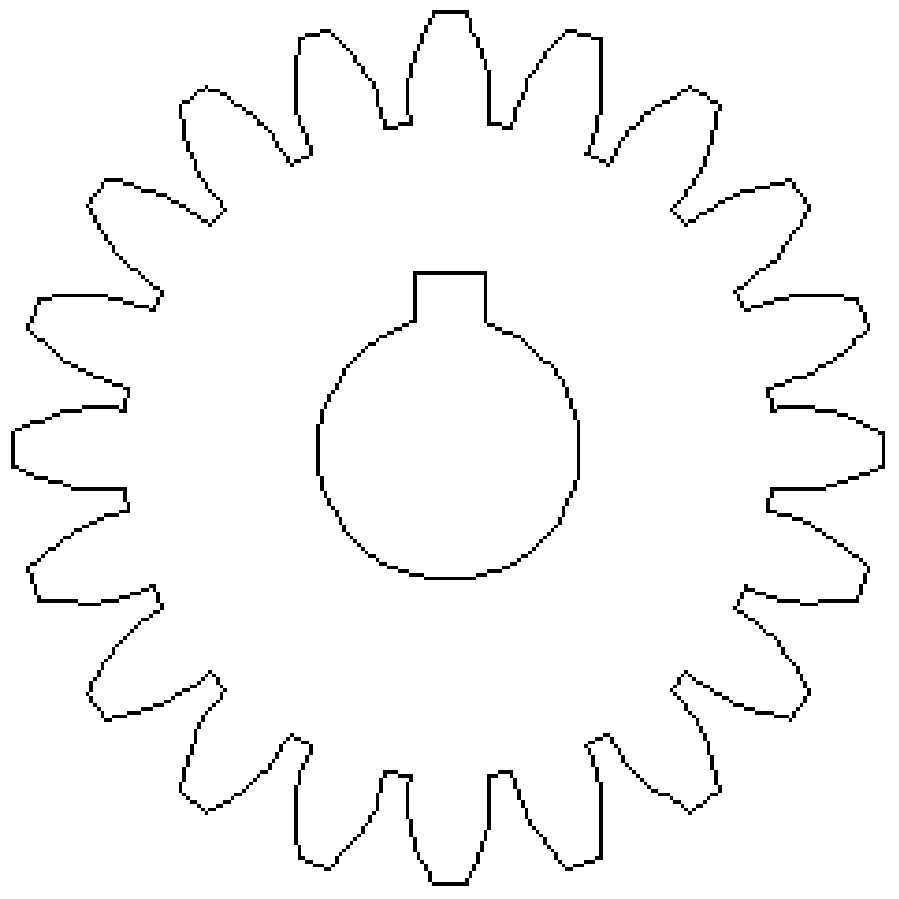

A kind of preparation method of tooth-shaped special-shaped ceramics

A ceramic and special-shaped technology, which is applied in the field of preparation of tooth-shaped special-shaped ceramics, can solve the problems of uneven green body, bad tooth shape, poor product size accuracy, etc., and achieve good surface finish, reduced deformation, and high shape and size accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

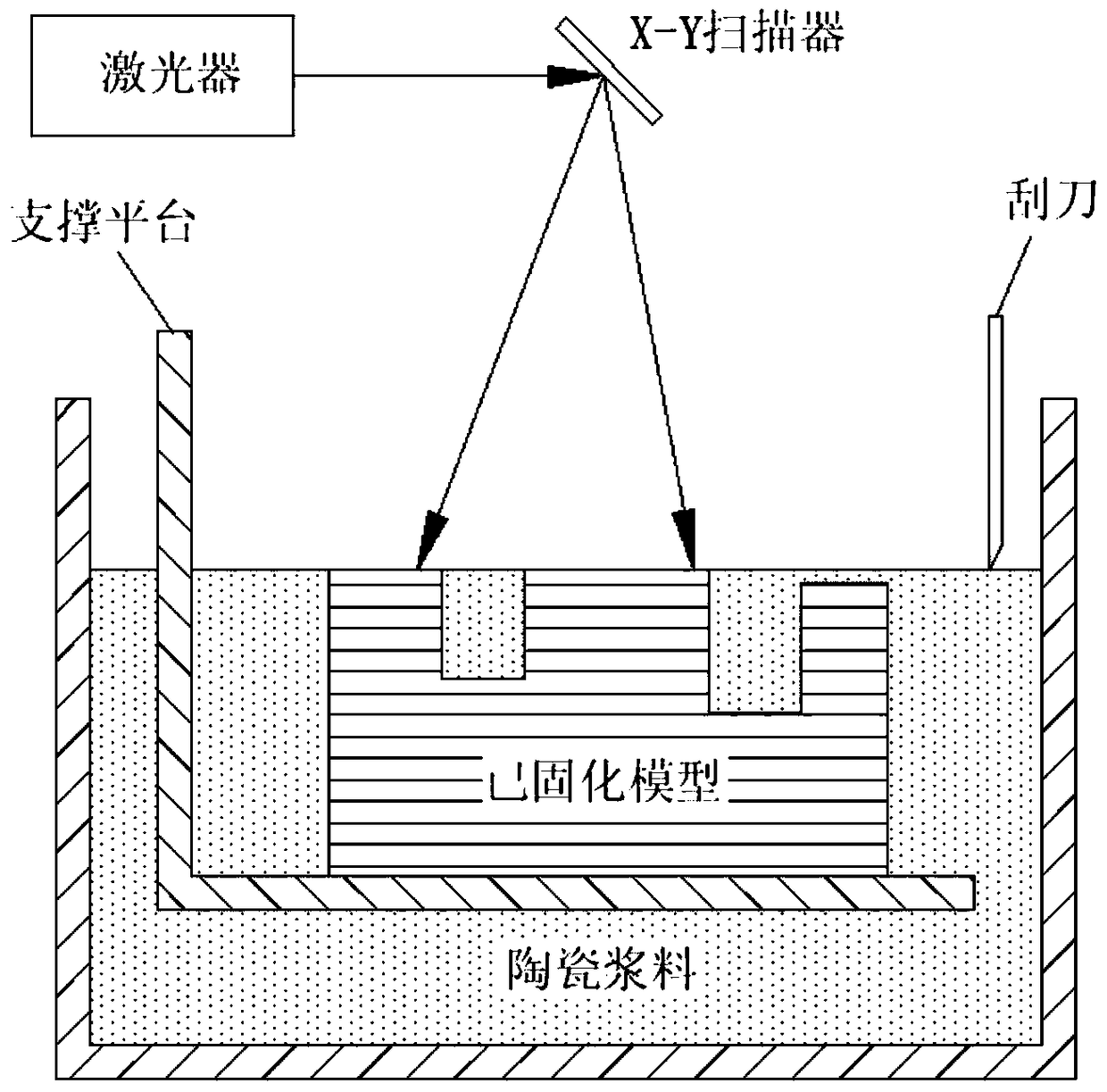

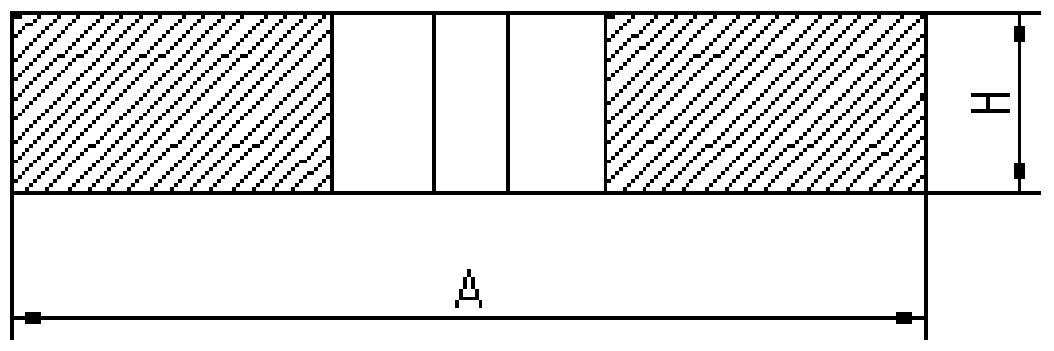

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a preparation method of tooth-shaped special-shaped ceramics, the specific steps are as follows:

[0037] (1) Preparation of slurry

[0038] Preparation of premix: Weigh 650g of deionized water and 100g of glycerin as solvent; respectively weigh 234.3g of acrylamide and 15.6g of N–N’methylenebisacrylamide as organic solute. Mix the organic solute and the solvent evenly to dissolve all the organic solute to obtain 1000 g of a slightly yellowish transparent premixed solution.

[0039]Take the above premixed solution, and weigh 3g ammonium polyacrylate, 1000g α-alumina (ceramic powder, with bimodal distribution structure; 0.1μm≤particle size≤0.5μm, purity 99.99%), 1g 2-hydroxy- 2-methyl-1-phenyl-1-propanone (photoinitiator 1173), 12 g stearic acid (surface modifier).

[0040] Preparation of ceramic powder dispersion: put the ceramic powder, ethanol, and part of the dispersant in a planetary ball mill for 6 hours to form a ceramic powder dispersio...

Embodiment 2

[0053] This embodiment provides a preparation method of tooth-shaped special-shaped ceramics, the specific steps are as follows:

[0054] (1) Preparation of slurry

[0055] Preparation of premix: Weigh 760g of deionized water and 140g of glycerin as solvent; respectively weigh 290g of acrylamide and 10g of N–N’methylenebisacrylamide as organic solute. Mix the organic solute and the solvent evenly to dissolve all the organic solute to obtain 1200 g of a slightly yellowish transparent premixed solution.

[0056] Take the above premixed solution, and weigh 14.4g PVP, 1800g α-alumina (ceramic powder, with bimodal distribution structure; 0.1μm≤particle size≤0.5μm, purity 99.99%), 12g 2-hydroxy-2- Methyl-1-phenyl-1-propanone (photoinitiator 1173), 18 g stearic acid (surface modifier).

[0057] Preparation of ceramic powder dispersion: put the ceramic powder, ethanol, and part of the dispersant in a planetary ball mill for 3 hours to form a ceramic powder dispersion. The ball mill...

Embodiment 3

[0070] This embodiment provides a method for preparing tooth-shaped special-shaped ceramics. The specific steps are basically the same as those in Example 1. The difference is that the parameters set by the light-curing molding equipment in the molding step are different. The details are as follows: set the parameters of the light-curing molding equipment The scanning speed is 800mm / s, the scanning distance is 0.2mm, and the scanning method is XYSTA.

[0071] Density of the tooth-shaped special-shaped ceramics prepared in this embodiment is 3.91g / cm 3 , Vickers hardness is 17.7GPa. The structure and size of the tooth-shaped special-shaped ceramics prepared in this embodiment are basically consistent with the target structure, the shrinkage is small, and the deformation is small and negligible. The shape of the teeth on the rim is intact, and the shape and size of the finished product are high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com