Method for improving sintering compactness of un-bonded phase tungsten carbide hard alloy

A cemented carbide and tungsten carbide technology, applied in the field of cemented carbide preparation, can solve the problems of sintering densification, uneven structure and performance, need to keep for several to ten hours, uneven temperature distribution, etc., and achieve dense sintering. The effect of improved performance, small organization and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

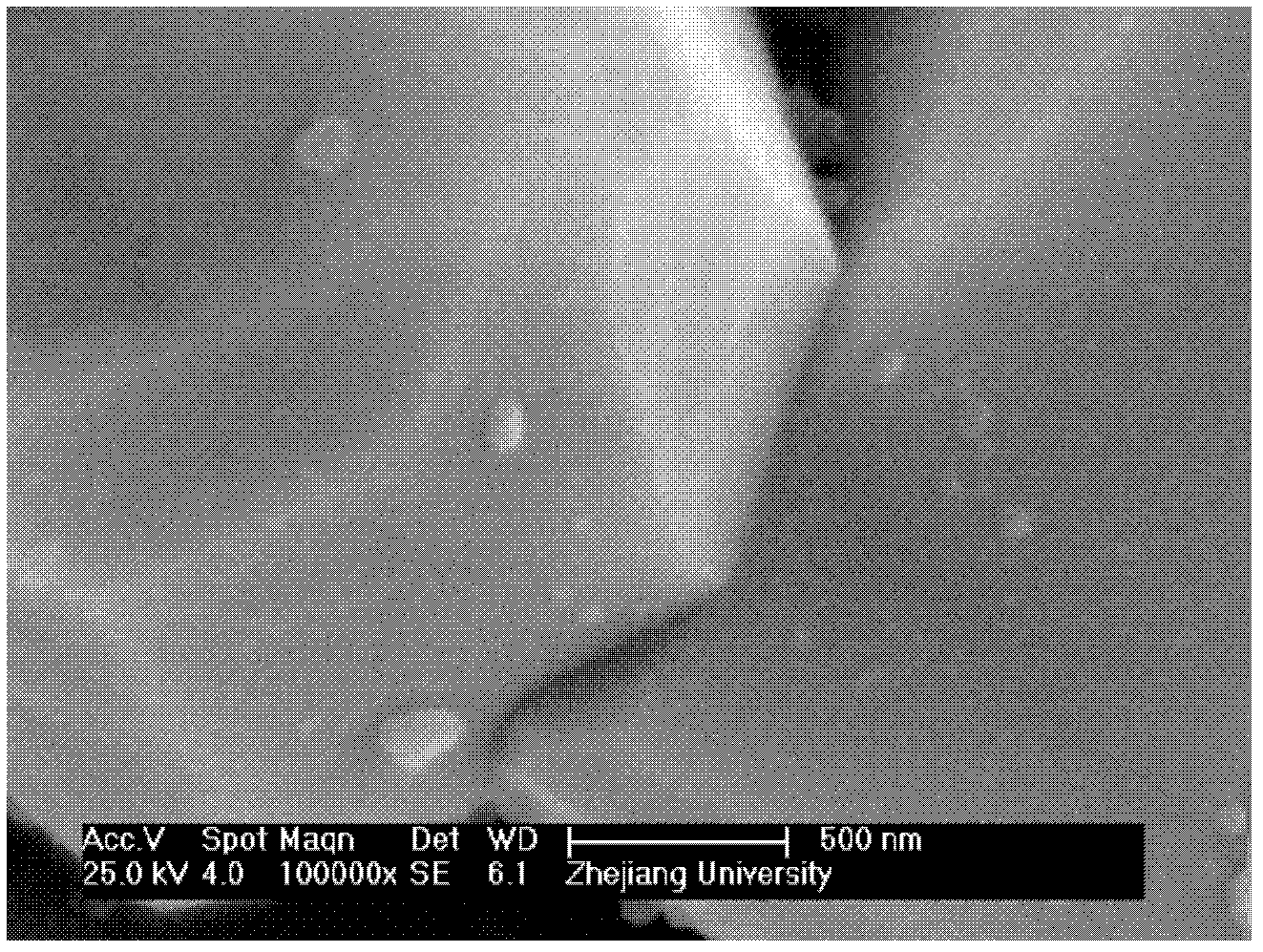

[0019] 1. Preparation of activated tungsten carbide powder

[0020] Put the tungsten carbide powder with a particle size of 1-3 microns in the activation solution, ultrasonically activate it for 30 minutes at room temperature, the ultrasonic frequency is 40KHz, and the power is 300-400W. After activation, wash with deionized water three times and dry at 170°C 4 hours to obtain activated tungsten carbide powder;

[0021] Described activation solution is the aqueous solution of hydrofluoric acid, ammonium fluoride and nitric acid, and the concentration of hydrofluoric acid is 30mL / L in the described activation solution, with the hydrofluoric acid solution of mass concentration 40%; The concentration of ammonium fluoride is 10g / L; the concentration of nitric acid is 60mL / L, based on the nitric acid solution with a mass concentration of 65%.

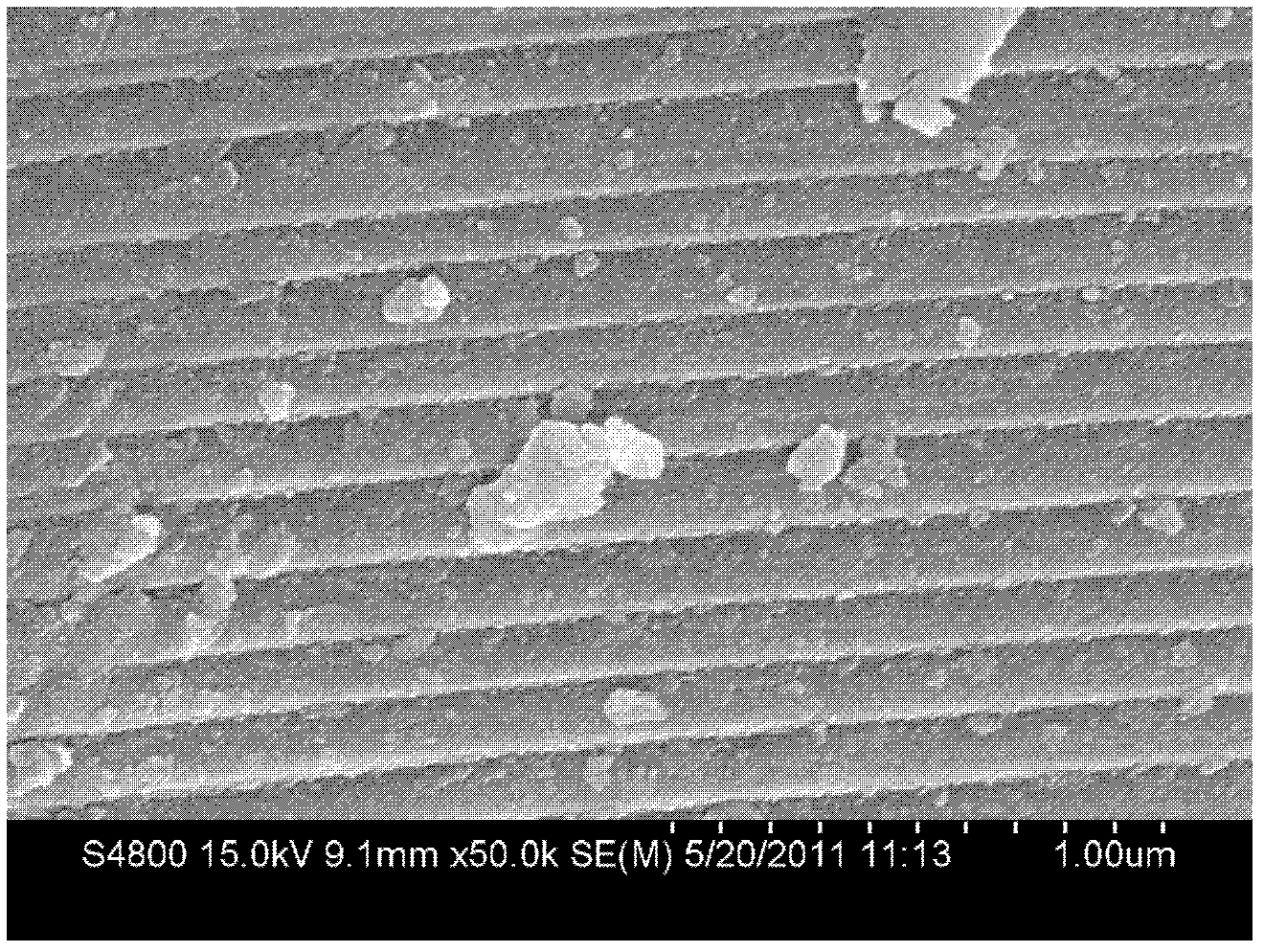

[0022] 2. Molded sintering

[0023] The prepared activated tungsten carbide powder is pressed into shape, and then the vacuum degree is 1...

Embodiment 2

[0026] 1. Preparation of activated tungsten carbide powder

[0027] Put the tungsten carbide powder with a particle size of 1-3 microns in the activation solution, ultrasonically activate it at room temperature for 35 minutes, the ultrasonic frequency is 40KHz, and the power is 300-400W. After the activation is completed, wash with deionized water three times and dry at 150°C 6 hours to obtain activated tungsten carbide powder;

[0028] Described activation solution is the aqueous solution of hydrofluoric acid, ammonium fluoride and nitric acid, and the concentration of hydrofluoric acid is 40mL / L in the described activation solution, with the hydrofluoric acid solution of mass concentration 40%; The concentration of ammonium fluoride is 11g / L; the concentration of nitric acid is 70mL / L, based on the nitric acid solution with a mass concentration of 65%.

[0029] 2. Molded sintering

[0030] The prepared activated tungsten carbide powder is pressed into shape, and then the v...

Embodiment 3

[0033] 1. Preparation of activated tungsten carbide powder

[0034] Put the tungsten carbide powder with a particle size of 1-3 microns in the activation solution, ultrasonically activate it at room temperature for 40 minutes, the ultrasonic frequency is 40KHz, and the power is 300-400W. After the activation is completed, wash with deionized water three times and dry at 180°C 3 hours to obtain activated tungsten carbide powder;

[0035] Described activation solution is the aqueous solution of hydrofluoric acid, ammonium fluoride and nitric acid, and the concentration of hydrofluoric acid is 50mL / L in the described activation solution, with the hydrofluoric acid solution of mass concentration 40%; The concentration of ammonium fluoride is 12g / L; the concentration of nitric acid is 50mL / L, based on the nitric acid solution with a mass concentration of 65%.

[0036] 2. Molded sintering

[0037] The prepared activated tungsten carbide powder is pressed into shape, and then the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com