Electrocondution slurry for chip component termination electrode

A technology of conductive paste and terminal electrodes, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of reducing the metal content of conductive paste, the adhesion strength of terminal electrodes, and the reduction of sintering compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

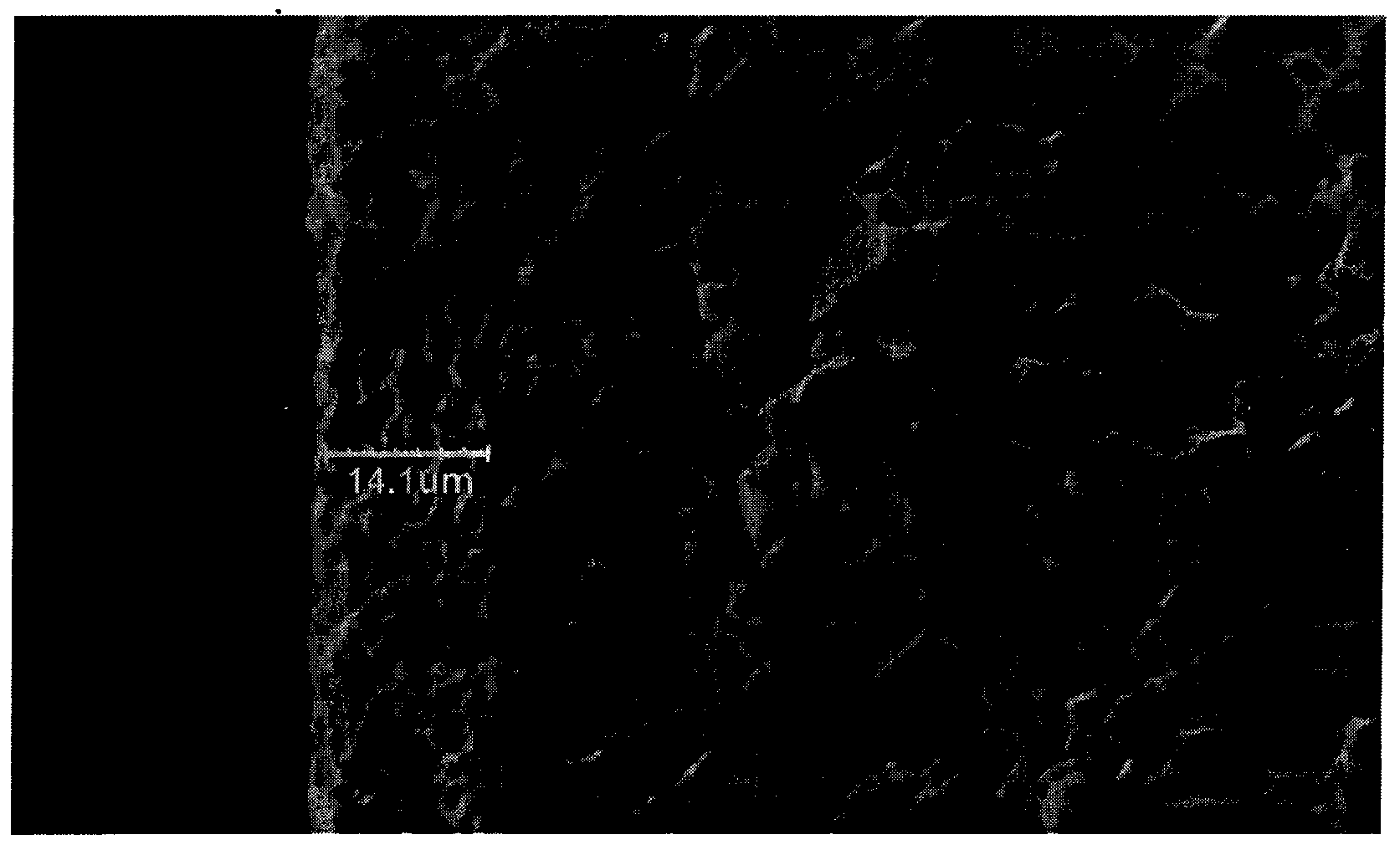

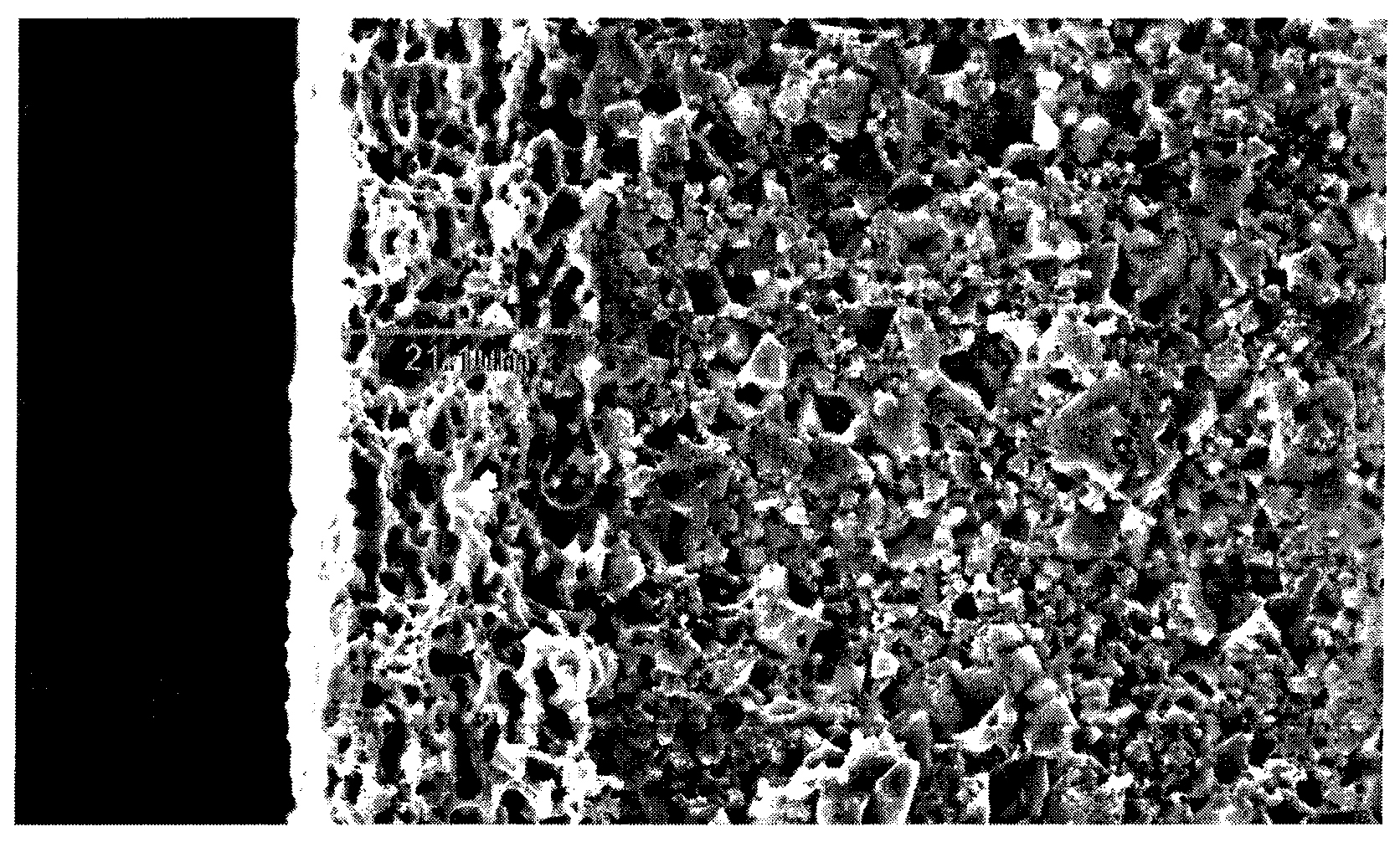

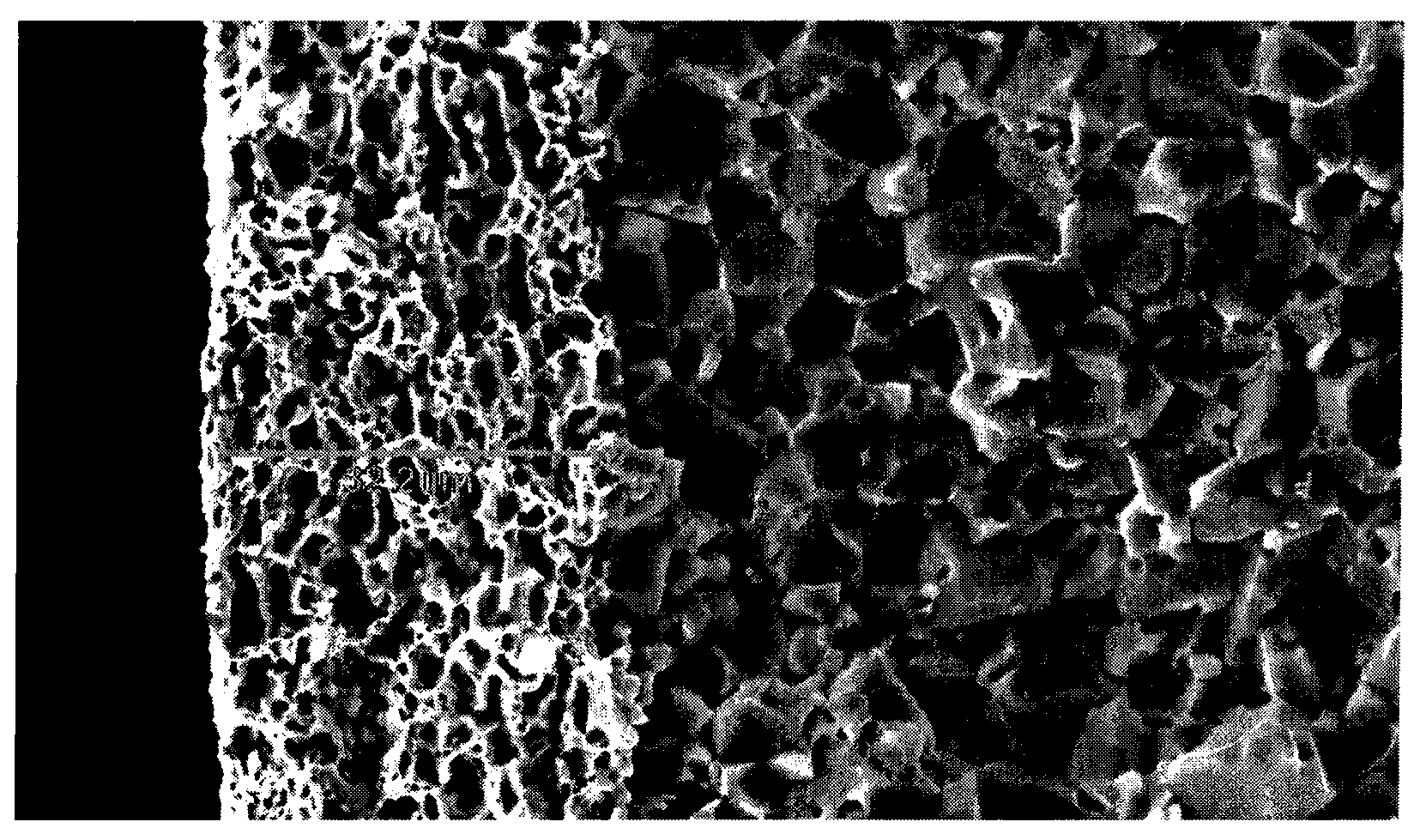

Image

Examples

Embodiment 11

[0043] Example 11 does not add silver micropowder, and the adhesion strength of the terminal electrode is as good as that of Example 13 which adds 10% silver micropowder. It shows that when the silver content is high, silver paste with excellent performance can also be produced without adding silver powder.

[0044] But, when silver content is 55% and 65%, do not add embodiment 1 and embodiment 6 of silver micropowder, the adhesion strength of terminal electrode is very low, when adding the amount of silver micropowder less than 5% of silver powder total amount, The adhesion strength of the terminal electrodes was also low, as in Example 2 and Example 7. In Example 3 and Example 8 with 10% silver powder added, the adhesion strength of the terminal electrode is very good, which is equivalent to the silver paste with 75% silver content. When the amount of silver powder added is greater than 50% of the total amount of silver powder, the adhesion strength of the terminal electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com