Ultralow-temperature liquid nitrogen test box

A test chamber and ultra-low temperature technology, used in the field of test chambers, can solve problems such as inability to solve sealing problems, and achieve the effects of good frost resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

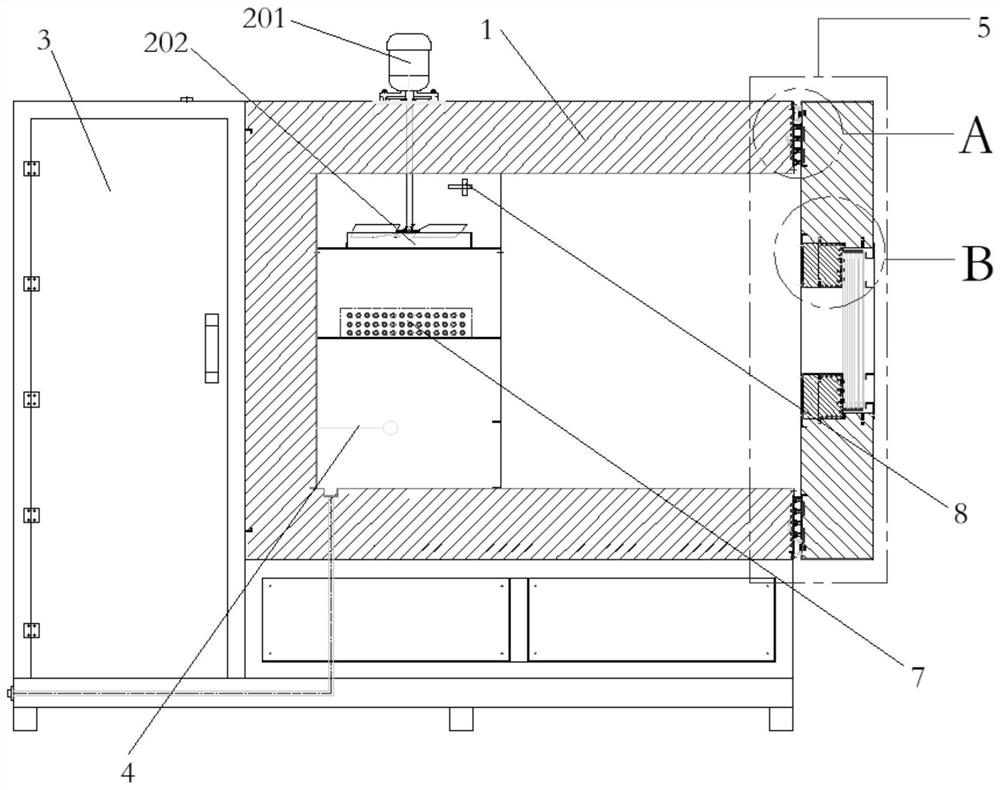

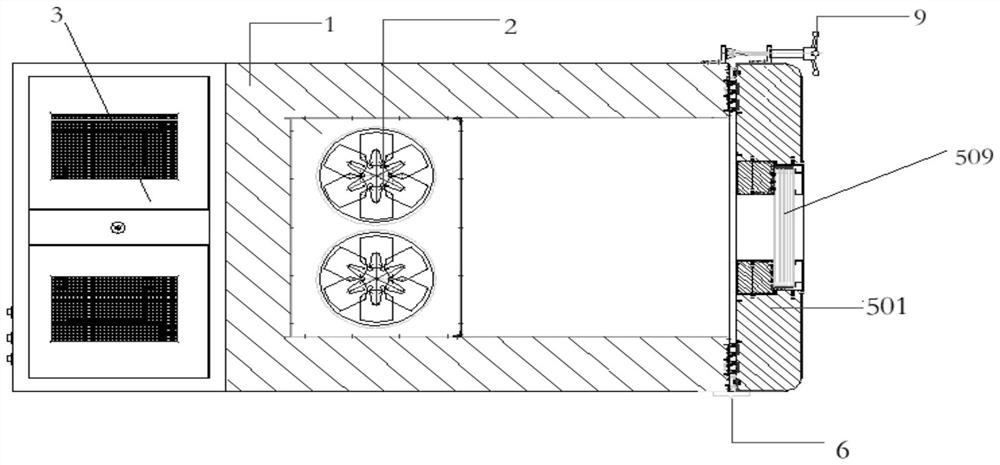

[0019] According to the above technical problems, the present invention provides an ultra-low temperature liquid nitrogen test chamber, including a test chamber body 1, an air circulation device 2, a control device 3, a liquid nitrogen spray device 4, a door sealing system 5, a hinge 6, and a heater 7 , a temperature sensor 8, a door lock 9, the control device 3 is arranged next to the test chamber body 1, and the test chamber body 1 is provided with a wind circulation device 2, and the wind circulation device 2 includes a motor 201 and a wind wheel 202. The motor 201 is fixedly mounted on the top of the test chamber body 1, the wind wheel 202 is connected to the output shaft of the motor 201, a temperature sensor 8 is arranged between the wind wheel 202 and the test chamber body 1, and the wind wheel 202 is below the A heater 7 is provided, and a liquid nitrogen spraying device 4 is provided below the heater 7, and the liquid nitrogen spraying device 4 is used for spraying unv...

Embodiment 2

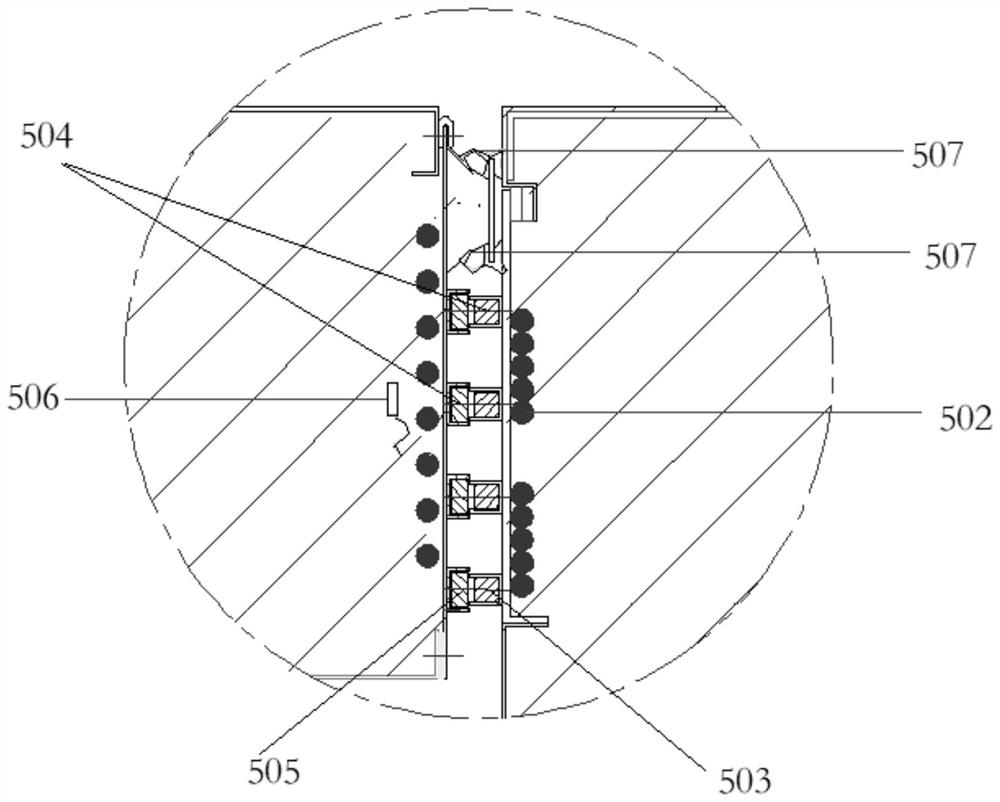

[0028]Working principle: when the present invention is in use, the test box body 1 and the test box door 501 are made of strong heat-insulating materials, so that the test box body 1 maintains a stable low-temperature environment under the premise that the test box door is effectively sealed. The wind circulation device 2 is used to uniformly pass the air in the test chamber through the liquid nitrogen spray device 4 to realize the rapid cooling of the test chamber body 1, and the temperature sensor 8 device is used to collect the temperature parameters in the test chamber body 1, And the temperature parameter is transmitted to the control device 3, and the control device 3 is used to control the working state of the liquid nitrogen cooling system in combination with the temperature parameter and the preset temperature value. The sealing of the test box door 501 and the test box body 1 is completed by the door sealing system 5. The test box door 501 and the test box body 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com