A kind of platinum-ceramic composite powder and its preparation method and application

A technology of ceramic composite and ceramic powder, which is applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of weakened response performance of platinum electrodes, inability to meet high temperature sintering, high powder shrinkage, etc., and achieve improved response performance and sensitivity, heating High uniformity and stability, high compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

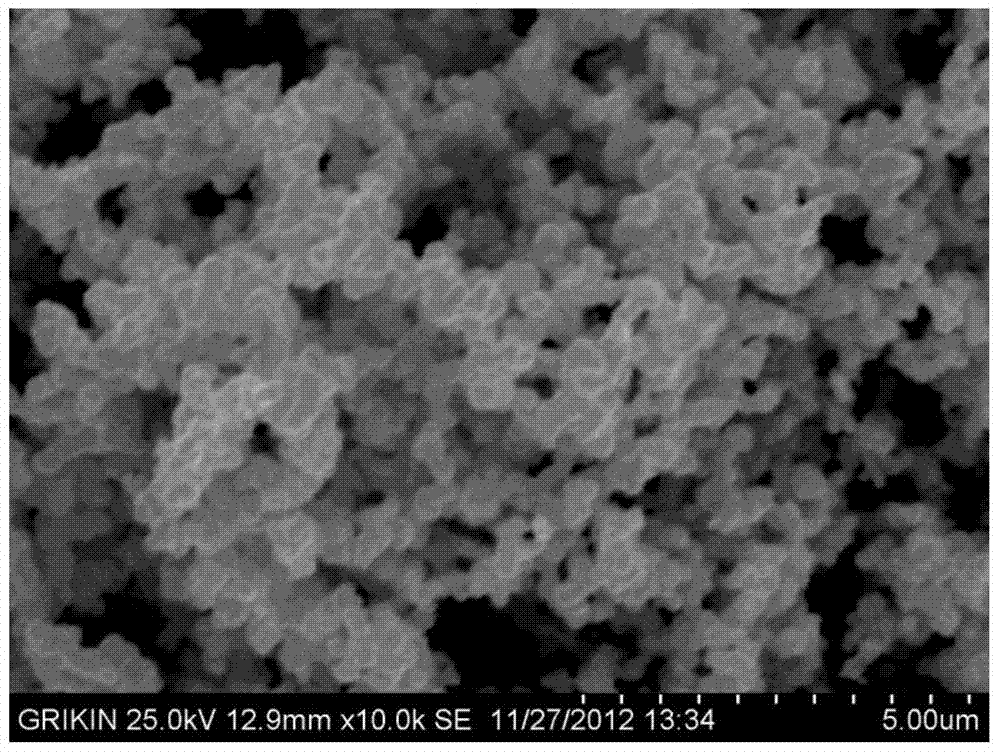

[0065] Embodiment 1: Production of platinum-ceramic composite powder 15g

[0066] 1) Pretreatment of ceramic powder

[0067] Weigh 10 g of metal oxide ceramic powder, wash with 100 mL of 20% NaOH solution for 20 min, filter and wash; then wash and soak with absolute ethanol for 1 h, filter and wash, then dry.

[0068] 2) Ceramic powder sensitization treatment

[0069] Put the metal oxide ceramic powder obtained in step 1) into the SnCl with concentration of 15g / L 2 solution, ultrasonically rinsed for 30 minutes, then centrifugally filtered, then washed four times with deionized water, and centrifugally filtered.

[0070] 3) Ceramic powder activation treatment

[0071] Put the ceramic powder obtained in step 2) into a concentration of 0.3g / L PdCl 2 In the solution, ultrasonically rinse for 30 minutes, then centrifugally filter, then wash six times with deionized water, dry after centrifugal filtration, and obtain activated ceramic powder.

[0072] 4) Dissolved spongy plati...

Embodiment 2

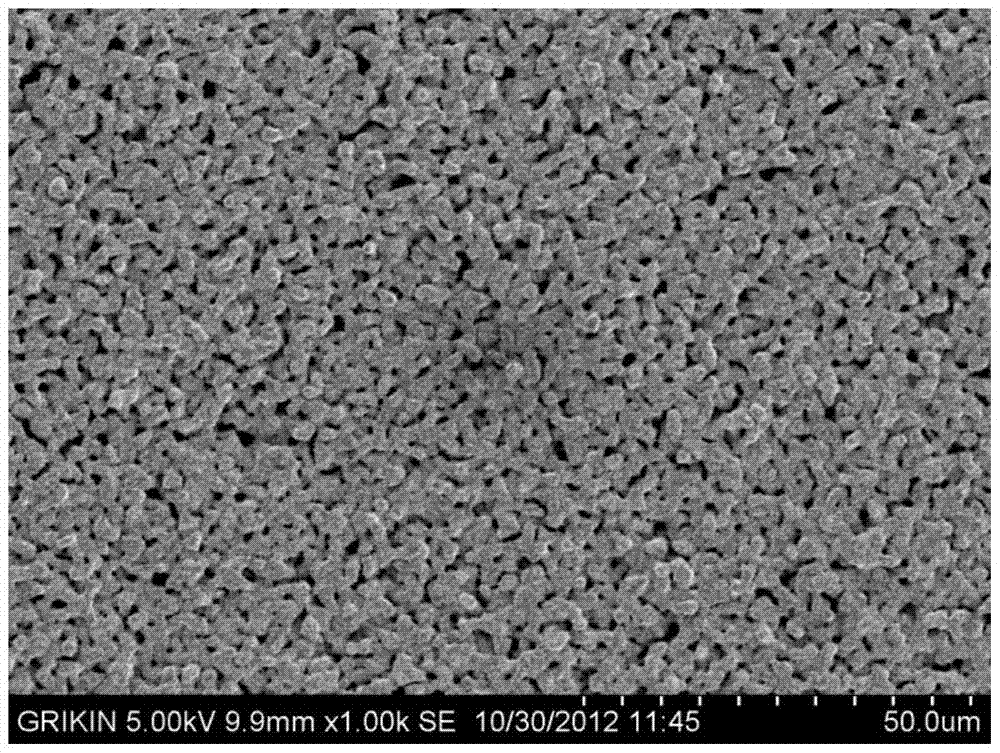

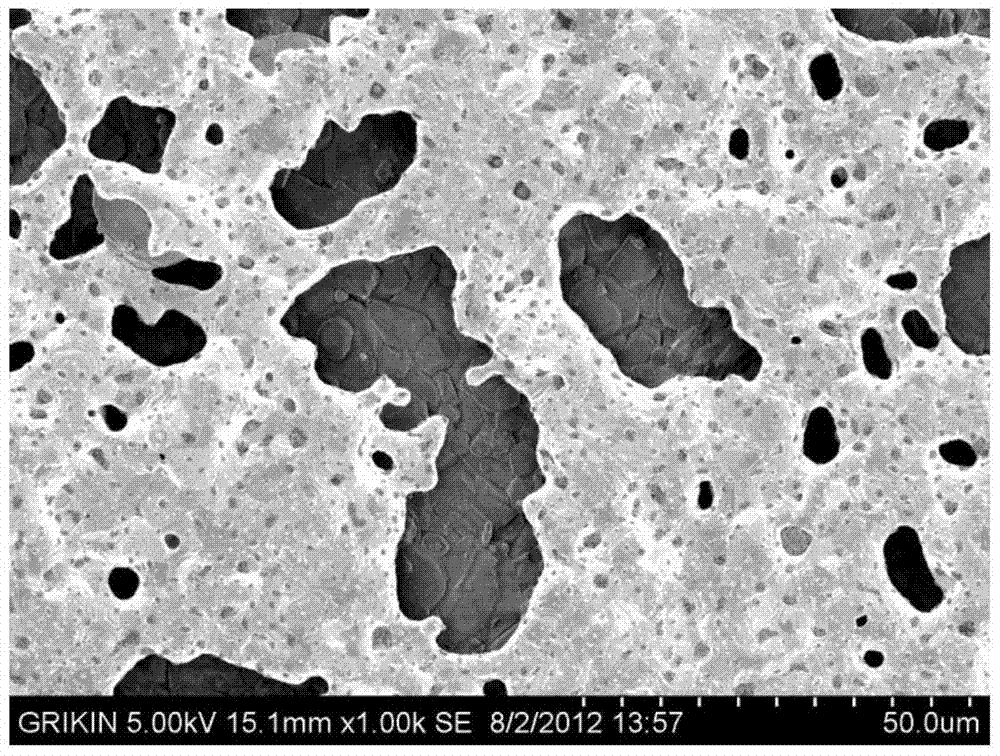

[0085] Weigh platinum powder in the same proportion as platinum-ceramic composite powder and metal oxide ceramic powder that has not been activated and sensitized, mix them evenly, add an organic binder, and prepare a platinum electrode slurry; - The platinum electrode paste prepared from the ceramic composite powder was screen-printed under the same experimental environment, and then sintered at a high temperature of 1450 °C. The morphology of the platinum electrode slurry prepared by using platinum-ceramic composite powder after high temperature sintering is as follows figure 2 As shown; the morphology of the platinum electrode slurry prepared after simple mixing of platinum powder and ceramic powder after high temperature sintering is shown in Fig. image 3 shown.

[0086] It can be seen from the figure that the platinum electrode slurry prepared by using platinum-ceramic composite powder, after screen printing and high-temperature sintering, obtains a highly dense porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com