Aluminum-silicon alloy graphite composite heat conduction material and preparation method and application thereof

A composite heat-conducting material, aluminum-silicon alloy technology, applied in the field of thermal management materials, can solve problems such as unsmooth development of aluminum-based graphite composite materials, difficulty in composite forming of aluminum matrix and graphite sheet, damage to thermal conductivity and strength of composite materials, etc., to achieve Shorten the preparation time, reduce the formation of harmful interfacial phases, and ensure the effect of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

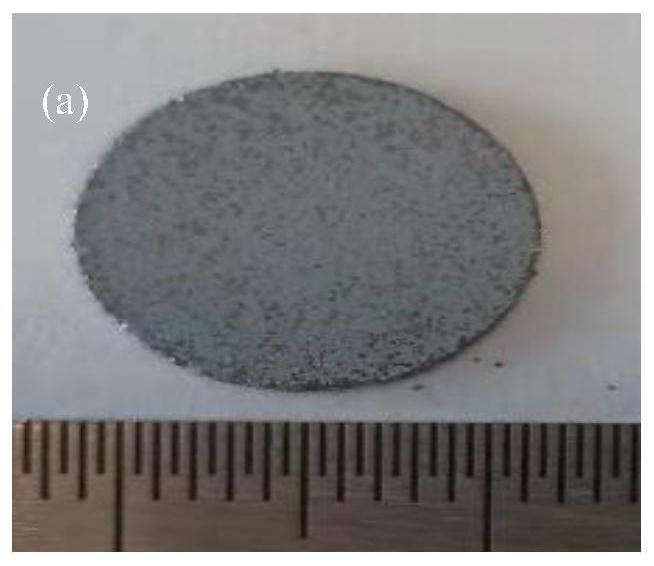

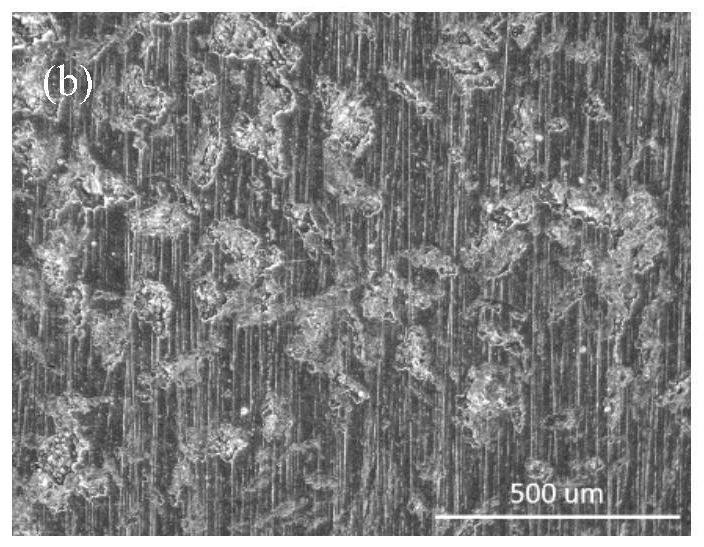

[0049] This embodiment provides an aluminum-silicon alloy graphite composite thermal conductive material, which is a dried aluminum-silicon alloy powder matrix material (aluminum-silicon alloy powder produced by Hunan Ningxiang Jiweixin Metal Powder Material Co., Ltd., with a particle size of 2 -8μm, nearly spherical shape) and dried flake graphite flake reinforcement (Graphite Flakes, abbreviated as GF, which is a high-purity flake graphite numbered XF050 produced by Jiangsu Nanjing Xianfeng Nano Material Technology Co., Ltd., the mesh number is 80 mesh, purity of 99.9wt%) after mixing in a glass;

[0050] The obtained mixture is compacted in a graphite mold, and then prepared by hot pressing and sintering under vacuum conditions. The aluminum-silicon alloy graphite composite thermal conductive material prepared in this example is recorded as material 1#, material 1# , The flake graphite is evenly distributed in the base material Al-Si alloy powder Al-20%Si, and there is no brid...

Embodiment 2

[0056] This embodiment provides an aluminum-silicon alloy graphite composite thermal conductive material, which is obtained by mixing aluminum-silicon alloy powder Al-20%Si (same as Example 1) with flake graphite flakes (same as Example 1) It is compacted in a graphite mold and then prepared by hot pressing and sintering under vacuum conditions. The vacuum hot press and the graphite mold used in the hot pressing and sintering process in this embodiment are the same as those in Example 1;

[0057] The aluminum-silicon alloy graphite composite thermal conductive material prepared in this embodiment is recorded as material 2#. In material 2#, the flake graphite is evenly distributed in the aluminum-silicon alloy powder Al-20%Si, which is the base material, and no bridging phenomenon occurs;

[0058] Wherein, based on the total weight of the mixture being 100%, the content of the flake graphite flakes is 15 wt%, and the content of the aluminum-silicon alloy powder Al-20% Si is 85 wt%;

...

Embodiment 3

[0061] This embodiment provides an aluminum-silicon alloy graphite composite thermal conductive material, which is obtained by mixing aluminum-silicon alloy powder Al-20%Si (same as Example 1) with flake graphite flakes (same as Example 1) It is compacted in a graphite mold and then prepared by hot pressing and sintering under vacuum conditions. The vacuum hot press and the graphite mold used in the hot pressing and sintering process in this embodiment are the same as those in Example 1;

[0062] The aluminum-silicon alloy graphite composite thermal conductive material prepared in this embodiment is recorded as material 3#. In material 3#, the flake graphite is evenly distributed in the aluminum-silicon alloy powder Al-20%Si, which is the base material, and no bridging occurs;

[0063] Wherein, based on the total weight of the mixture being 100%, the content of the flake graphite flakes is 15 wt%, and the content of the aluminum-silicon alloy powder Al-20% Si is 85 wt%;

[0064] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com