Thrust compound power device and method for producing special-shaped wire using the device

A compound power and thrust technology, which is applied in the field of thrust compound power devices and the production of special-shaped wires, can solve the problems of inability to produce complex cross-section special-shaped wires and difficult molding, and achieve the effects of improving operating efficiency, high shape and dimension accuracy, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

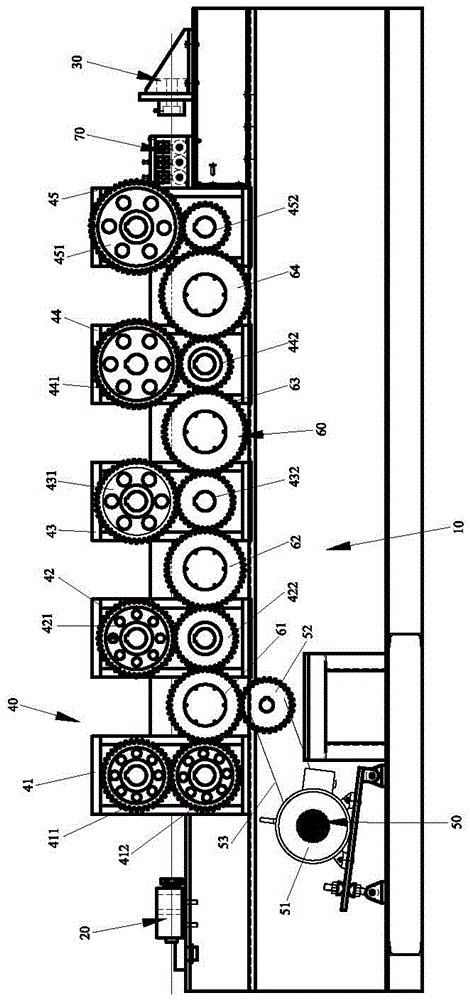

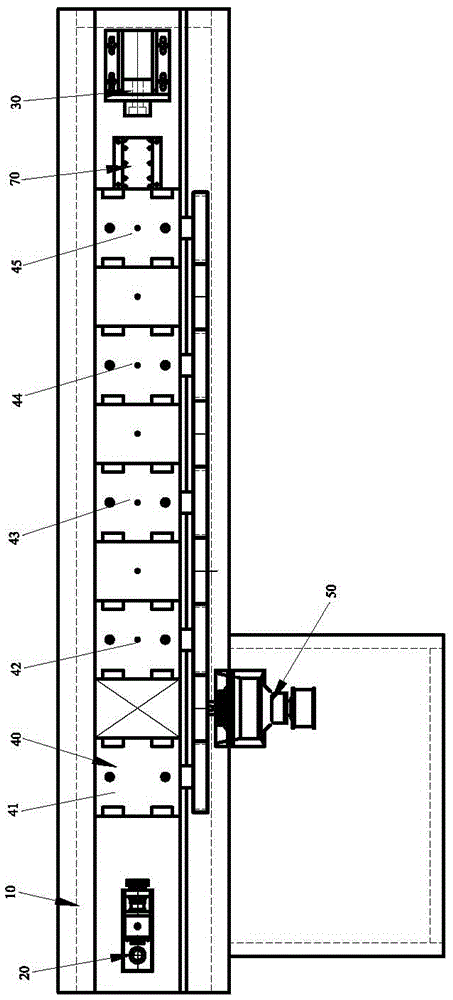

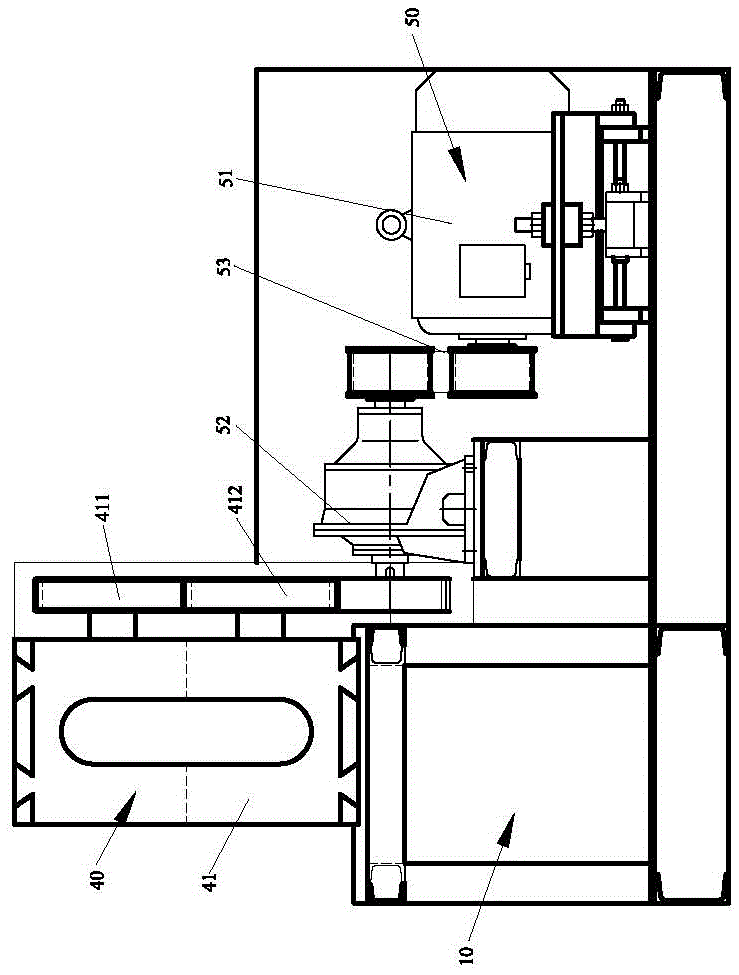

[0037] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, including frame 10, drawing die 20, forming die 30, a plurality of roll pushing mechanism 40 and driving mechanism 50;

[0038] The drawing die 20 and the forming die 30 are respectively arranged on the two ends of the surface of the frame 10; the plurality of roll pushing mechanisms are arranged side by side horizontally, and the plurality of rolling rolling mechanisms are located between the drawing die 20 and the forming die 30, and A transmission toothed disc 60 is connected between two adjacent roller pusher mechanisms 40, and the drive mechanism 50 drives one of the transmission toothed discs 60 to rotate, and the plurality of roll pusher mechanisms 40 operate simultaneously.

[0039]Specifically, in the present embodiment, the plurality of roll pushing mechanisms 40 include a first rolling rolling mechanism 41, a second rolling rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com