Low-temperature sintering method of ultra-high-temperature ceramic

An ultra-high temperature ceramic and low temperature sintering technology, applied in the field of dense ceramic preparation, can solve the problems of low atomic self-diffusion coefficient, difficult preparation of ultra-fine powder, easy to bring in impurities such as oxygen, etc., so as to reduce the sintering process and reduce the possibility , the effect of prolonging the burning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 20ml polyborosilazane to 60ml n-hexane solvent, then mix with sieved ZrB 2 The ceramic powder is mixed at a mass ratio of 1:4 (that is, the mass ratio of polyborosilazane to ceramic powder is 1:4) to obtain a mixed slurry, and then the mixed slurry is put into a ball mill for 35 minutes, and the ball milling speed is 80r / min;

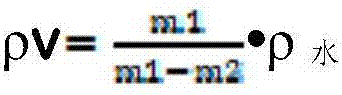

[0026] (2) After step (1) is completed, take out the mixed slurry and place it in a petri dish, and use n-hexane solvent to remove the remaining ZrO 2 Rinse off the mixed slurry on the grinding ball, let it stand at room temperature for 1 hour, then take out the mixed powder and put it into a hot-pressed graphite mold. The inner wall of the graphite mold is coated with BN, and the mixed powder and the inner wall of the graphite mold are covered with graphite paper. In order to prevent the mixed powder from reacting with the inner wall of the graphite mold at high temperature, use a cold press to cold press the mixed powder at 40MPa for 1...

Embodiment 2

[0030] (1) Add polyborosilazane to n-hexane solvent, then mix it with sieved SiC ceramic powder at a mass ratio of 1:4, then put the mixed slurry into a ball mill, mill for 30 minutes, and control the milling speed at 100r / min;

[0031] (2) After step (1) is completed, take out the mixed slurry and place it in a petri dish, and use n-hexane solvent to remove the remaining ZrO 2 Rinse off the mixed slurry on the grinding ball, put it at room temperature for 1 hour, then take out the slightly humid mixed powder and put it into a hot-pressed graphite mold. The inner wall of the graphite mold is coated with BN, and the powder and the mold are sealed with graphite paper The inner wall is isolated to prevent the powder from reacting with the inner wall of the mold at high temperature, and the mixed slurry is cold-pressed at 40MPa for 10 minutes with a cold press;

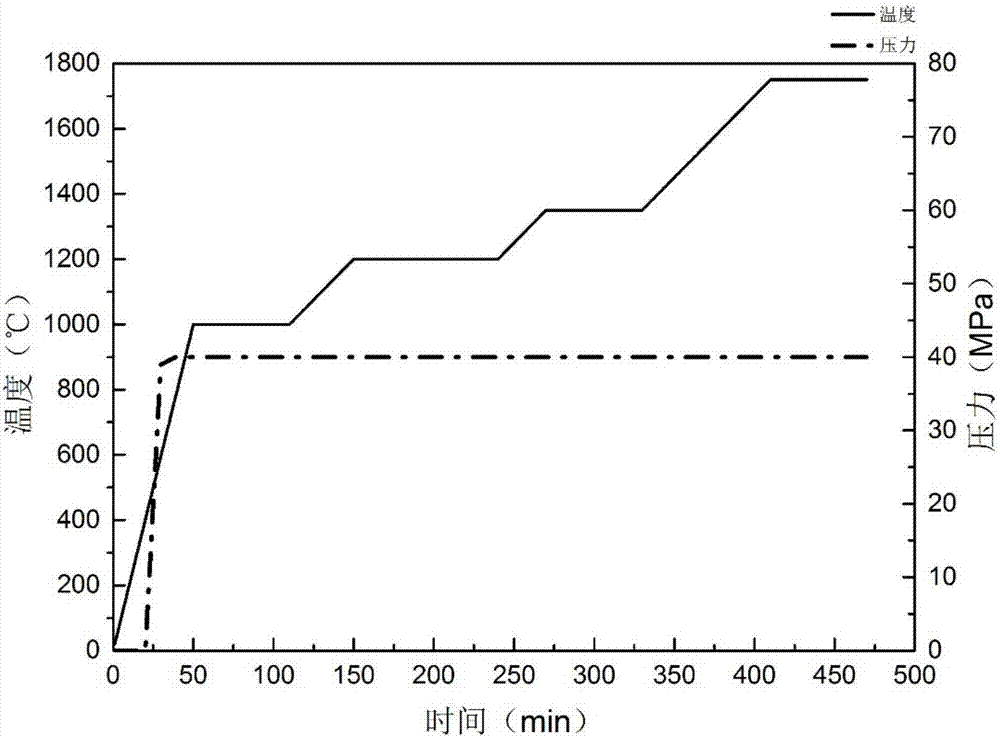

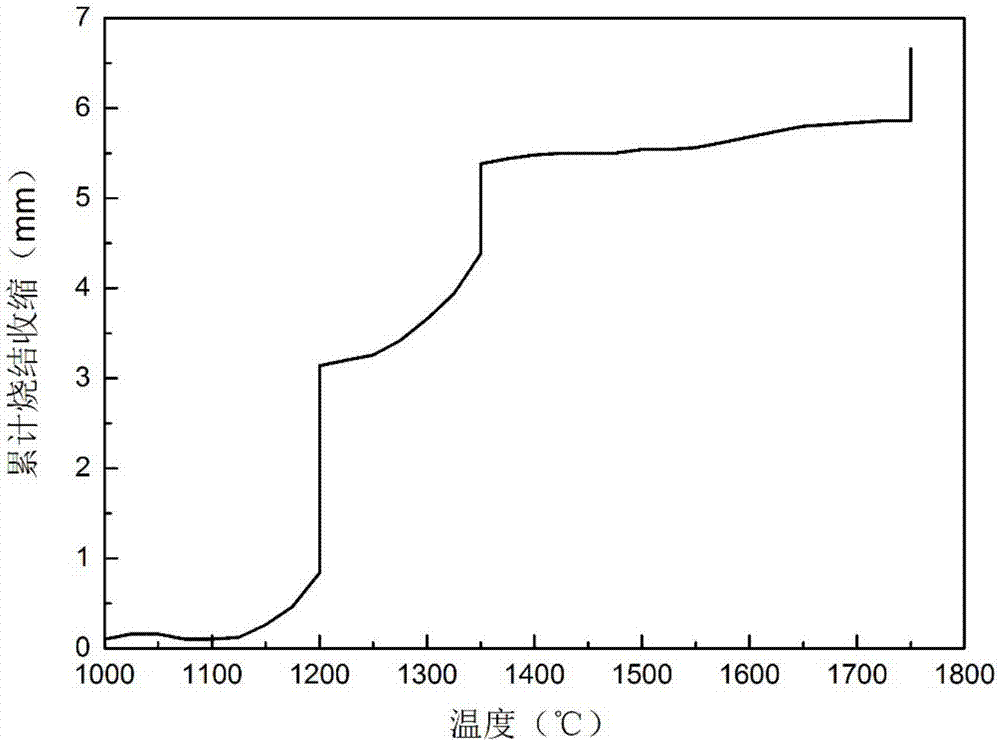

[0032](3) After step (2) is completed, the graphite mold is put into a hot-press sintering furnace, and the furnace te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com