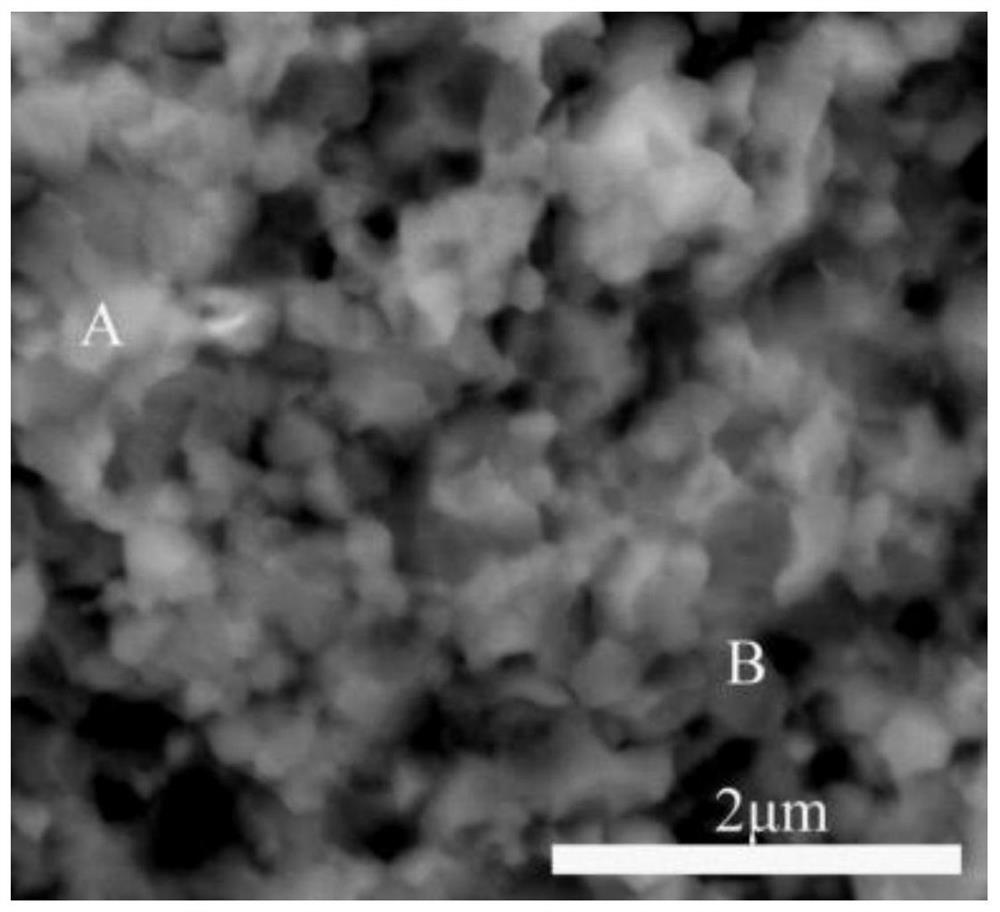

Method for preparing titanium subgroup carbonitride solid solution composite ceramic material by sintering

The invention relates to a method for preparing a titanium subgroup carbonitride solid solution composite ceramic material by sintering. The invention belongs to the field of multiphase ceramic materials. The invention aims to solve the technical problems of poor sinterability and fracture toughness of the existing multiphase ceramic. The method comprises the following steps: step 1, mixing titanium subgroup carbide powder and titanium subgroup carbonitride powder or adding titanium subgroup carbonitride powder, ball-milling, mixing and sieving to obtain mixed powder; and step 2, carrying out spark plasma sintering or hot pressed sintering on the mixed powder obtained in the step 1 to obtain the titanium subgroup carbonitride solid solution composite ceramic material. According to the preparation method disclosed by the invention, elements in the same family are mutually used as sintering aids according to solid solution characteristics, so that the phase boundary can be enriched, the sintering performance of the titanium subfamily ceramic is improved, and the solid solution strengthening effect is achieved. Besides, after the titanium subgroup hydride is added, heat preservation is carried out in the initial stage in the sintering process, vacancy is introduced, and the density is remarkably improved.

Owner:HARBIN UNIV OF SCI & TECH

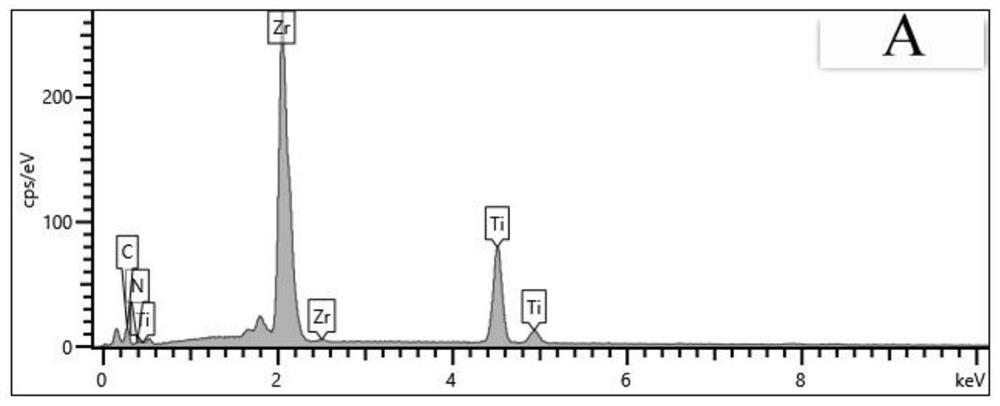

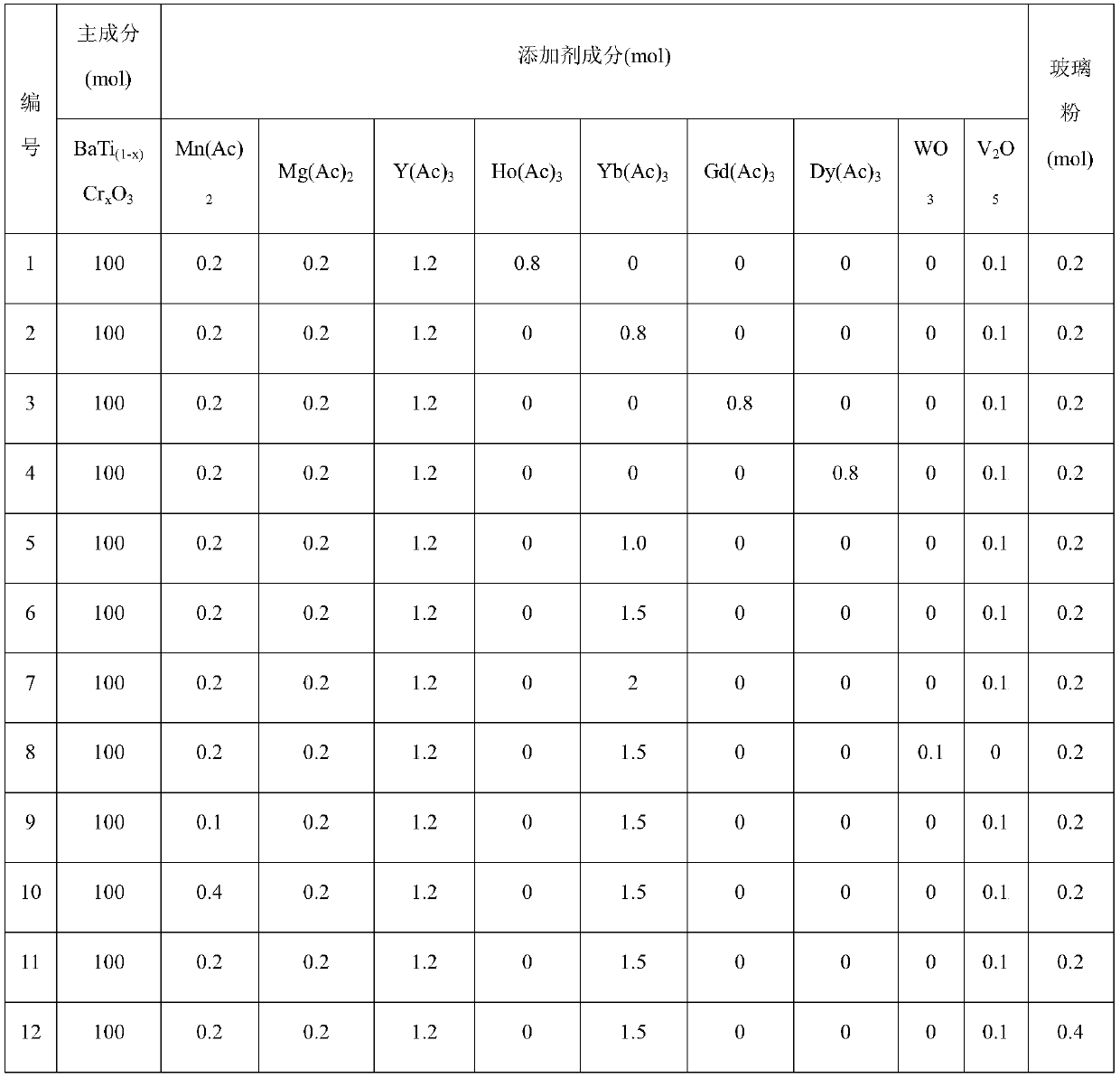

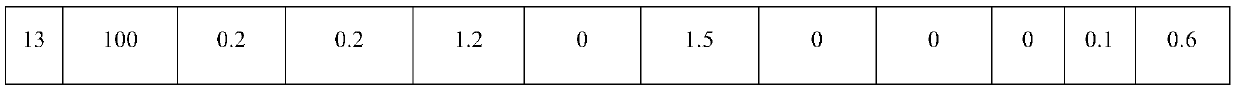

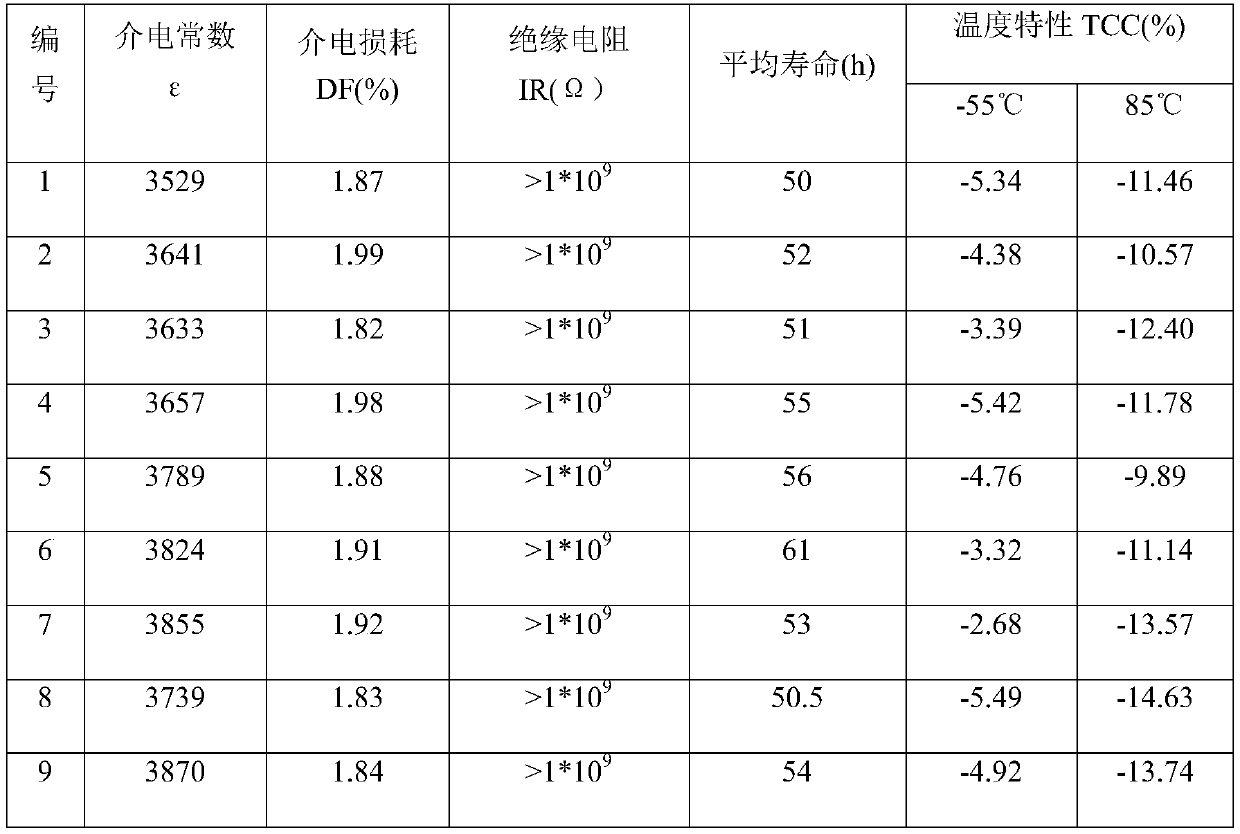

A kind of thin dielectric material for x5r type multilayer ceramic capacitor and its preparation method

ActiveCN106747420BImprove temperature stabilityImprove reliabilityFixed capacitor dielectricStacked capacitorsRare-earth elementBarium titanate

The invention provides a thin dielectric material for X5R multilayer ceramic capacitors. The thin dielectric material for X5R multilayer ceramic capacitors is composed of a main component and an auxiliary additive, wherein the main component is BaTi(1-x)CrxO3 (0.005<x<=0.05); on the basis of 100mol of the main component, the addition amount of the auxiliary additive is 0.32-5.6mol; and the auxiliary additive is composed of acetates, transition metal oxides and glass powder. The dielectric material provided by the invention has the advantages of favorable temperature stability and high reliability. By using the chromium barium titanate as the main component, the additive introduced into the formula mostly adopts water-soluble acetates, thereby being more beneficial to the mixing of the additive and main component on the atom level. The thin dielectric material solves the problem of poor product reliability since the oxides used as the main additive and the main component can not be mixed uniformly in the existing dielectric material. The glass powder added into the formula can effectively lower the sintering temperature of the product and enhance the sintering compactness of the product. The introduced rare earth element can enhance the reduction resistance of the dielectric material.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Preparation method of new phosphate composite ceramic solidified body material

The invention discloses a method for preparing a novel phosphate composite ceramic solidified body material, which comprises the following steps: mixing raw materials, pre-sintering to obtain a precursor, adding sintering aids to the precursor, mechanically activating, molding, and sintering to obtain A new type of phosphate composite ceramic solidified body material; wherein, the phosphorus source in the raw material is ammonium dihydrogen phosphate or phosphorus pentoxide; the raw material of A, B, Ln, An elements in the raw material is nitrate, metal alkoxide or oxide One; A is +1 or +2 valence element, B is +4 valence element, Ln is +3 or +4 valence lanthanide, An is +3 or +4 valence actinide. The NZP type ceramics and the monazite ceramics in the novel phosphate composite ceramic solidified body prepared by the invention are all solidified body materials with excellent chemical stability, so the phosphate composite ceramic solidified body has a large waste holding capacity and good stability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of ultra-low dielectric constant microwave dielectric ceramic material and preparation method thereof

ActiveCN108455979BHigh dielectric constantLow dielectric constantCeramicsMicrowave substrateDielectric permittivity

The invention discloses an ultralow dielectric constant microwave dielectric ceramic material. The material is prepared by sintering, by mass, 93-95% of fused silica powder, 2-4% of nanometer silica powder, 0.5-2.5% of CaF2 and 0.5-2.5% of MnO2, and the principal phase of the ultralow dielectric constant microwave dielectric ceramic material is crystalline state SiO2. The invention further discloses a preparation method of the ultralow dielectric constant microwave dielectric ceramic material. The method comprises the steps that S1, CaF2 and MnO2 powder are ground and mixed; S2, the fused silica powder and the nanometer silica powder are mixed, the CaF2 and MnO2 mixed powder obtained in step 1 is added, and wet process ball milling is performed to obtain a mixture; S3, the mixture obtainedin step 2 is dried, granulation and pressing are performed to obtain a perform body, and the perform body is sintered to obtain the ceramic material. The ultralow dielectric constant microwave dielectric ceramic material is wide in raw material source, the preparation method is simple and convenient to implement, practical application and production are facilitated, the obtained ceramic materialis low in dielectric constant, the temperature coefficient of resonance frequency approaches to zero, and the ultralow dielectric constant microwave dielectric ceramic material can be widely applied to manufacturing microwave devices such as a microwave substrate and a missile radome.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Electrocondution slurry for chip component termination electrode

InactiveCN102842353BReduce thicknessImprove adhesion strengthNon-conductive material with dispersed conductive materialMetallurgySlurry

The invention provides electrocondution slurry used for a chip component termination electrode. The electrocondution slurry comprise the following components in percentage by weight: 45-75% of silver powder, 2-10% of glass powder, 20-50% of organic carriers and 0-3% of inorganic additives. The chip component termination electrode manufactured by the electrocondution slurry can reduce thickness of a silver layer obviously, thus reducing manufacturing cost of a chip component obviously.

Owner:廖晓峰

A powder metallurgy preparation method of fine-grain diamond-copper-based composite heat dissipation material

Owner:JILIN UNIV

A kind of platinum-ceramic composite powder and its preparation method and application

ActiveCN105195732BImprove compactnessImprove catalytic performanceMaterial electrochemical variablesPlatinumCeramic composite

The invention discloses platinum-ceramic composite powder as well as a preparation method and an application thereof and belongs to the field of metal and ceramic powder composite. The platinum-ceramic composite powder is spherical powder, the particle size distribution is 0.2-1.2 mu m, the average particle size is 0.45 mu m, the specific surface area is 20-45 m<2> / g, the bulk density is 0.5-1.2 g / cm<3>, and the tap density is 0.8-1.8 g / cm<3>. The preparation method of the platinum-ceramic composite powder comprises steps as follows: sensitized and activated ceramic powder is mixed with a sodium chloroplatinate solution, reduction is performed with a chemical reduction method, and the platinum-ceramic composite powder is prepared. The platinum-ceramic composite powder can be used as platinum electrode paste, and the performance of a platinum electrode prepared by sintering the powder on the ceramic surface is remarkably improved. The preparation method of the platinum-ceramic composite powder is simple and easy to implement, and industrial production is facilitated.

Owner:山东有研国晶辉新材料有限公司 +1

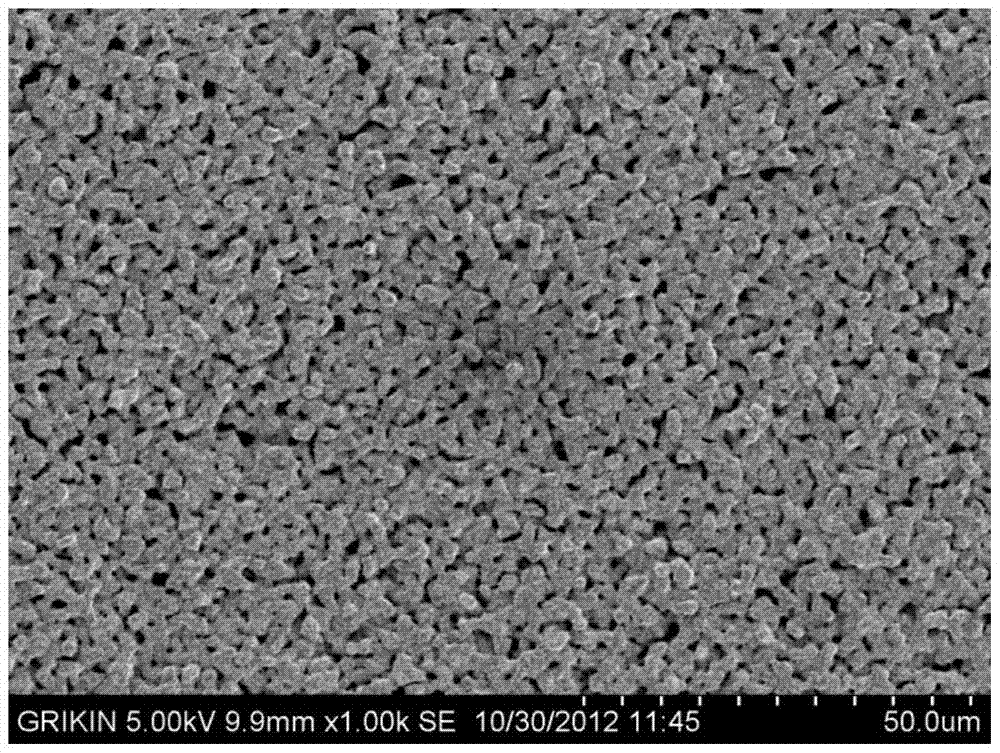

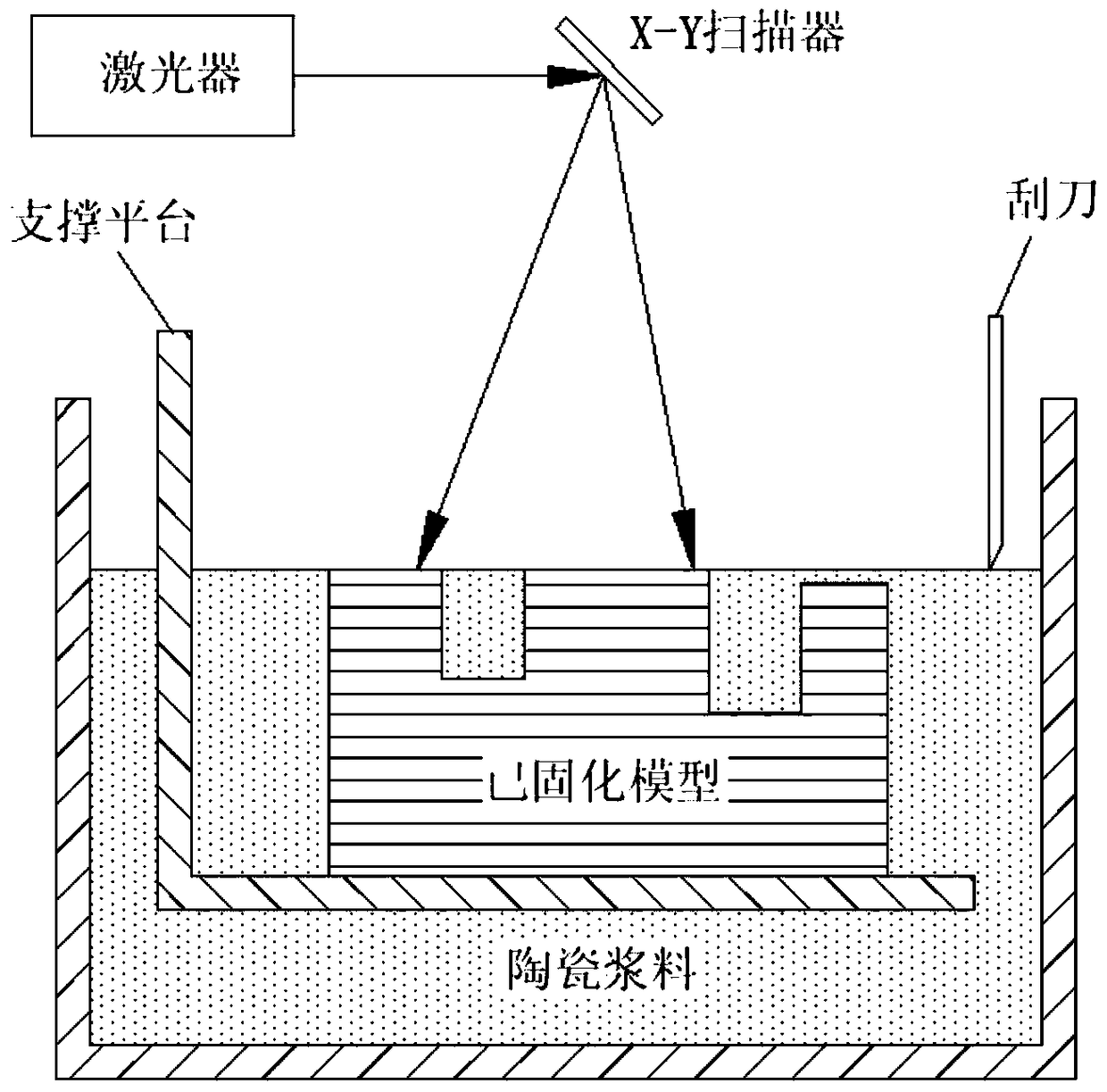

A kind of preparation method of tooth-shaped special-shaped ceramics

The invention relates to the technical field of ceramic preparation, in particular to a preparation method of tooth-like special-shaped ceramics. Slurry is applicable to a photo-curing forming method to prepare tooth-like ceramic bodies by optimizing the composition and proportioning of the slurry, the forming efficiency is high, ceramic particles in the bodies can be also dispersed evenly, and the shape and size accuracy of the bodies is high; the bodies cannot deform and crack in the producing process by controlling process parameters in degreasing and sintering steps, the sintered compactness is higher, tooth-like ceramic products are more uniform in structure, higher in accuracy and better in surface smoothness, the thickness of the tooth-like ceramic products can be greater than 8 mm, and accordingly the reliability of the ceramic products is improved.

Owner:GUANGDONG UNIV OF TECH

Glass paste for thermal printing head and preparation method of glass paste

The invention relates to glass paste for a thermal printing head and a preparation method of the glass paste. The glass paste comprises the following components in percentage by weight: 70-75% of lead-free glass powder, 2-5% of an inorganic additive and 20-28% of an organic carrier. The lead-free glass powder comprises the following components in percentage by weight: 15%-40% of BaO, 10%-30% of CaO, 5%-50% of SiO2, 5%-15% of Al2O3, 5%-20% of SrO and 1%-5% of ZrO2; and the lead-free glass powder is subjected to heat treatment of roasting for 2-3 min within a temperature range of 760-780 DEG C.The method comprises the following steps: (1) dissolving the organic carrier; (2) preparing the glass paste; and (3) rolling the glass paste to finally obtain a product. Compared with the prior art, the method of the invention has the advantages of high initial particle melting temperature, high high-temperature fluidity, low viscosity, uniform particle size, small morphological difference, high bulk density, good high-temperature viscosity, high sintering power, difficulty in generating bubbles or pores and the like.

Owner:西安宏星电子浆料科技股份有限公司

A kind of lithium-based microwave dielectric ceramic material, its preparation method and lithium-based microwave dielectric ceramic

ActiveCN112608144BLower sintering temperatureReduce the temperatureGlass furnace apparatusLithiumMicrowave

The invention provides a lithium-based microwave dielectric ceramic material. The raw materials include: main powder and auxiliary powder shown in formula (I); the auxiliary powder includes glass powder and 0.5-1.5 wt% of the main powder Accounting for 5-10wt% rutile TiO in the main powder 2 Micropowder; Li 2 (Zn (1‑x) Cu x )(Ti (1‑y) (Mg 1 / 3 Nb 2 / 3 ) y ) 3 o 8 , formula (I). The specific glass powder of the present invention reduces the sintering temperature of the system and introduces Mg 2+ , Nb 5+ replace Ti 4+ Improve frequency temperature coefficient, introduce TiO 2 Can increase Li 2 CO 3 ‑ZnO‑TiO 2 The sintering density of the system can be adjusted by τ f value. Cu 2+ Substitution and specific glass frits successfully make Li 2 CO 3 ‑ZnO‑TiO 2 The system is perfectly sintered at 850-890°C and has excellent dielectric properties, so that the material can be co-fired with Ag electrodes.

Owner:LUOYANG ZHONGCHAO NEW MATERIAL SHARES CO LTD

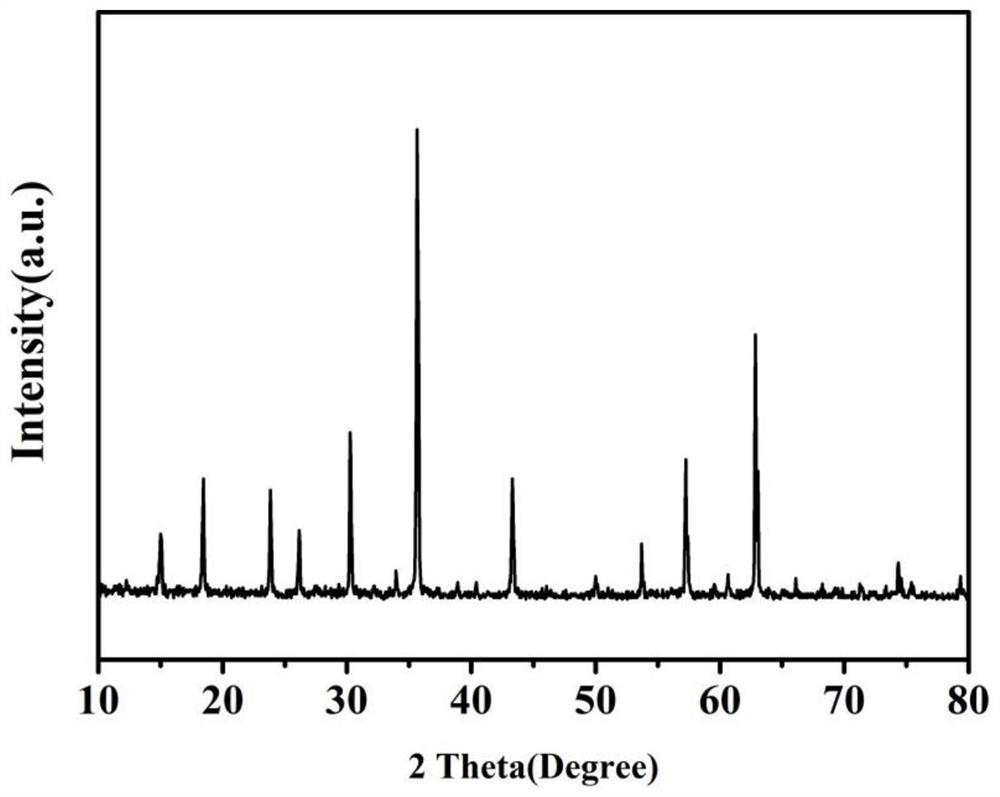

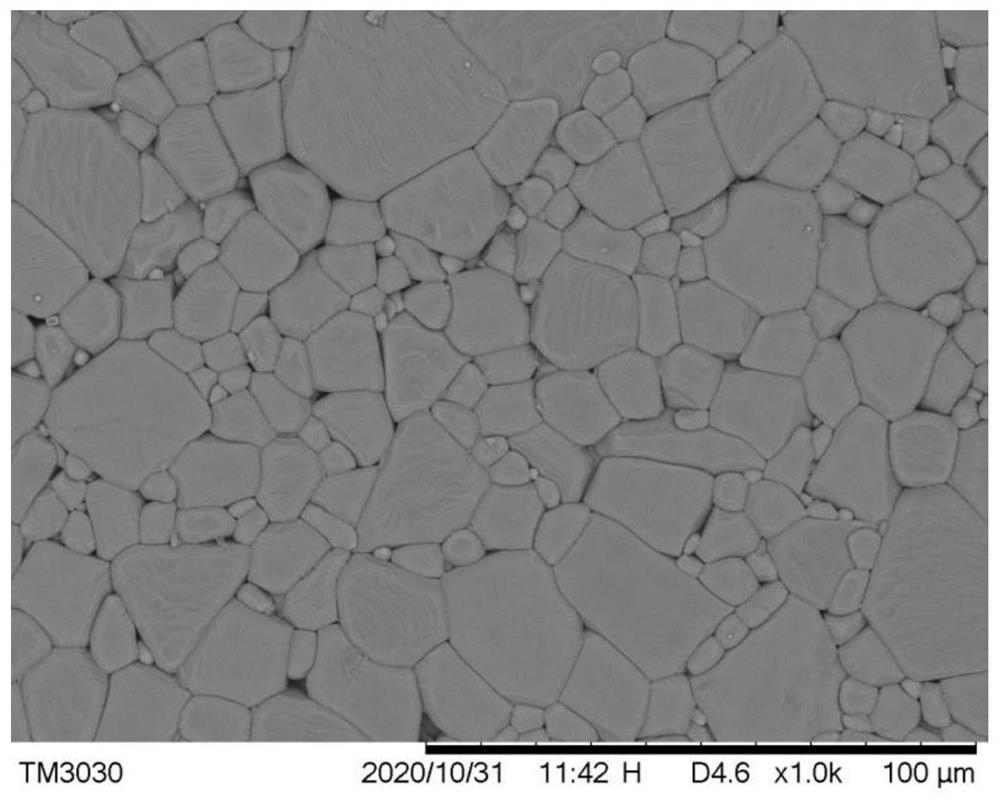

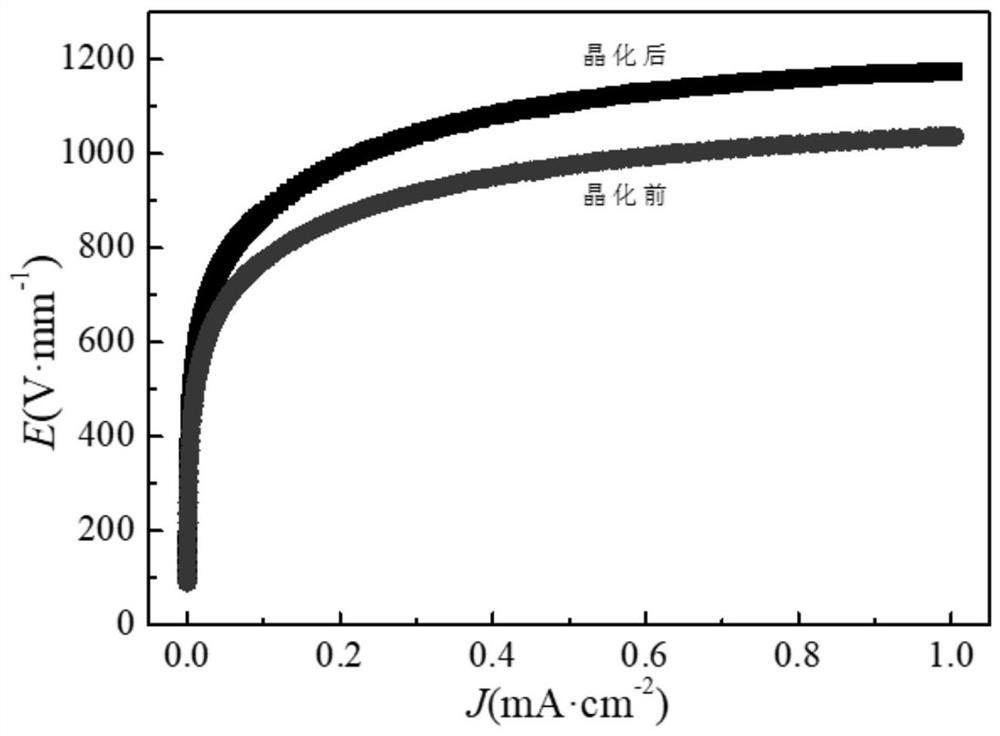

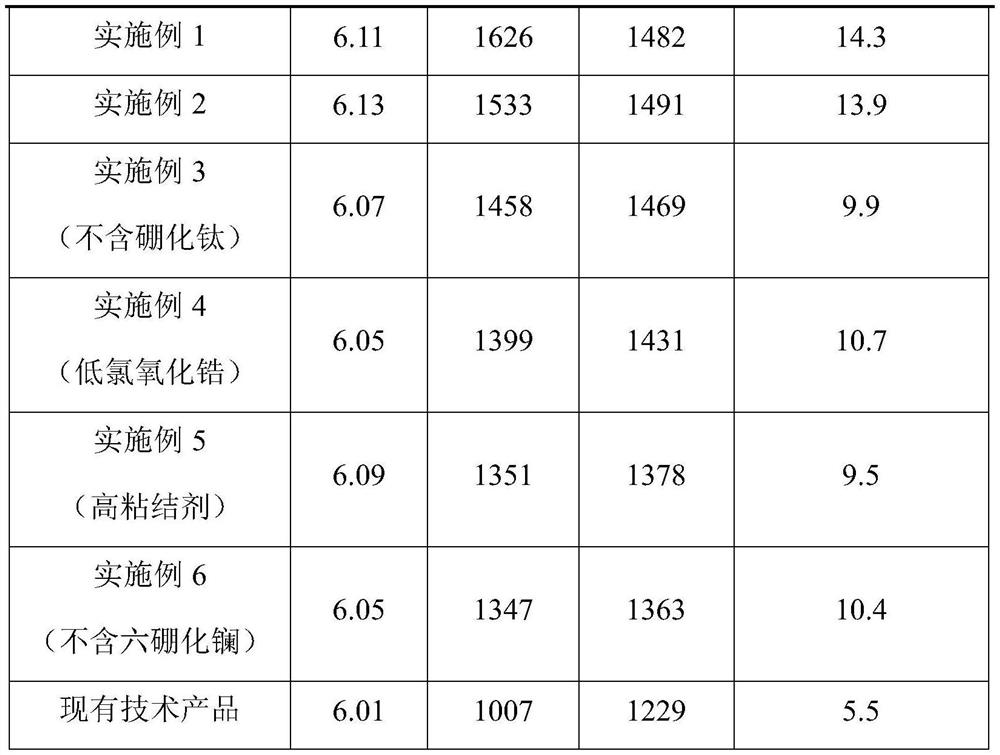

Zinc oxide resistor disc and preparation method thereof

ActiveCN113105229AImprove performanceImprove electrical performanceVaristor coresElectrical resistance and conductanceMetallic materials

The invention relates to the technical field of inorganic non-metallic materials, and particularly discloses a zinc oxide resistor disc with excellent comprehensive performance and a preparation method thereof. According to the method, on the basis of an existing solid phase method, the density of a green body is improved through raw material particle size grading, the influence of factors such as high porosity, low sintering density, poor particle size uniformity after sintering and uncontrollable grain boundary thickness which are likely to happen to a single raw material particle size on the performance of the zinc oxide resistor disc is overcome, and then the sintering compactness of the resistor disc is improved. According to the invention, crystallization of the resistor disc after sintering is further controlled, the uniformity of the particle size after sintering is improved, and the thickness of the grain boundary layer is regulated, so that the electrical performance of the zinc oxide resistor disc is improved; and the zinc oxide resistor disc prepared by the method has the advantages of high potential gradient, nonlinear coefficient and energy density, low leakage current and residual voltage ratio and the like, the preparation process is simple, the requirement on equipment is low, and batch production is easy.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

A zirconia-based ceramic back plate and its preparation method and application

The present invention provides a zirconia-based ceramic back plate and its preparation method and application, by using zirconia, zirconium oxychloride and lanthanum hexaboride as initial raw materials, and then mixing, hydrolyzing, Dried and pretreated by ultra-high pressure cold isostatic pressing to obtain a green body, which has no organic volatilization, low porosity, and no density gradient. The green body is pre-sintered, sliced and secondly sintered to obtain a zirconia ceramic back plate. After the green body is sintered, the zirconia ceramic back plate obtained after sintering has good sintering density, high strength, strong wear resistance and high toughness. , strength, hardness and excellent wear resistance and thermal stability.

Owner:HUNAN KOSEN NEW MATERIAL

Preparation method of high-performance vanadium wire for self-powered neutron detector

ActiveCN113755706AImprove sintering densityAvoid oxidative getterNuclear energy generationNeutron radiation measurementElectrical resistance and conductanceElectrolysis

The invention discloses a preparation method of a high-performance vanadium wire for a self-powered neutron detector. The method comprises the steps of vanadium powder pretreatment, cold isostatic pressing forming, vacuum sintering, vacuum vertical melting, electron beam floating zone smelting, rotary swaging, wire drawing, continuous electrolytic polishing and annealing treatment. According to the method, the purity of the vanadium wire is greater than or equal to 99.9%, the content of impurity elements of B, Cd, Cr and Cu is smaller than or equal to 30 ppm, the diameter of the finished vanadium wire is 1.00-1.50 mm, the precision reaches + / -0.005 mm, the surface roughness is smaller than or equal to Ra1.6 microns, the tensile strength is larger than or equal to 400 MPa, the ductility is larger than or equal to 10%, the resistance uniformity is + / -1.5%, the precision is high, the stability of the mechanical property and the surface quality is good, and the use performance requirement of a self-powered neutron detector emitter material of nuclear power engineering can be met.

Owner:CHONGQING MATERIALS RES INST

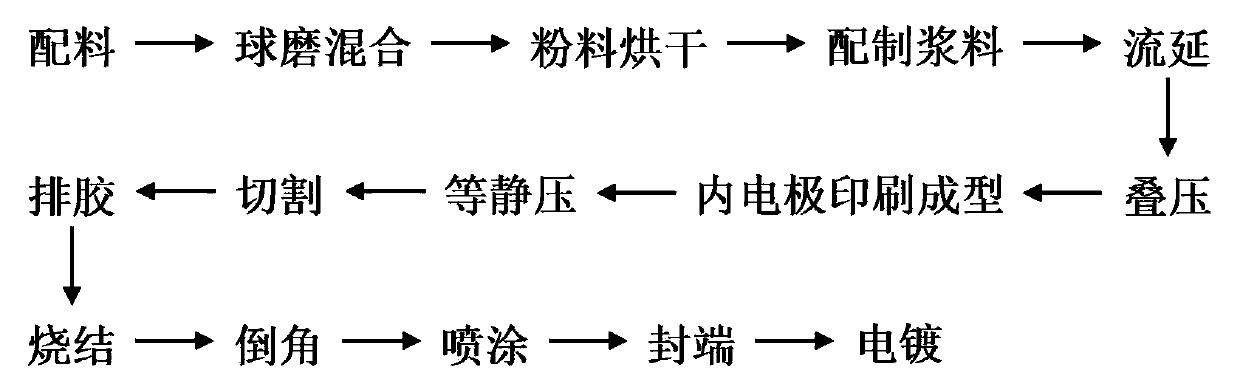

A kind of high temperature X8R type ceramic capacitor dielectric material and preparation method thereof

ActiveCN106348748BHigh curie temperatureExtended operating temperature rangeFixed capacitor dielectricRare-earth elementBarium titanate

The invention belongs to the technical field of multilayer ceramic capacitor materials, in particular to a high-temperature X8R type ceramic capacitor dielectric material and a preparation method thereof. This kind of high-temperature X8R ceramic capacitor dielectric material is based on the eutectic of barium titanate and bismuth sodium barium titanate, and the eutectic of oxides of niobium, manganese and A, silicon lithium eutectic, and boron barium are added. Fusion, Re 2 o 3 , wherein the element A is one or more of cobalt, nickel, zinc, bismuth, etc., and the element Re is one or more of rare earth elements such as praseodymium, samarium, gadolinium, neodymium, and dysprosium. The capacitor made by using the high-temperature X8R type ceramic capacitor dielectric material of the present invention has high dielectric constant, high compressive strength, high temperature stability, and can be combined with medium-low temperature sintered 30Pd-70Ag inner when preparing multilayer ceramic fixed capacitor The electrodes are matched to achieve medium-temperature sintering, and realize the application in high-temperature environment, which has high industrialization prospect and industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

A low-temperature sintering method for ultra-high temperature ceramics

InactiveCN107879743BReduce the possibilityReduce sintering processBorideUltra-high-temperature ceramics

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

A kind of aluminum-silicon alloy graphite composite heat-conducting material and its preparation and application

ActiveCN111636006BImprove thermal conductivitySmall coefficient of thermal expansionThermal dilatationHigh density

The invention provides an aluminum-silicon alloy graphite composite heat-conducting material and its preparation and application. The aluminum-silicon alloy-graphite composite heat-conducting material is obtained by mixing aluminum-silicon alloy powder and graphite filler, and then subjecting the obtained mixture to It is prepared after hot pressing and sintering; in the said material, the graphite filler is uniformly dispersed in the aluminum-silicon alloy matrix. The material provided by the present invention has higher thermal conductivity, higher compactness, higher effective strength and lower coefficient of thermal expansion, and can be used to make high-power electronic devices to solve the problem of high-power electronic devices. heat conduction problem.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com